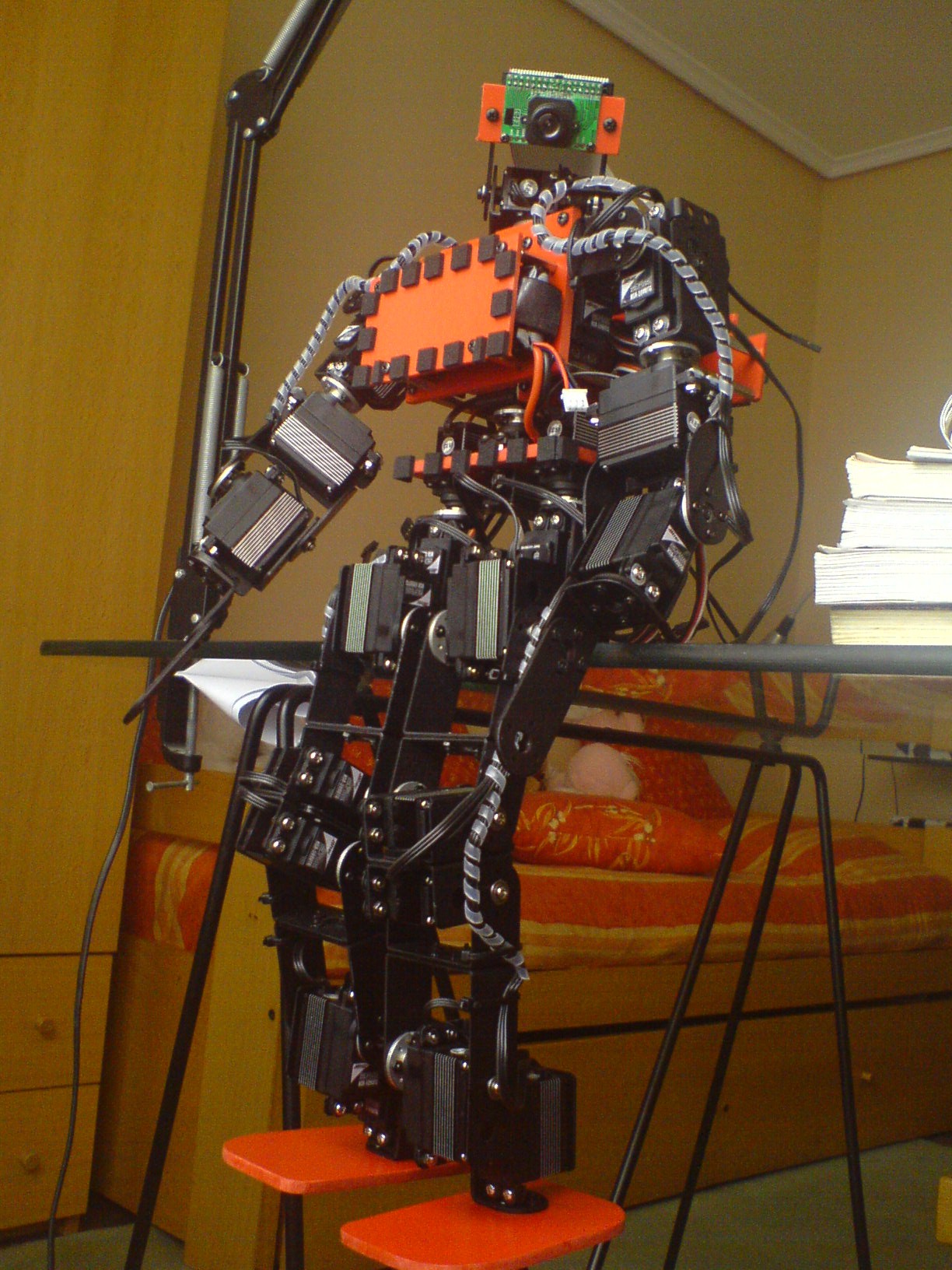

This project was born as a necessity of mine to build a biped robot with intelligent servos to be able to “feel the muscles” to walk more human like. In the past we had OpenServo, and I think this project inherits something from it, but OpenServo died many years ago and it didn't reach my expectations anyway (power, communications...), and the commercial alternatives are way too expensive (Dynamixel, Herkulex, Lynxmotion...).

It’s not hard to find servo motors with about 25-30 kg/cm of torque nowadays with quality ok, not great but ok for less than 20-25€ each although now everything has increase their price, and with that power from one of the well-known companies a smart servo costs more than 120-150€ easily, so we have room to play with. We can use cheap servo motors, just the hardware, with the coolest servo controller I can design for under 40€ everything.

My goal with LibreServo is to make any standard servo the “smartest” one in the market. The "gold standard" nowadays is Robotis-Dynamixel, LibreServo should be better than that, that’s my goal at least.

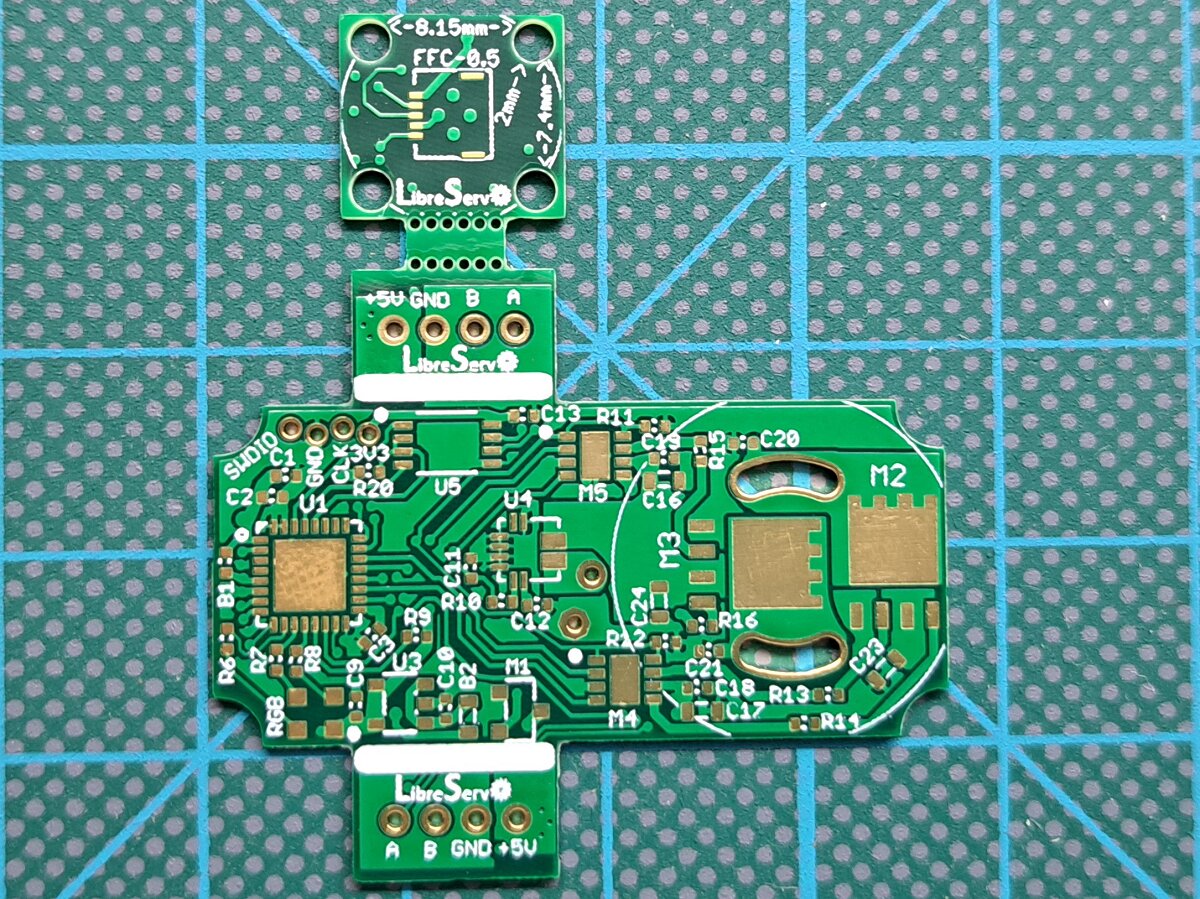

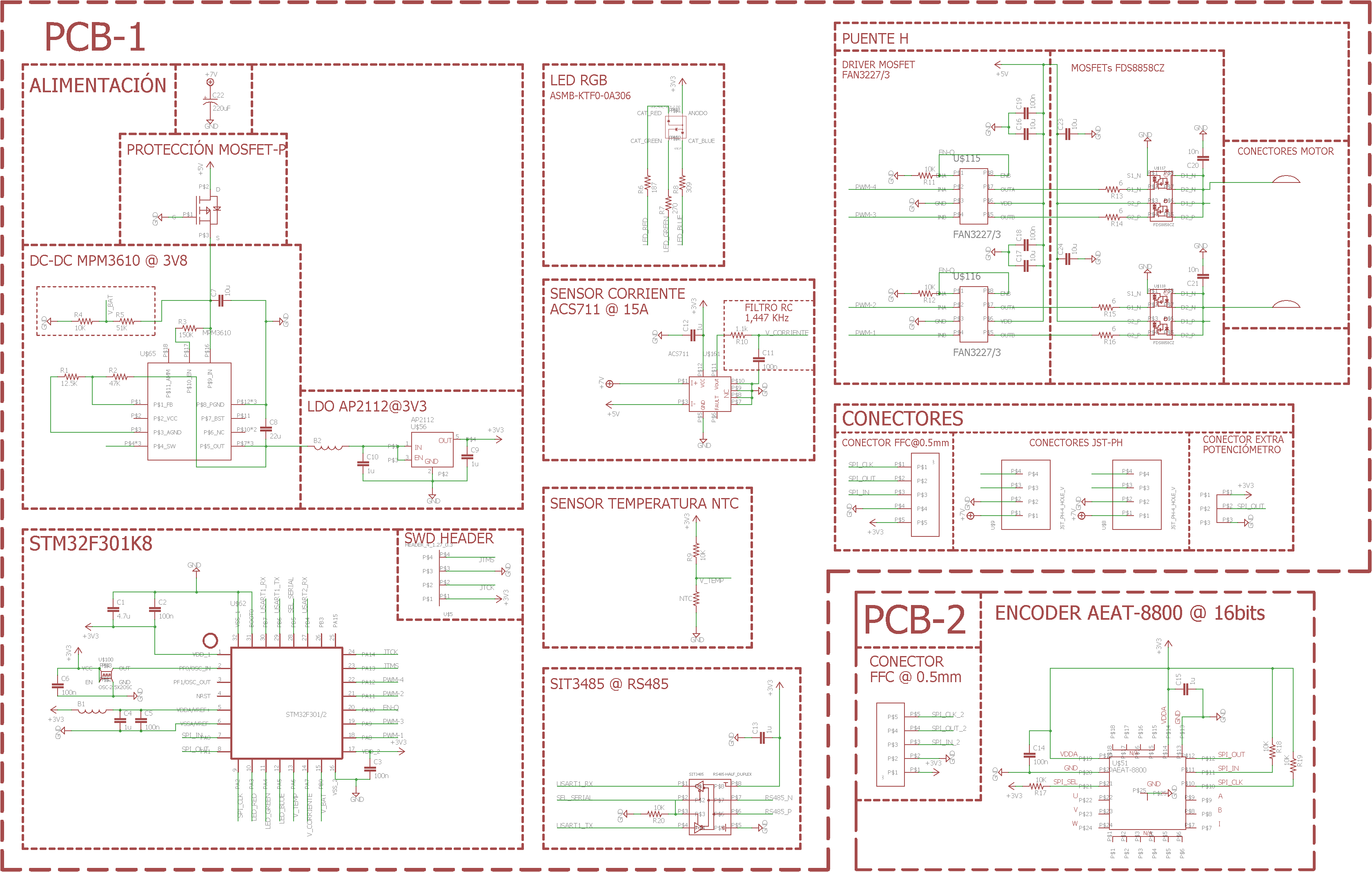

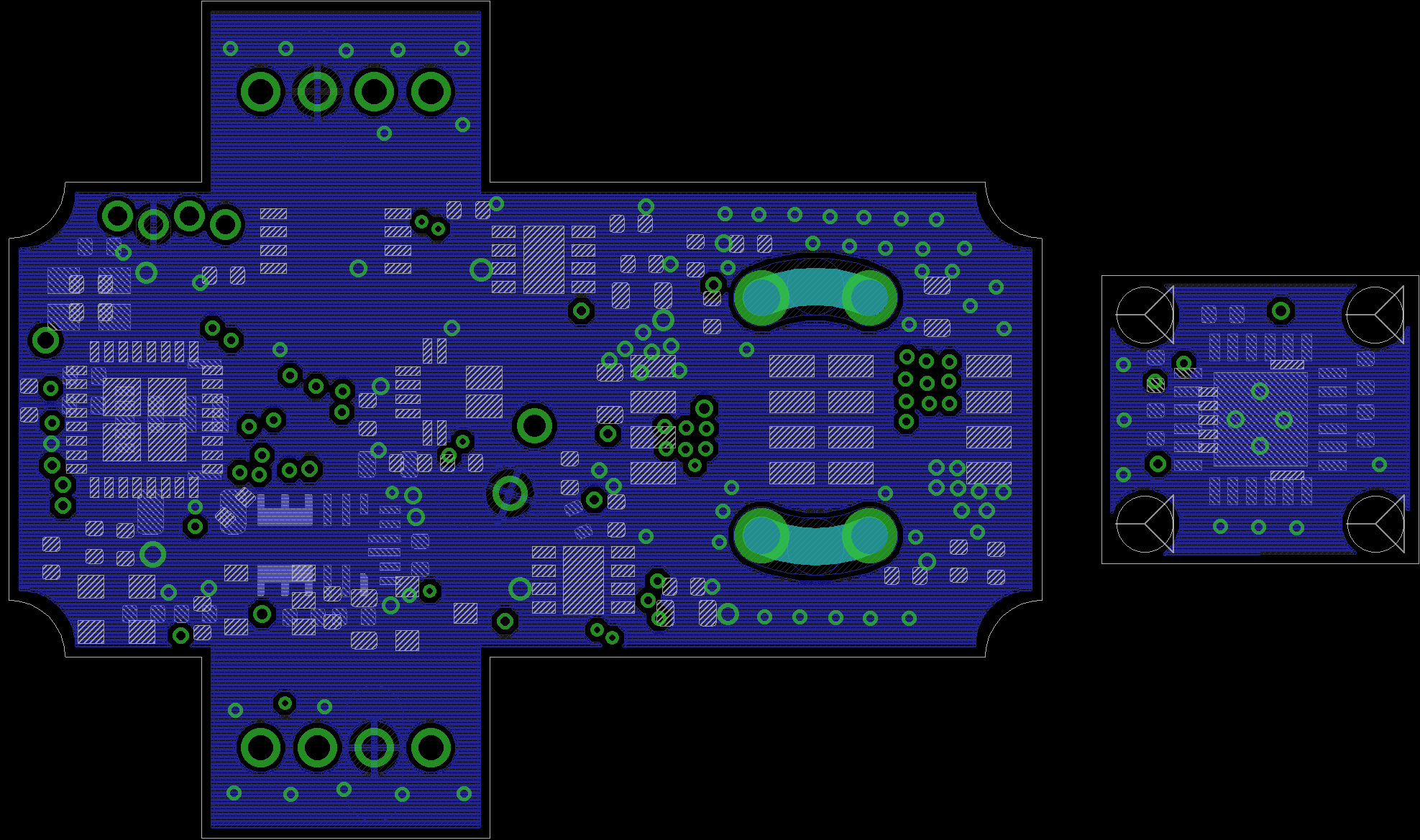

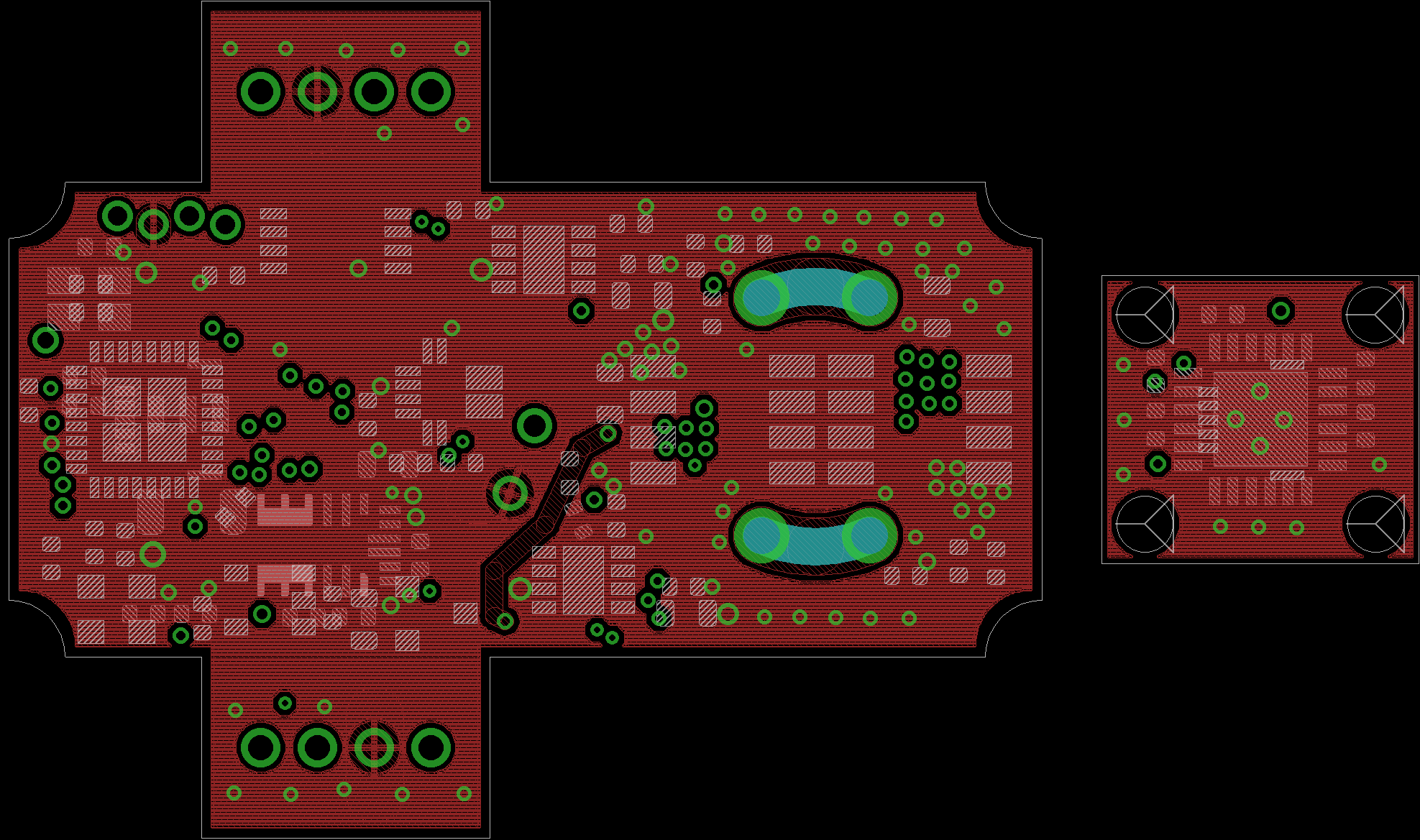

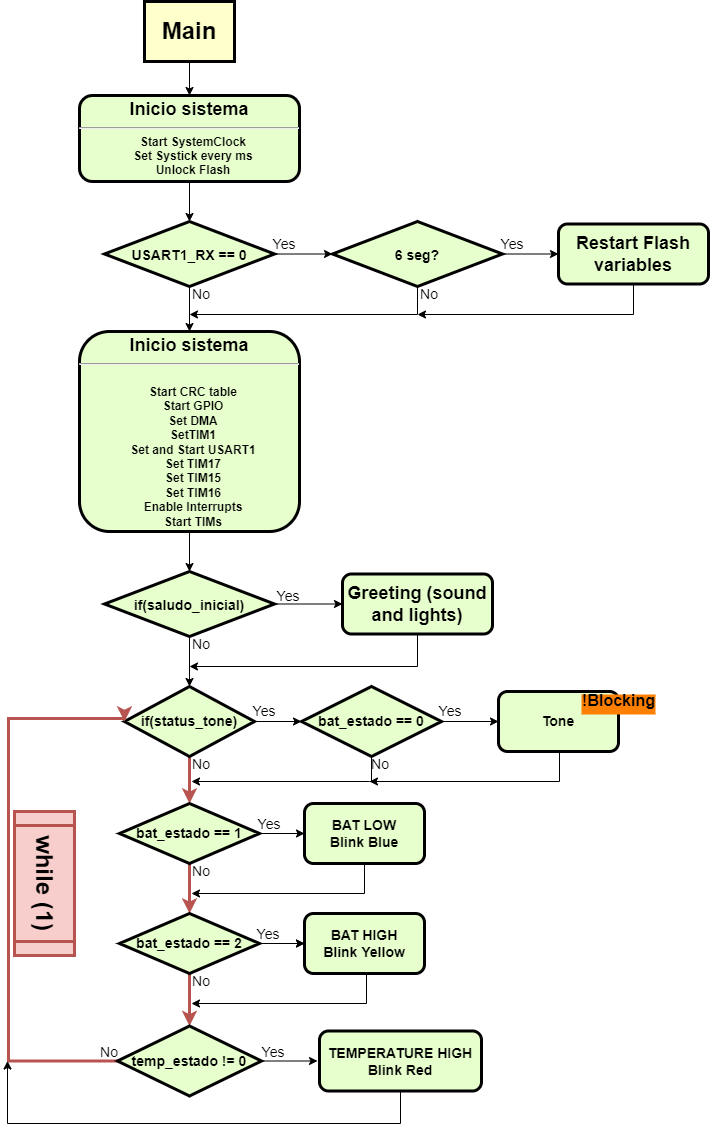

A few characteristics of LibreServo:

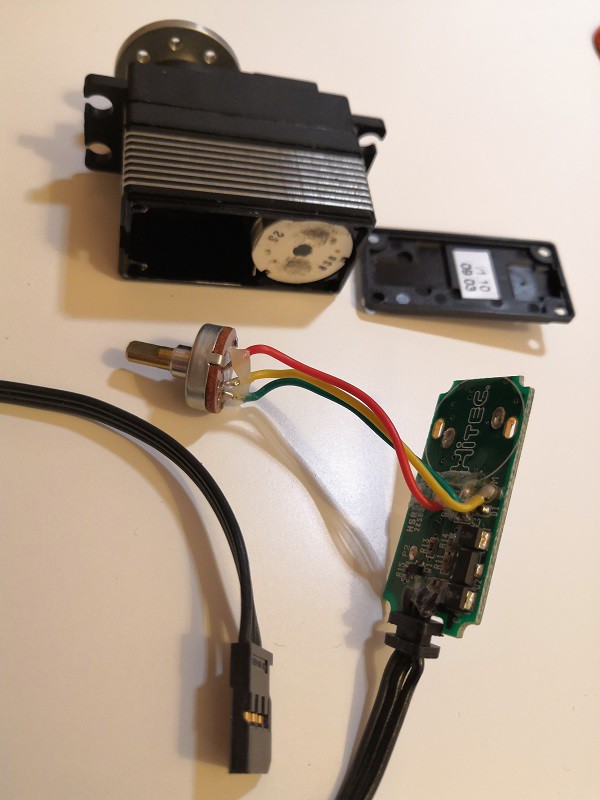

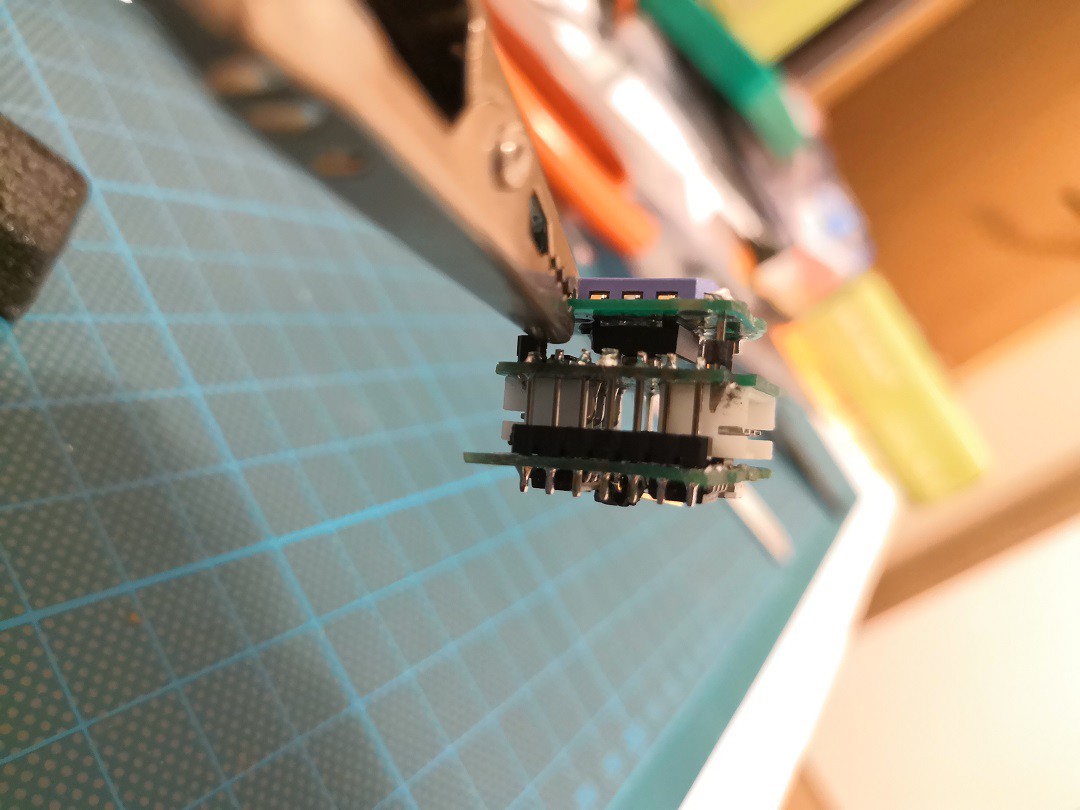

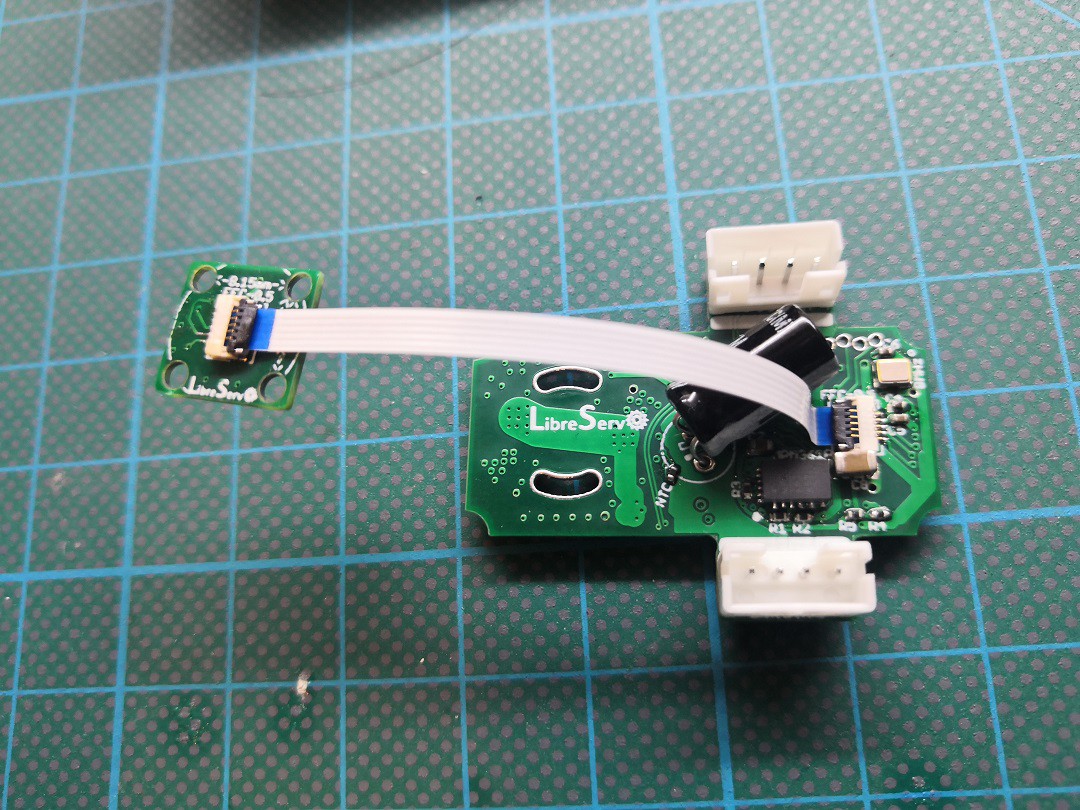

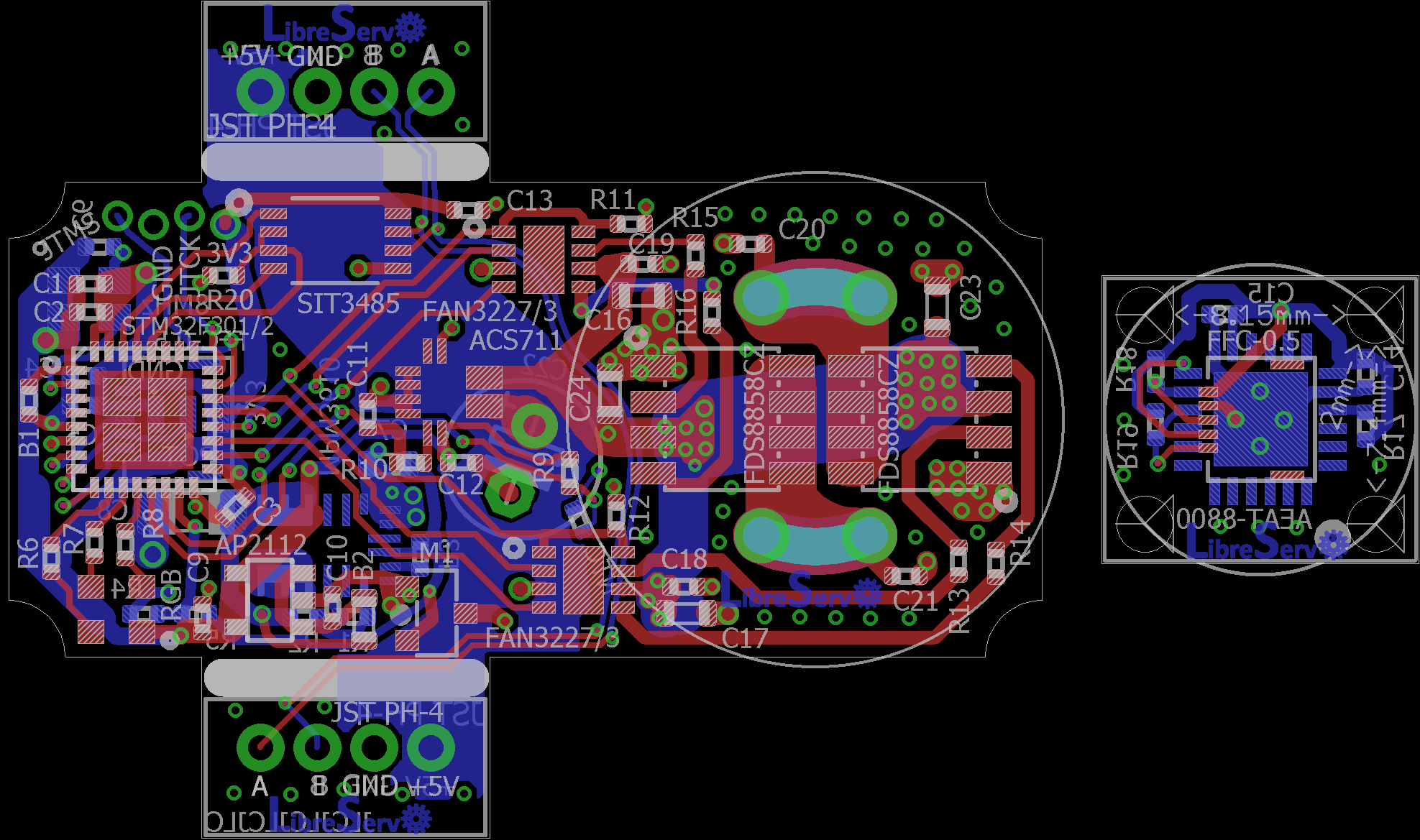

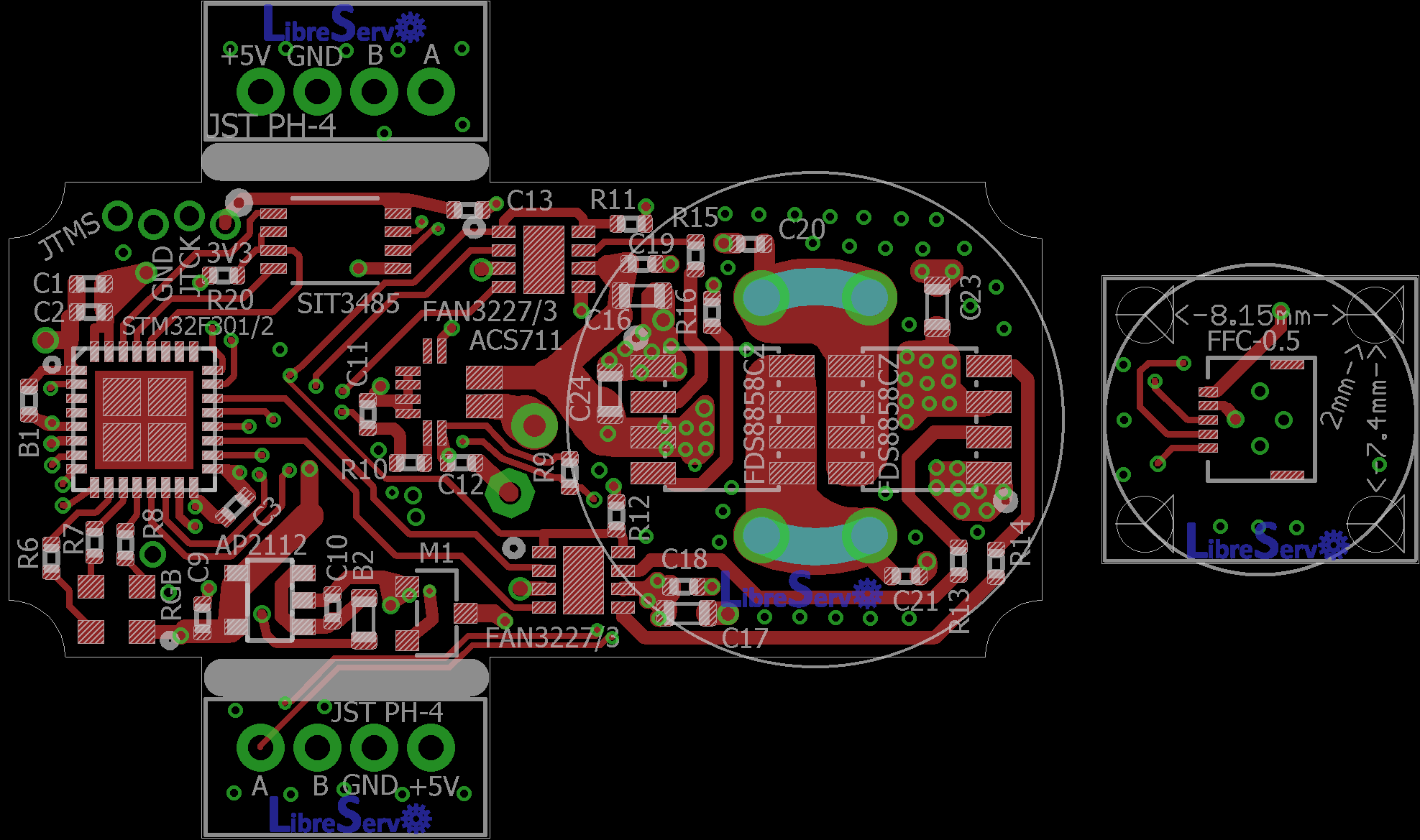

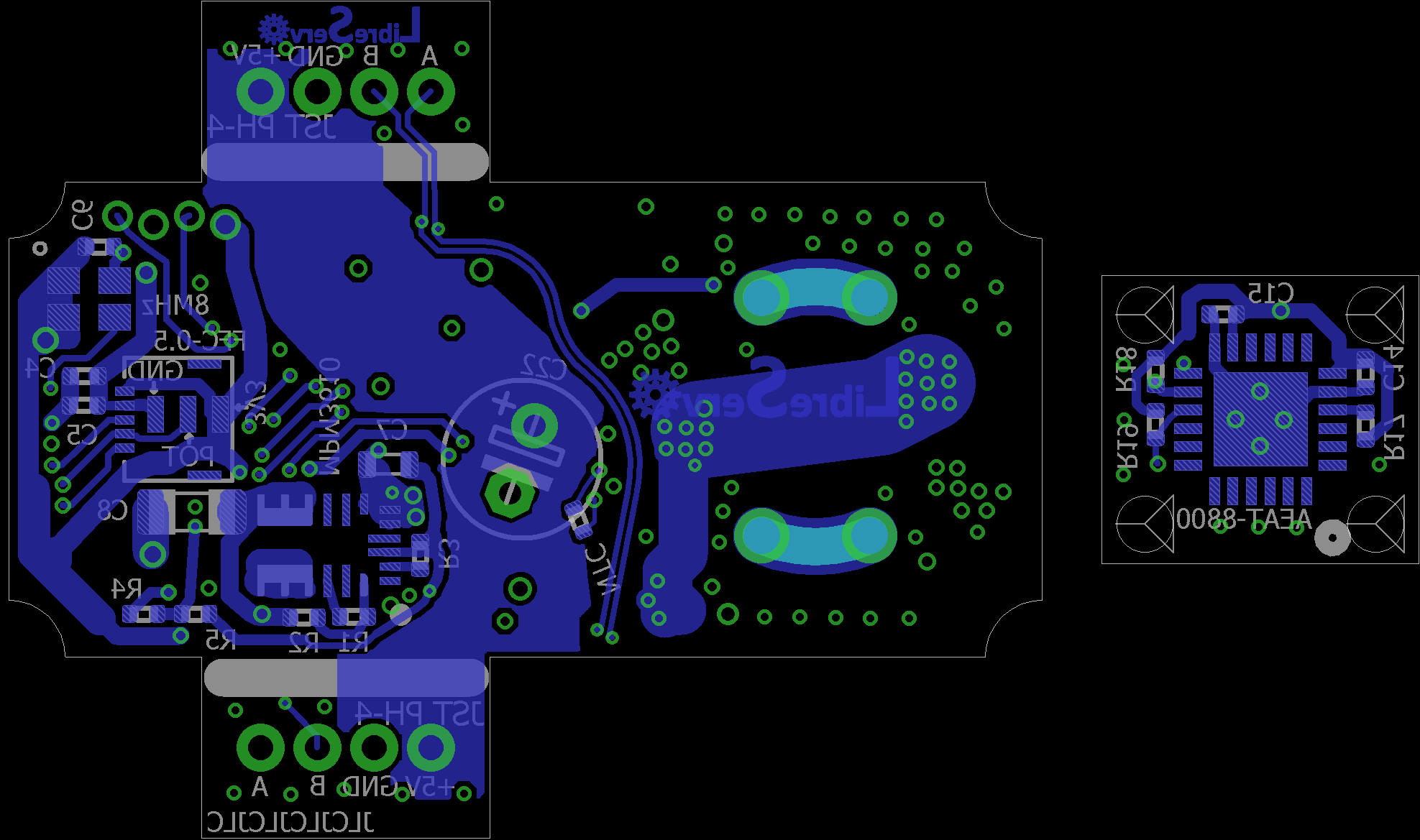

- Compatible with standard servo motors (No need to change the bottom cover of them!)

- Voltage: From 4.5V up to 18V (Recommended: 5-13V)

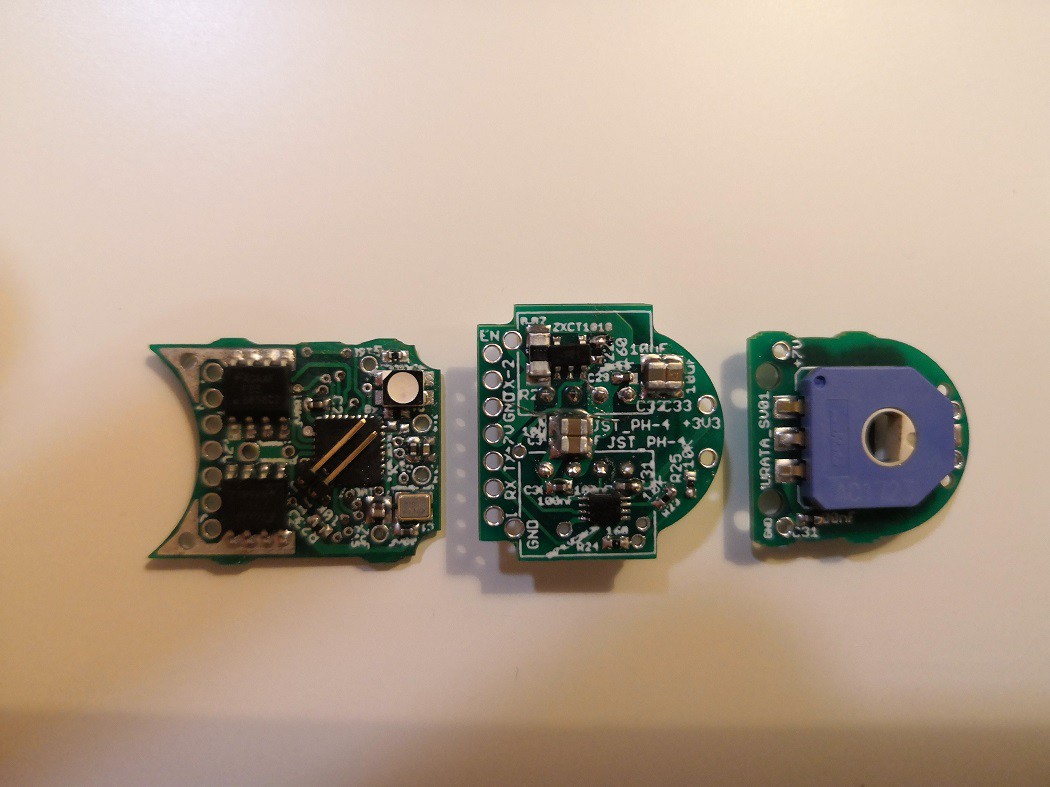

- Communications: RS-485 half-duplex. Max Speed 9Mbps. Daisy chained. CRC-16

- Amp: Up to 7A continuous (FDS8858CZ || VBA5311)

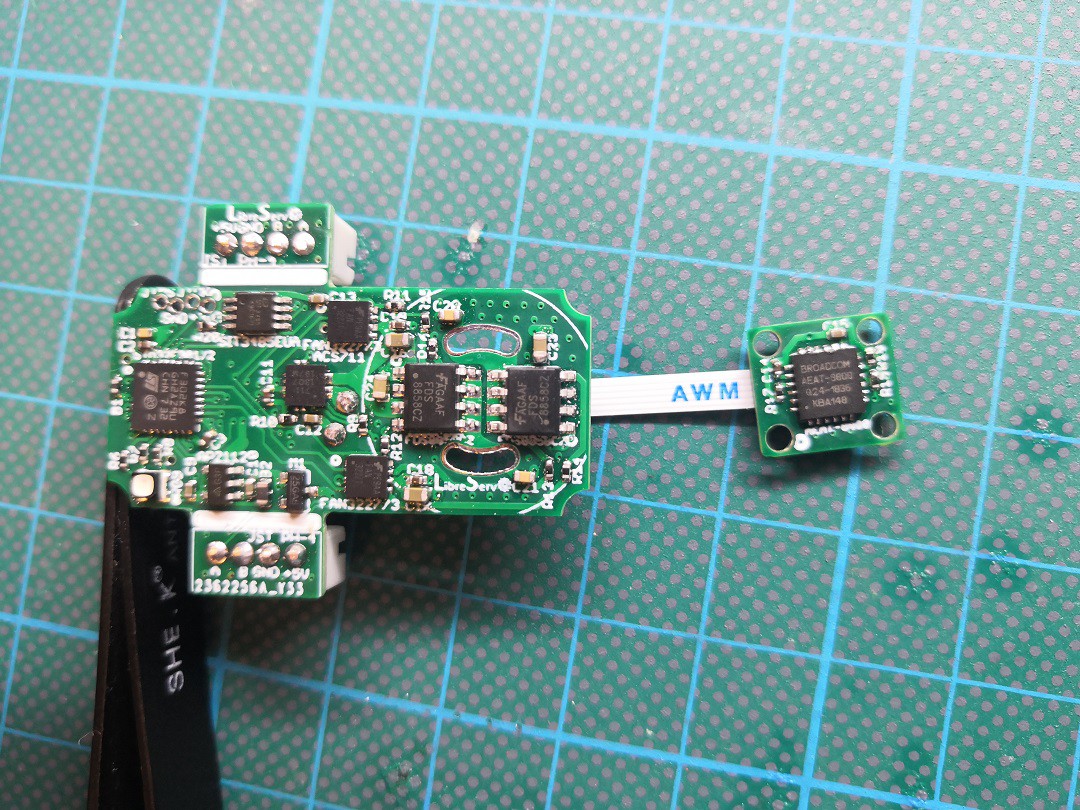

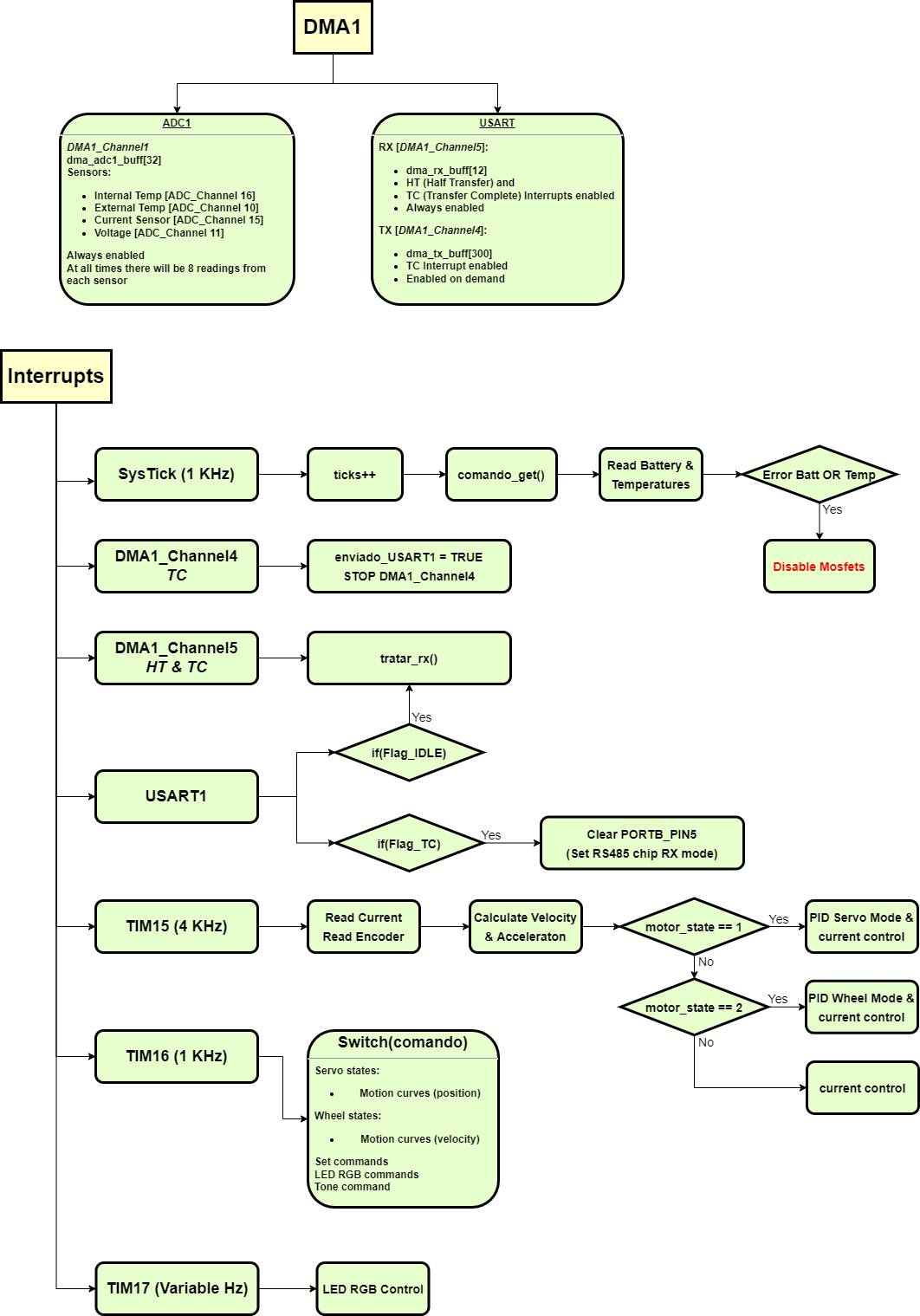

- Micro-Controller: STM32F301k8 (cortex-M4@72MHz)

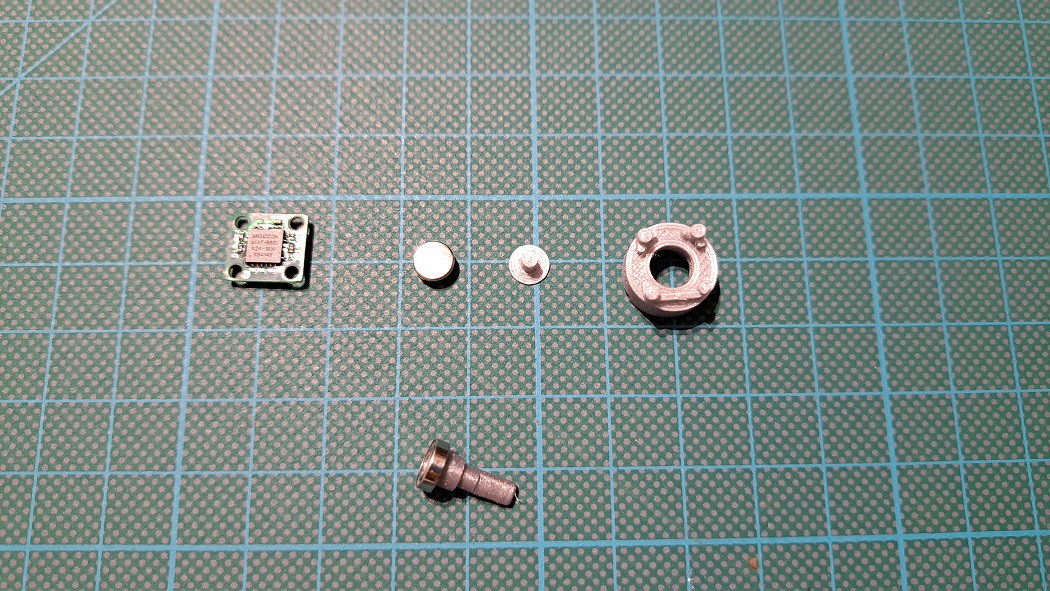

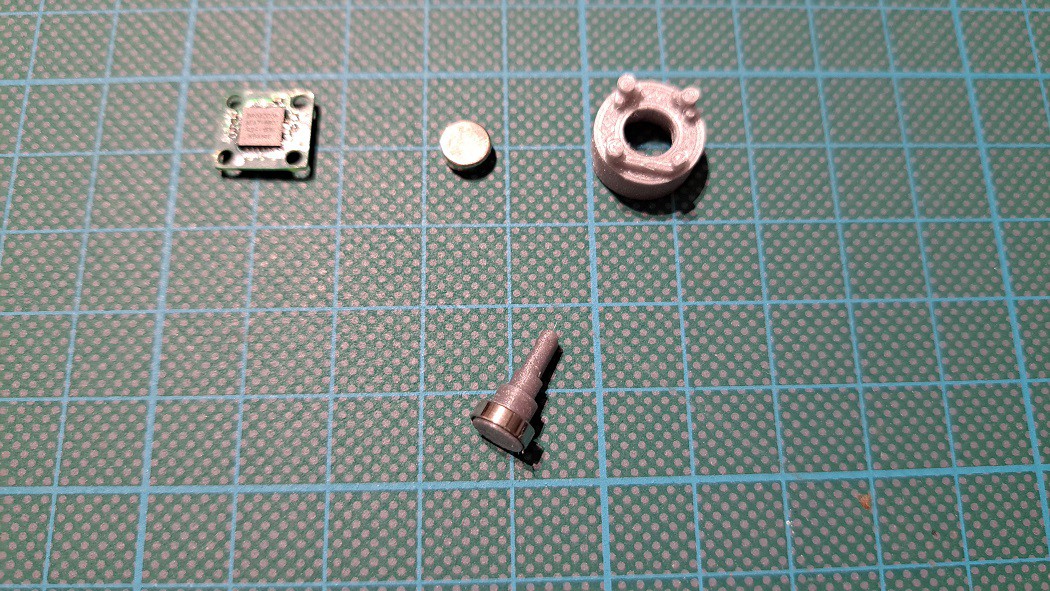

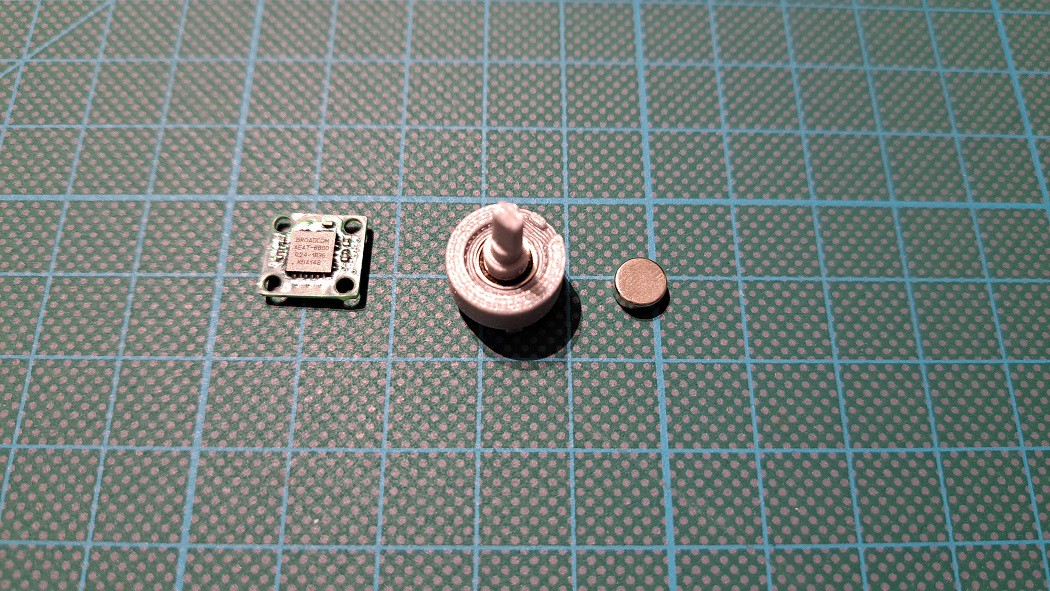

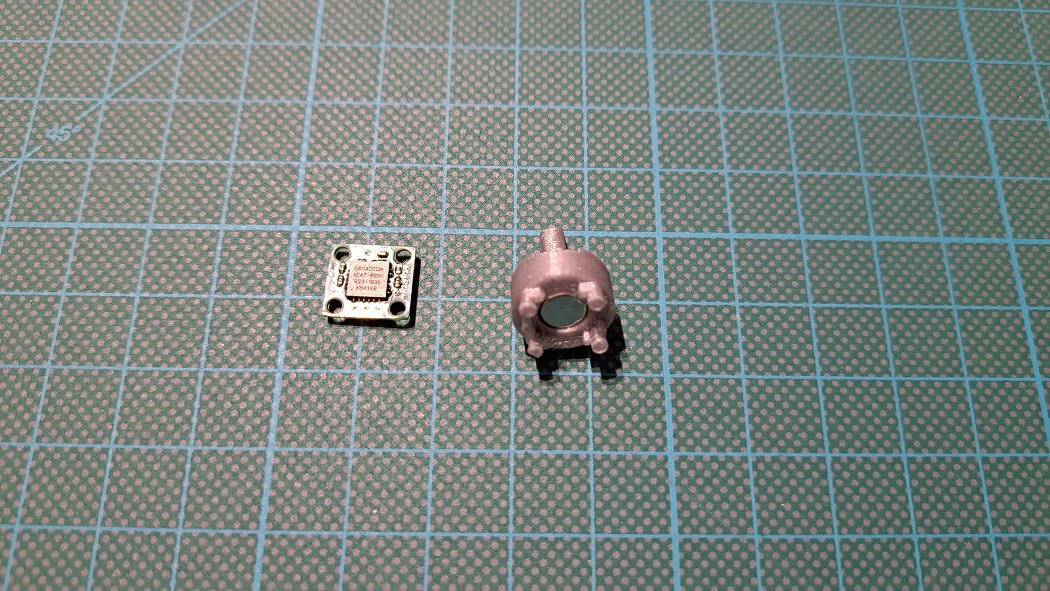

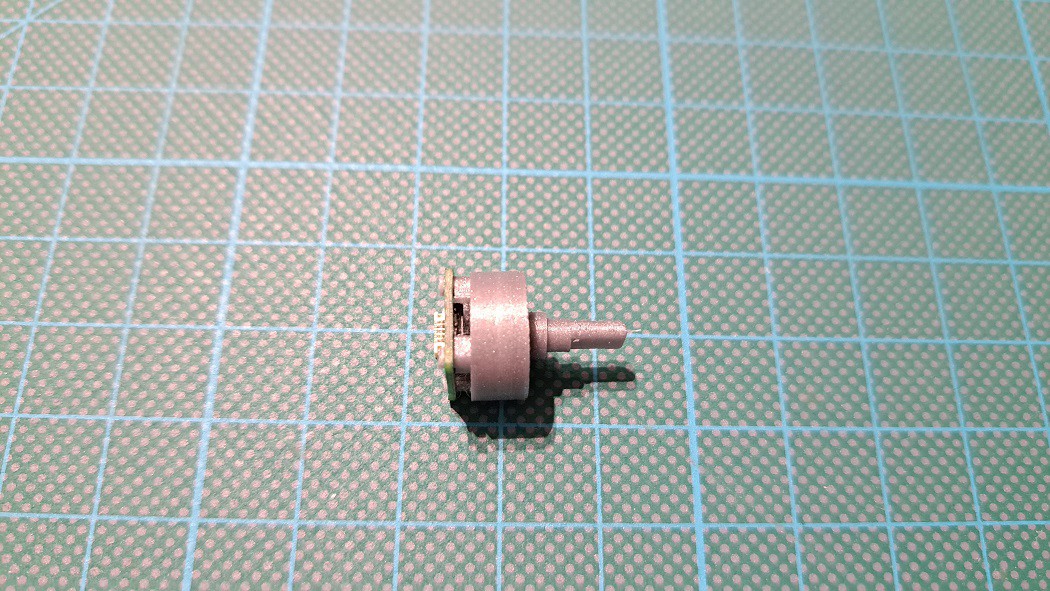

- Position sensor: Magnetic encoder, 16 bits of resolution! 360 degrees (AEAT-8800). Using the servo motor potentiometer will be possible to lower the cost but will lost precision and some characteristics.

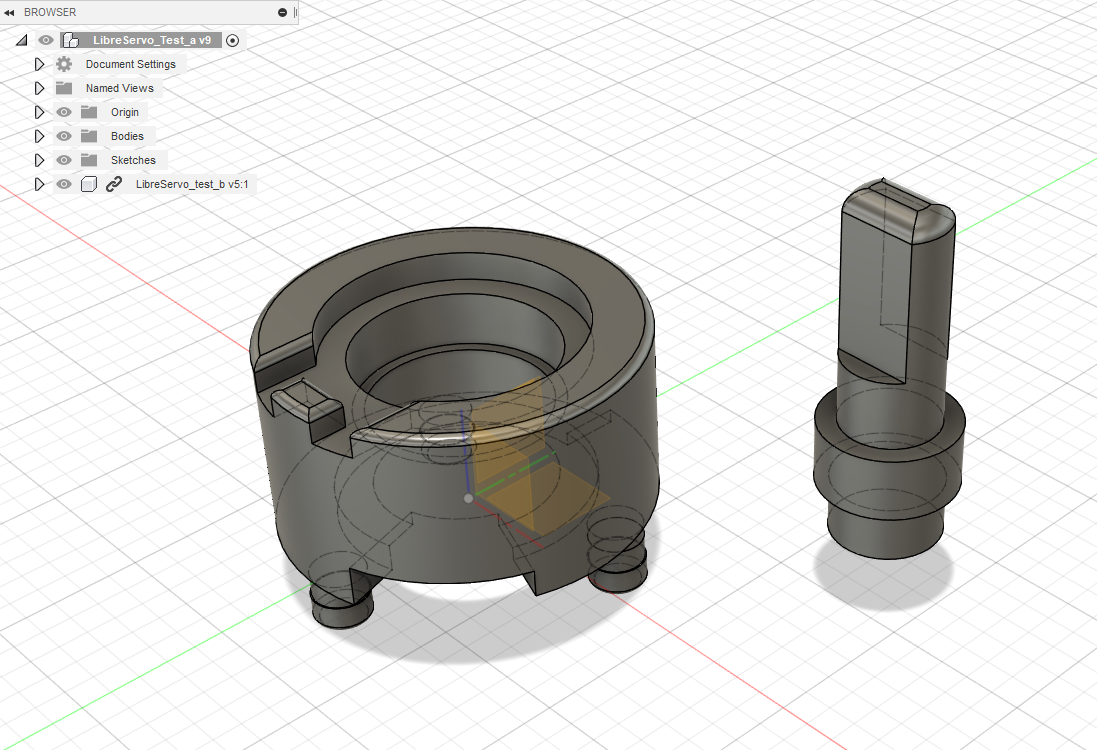

- For the encoder I have designed 3D parts to substitute the potentiometer and used the same hole/space than the original.

- LibreServo will generate their own curves (sine ramps, trapezoidal ramps, hermitian curves...)

- Current sensor: +-15A ACS711

I have tried to use good hardware, better than the commercial ones, and then, in the software side, I will try to really shine against the competence, communication protocol, huge flexibility, different motor curves...

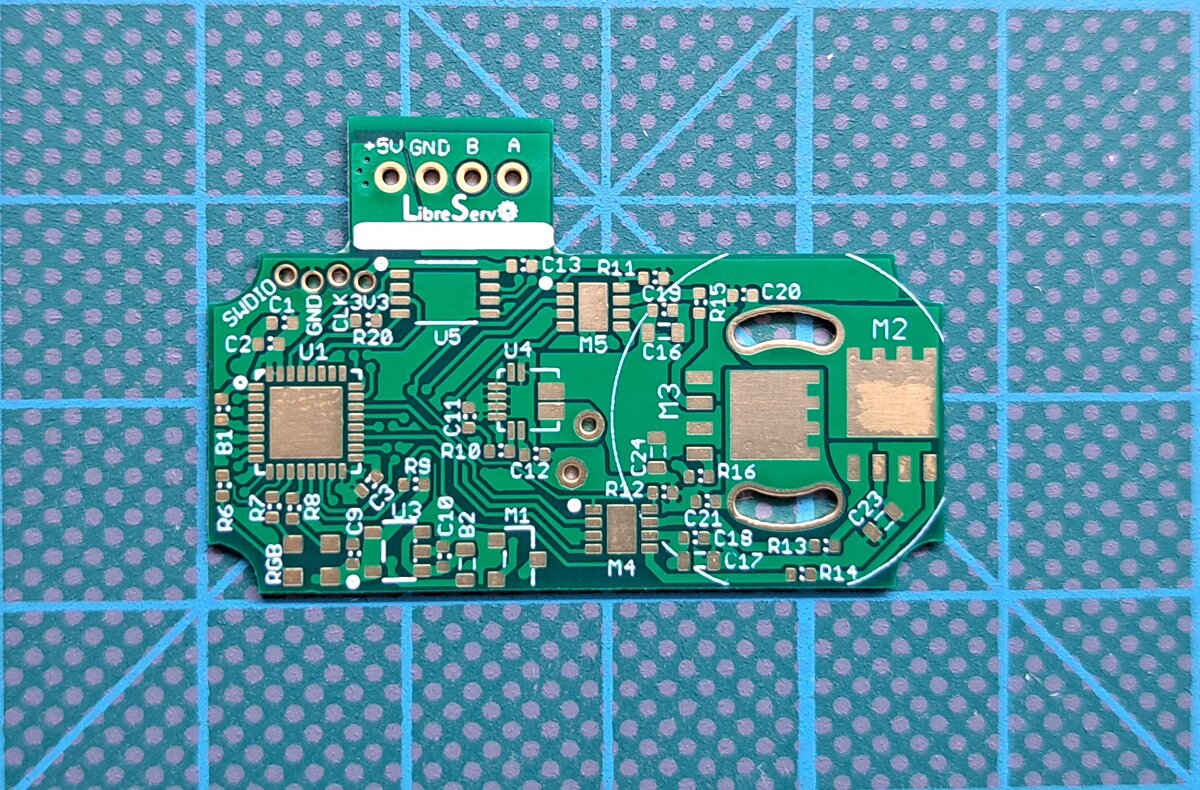

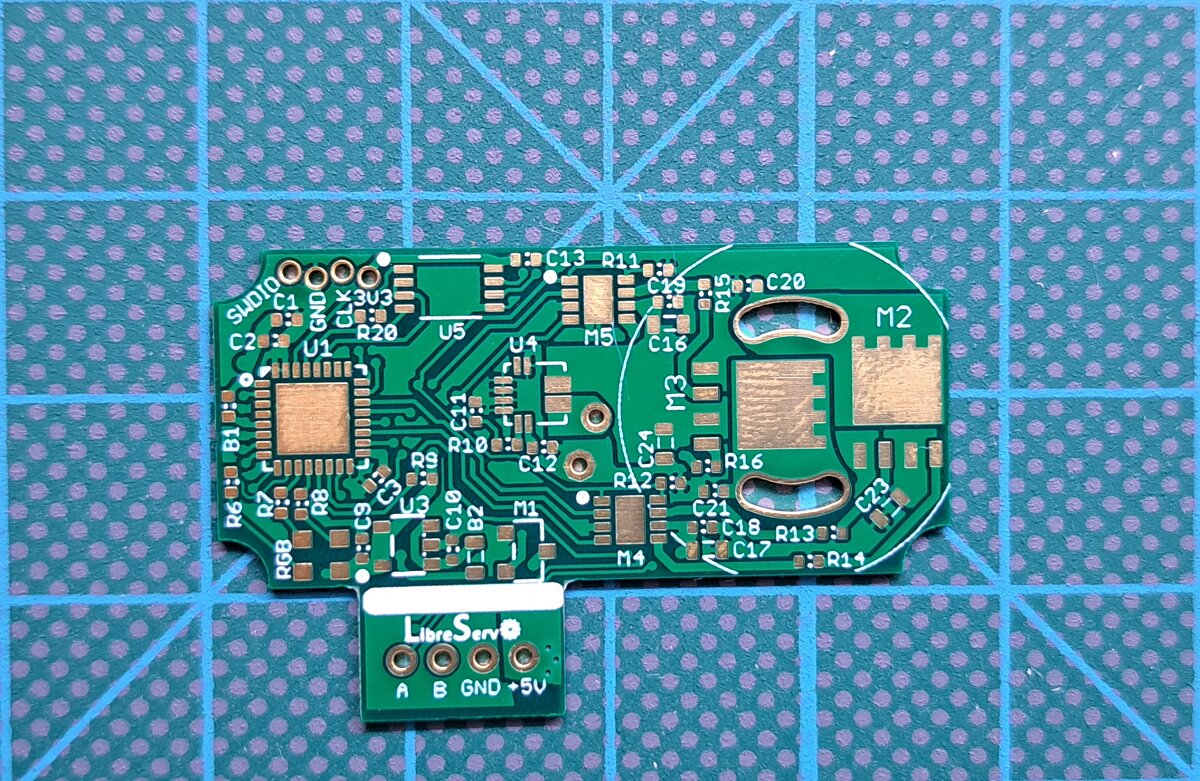

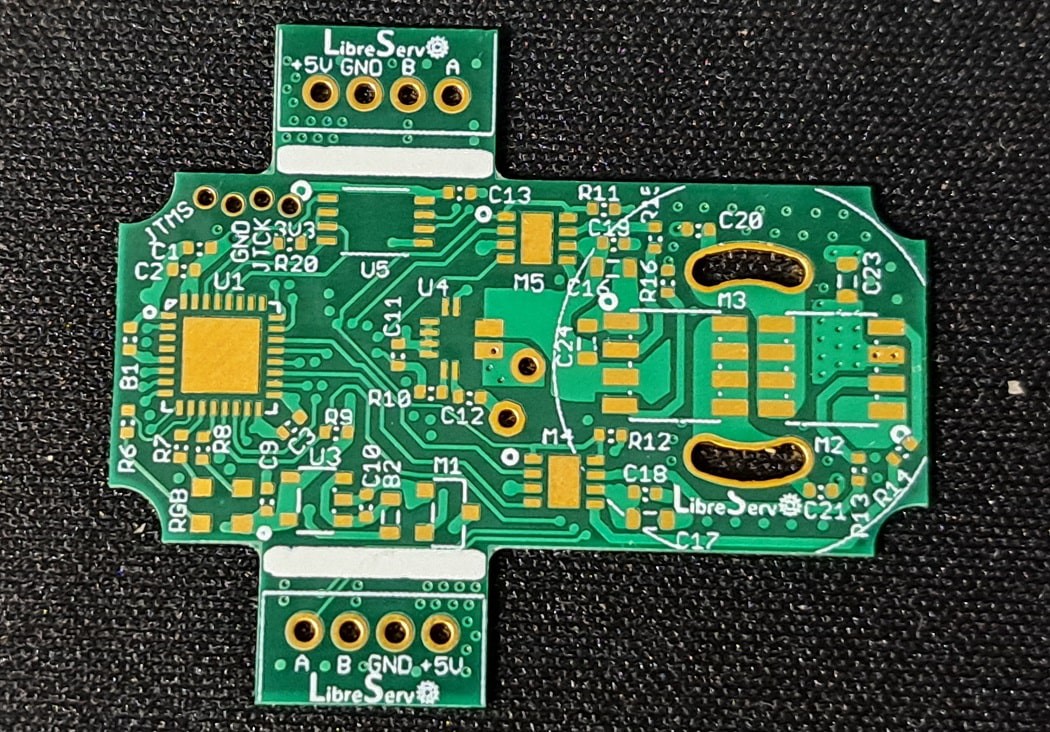

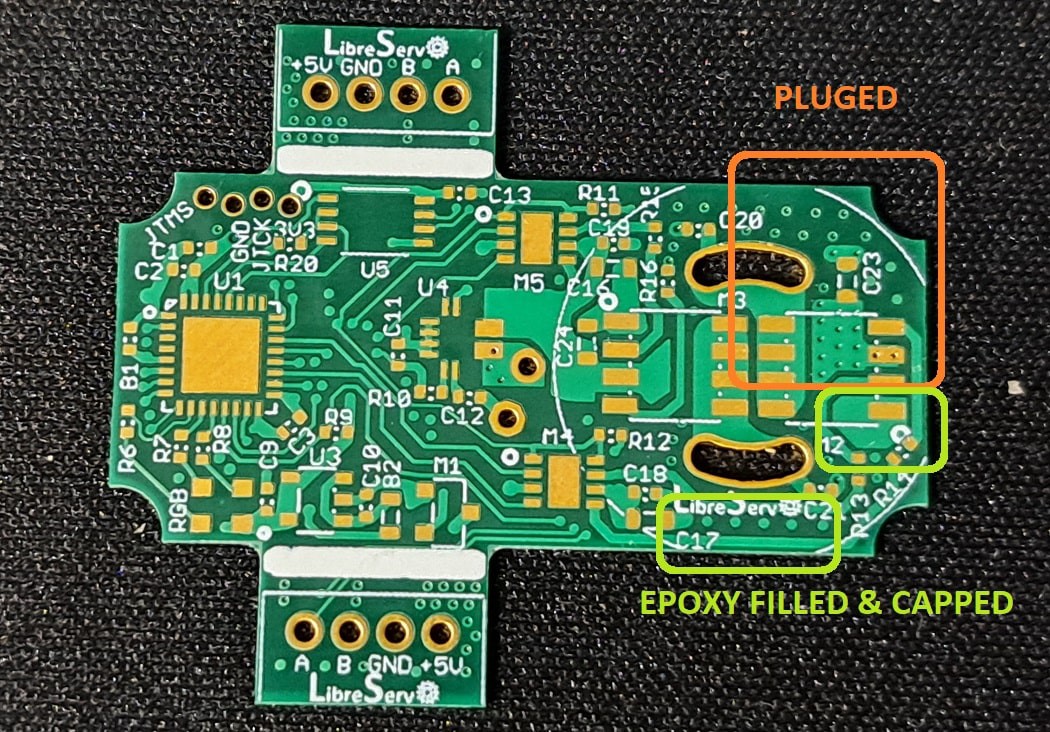

The project started 3 years ago, it has been progressing slowly because my lack of time but it will finish 100% sure even if it takes me 3 more years. I have been documenting my slow progress in the web/blog of LibreServo (partially translated). I have finished the third version of LibreServo, with every component tested and selected. I have changed lots of components from the first designs and also the final form factor.

**There will be versions with only one connector on one side or the other.

The following video is from the second version of the PCB test.

Luis

Luis

shane kirkbride

shane kirkbride

sq7bti

sq7bti

Joshua Vasquez

Joshua Vasquez

Looking forward to seeing this come to life! Currently learning how to maximize the potential of my servos and lx16a serial servos, but would love to mod my old dumb servos and give them new life!