Ended up reconfiguring the pump for suction instead of blowing, in order to keep the lid from getting blown off. It managed to suck without stalling & kept up with the dewpoint.

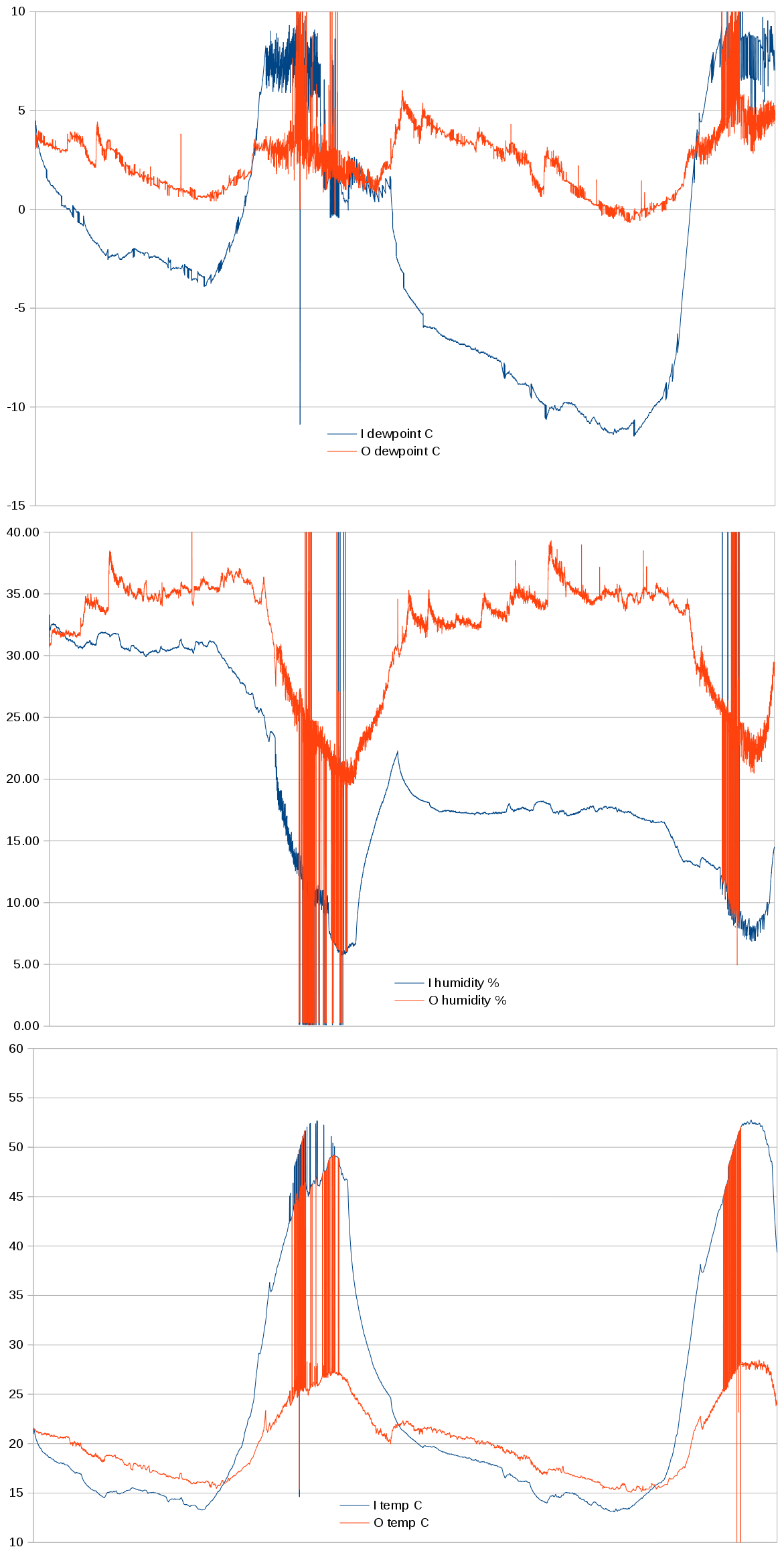

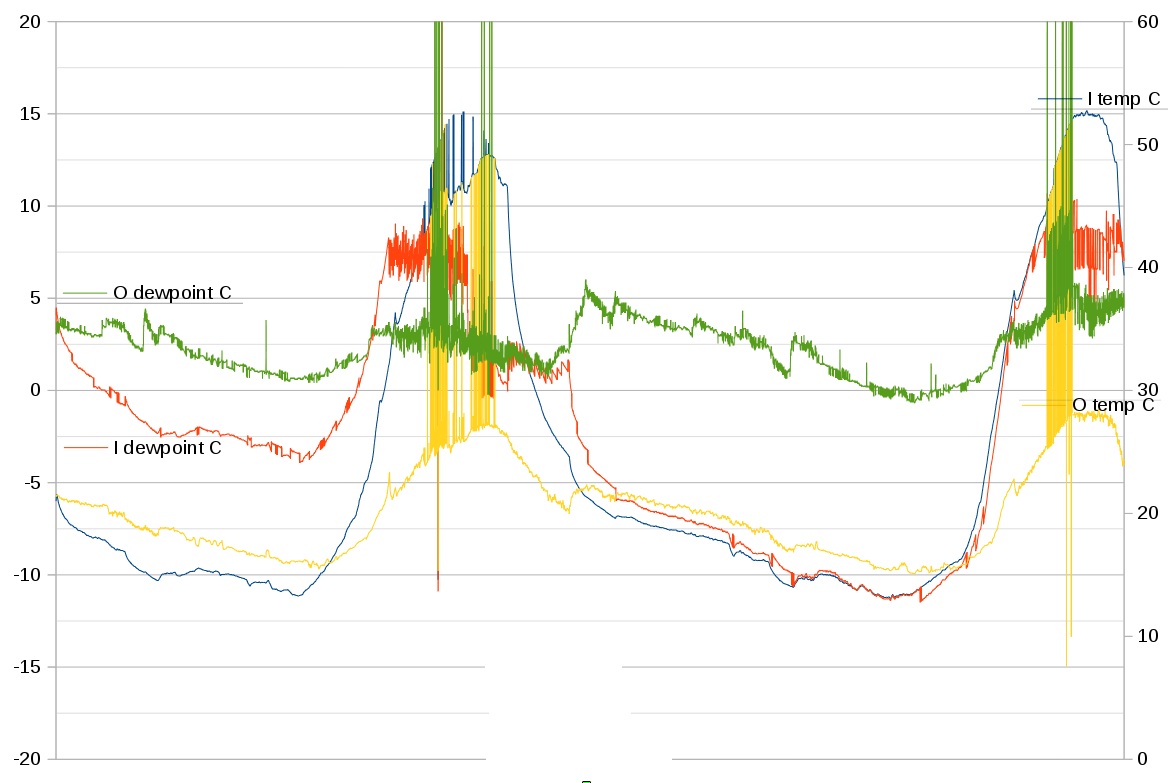

Over 2 days, we see the night time dew point falling while the daytime dewpoint is clamped by the pump. The lower night time dewpoint on day 2 would be from drier filament absorbing more water. There's no way to know how much water is released during the day because the pump is clamping the dewpoint.

There could be a resistor & BJT to heat the filament when it's absorbing water. The fan power would feed the heater & only 1 more wire would be required to turn it on. The question then becomes when to turn on the heater. Filament begins absorbing water when the dew point is maximum & the pump shuts down for the last time of the day. The best a heater can do is turn on when maybe the dew points are equal or maybe when the inside temp is lower than the outside temp, but it's never going to know the optimum time to turn on.

Incomplete data shows temperatures crossing over before the dewpoints cross over, but some time after the max & min dewpoints.

It is believed the dew point will take longer to rise during the day as the filament dries out until the dew point can no longer be raised above ambient by any amount of heat.

Similarly, the dew point will fall lower at night until not enough water still remanes in the air to fully hydrate the filament. At this equilibrium, the filament is the driest it will ever be during the peak dewpoint & the wettest it will ever be during the minimum dewpoint. Regardless of whether it uses a heater, it'll be a waste of money to leave the dehydrator on forever.

The easiest next step is to have the fan turn off when the inside temperature is below the outside temperature to try to reduce the resorption. Seal off the dehydrator & use a desiccant when it hits maximum dewpoint.

A new design continued evolving. It now involved putting all the wiring in the air ducts & having 2 air ducts coming out of the top, going below the bottom. 1 air duct connects to a blower.

The mane problems with the new design are the amount of space for the larger ducts, mounting the blower below the enclosure, creating interfaces to the ducts. The existing pump has proven perfectly capable of keeping up with the dew point. The mane concern with the current system is now tuning the feedback so it sucks in enough air to draw water out of the filament while not drawing in enough air to adversely raise the humidity in the container.

Whereas some of the data was lost on day 1 when the pump was on, all of the data was lost on day 2 when the pump was on. It actually continued to be lost when the pump turned off. It was temperature related instead of pump related. The PIC's RC oscillator is temperature sensitive.

The new problem is placing the electronicals somewhere more permanent, where they don't get flaming hot. Getting filament in & out of the container with all the bits hanging off is a big deal.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.