A handy extremely sturdy workbench

To make the experience fit your profile, pick a username and tell us what interests you.

We found and based on your interests.

So it time to transport it! The whole table is modular so it fitted neatly in to a trailer:

Once it was home it was time to assemble it. Due to the assembly process being tool-less it is quite quick to set up.

aaand Tada!:

The light is a phillips hue lightstrip integrated into the shelf. It is controlled via home assistant (automation system). The light will can change colour and will be automated so it changes color acording to the time of day. That way it can have a warm colour at night so I don't get fatigued so quickly by blue light in the night.

So today I finished the table! I started with mounting the led strip to the shelf.

I made a little hook from a picture hanger to manage the excess cable. Since i did not trust the included tape on the back of the led strip I added double sided tape in the groove for the LED strip.

I the started making to polycarbonate strip appear frosted. This was done with a belt sander:

I the started making to polycarbonate strip appear frosted. This was done with a belt sander:

after sanding the polycarbonate strip I glued it down with locktite epoxy.

I fount out that hammers worked excellently as weights while the glue dried! I then started cutting the threaded rods to length:

Tada! The table is finished!

It feels so good to be finished! Now i just need to transport it. The whole table can be disassembled into 4 main parts without any tools. The parts are the legs, frame, tabletop, and shelf. There will be a assembly video soon :)

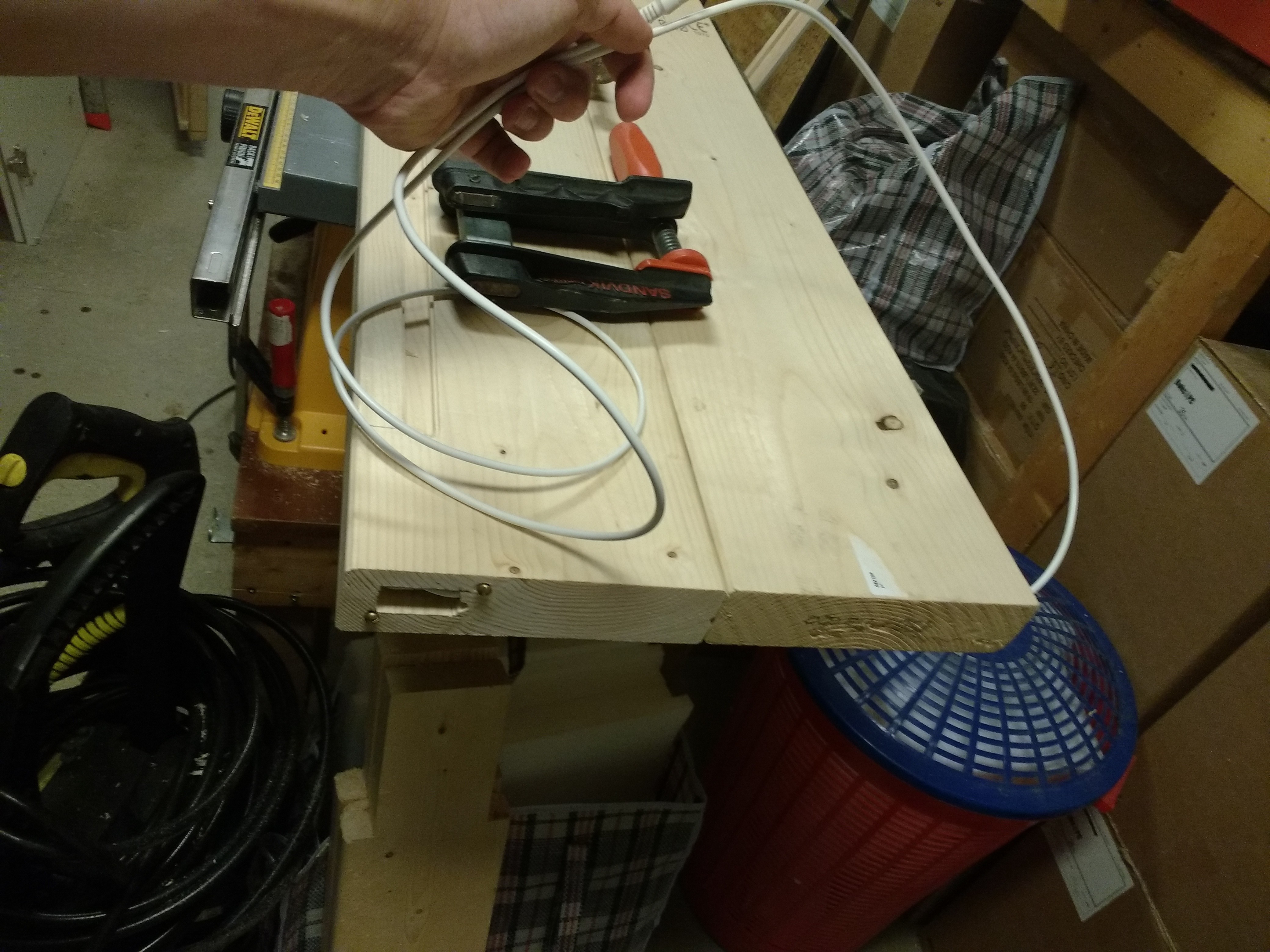

So two days ago I bought a second tabletop so that my tabletop can be the right depth. I then made sure to align it and glued it with essve easytack:

While I would ideally use a car full of clamps this approach worked very well. I then needed to cut the tabletop to length. As you can see the to parts of the tabletop i snot the same size. I measured the length of the shelf and used a some scrap material as a guide for the circular saw:

With the sawing complete I started with attaching the tabletop to the frame.

I got a brilliant advice that I should just make four wooden square blocks and align them to the inside corners of the frame. This way the tabletop was secure and easy to transport. I used double sided tape to place the blocks on to the tabletop and secured it with four screws.

Voilà! A secure and easy transportable tabletop. I the proceeded to mount the shelf to the table top. The first step was to use drill through the shelf and tabletop while clamped together. the next step was to drill wholes in the steel angles that hold the to parts of the shelf together. Ithen made a very quick mock up of how the table will look like!

It was very dark so the image is in suuper poor quality. It was very nice to see it come together. And how easy it was to disassemble to store it indoors. Tomorrow I will trim the rods and install the LED strip!

So today i continued with the shelf. I continued making the cable management hole in log number 2. I also start working on the steel brackets.

Here is the cable management hole tested:

I also cut the steel brackets to length.The plan is to use threaded rods and locking nuts to connect the shelf to the table.

tipptopptommelopp!

So now its time to build the shelf that will sit on top of the table! The table will conist of two 5X20cm planks and have a integrated phillips hue downlight. First I cut the plank to size and started to make the groove for the ledstrip.

I used a router to cut the grooves. I had to cut the grooves in parts because of the clamps.

Now i need ed to cut the second groove. the first one was for the led strip and the second is for frosted polycarbonate to have infront of the LED strip. A mock up is shown below:

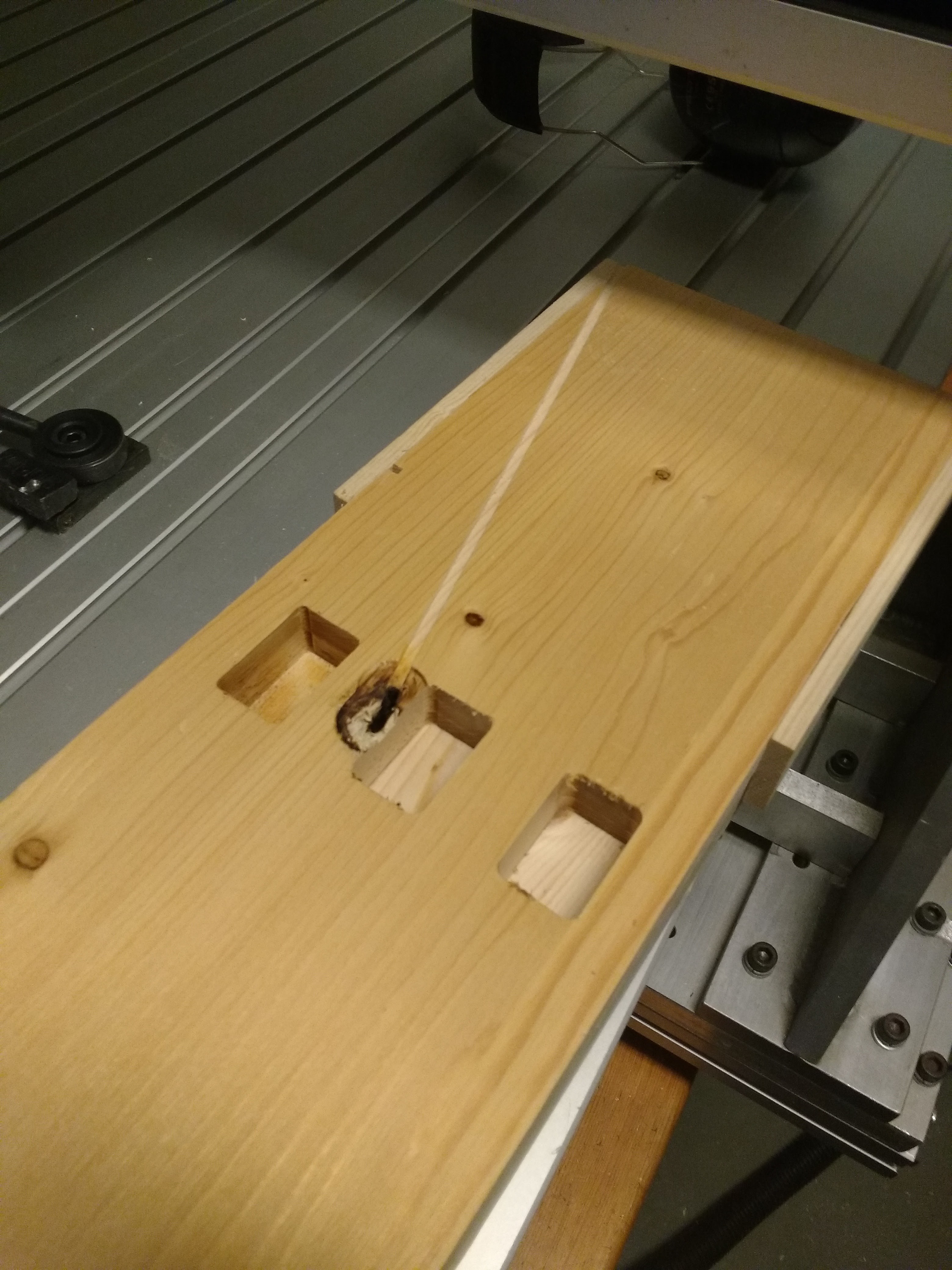

on the end of the LED strip there is an controller. I wanted this to be hidden so that the downlight was fully integrated into the shelf. I therefor started to make a pocket that could house the controller.

I measured how big the pocket needed to be and drilled multiple holes to make it easier to use the chisel.

Tada! Finnished pocket hole with controller inside:

I then needed to drill a hole into the pocket so that i could route the power cable to the back of the table.

I made a smal hole connecting the groove and the pockethole together so that the LED strip and the controller could be connected. Now I just need to make a coverplate.

Tada! Coverplate completed. (sort of, I am going to make it look nicer later when its not so late). Tomorow I will try to join the two planks and make finger joints.

Tada! Coverplate completed. (sort of, I am going to make it look nicer later when its not so late). Tomorow I will try to join the two planks and make finger joints.

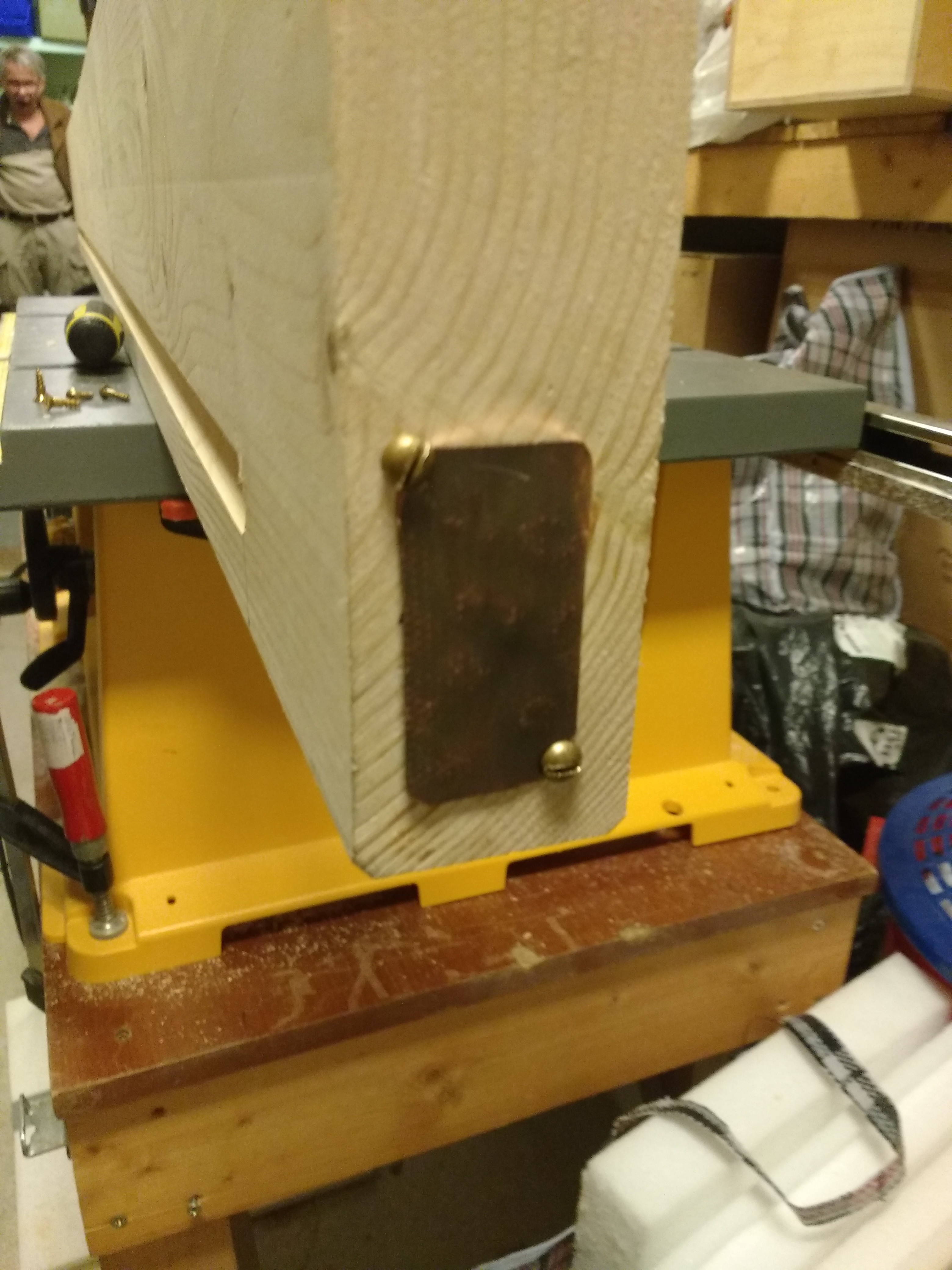

So next I have to make a tabletop support beam that the tabletop can be mounted to. I started making a cutout that the back end of the beam can slot into.

This was done with the Japanese handsaw and a chisel. On teh other side of the supportbeam I needed a plate that could be monted with screws. I straightened an angle iron and countersunk the holes.

Now that all of the components of the structure is complete I sanded it and glued it together.

Now that all of the components of the structure is complete I sanded it and glued it together.

Next step: A shelf to sit on top of the tabletop(cant go to the store to buy the tabletop for some days so I build the shelf first instead)!

So yesterday I made some patterns for where I would like the screws to be. This was to ensure that the whole thing would stay together:

I also countersunk the screwholes with a countersink bit :

First set of screw holes finished

Table assembled with screws. Sanding and tabletop support beam next.

Sooo, It´s been a while since I have worked on this project. But now I finally got time and opportunity to continue to work on this project. I tried to make the finger joints with a router and a guide. Almost half a year has past and I decided to use this newly acquired thing instead:

A Japanese handsaw. This turned out to work beautifully. So I used the guide to draw out where I should cut got to work.

After some sawing I started using a file for the small details.

I started with the fingerjoint on the sidepieces of the table. I then made the fingerjoints on the eeehm, long pieces.

and a preview withe a tableleg attached(I held the leg up with my foot hence the blurry picture):

and a preview withe a tableleg attached(I held the leg up with my foot hence the blurry picture): Test the front assembled

Test the front assembled  Finger joint on the back side table.

Finger joint on the back side table. Suddenly:

Suddenly:

Whoa! A frame!

Whoa! A frame!

ooh, the frame is assembled with legs! It still needs glue and screws but quite a lot of progress has been made. I also put the tabletop just to see how it looked:

So.. I got the new router spindle from Grønvold maskin. It arrived from Bosch to the store yesterday and I picked it up today.

I got to the workshop and realised that they had sent me an 6mm router spindle. My custom router bit has a 8 mm shaft. As you can see in the picture it is a decent amount of nope, that wont work. So no I have to order a 8mm router spindle. *Sigh*.

So next up was finishing the templates. The first try the cnc-machine wasn't properly zeroed and it ended up like this:

Ouch. that does not look good. and trust me it wasn't. It broke the 4mm end mill bit in half. Well, lets try again:

Well, the reason this template isn't finished is because the end mill broke. again. By this time I was having a strong feeling that something was done incorrectly. We moved up to a 7mm bit that solved the problem.

But "stop!" I hear you say. "Why are the holes in the midle and not the edge?". Well for some reason the cnc program decided that this specific modell should be in that direction. We solved by just obeying the cnc program and cut in on a tablesaw later. Some support brackets and a testfit later it looked like this:

Not to bad! now, lets flip the template and the other side.

Exactly as planned(except for those cnc mistakes that will have no practical complications).

"But what are those screws for?"

well to make the templates I needed them to be hold down securely and have some kind of sacrificial bed. so what i decided to do was to take one of the extra pieces I had for the table and make the side brackets and mount it to that piece with screws. That way I knew it would not move when the cnc was, well cncing. The clock was like really late now so I was so excited to try the template. I did. and failed completely. The problem was that I was cutting to fast in to the workpiece and the router but jammed itself and flew a couple of meters. It destroyed the router spindle so, lets not do that again... Luckily and going on a trip this week and the new spindle is already ordered so it should not set me back time wise.

Create an account to leave a comment. Already have an account? Log In.

Thanks for the thorough feedback. A lot of interesting ideas here. Power isand net connections is always neat. In the same room I have my LAN/office table that I use for my computer Tasks.

https://hackaday.io/project/4236-the-lan-table

I might add a slot in power strip some day. I have seen those that can easily be integrated into the table top:

But for now I am satisfied with how it is. The back plate is a good idea and I might add it if I get heavier loads on the shelf. Under the table I have toolboxes on casters so that it is easily accessible. Thanks for the comment :)

Become a member to follow this project and never miss any updates

Geoff Nicholson

Geoff Nicholson

Øystein

Øystein

David Tucker

David Tucker

Your joints turned out nice. I have two constructive comments, these may have been design choices, but things to ponder.

The first comments are on the shelf/light. I would add a couple of things to it. The first one is a long flat piece of wood to go between the threaded rods. You could get fancy and make pockets for it, or just count on the threaded rods to clamp it in place. The thing is at some point in time you are going to put something heavy on the shelf and the wood will take the load and not the rods. The wood would have a larger surface to distribute the load over. On my bench I laminated 2 pieces of 1x8 wood together for the sides so one piece of he 1x8 sits on top of the bench, and the other piece overhangs the sides by the length of the benchtops skirt, and it is screwed into the skirt with high quality star drive deck screws that are easy to get back out if I ever need to move it. The other thing I did with mine is I built a skirt on the back of the shelf that hangs down roughly 3" and is screwed in all along the back edge of the back and into the sides. This acts as a gusset and keeps the wood from bending under load and also gives the shelf side to side rigidity. On the front of the shelf on one side I mounted an industrial power strip and on one end, hanging from the bottom, I mounted an Ethernet switch. Now I have power and ethernet handy at my bench. I have two different colored ethernet cables running to it that I can plug in. One is my home network, and the other is a dedicated DMZ that has internet access but not access to anything else. I can use the switch as an island with nothing plugged in, as a switch on my network with one cable plugged in, and as a generic internet connection if I plug the other wire in. About the only thing I don't wanna do is plug them both in at once. I count on my brain for that. Perhaps not the best of ideas but it works for me.

The other thing is with your legs. It looks like you are counting on gravity to hold them in. I would do a bit more. You could cut out along skinny rectangle in the center and use a piece of threaded rod to hold them in place, that would look cool and similar to the way the sides are constructed. You could also drill small holes in the skirt where the legs come through and stick a nail in there as a pin. Or use a good quality star drive deck screw that is easy to get in and out to hold it. And last, I would put struts on the bottom for a shelf. You have a lot of space for a shelf down there and that piece and the stuff to hold it would stabilize the legs. Now they are long and have nothing to keep the properly spaced at the bottom. This would give you storage and solve that. I keep my laser cutter on one side of my bench (and put a cover over it when not in use so I can put notebooks and stuff I am working on, literally on top of it.. I keep my cooling system for it on the shelf as well as the little airbrush compressor for the air assist. as well as tons of other stuff that I like to keep on hand.

I like the looks of it though. Benches and storage are always handy. as is power and net connections.