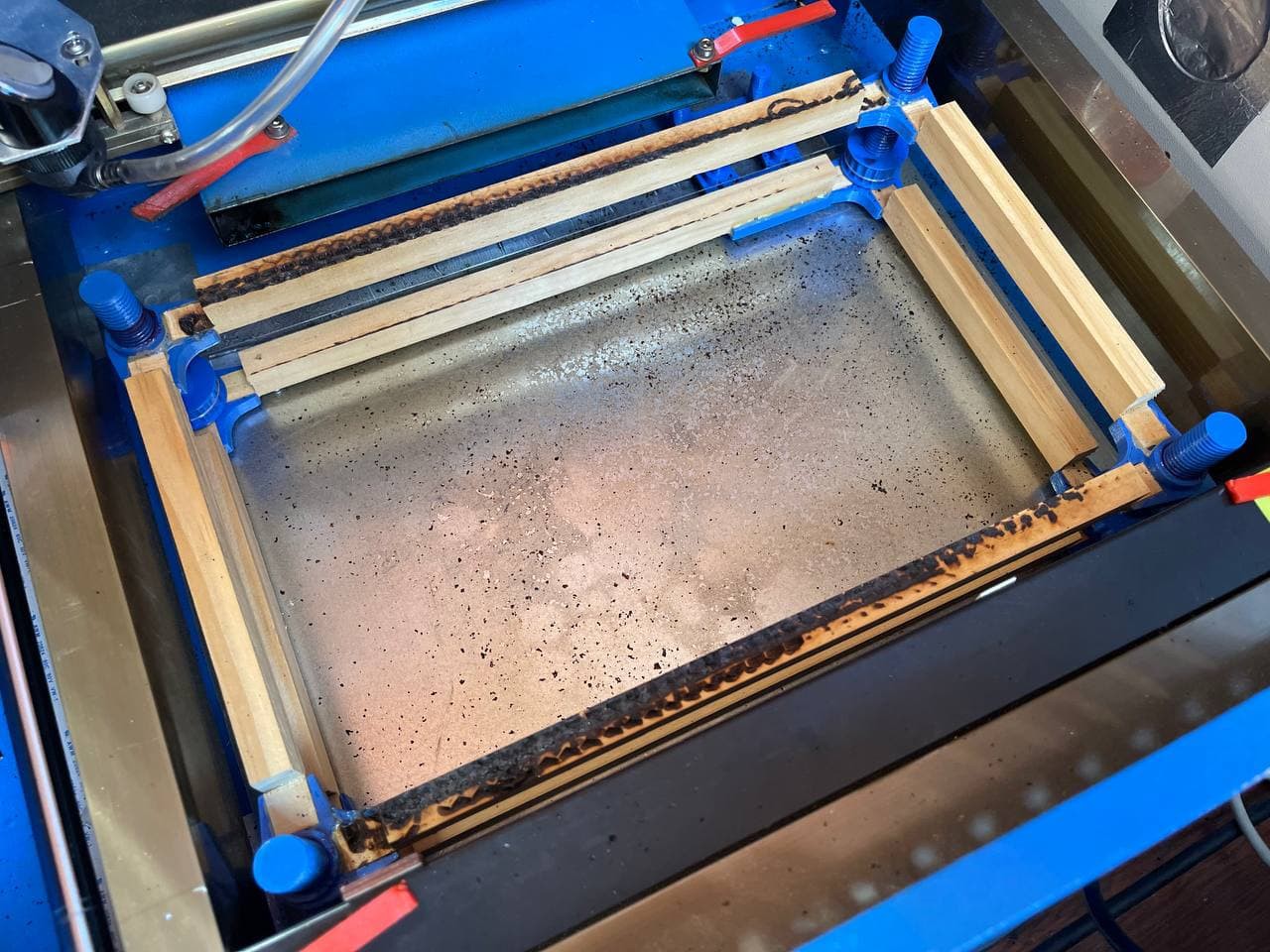

This is that table. The design already has all the properties of what I wanted to accomplish here: It's either 3D printed or laser cut parts, all components are integrated into simple multi-purpose parts that are easy to print by pretty much anyone, and it can be belt driven.

I made a huge error during my initial design, though, and calculated the belt length completely wrong (I had one 1440mm long T5 belt sitting on the shelve for years) and couldn't get the belt drive to work. So I used fishing wire to wrap around the printed T5 pulleys and kinda sorta used it that way to manually adjust the thing.

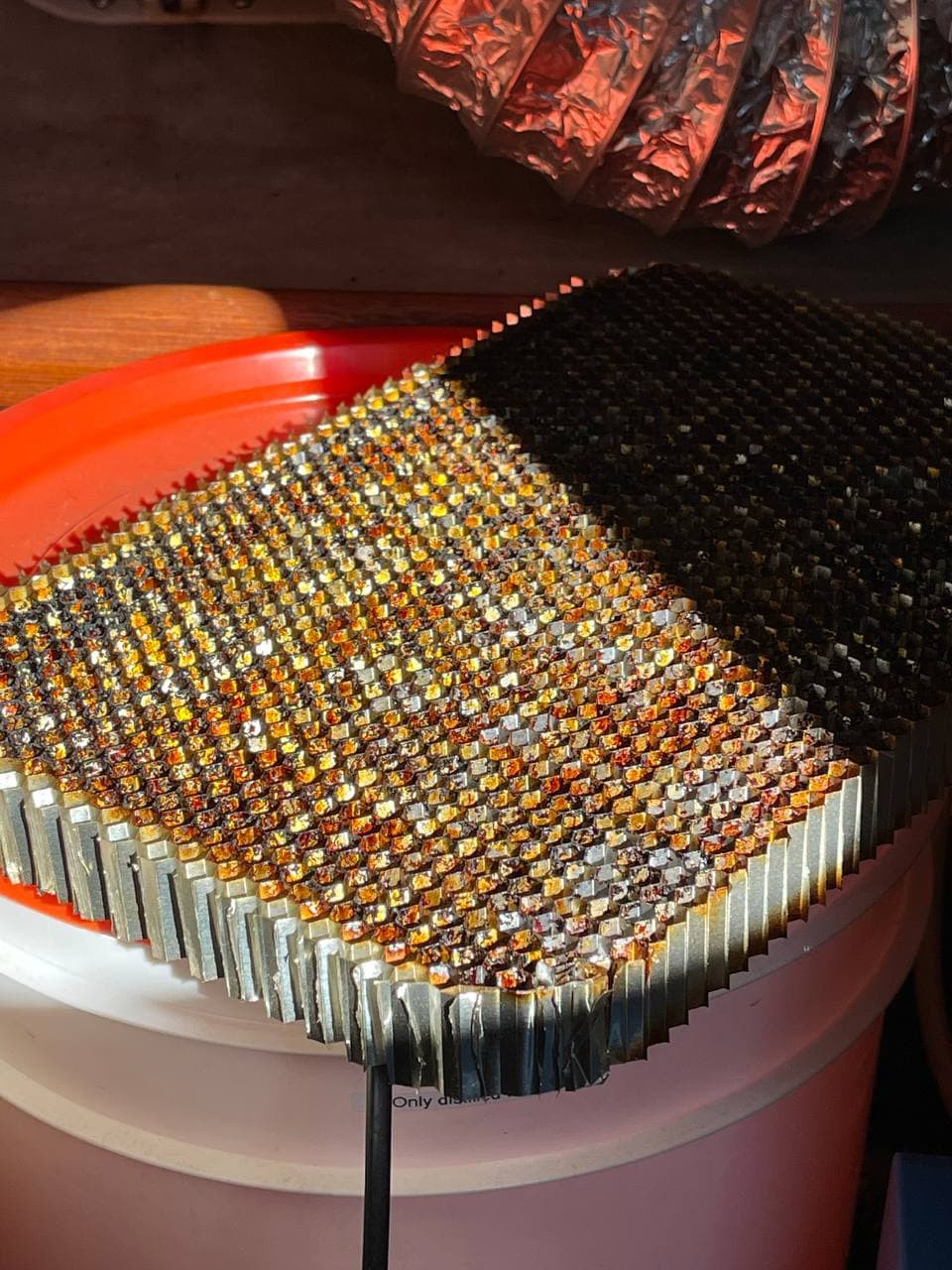

On top of the frame sits a honycomb mesh which is worth every penny!

As one can see, it's well used!

The table was usable until I got the great idea to finally add a stepper motor to it. I designed a hex-piece that fits over one of the threaded rods and allows me to connect my stepper motor.

After I connected it to my controller board (which I wisely designed to eventually maybe support this feature) I drove the table up and down few times only to realize that my "held together by gravity and wood-glue" setup is about to entirely disintegrate. That was five minutes after I tested the stepper for the first time. Great win!

Well, I guess I knew that wood glue doesn't work with PLA but at the time of putting the first table together, I was desperate and just needed this thing to be complete. It lasted many years of not being moved but when I moved it, every single joint broke and the ball-bearings just popped out of their seats. Great job. Well done.

Timo Birnschein

Timo Birnschein

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.