Driving them off the same PWM does work. Get the confuser to close the valves before installing the servo. Then install the servo in the closed position with slight tension on the TPU. The valve closes by turning counter clockwise, so the TPU has to be twisted slightly in the clockwise direction.

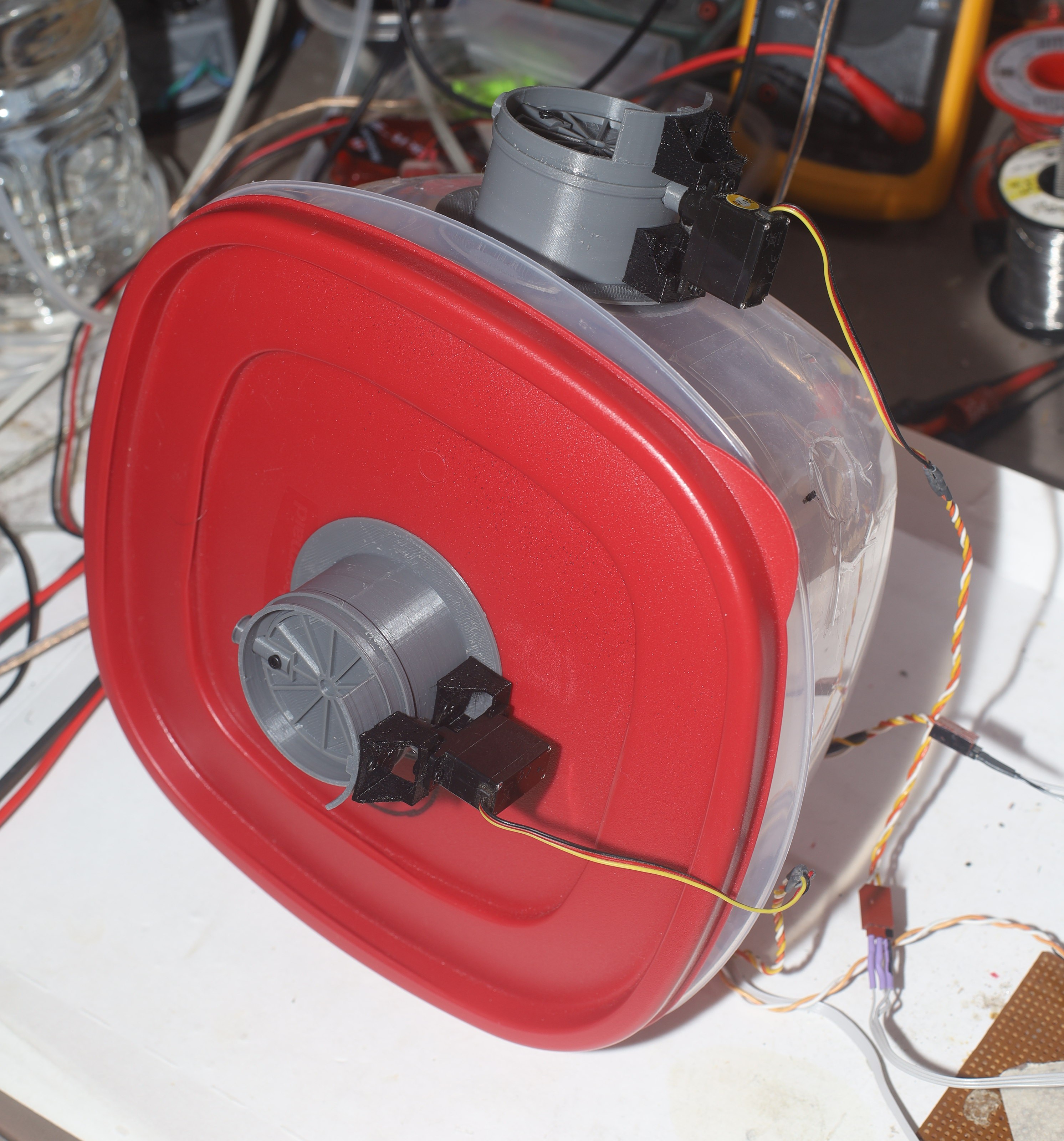

There was no way to put the 2nd valve any lower than half way, so it went as close as possible to the circulation fan. The mane problem with valves is the inlet air is much warmer than the outside sensor. The sensor can't go near the heated container.

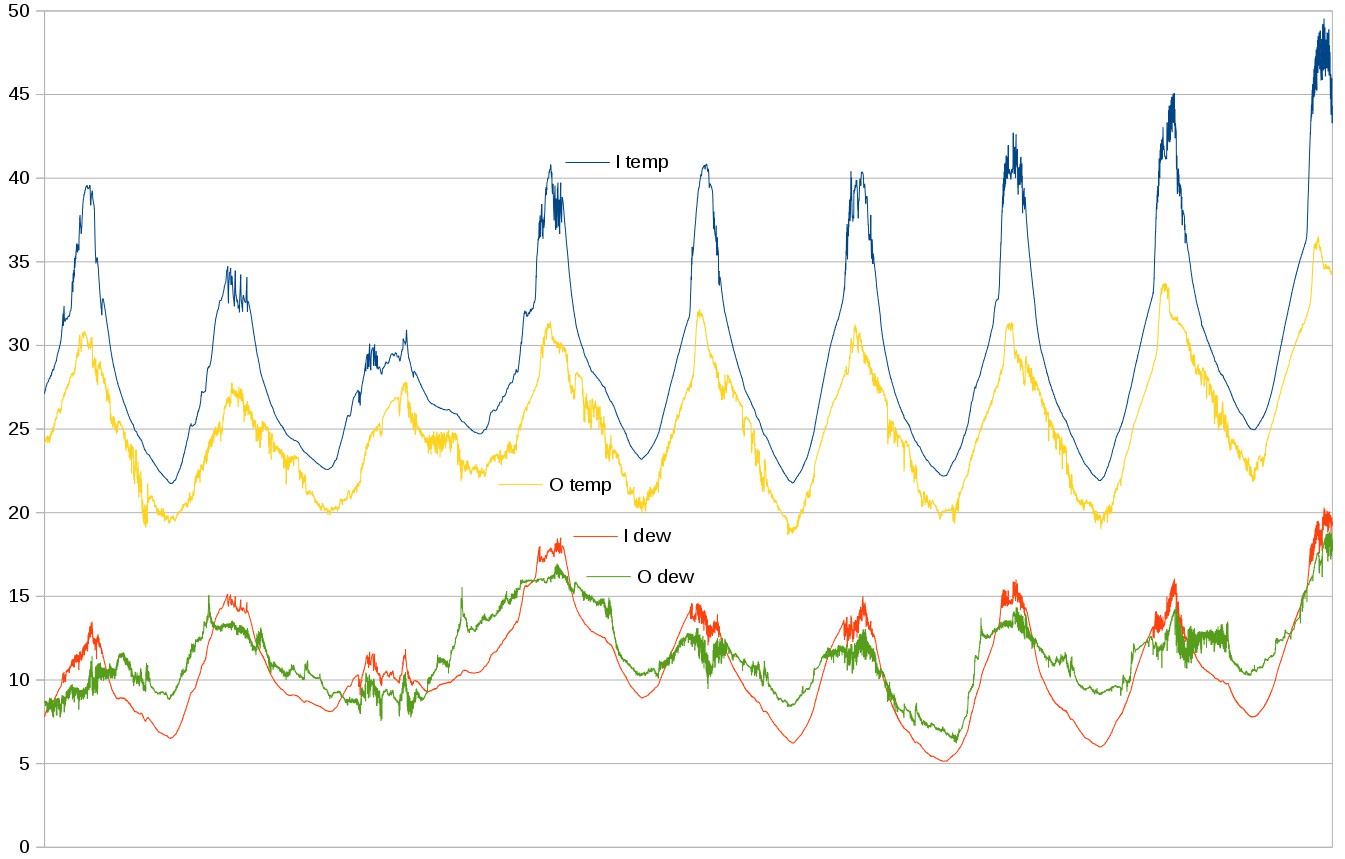

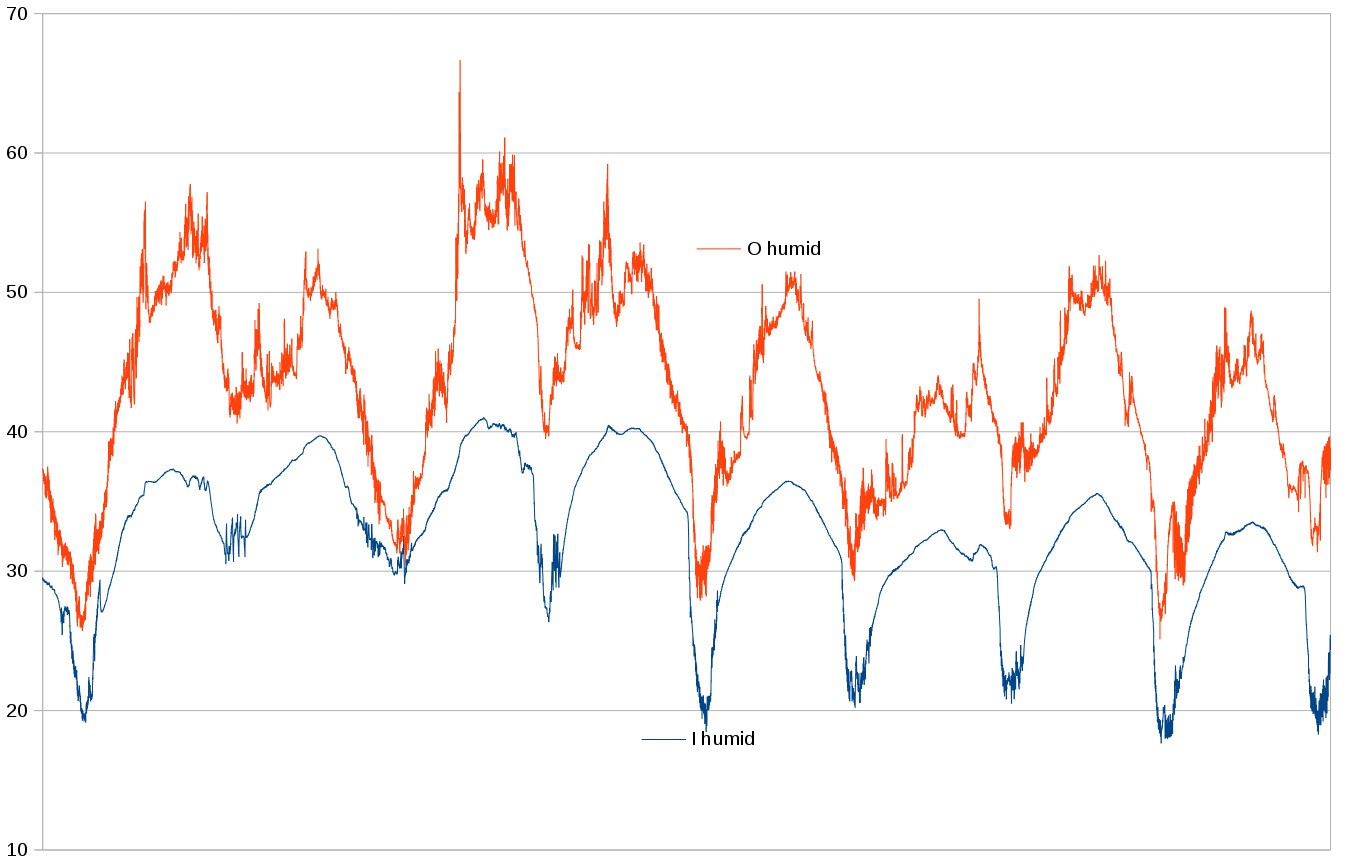

A week of drying showed a 10-15% difference in humidity being manetained & no difference in night time dew point being manetained.

The last set of data with the pump showed a 20-30% difference in humidity during the day & nighttime dew point pulling 10 deg below ambient.

https://hackaday.io/project/183147/log/206421-changing-pumps

This proved the air seal with the pump made a difference. The valves are no match against the volume changes of the air.

The next task is reconstituting the pump system & making it quiet. Despite its tendency to stay on all day like it wasn't working, it actually was working better than than the passive valves & it's already paid for. The times when it came on at night were only when a cold front moved through.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.