Some history

At the origin of the horizontal blade flip technology clock, patented in 1958 by Solari & C, sits the "Cifra 5". This clock was the first of a family of industrial timepieces developed from a technology studied by Remigio Solari, who revolutionized the usual methods of displaying time and information to the public

The clock consisted of four palettes of ten numbers to display the time in the military format "HH:MM." There were two types of this clock: the first one, called "master," had inside a whole electromechanical clock including a device capable of delivering a polarity alternate 24V pulse every minute. The second type, called "slave," can display the same time in sync using the alternating pulse coming from the master. This configuration was beneficial when used in train stations or airports where many clocks should display the time simultaneously through all the installed devices.

Since the slave clock's production outnumbered the master one, it's pretty common to find a used slave; many people consider it a simple decoration object since it can't keep time. When I saw this clock in an antique shop in Bologna, I quickly fell in love; the early 70's style was unique. After a lengthy negotiation with the shop owner, I walked away with this piece of history. The owner warned me the clock was a slave; without the master, it would never show the time. For me was like ice over the cake; not only I was a proud owner of an original Cifra 5, but also it would be the inspiration for a great hack. My intentions were quite ambitious. I wanted to modify the clock to be completely autonomous: when powered to self adjust to the current time and then keep time.

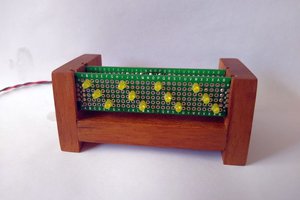

In the video below you can see the control board fully assembled and the internal actuator and sensors used to adjust the clock.

A fully automated modern clock

The slave version had many similarities with the master; the main difference, a massive coil was used to flip the single minute's palette; all other palette movements: like tens of minutes, hours, and tenth of hours, were generated by mechanical levers; just a flip polarity pulse every minute was necessary to make the clock fully functional. Some practical tests confirmed my analysis: the timekeeping was relatively trivial; just send an alternating pulse, and the clock will take care of everything.

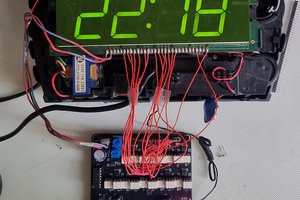

On the other hand, setting the correct time as the initial adjustment wasn't a simple task. Further analysis revealed the control board needed two critical signals: one for the new hour mark and another for a midnight mark (when the clock shows 00:00). With these two signals at hand, it was simple to draft a basic algorithm to set the clock to any specific time.

It was imperative to not modify in any way the original mechanism, so harvesting those signals from the clock required some 3D printed parts to position two Hall sensors and two magnets.

For the new hour mark, it was tracked the movement of the lever that increments the hours by one. To simply test if the minute pulse has triggered a new hour, you just have to compare the previous read of the sensor and a new read after the pulse; if the status of the sensor has changed from Off to On, the minute's digit will show "00".

Similarly, for the new day mark, it was tracked the movement of the lever responsible for the increments of the days by one. This lever was used on the Dator series (the full date version); in the Cifra 5, this lever has no use. To simply test if the minute pulse has triggered a new day, you just have to compare the previous read of the sensor and a new read after the pulse; if the status of the sensor has changed from On to Off, the whole display will show "00:00". You can see in the picture below the magnet holder on the lever and the hall sensor hall on the bottom sensing the lever movement.

alcor6502

alcor6502

danjovic

danjovic

K.C. Lee

K.C. Lee

zst123

zst123

Hello! Very interesting what you've done. I have a

Solari Cifra 5 that has given me many problems. Currently getting stuck on the minutes side. Possibly a bent or broken pin. I've put so much time into this and am looking for someone to take a look at it and repair it as it is special to me. Would you or someone you know be interested? Thanks so much,