The Adler class 8, like many older machines, is finished in black japanning. The golden decorations may be water transfer decals or gold leaf - I don't know how the designs were applied to the Adler 8. To protect the decoration, there was a coat of shellac applied over the entire surface of the machine.

The shellac coat on my Adler was worn off in places - everywhere the gold decorations are damaged there was missing shellac.

Additionally, the shellac was soaked through with sewing machine oil.

Given the damage to the finish, I decided to strip off all the shellac and refinish the machine.

I felt bad about that for a while because of the (inevitable) damage that stripping the shellac does to the gold decorations. When I found that many people simply strip the machines to bare metal and repaint them with modern paint, I felt much better about how I cleaned up my machine.

Shellac disolves in alcohol. I used 99% pure ethanol to remove the shellac from my Adler. I buy what is known as "bio fire starter fluid" here in Germany. It's 99% ethanol, and it is fairly cheap (a couple of Euros for a one liter bottle.)

I used paper towels soaked in ethanol to wipe off the oil soaked shellac, then cotton pads (made for removing makeup) to do the final cleanup. The paper towels tend to leave scratches in the surface and to remove more bits of the decorations. The cotton pads do less damage, but soak up less shellac. Paper towels to remove the bulk of the shellac, cotton pads to carefully remove the last thin layer over the decals.

After removing the old shellac, I applied a coat of fresh shellac over all the japanned areas.

I removed most of the external metal parts to clean and polish them separately.

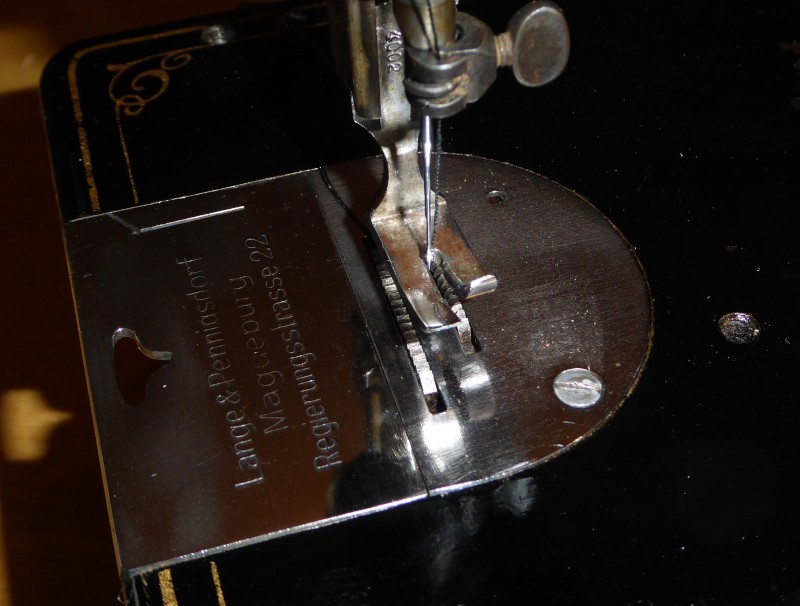

This is what the Adler looked like after clean up and refinishing:

I later polished some of the metal parts that I only cleaned the first time around.

Cleaned up like that, I'm not worried about it getting filth on the leather (or cloth) or the thread while sewing.

I wasn't going for some museum exhibition level restoration. The Adler is meant to be a working tool, not a decoration. All I wanted was clean enough to use and that it looks taken care of.

The mechanical parts were adequately clean and (overly) well oiled.

There was only one real mechanical problem, and it took me a long while to realize that it even existed.

I only discovered it when I tried to properly adjust the thread tension to sew cloth instead of leather.

That's a story for another day.

Joseph Eoff

Joseph Eoff

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.