A full 1kg roll arrived wet from the factory, so it went into the dehydrator for 7 days.

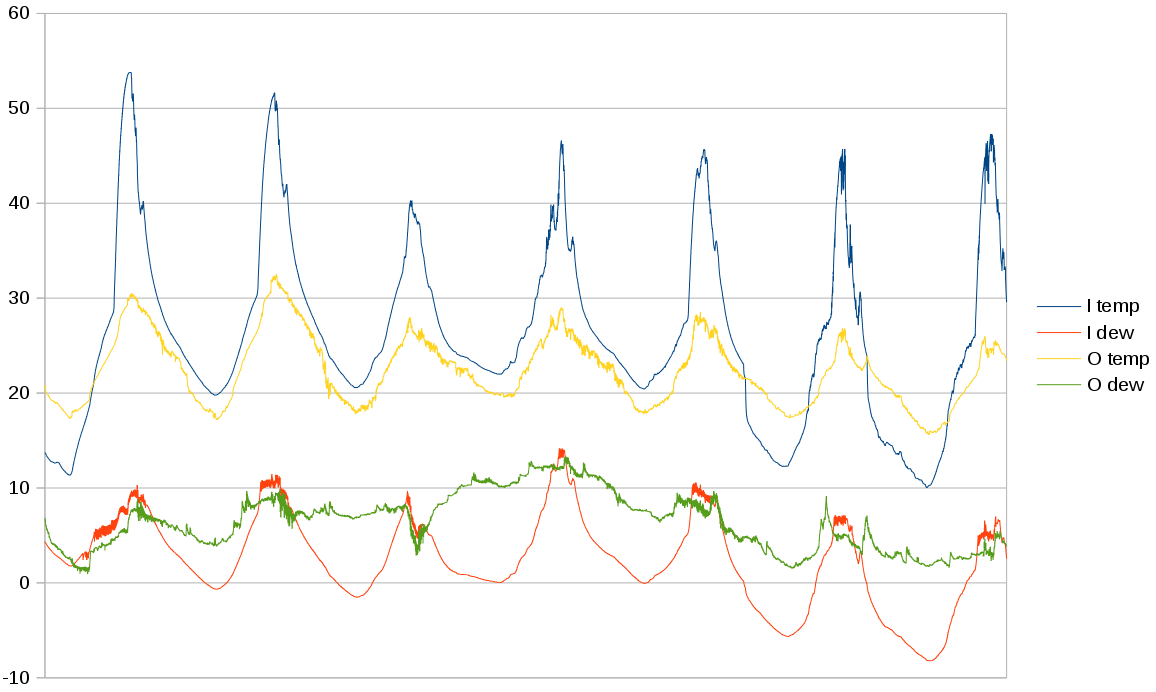

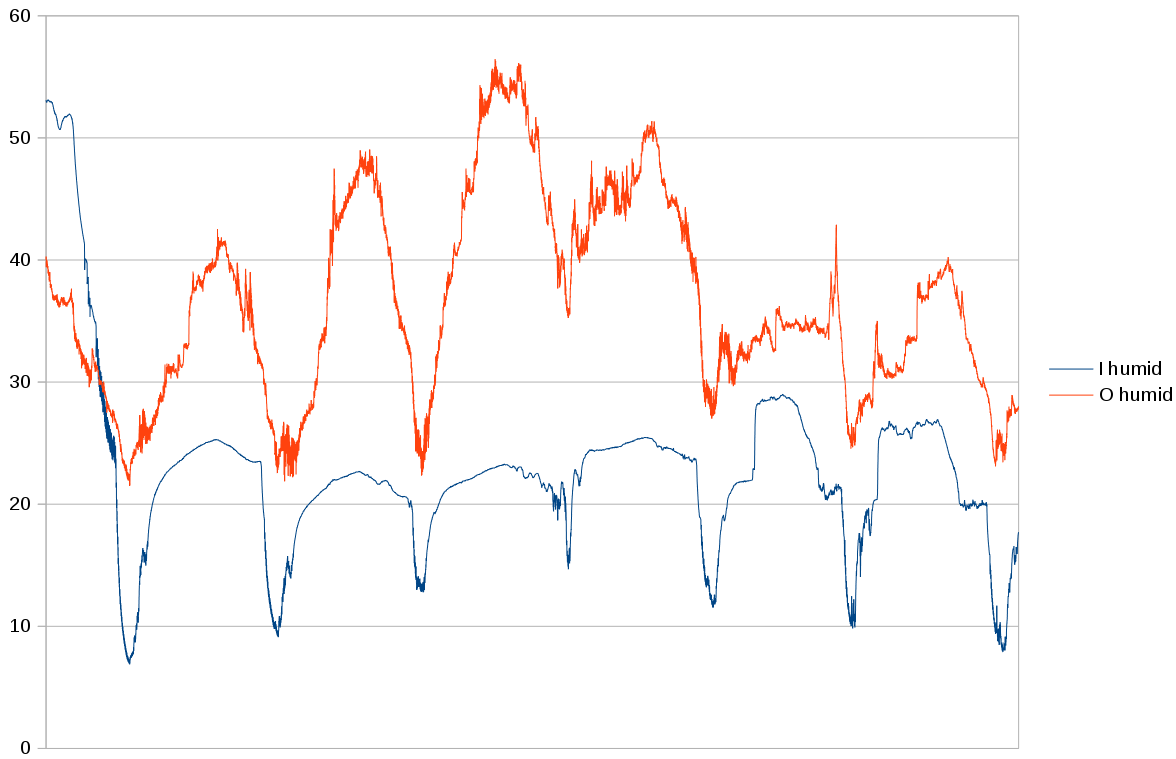

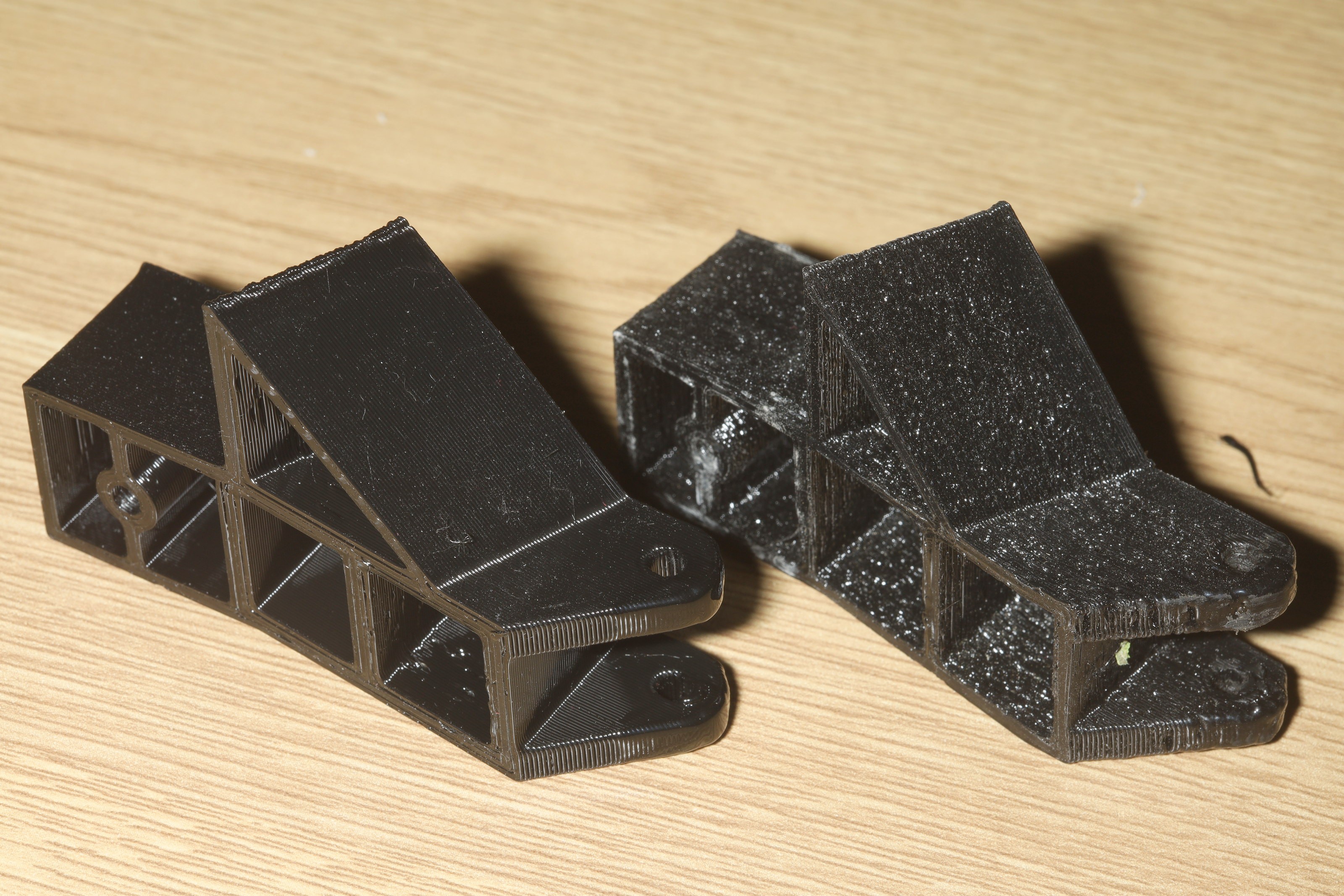

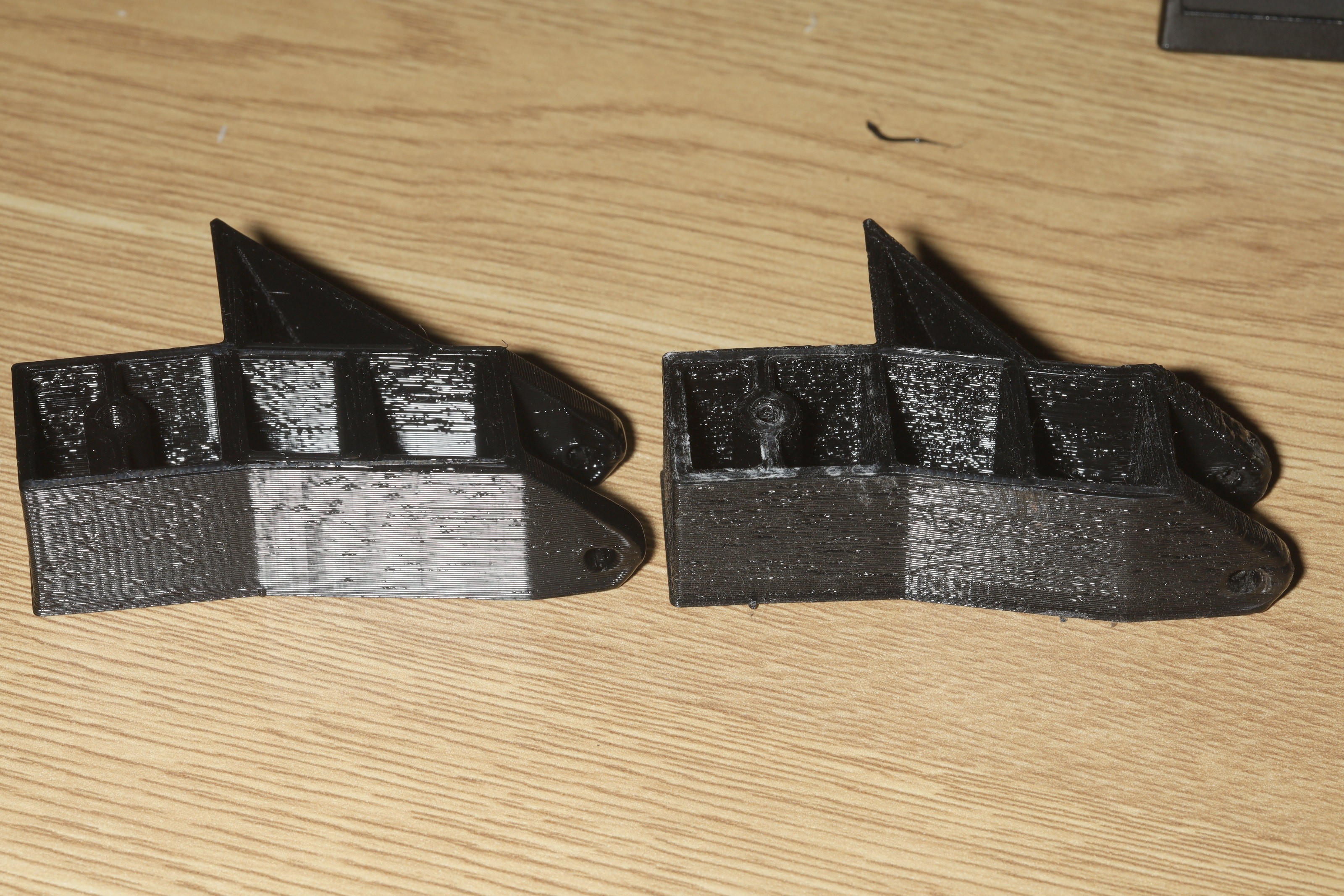

Most of those days were cloudy, but temperatures & humidity were higher than winter. The dried filament still did a lot better on a part than the new filament. It wasn't perfect, but it was good enough to not bother enhancing the drier.

Lions have found filament which isn't on a roll doesn't dry at all. It seems to absorb water from being handled by lion paws.

The dehydrator has problems. Blocking the inlet doesn't slow the pump down, so it's not very air tight anymore. The pump is real noisy, now runs all day continuously, & turns on at night when the roll is fresh. Waking up to the pump is brutal. The pump has a duty cycle to limit the noise, but lions don't care if it wears out. The best it can do is reach a constant equilibrium where the humidity is always lower on the inside than the outside & the filament is heated for part of the day.

There could be leaks where the tubes enter the container or the container itself could be keeling over. That was the only container a lion could afford.

The plan is to replace the pump with a vintage Nidec blower. Use the largest clear tube which is flexible. Print right angle connectors & a connector to the blower. Route all the wires through the air tubes. The 1st step would be measuring how much air the blower can force through a tube of a certain diameter.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.