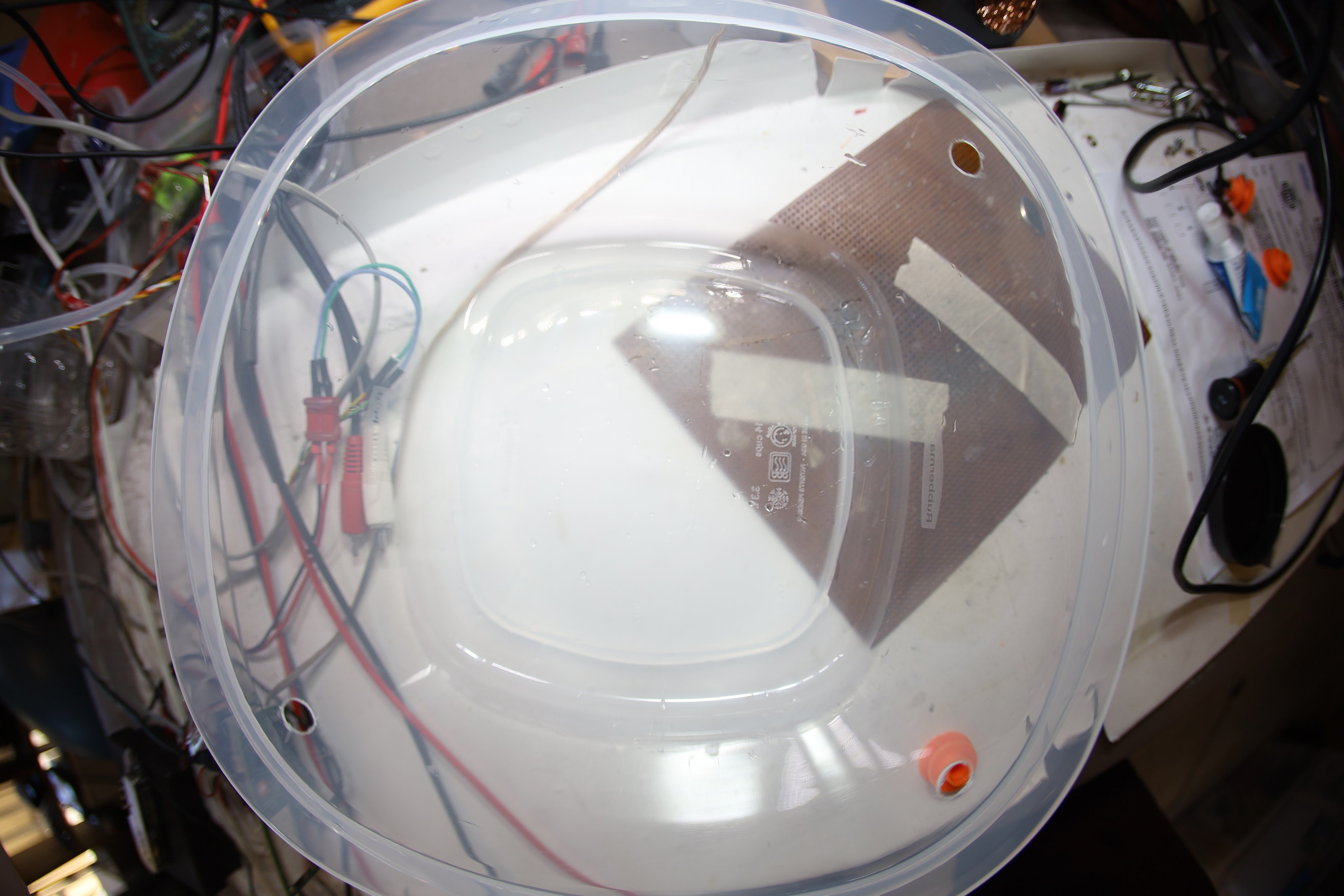

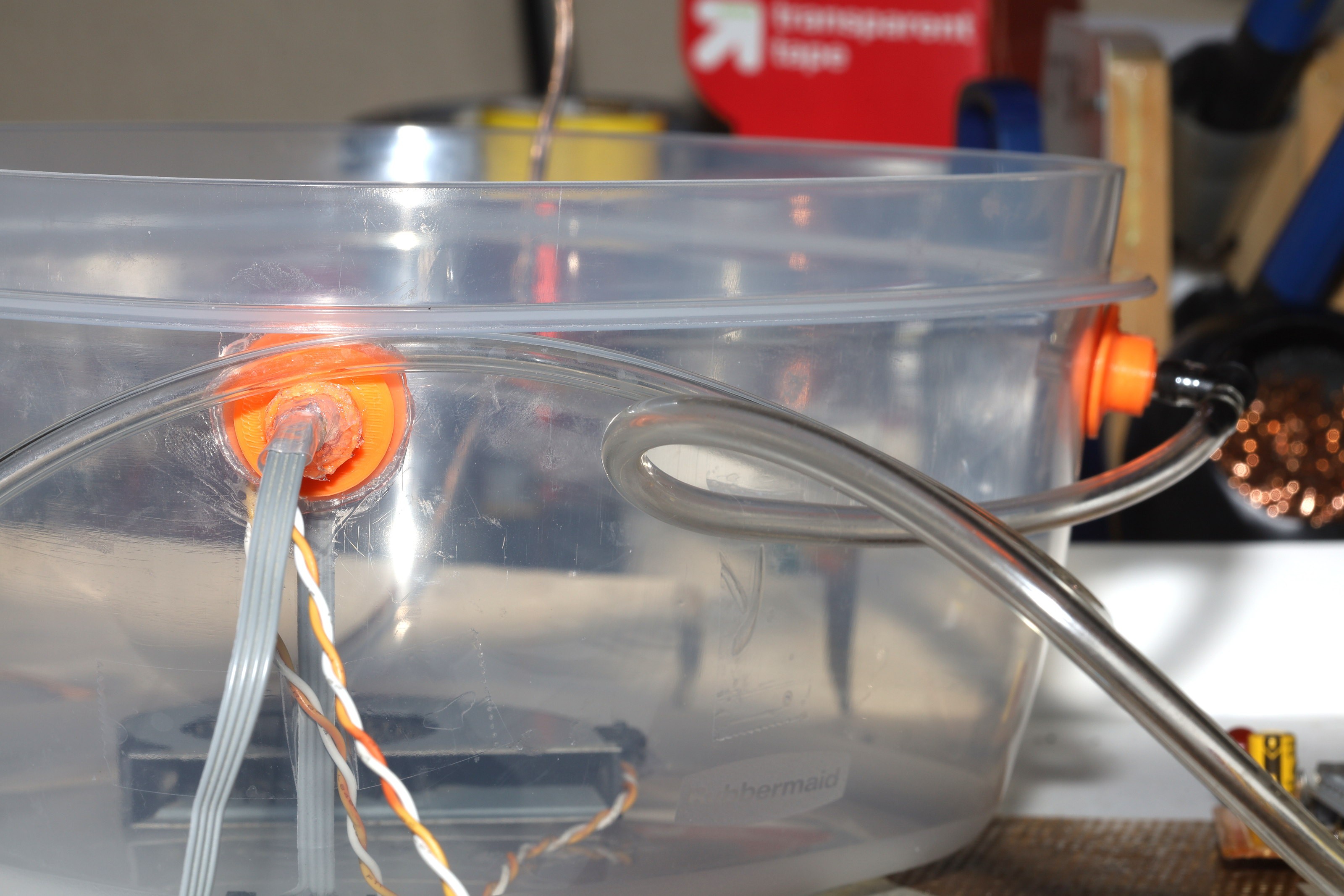

Installing the tubes for the 2nd time in a new container, the lion kingdom noted some essential techniques to get an airtight seal. Melt the plastic & sand the edges to make holes. Cutting with an xacto or drilling cracks the plastic.

The new holes went right against the lid.

Install the inner components 1st. Mark which way is up. Melt them all to conform them to the inside shape. Then apply Loctite clear silicone to all the inner components & press them in place. Only after all the inner components are loosely adhered in place, slide the outer components on. Melt them to conform them to the outside shape. Apply CA glue to bond the 2 pieces after everything is in place.

To get the best silicone seal, the outer pieces have to slide on loosely. Melting the outer pieces stops them from sliding loosely.

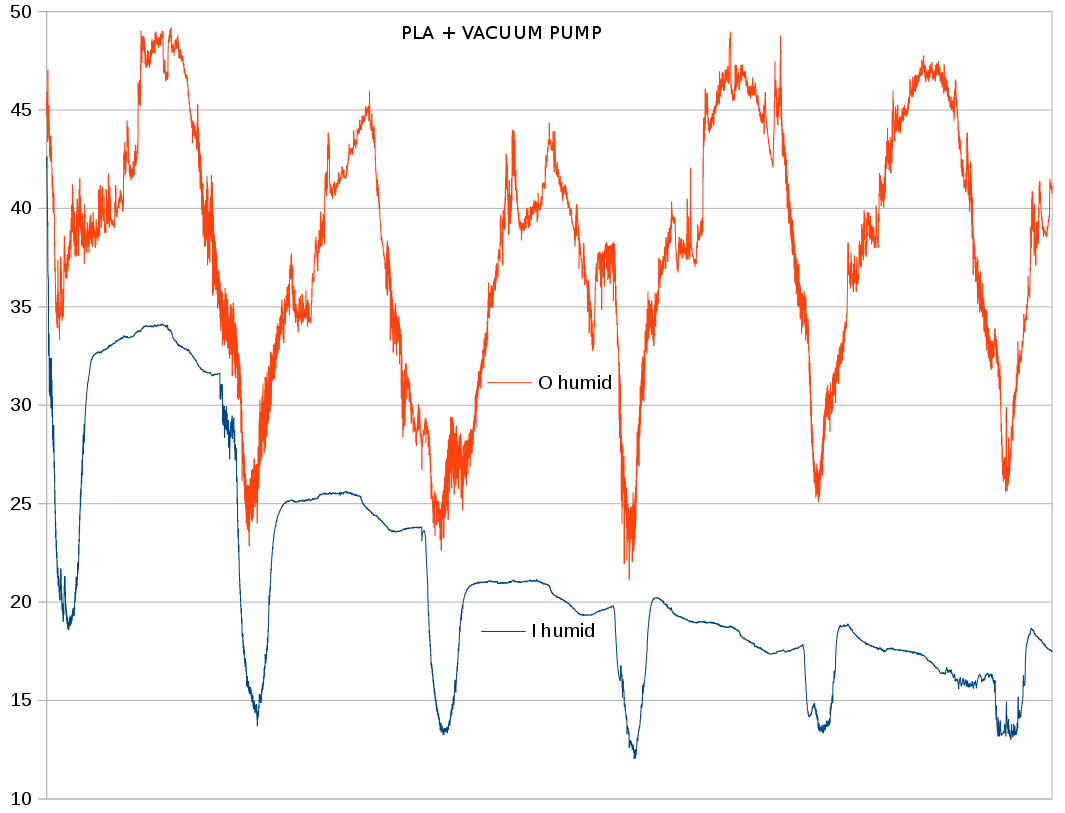

The lion kingdom has a PLA hydration problem.

Silicone was stuffed in the wiring hole.

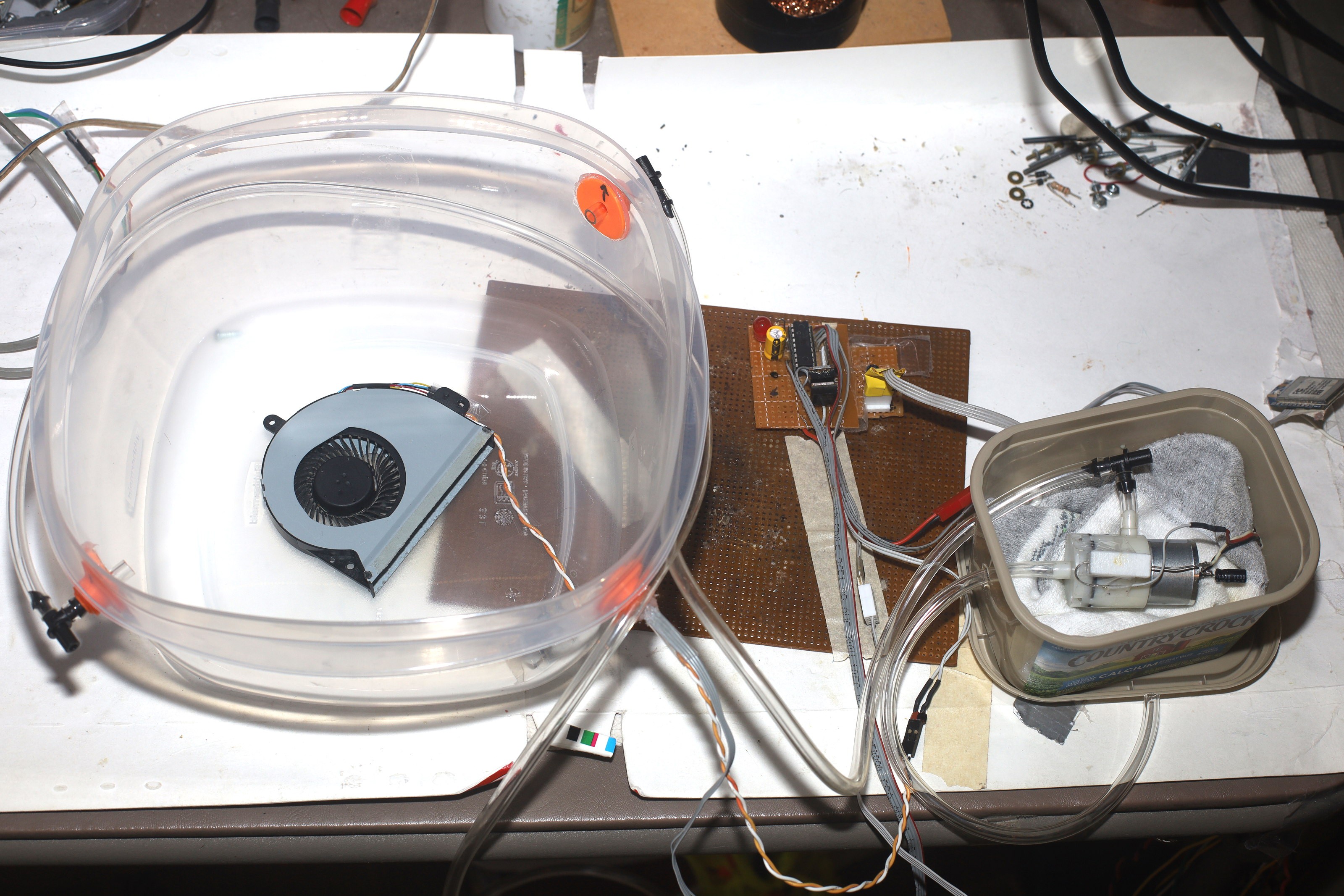

The pump was stuffed between some stuff in a box to try to quiet it. This was not really any quieter.

Hoses used normal 1/4" drip tubing, which allowed many right angle connectors.

The rebuilt pump MOSFET got no flyback diode or pulldown resistor. The fuse resistor might reduce the flyback current.

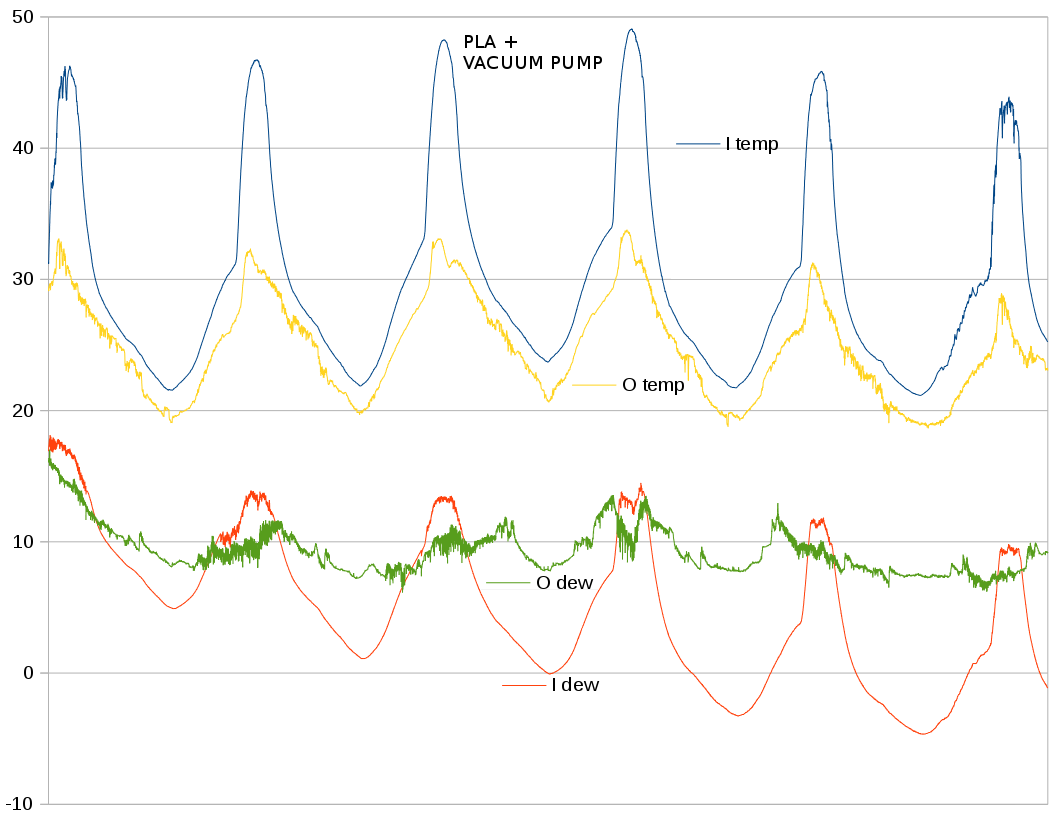

Humidity was pumped back down to 30% below ambient. Dew point was pumped back down to below 0.

After a few days of pain from that pump running continuously all afternoon, attention turned to a silent aquarium pump. Silent vacuums don't exist. It has to be a pump. They all use 1/4" tubes & manes voltage.

https://www.amazon.com/gp/product/B0009YJ4N6

A thyristor is required.

https://www.amazon.com/Module-Thyristor-Control-Trigger-High-Power/dp/B07P6HX85G/

The pump has to go in the inlet on the bottom. The outlet tube now has to wrap over the top. There have to be 2 manes plugs.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.