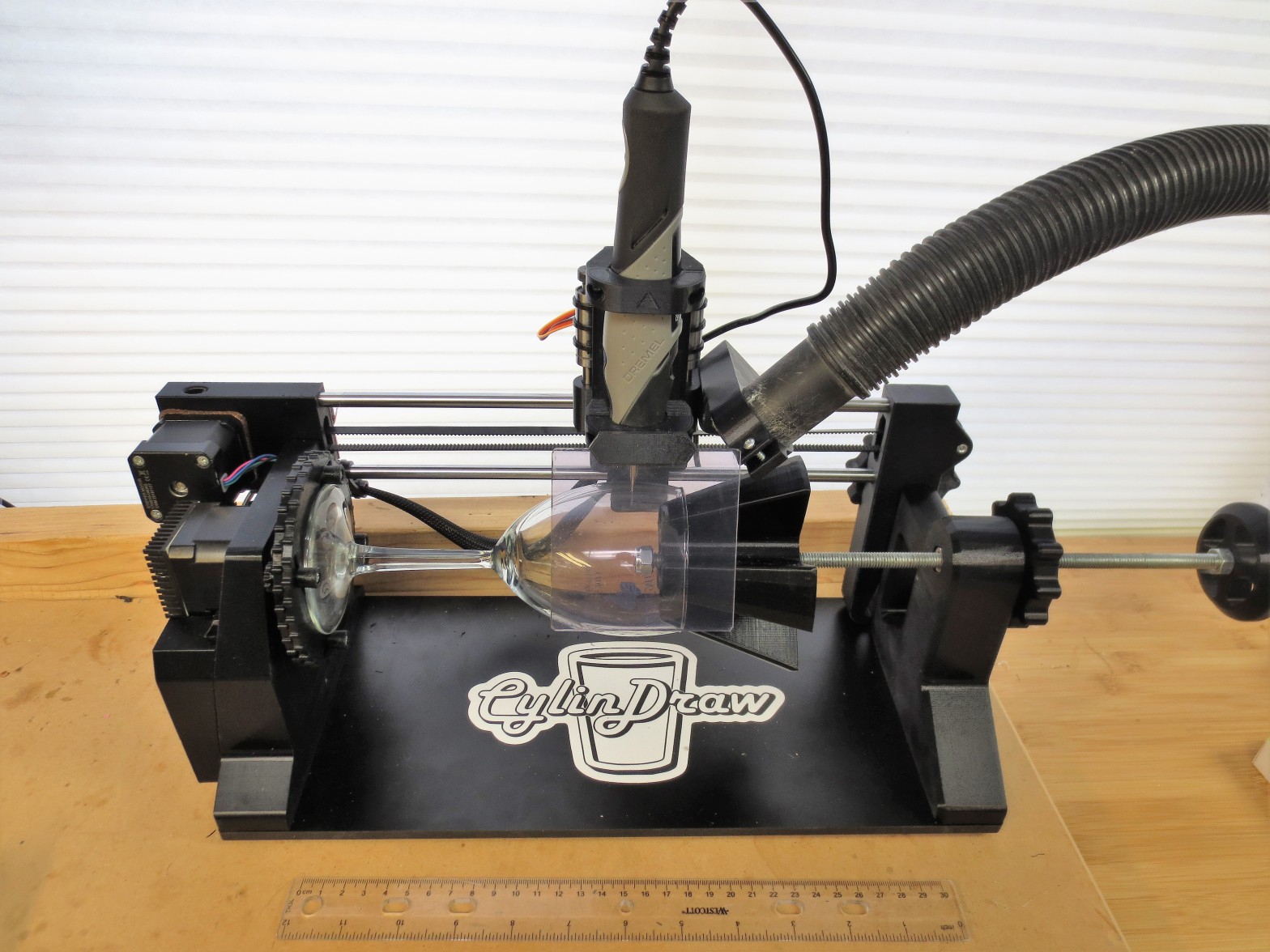

Of the many things a CylinDraw can do, engraving tumblers excites me the most because it is the most disruptive when compared to existing tech.

Our product is so new most people aren’t yet aware of the value our tool brings to this industry, so this article will directly compare the capabilities of a CylinDraw against a laser engraver.

If you shop online (on say, Etsy) for a custom engraved tumbler there is a 100% chance the seller is making them using a laser engraver with a rotary table add on. That’s just the way it’s done for low volume production.

High volume custom tumblers are usually made with a different process like screen printing, pad printing, heat transfer decals, full color digital printing (can produce gradients), or acid etching. But those processes have a costly labor intensive setup not worthwhile for a one-off tumbler.

In the same way that 3d printing pays off against injection molding for small orders, so does physical engraving compare to the options listed above. What matters most then to a low volume process is unit cost, setup time, and of course how safe the tool is to use. So lets compare with those important criteria in mind:

Safety Concerns:

- Laser Engraver: “Never run the machine unattended” is listed on every laser machine manual ever made for obvious reasons. But burning things is inherently hazardous in more than one way. Lasers produce smoke & soot that must be vented to the outdoors or else filtered inside because it should not be inhaled. Either way the fumes require high cfm fans, noisy enough to call for a dedicated shop to accommodate the tool.

- CylinDraw: Mechanical engraving is a cleaner process since fumes and fire are not a factor. The physical byproduct is microparticles which can be safely contained with a steady flow of water or a shop vac. CylinDraw can readily accommodate either option. (Winner CylinDraw)

Startup Cost:

- Laser Engraver: Varies greatly but you can expect to pay north of $3000 for a name brand 40W C02 laser plus another $500 for the rotary jig. But the sky is the limit for professional equipment. You can go the cheap route & get a generic K40 from eBay, if you want to trust such a device. I’ve found the hidden costs for direct-from-China CNC equipment to be substantial and usually come in the form of mystery problems with no seller support. A K40 has all the appeal to me as a $600 car from craigslist.

- CylinDraw: At worst its $600 if you buy the machine fully assembled & deck it out with a water pump, a Dremel Stylo, & a Dremel 290. (Winner CylinDraw)

Recurring/Maintenance Costs:

- Laser Engraver: The software is almost always a paid subscription if you want something decent. Expect to pay in the range of ~$500 for a lifetime purchase or ~$20/month for a subscription. If you vent indoors with a filter then you have to replace the consumable filter every so often. (~$50/yr) . The tool requires regular cleaning of soot from the internals to remain safe to operate.

- CylinDraw: CylinDraw is a sturdy little tank with free software! The only thing you’ll be replacing is your (low cost) engraving bits every so often. And perhaps annually the $4 MG-90s lifter servo. (Winner CylinDraw)

Ease of Use:

Laser: Powerful software options come with a harder learning curve. Also lasers take tuning and often have to burn a bunch of bottles getting the tool dialed in.

CylinDraw: The software for the machine was designed to be as easy to use as possible. There aren’t many control parameters required. Just mechanically set the Dremel height, select the speed from a table to match your material & go. Of course using any new software has some learning curve so to counter my own bias I’ll call it a (Tie).

Quality:

Customers buying engraved glasses don’t care how it was made or how long it took. They only care about the quality of the result!

- Laser: Resolution between 0.1-0.5mm. Focus of the laser has to be adjusted to achieve a specific engraving width. Can leave scorch marks at the edges, but if you use masking tape these go away.

- CylinDraw: Resolution between 0.2-0.5mm, depending on the bit you use. (Tie)

Process Speed:

- Laser: (Marginal Winner Laser) Initial setup will take longer but the actual engraving speed is quicker. Expect a few minutes to run a single piece.

- CylinDraw: Takes a few minutes or potentially up to some order of 30 minutes to run a single piece, it varies with the complexity of the work (the reason why has to do with path planning as Ive discussed here). (I’ll add that CylinDraw’s initial cost is low enough that its feasible to buy 2 and run them in parallel to increase your process throughput!)

Overall:

In summary, CylinDraw is an order of magnitude less expensive in terms of upfront/operating/maintenance costs when compared to a rotary laser engraver, while offering an (arguably) much easier to use interface and equivalent output quality. So I am extremely pleased with the overall value offering a CylinDraw rotary engraver represents!

Michael Graham

Michael Graham

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.