The blower they said could never be mounted on anything 25 years ago finally was fixed to a tube. Through 2 ft of 3/4" ID tube, the airflow was greatly reduced but still useful. It needs 12V to move any air through. The tube could be doubled up.

Only a tiny flake of the original 90's Gamma 28 label remanes.

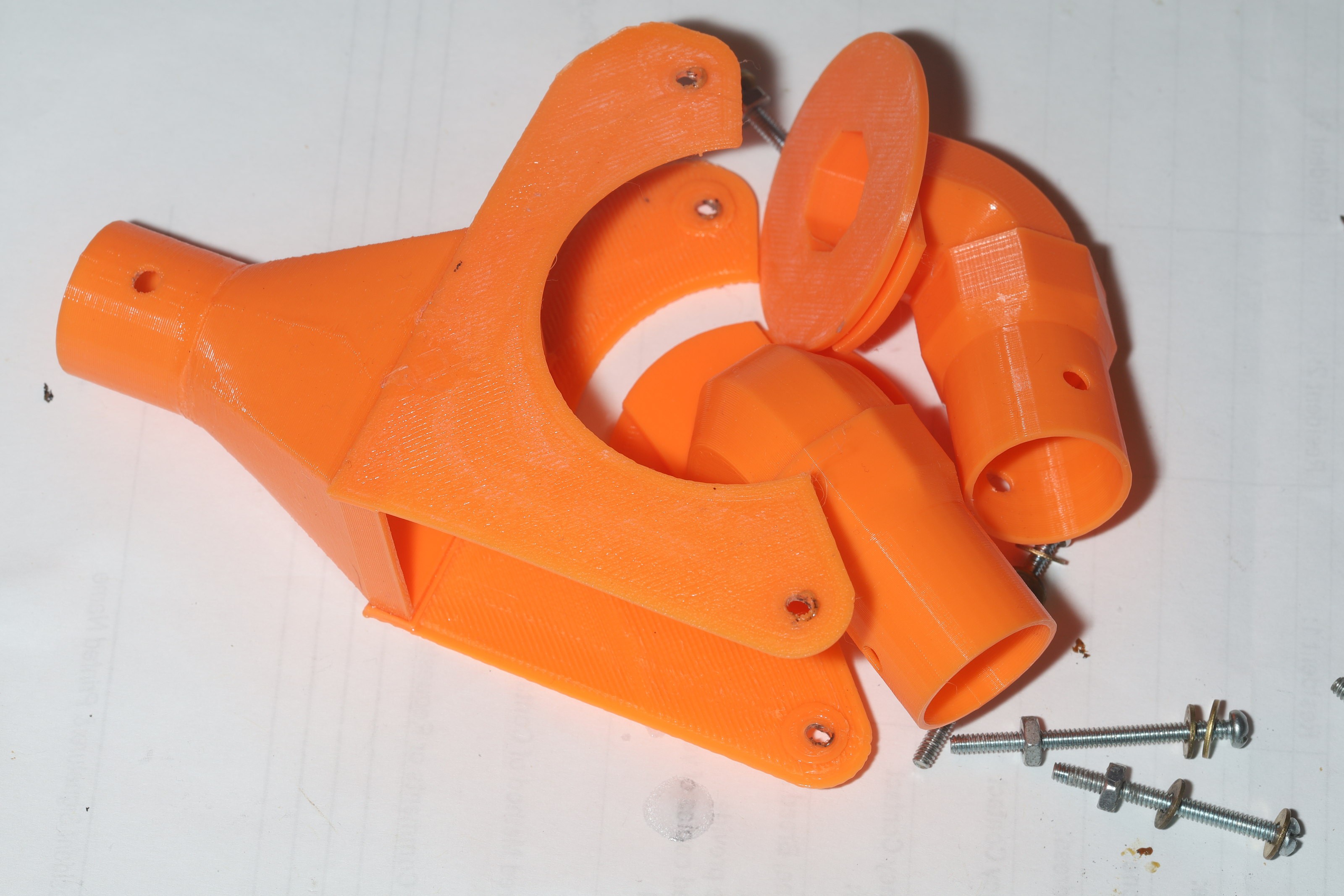

Another key development besides mounting the blower was printing an elbow. The only way to do it is to print an octagon sideways. Each end of the octagon needs a separately printed adapter to attach to whatever it's attached to. Holes were melted in the tube for farsteners. It's tight enough to not need nuts.

By now, it was clear that the new blower would make the dehydrator much bulkier & heavier. A new surface mount board could fit directly on the blower & greatly shrink the window usage. The wiring would have to go through a new orifice near the pump. The pump doesn't have to be air tight. Then there's the problem of balancing the container on the window.

The simpler solution is to keep the existing wiring in a container orifice, but the size requirement ended up making the lion kingdom go back to the inkjet pump. To change to the blower pump would require moving the electronicals to a surface mount board on the blower. Then, it would take less space than the inkjet pump. The space constraints of having a job make it hard to use all of the lion kingdom's through hole parts.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.