First log! For context, here's v1 and v2 (sorry about table formatting, couldn't figure out side-by-side images):

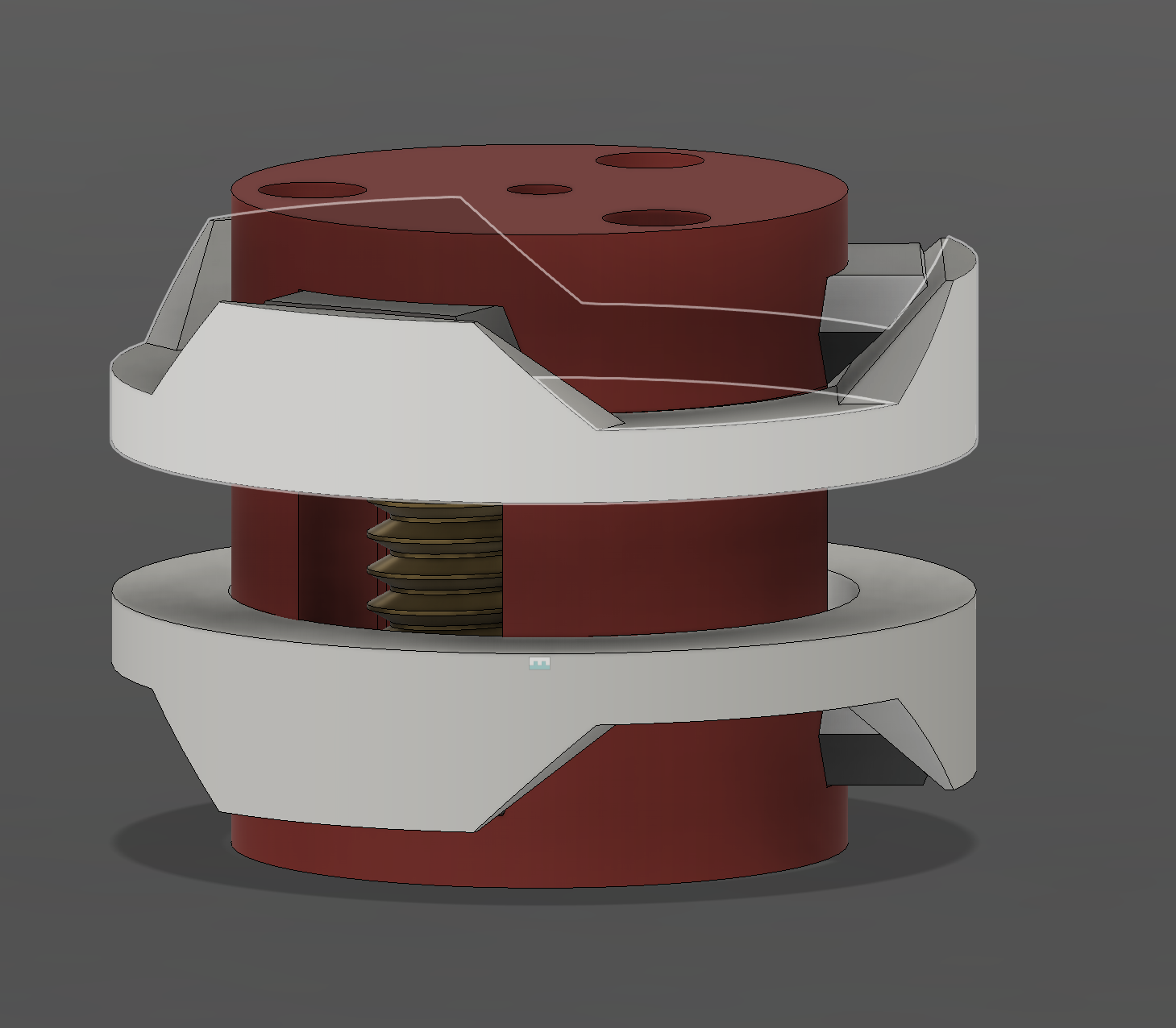

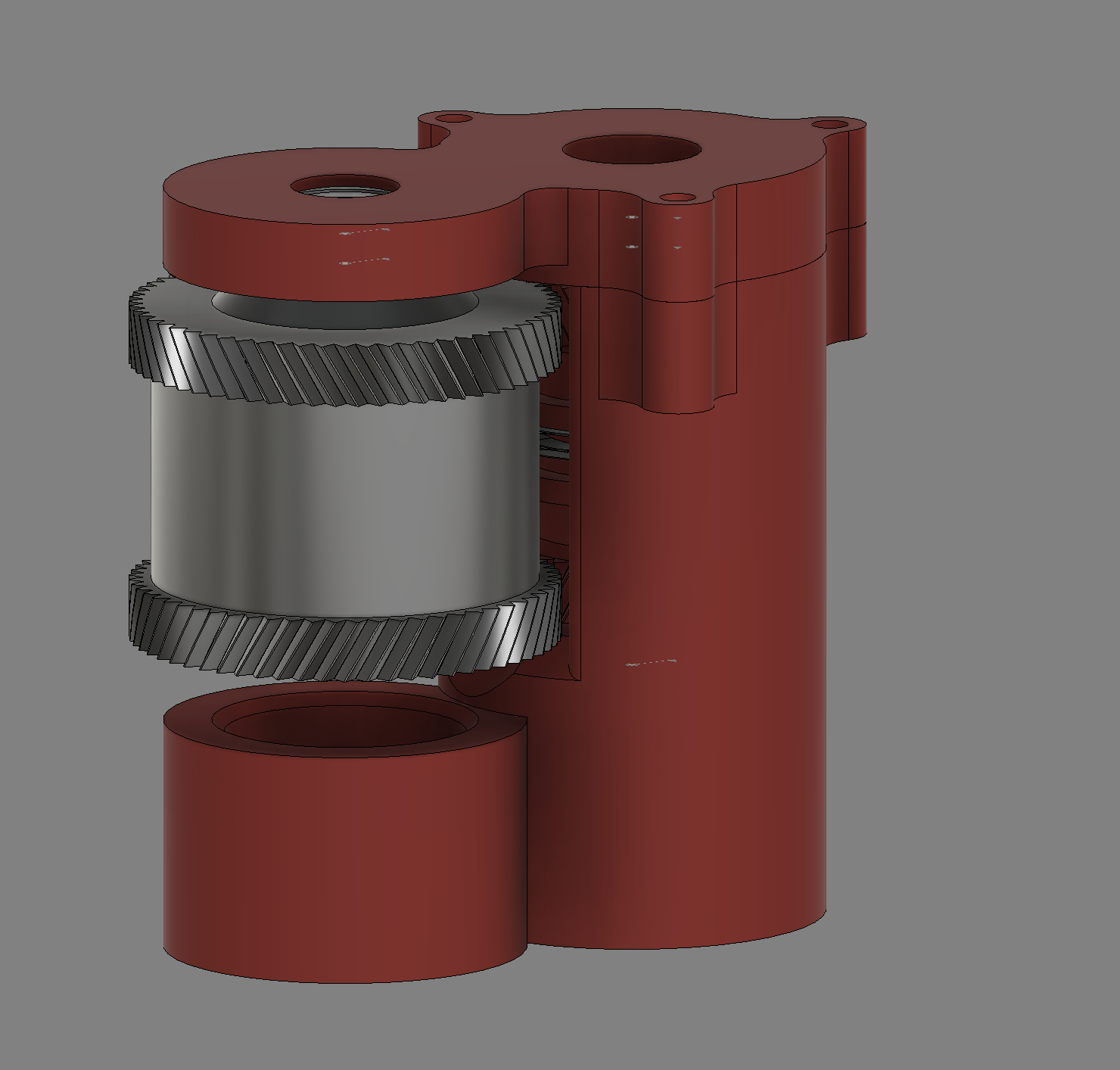

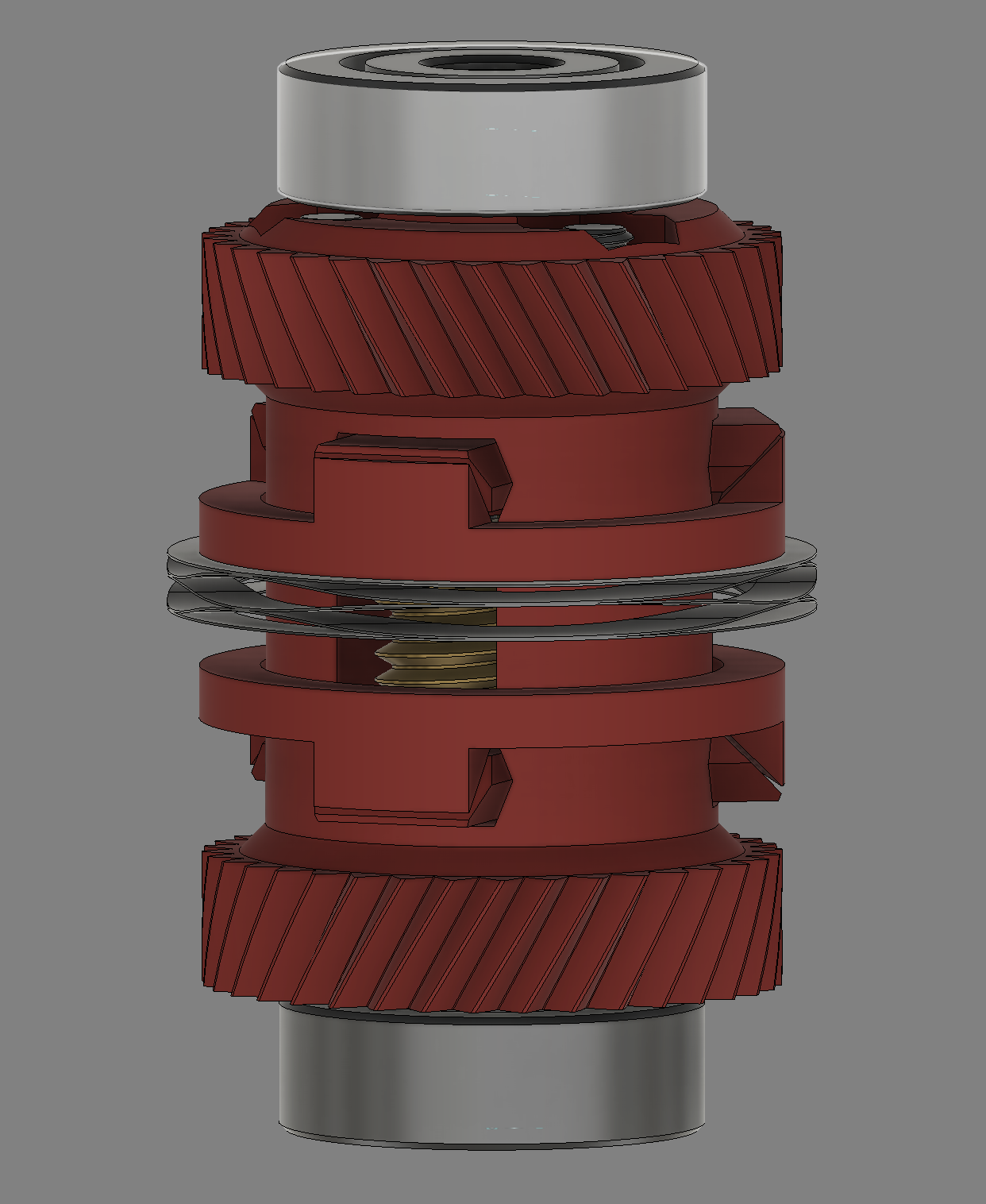

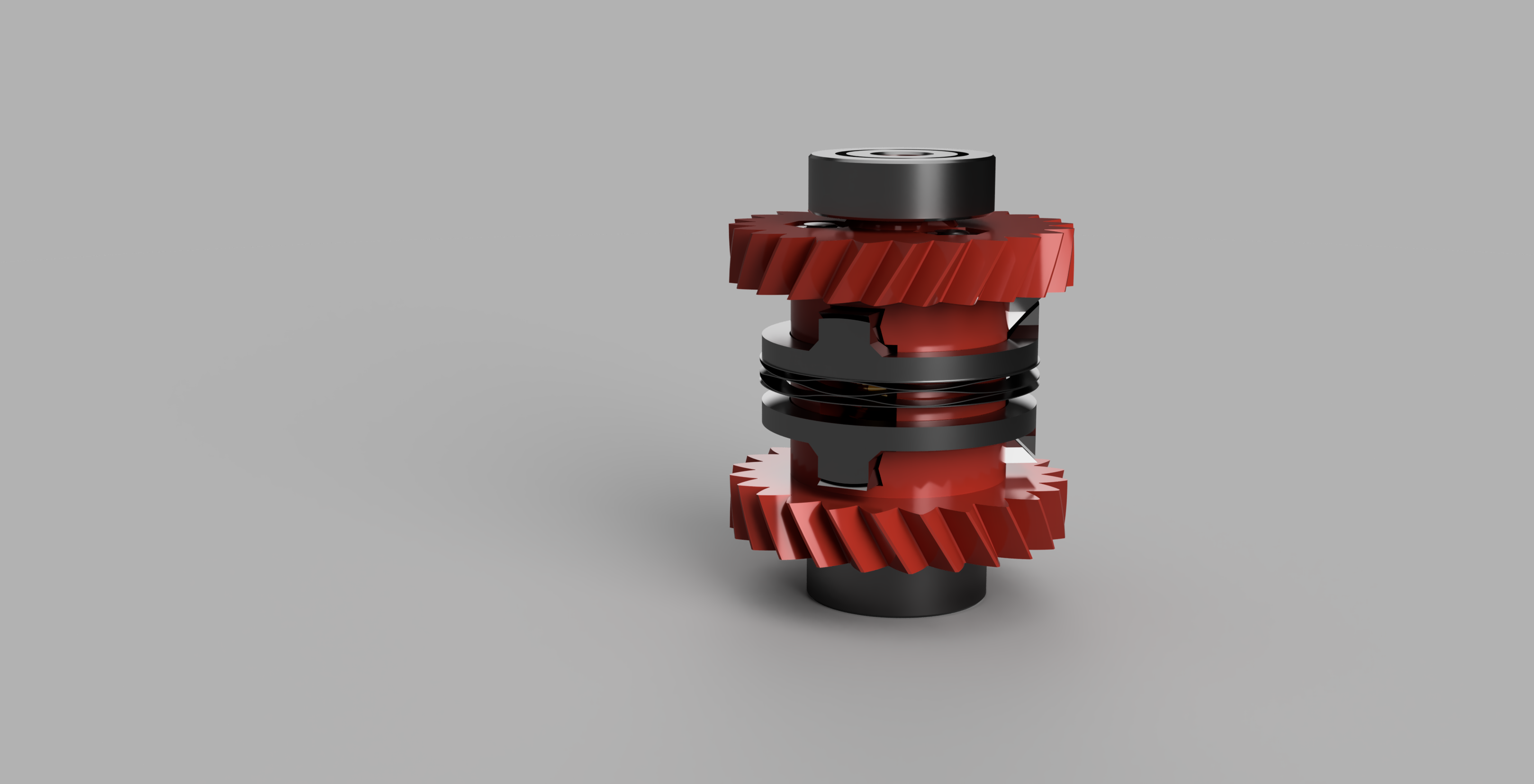

v1: | V2, with housing and drive gear: | V2, just the spinny bits: |

I just printed out all of the parts, and it's not going to work. Here are my observations:

- the gear teeth are way too tiny. They won't work.

- the sliding action of the parts that hold the screws is surprisingly smooth; the whole tensioning mechanism works better than expected

- the spring I bought (mcmaster 1561T43) is a little bit big. It doesn't stay centered on the housing

- everything is really small. Even with a jig, I still don't know how I'm going to drill a nice centered hole in the M6 screw.

- the hole in the center for the filament to go through came out way smaller than expected. I designed it as 2mm, it came out 1mm.

Taking those into consideration, I made V3:

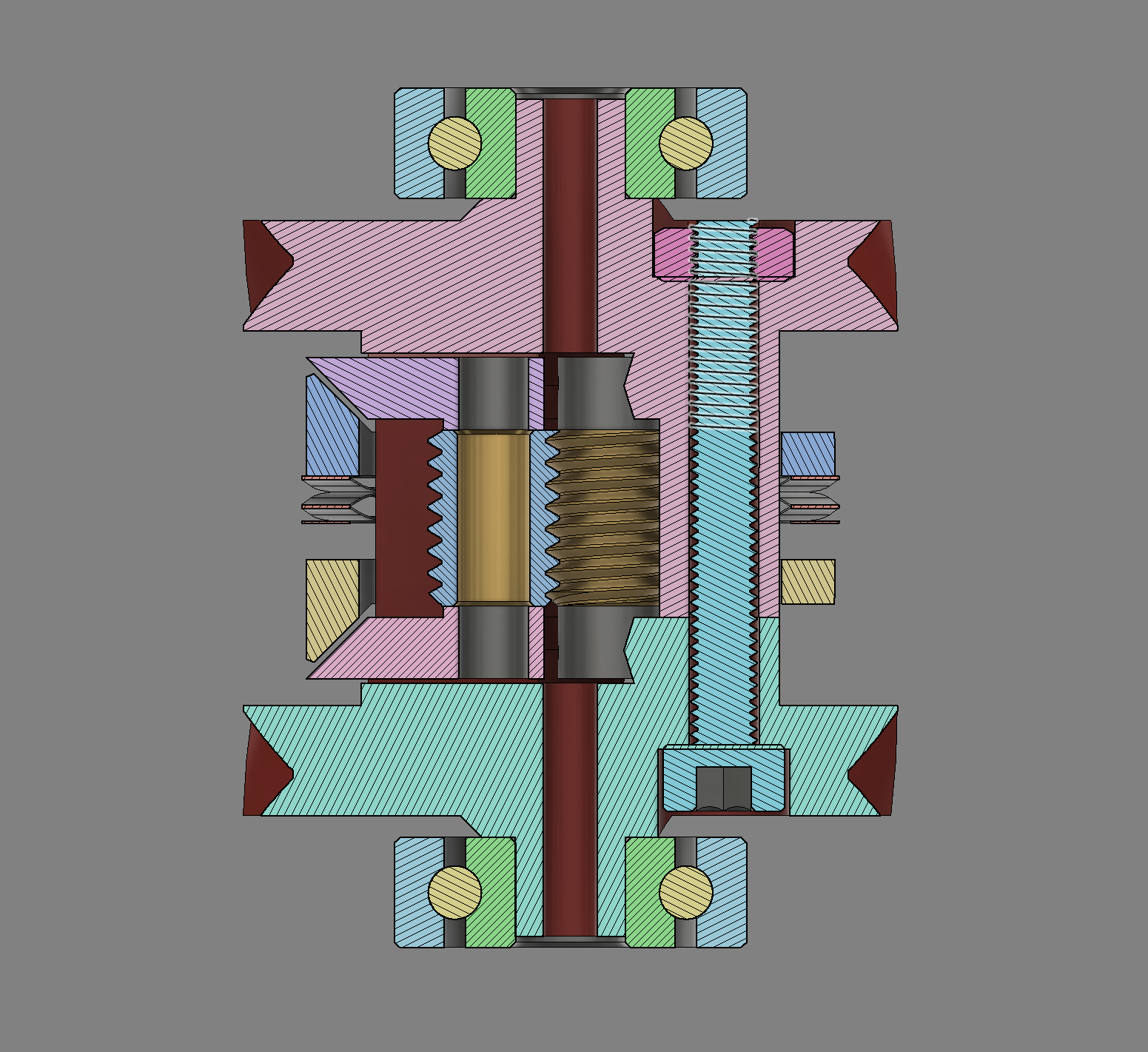

Here's a cross-sectional view. I think this makes it easier to understand. The small blue and yellow pieces on the left side of the middle are pushed apart by the spring (show compressed), which in turn push on the pink and purple wedge-shaped things. These wedges hold on to the axles for the screws, so the spring maintains constant pressure on the filament.

Only the left side really makes sense here because the mechanism is repeated every 60 degrees.

Here's what I changed:

- gear teeth are now twice as wide

- main housing is now 19mm diameter, to better fit the spring

- sliders are beefed up, and are >< shaped instead of <>. This makes them more stable.

I still need to design a v3 motor mount and housing, but that can wait until I know the base idea works. Time to start printing!

ReidDye

ReidDye

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

For screw boring, buy a small center drill with 1/8" body, and use a jig to hold the bolt and the drill in alignment. That way the smooth body of the drill won't damage the jig, and it won't be able to deflect away from the center of the bolt. Once you get the hole started, a regular drill with a second jig will happily follow through.

Are you sure? yes | no