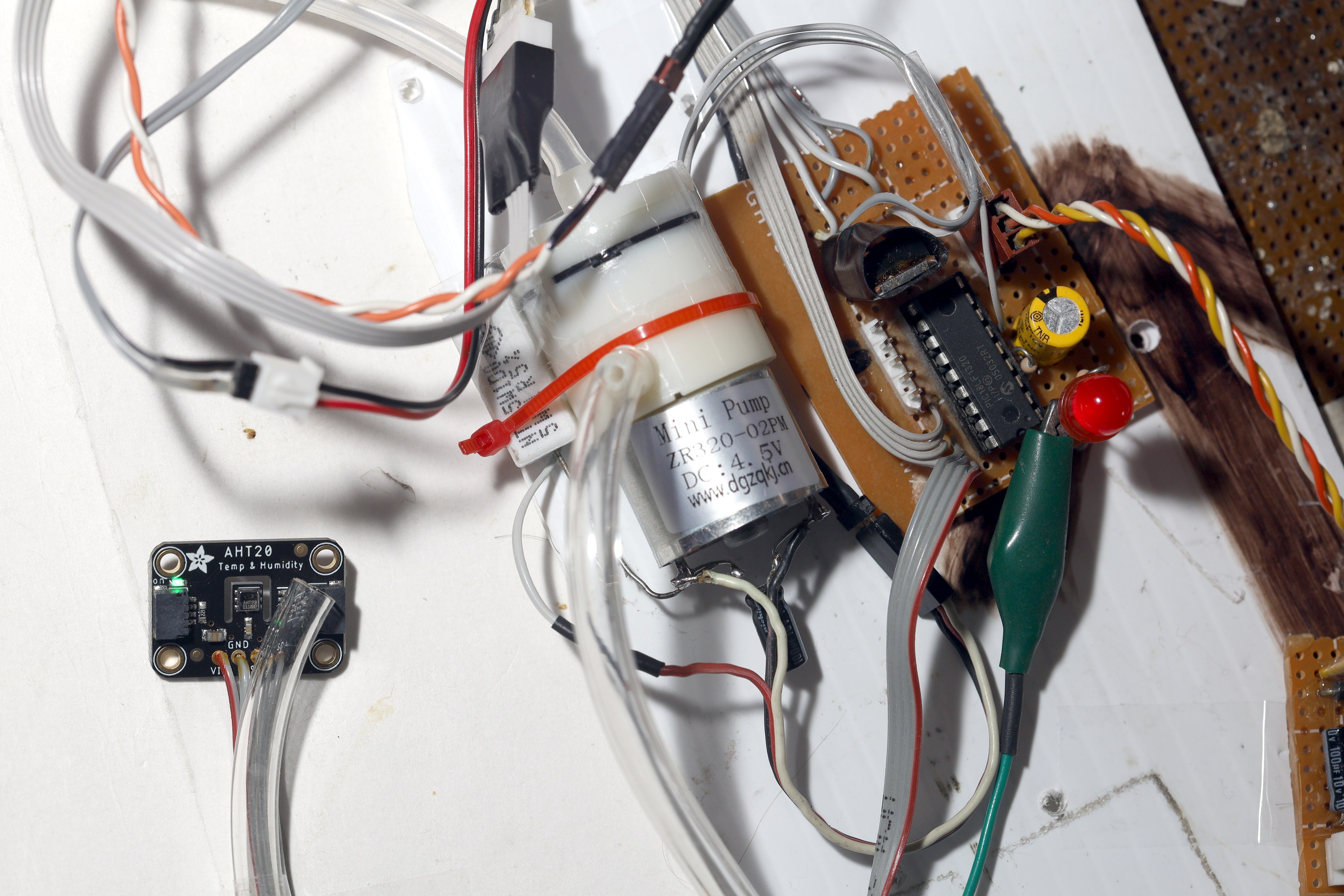

The motor fuse ended up being a 1R resistor which drops the voltage from 5 to 4.5. There's a 1 second deadband to wait for the starting torque, then the voltage is downsampled to 4Hz. If it stalls, the voltage goes to 3.3, the fuse is blown & the LED blinks. There's a slight spike from back EMF, but the resistor is so close to V+, it couldn't justify a flyback diode. It stalls quite easily if the tube gets obstructed.

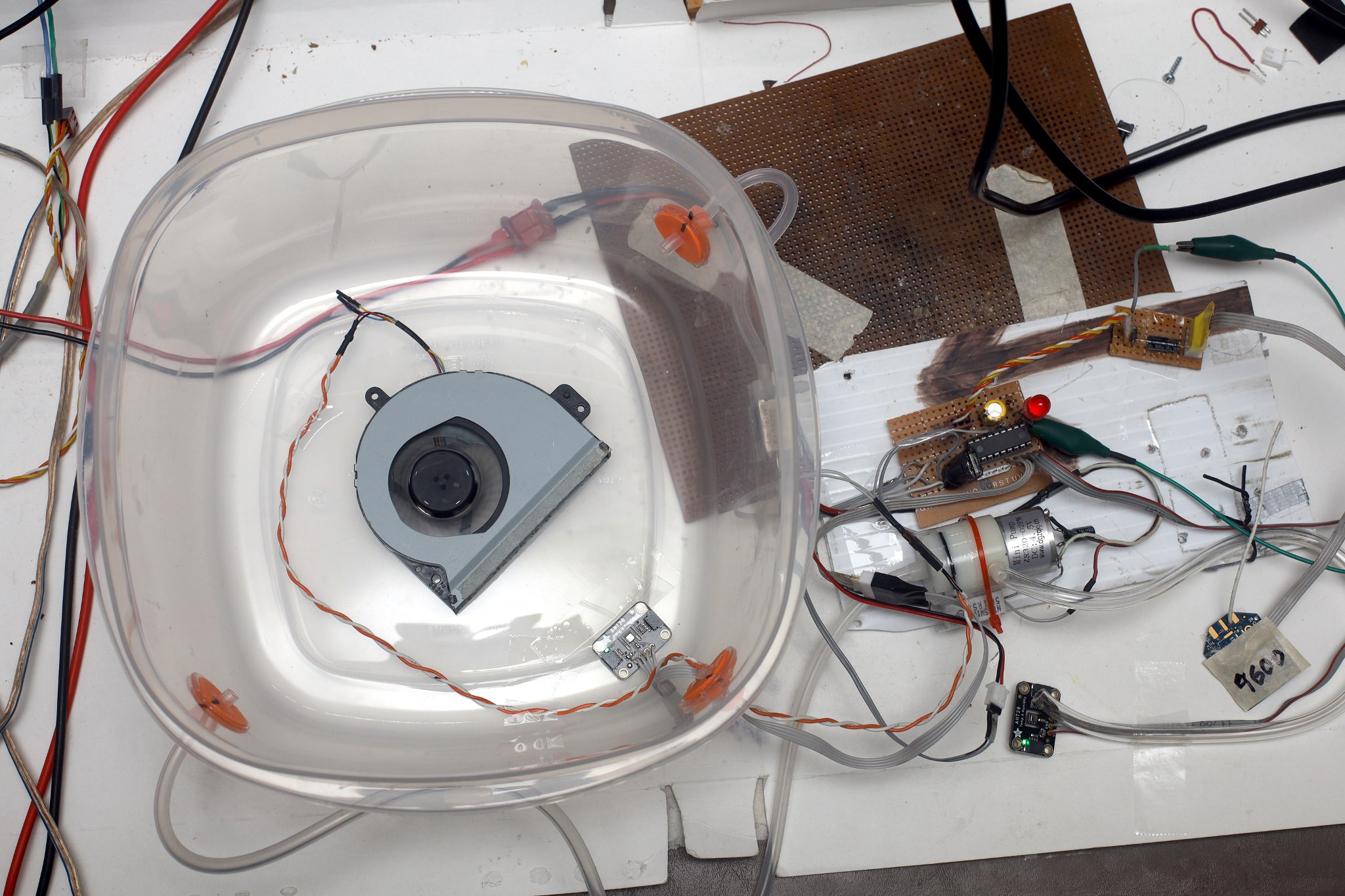

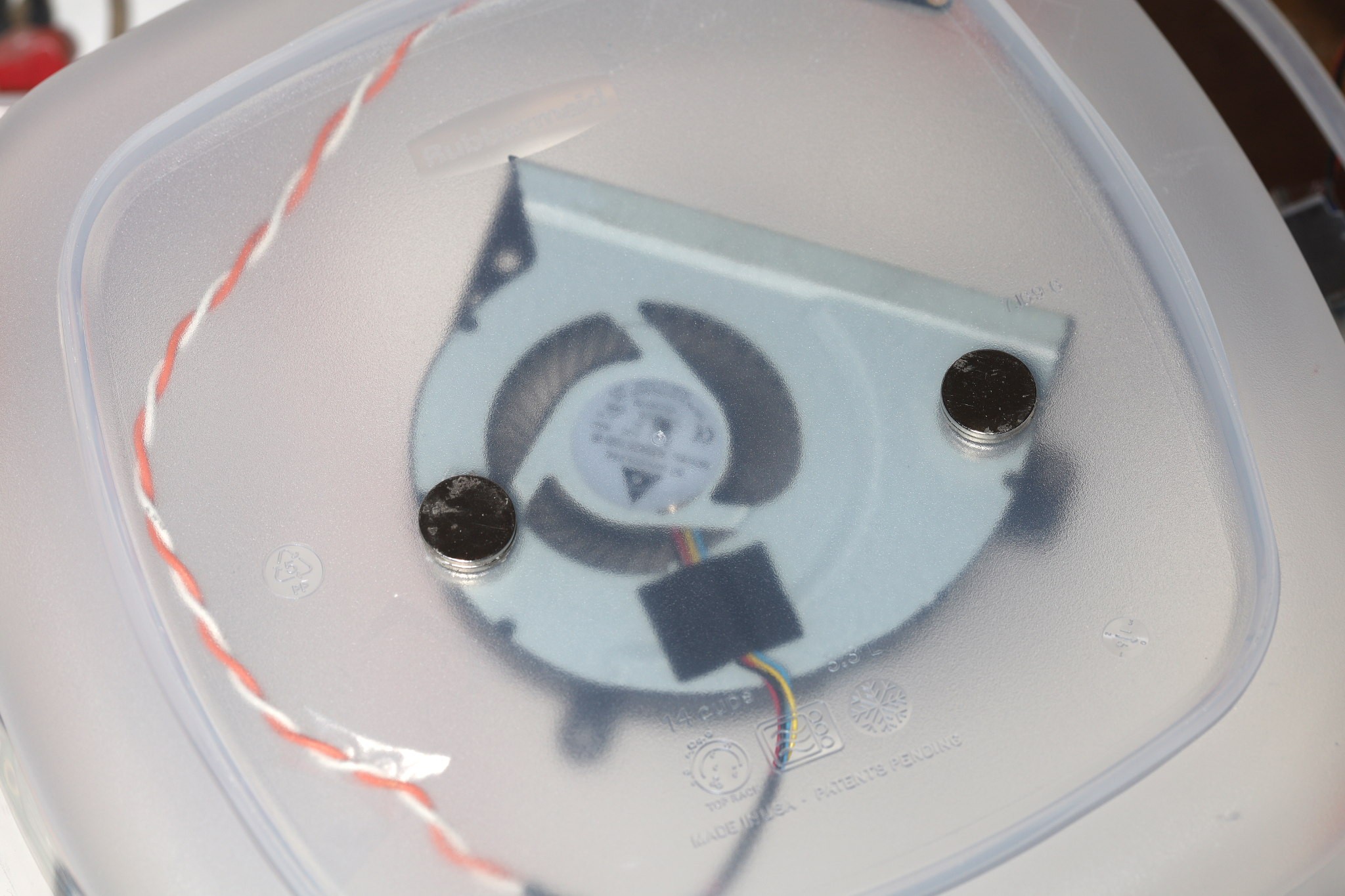

The tubes aren't held in very securely anymore. The PLA holes must have been under tension & expanded over time. The mane algorithm ended up being probing the sensors every 5 seconds. If the dew point difference is above a threshold, turn on the pump. If the dew point difference is below the same threshold - hysteresis, turn off the pump. Even with the fan on, the sensors have very stable readings & don't need averaging.

Getting debugging out of it to determine the right thresholds entailed hooking up an XBee.

Putting in a wet towel makes the dew point stay 20 deg higher & causes the pump to run forever. It needs a duty cycle of some kind.

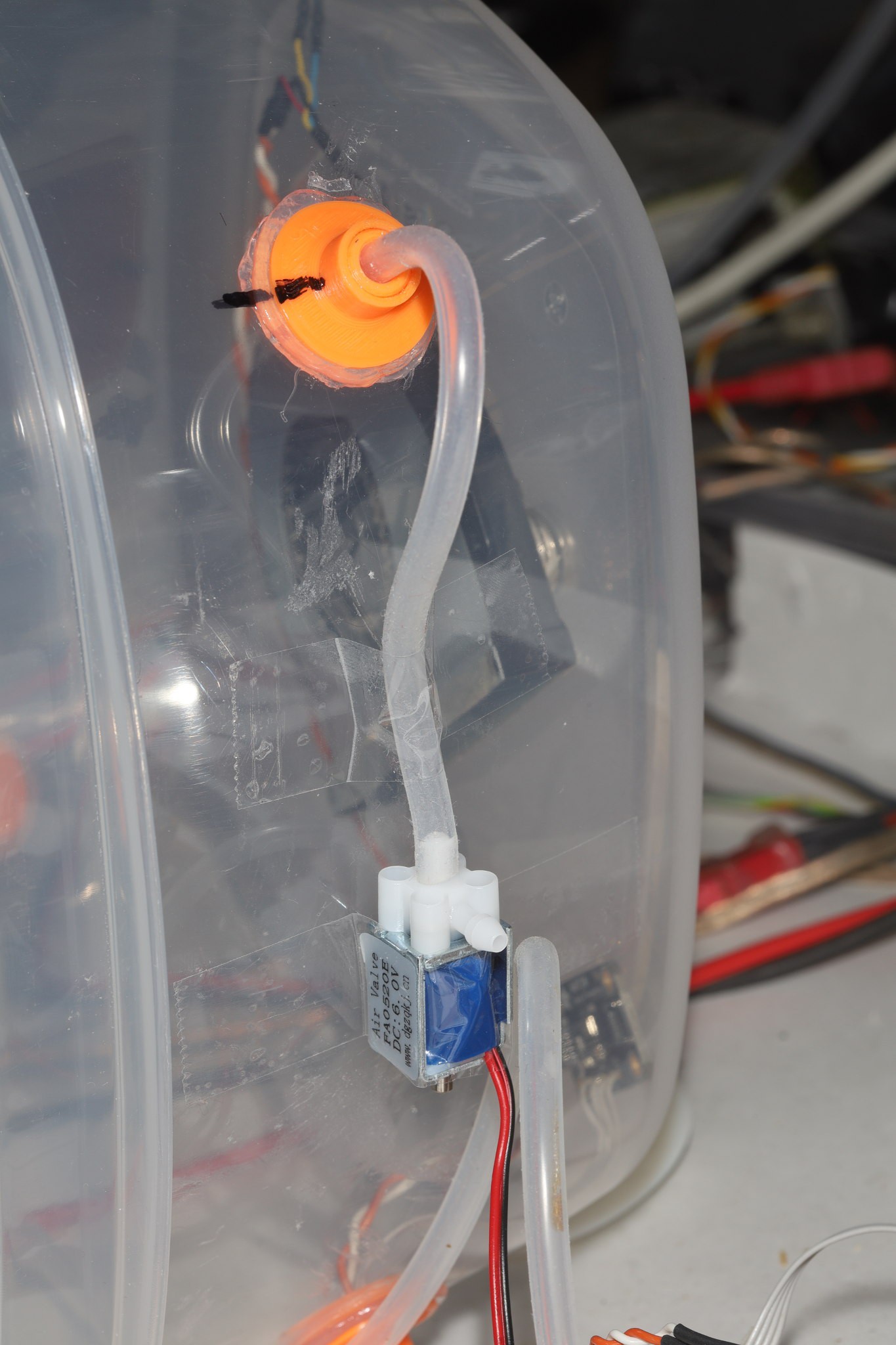

Another nugget not given by the 'fruit is the solenoid lets less air out than the 1.8L pump puts in. The container inflates like a balloon & the pump gets warm. Obviously the container is very air tight. It's definitely not letting any air in when pumping. What's really needed is a pressure relief valve instead of a solenoid.

There is a theory that the valve can be left out if the tube goes from above to below the container. If the air in the container is hotter than outside, it won't reach the tube's low point. If the air in the container is colder than outside, the inside air won't reach the tube's high point. The mane unknown is if osmotic pressure equalizes the humidity inside & outside.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.