There is an art to designing a back scratcher.

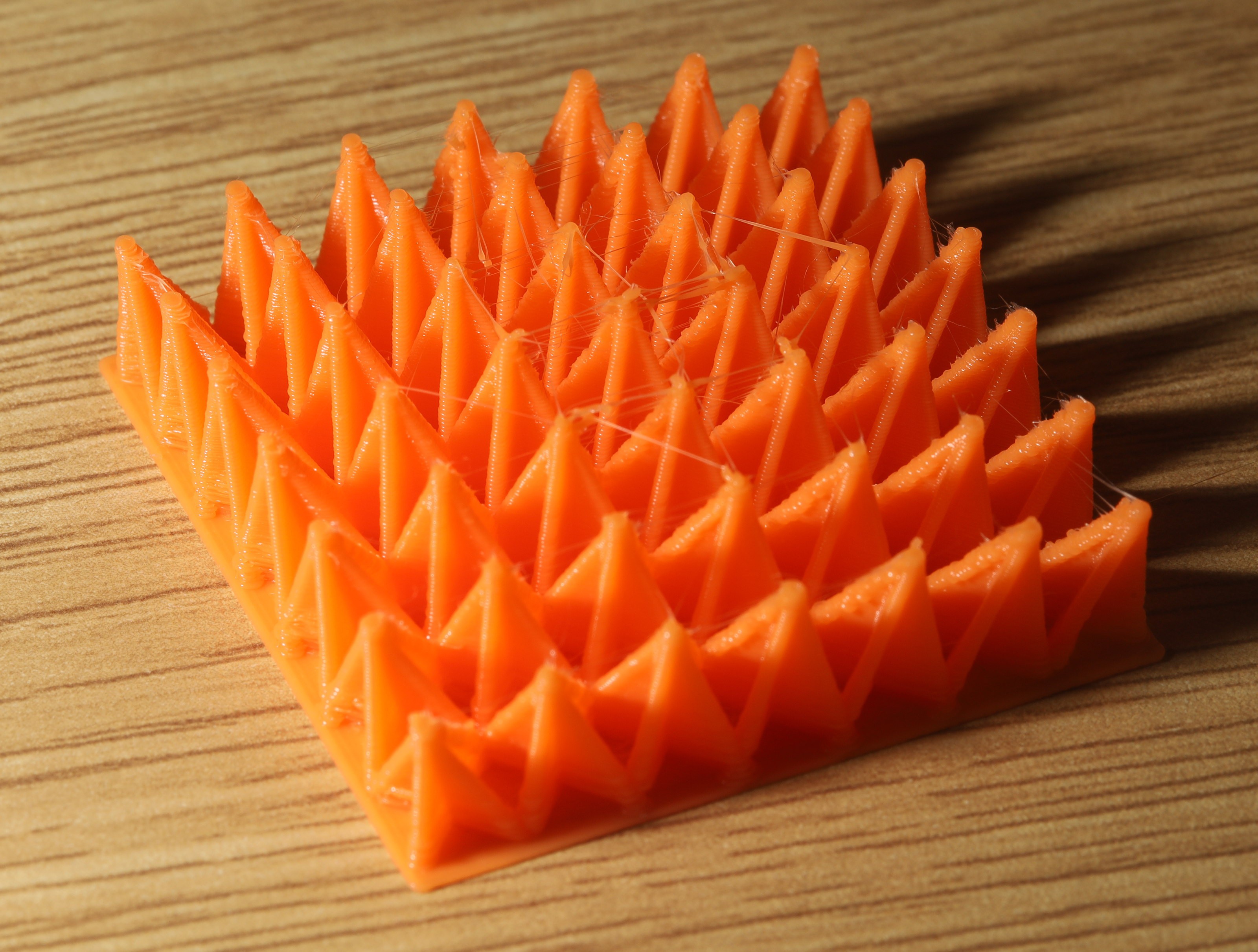

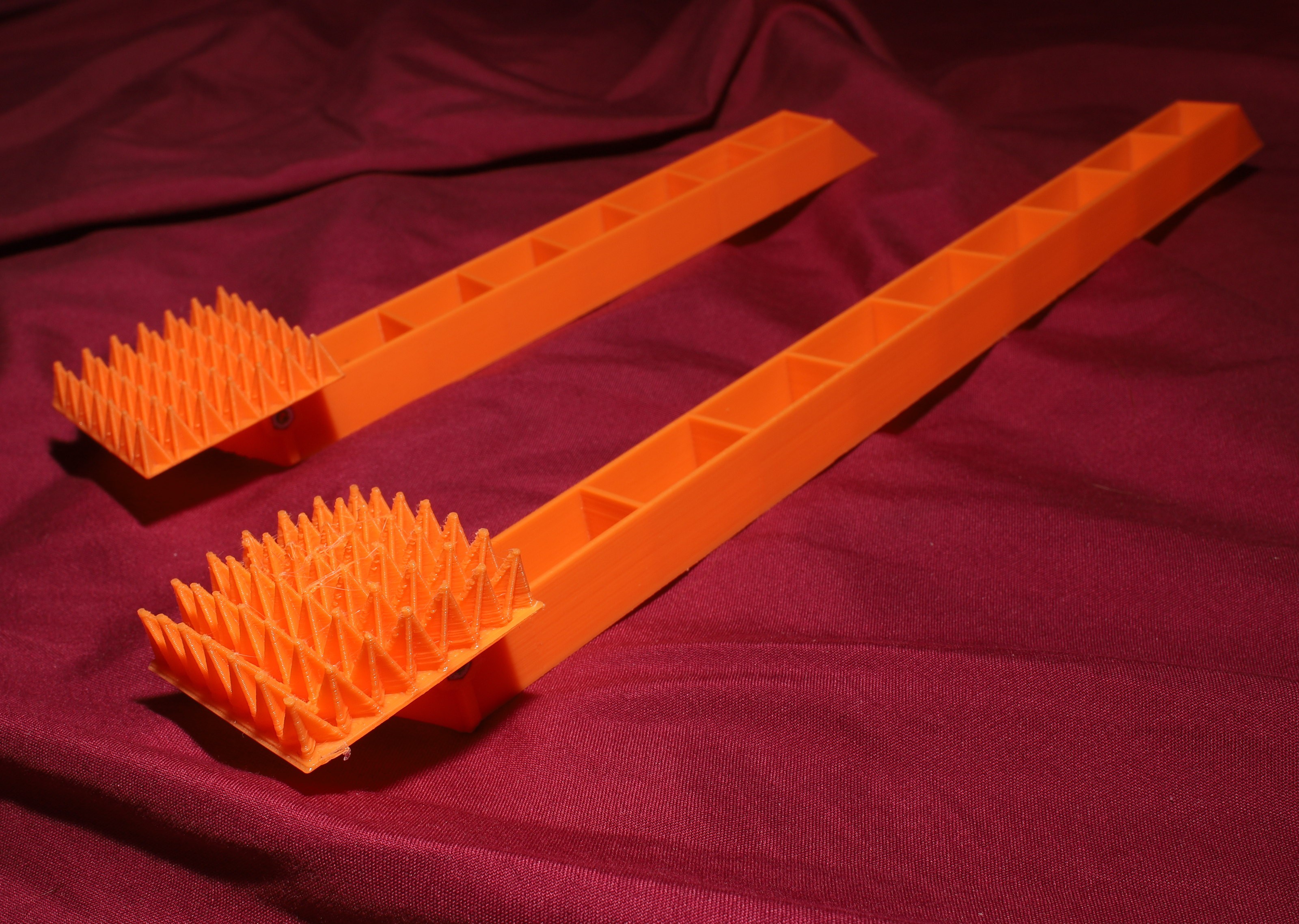

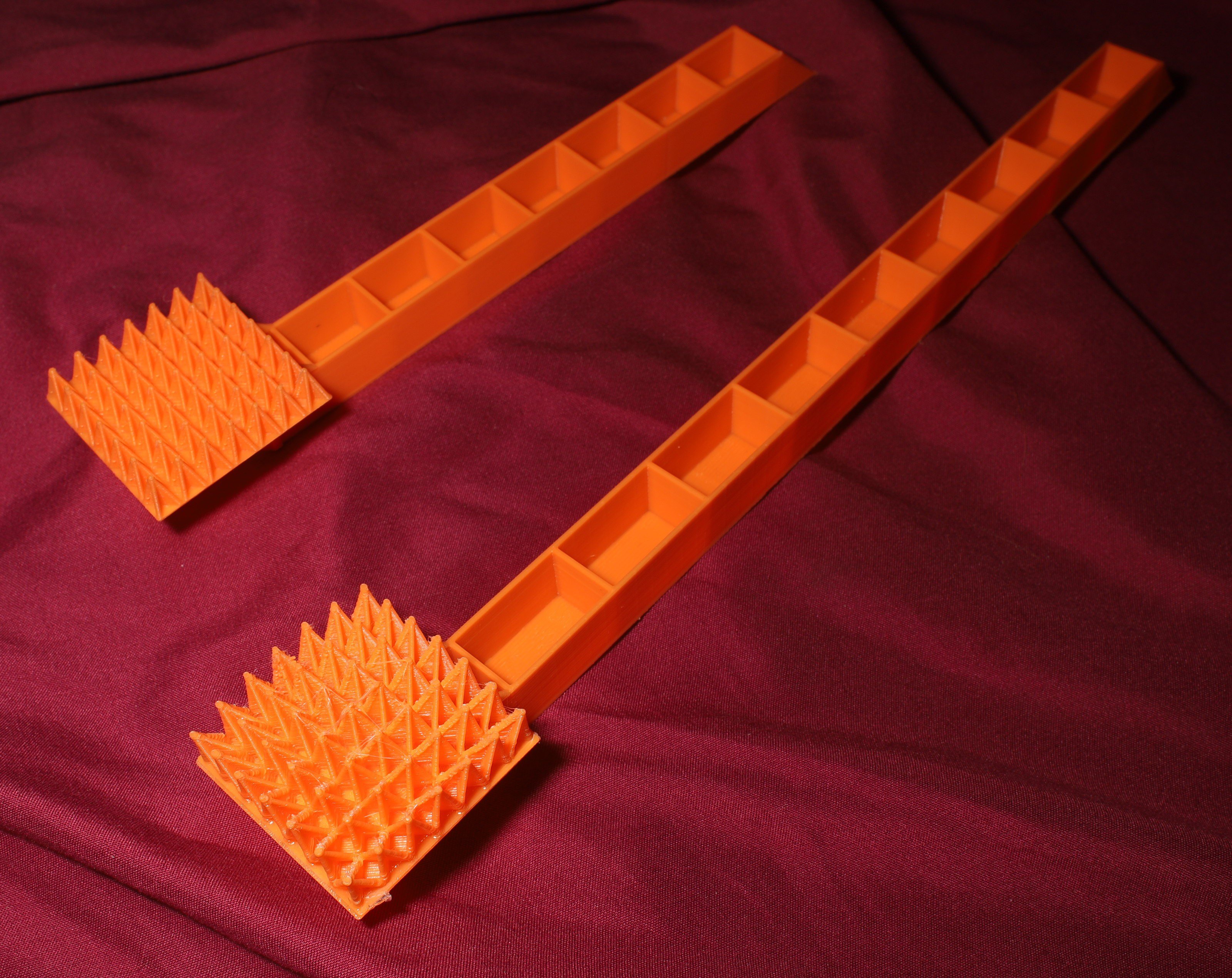

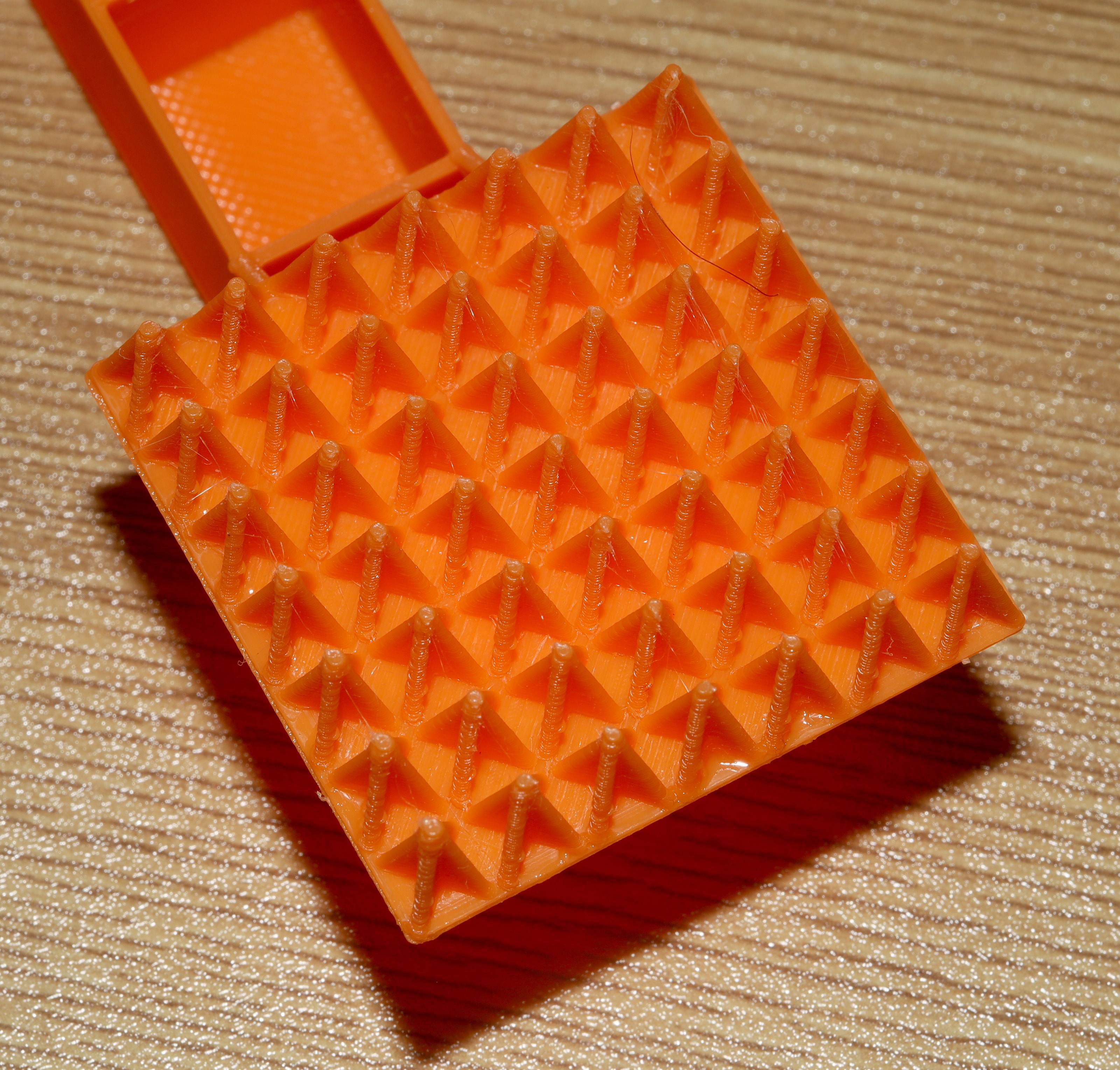

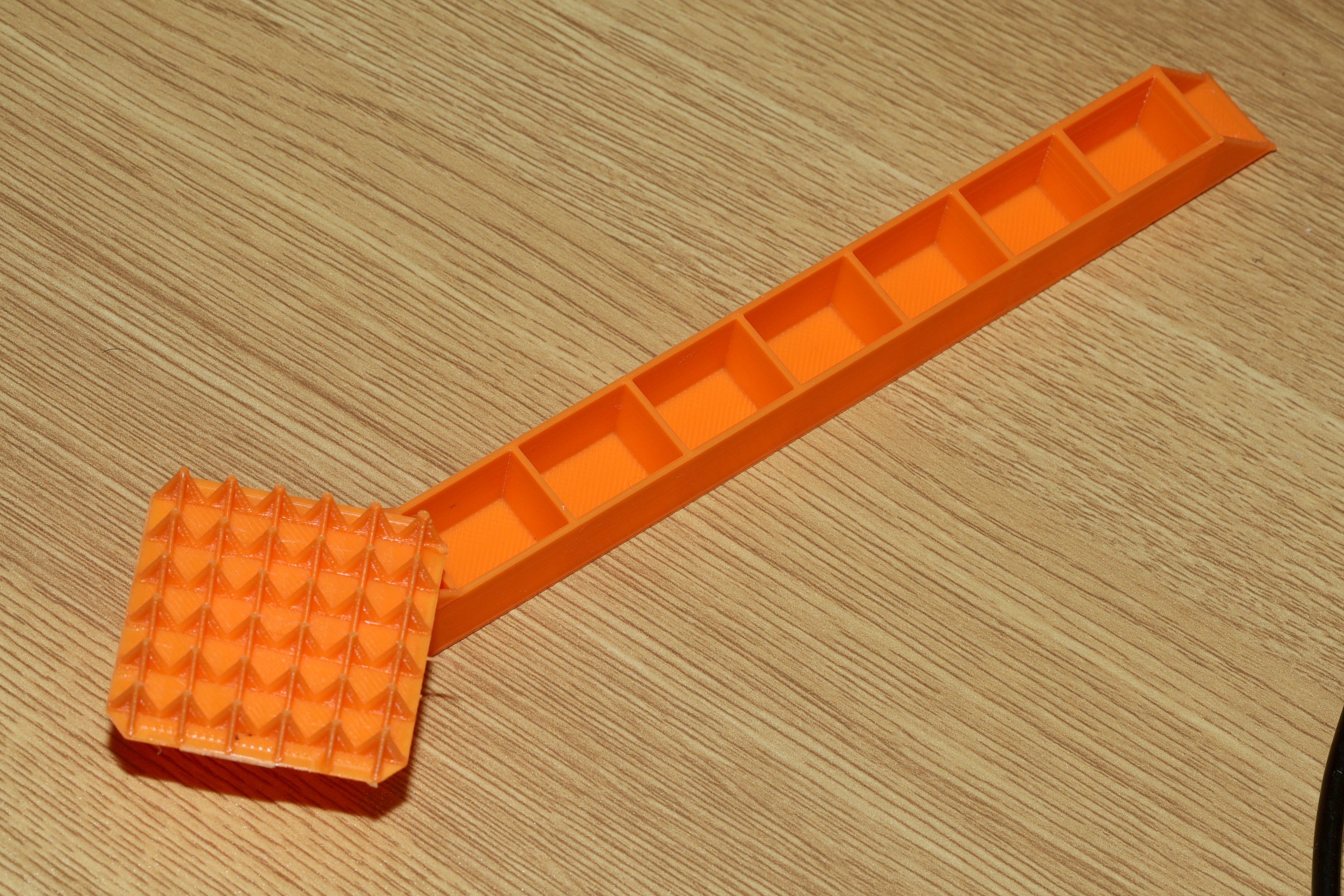

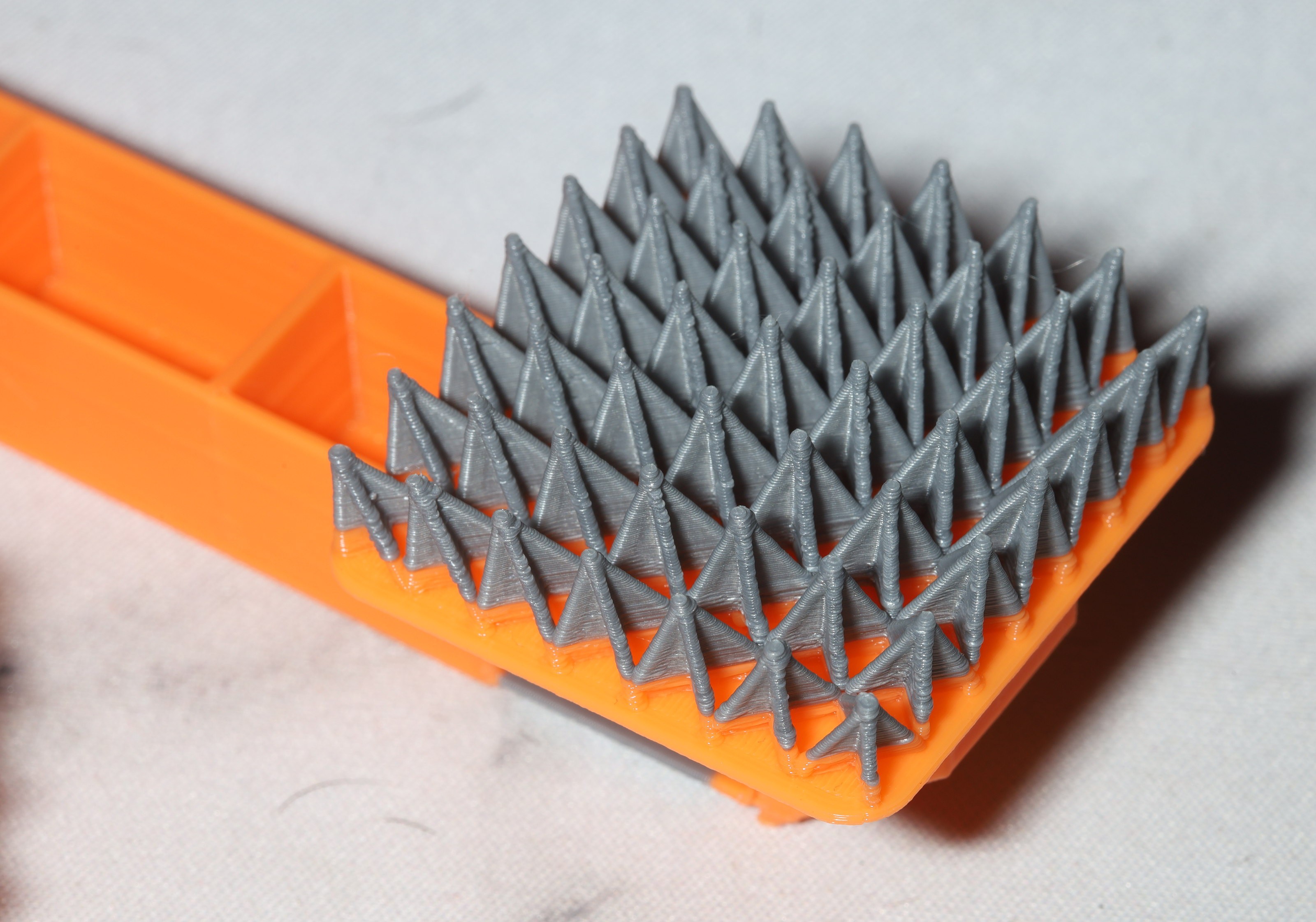

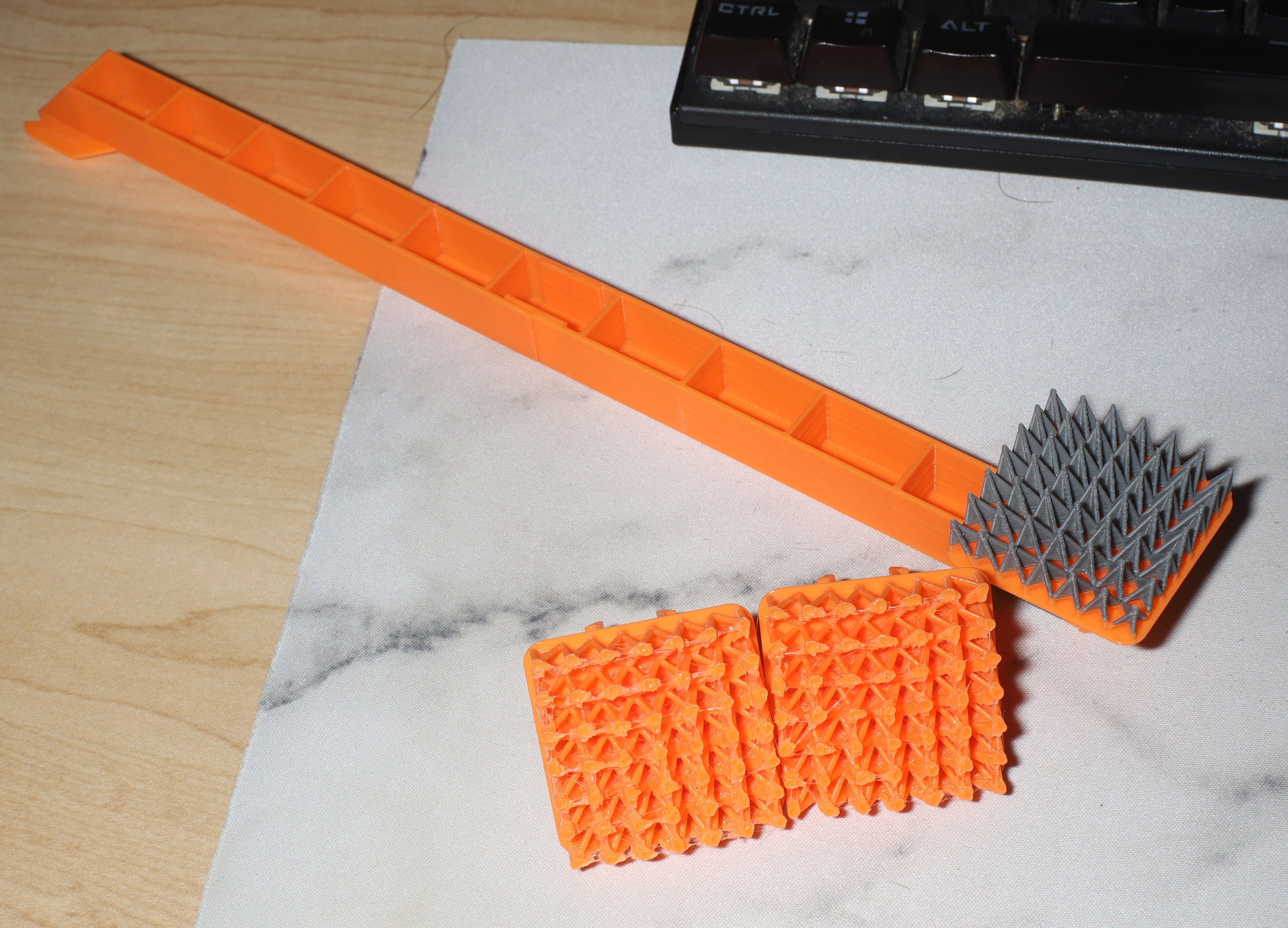

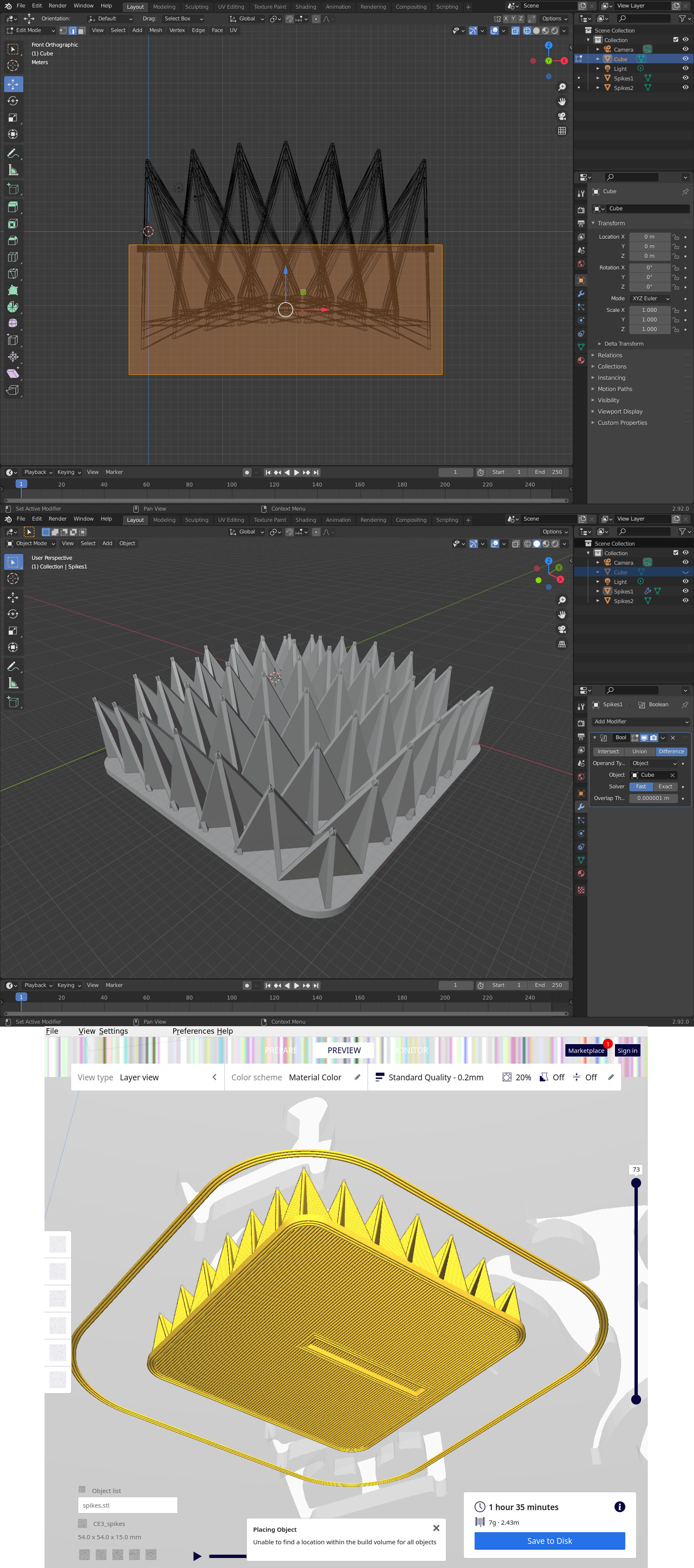

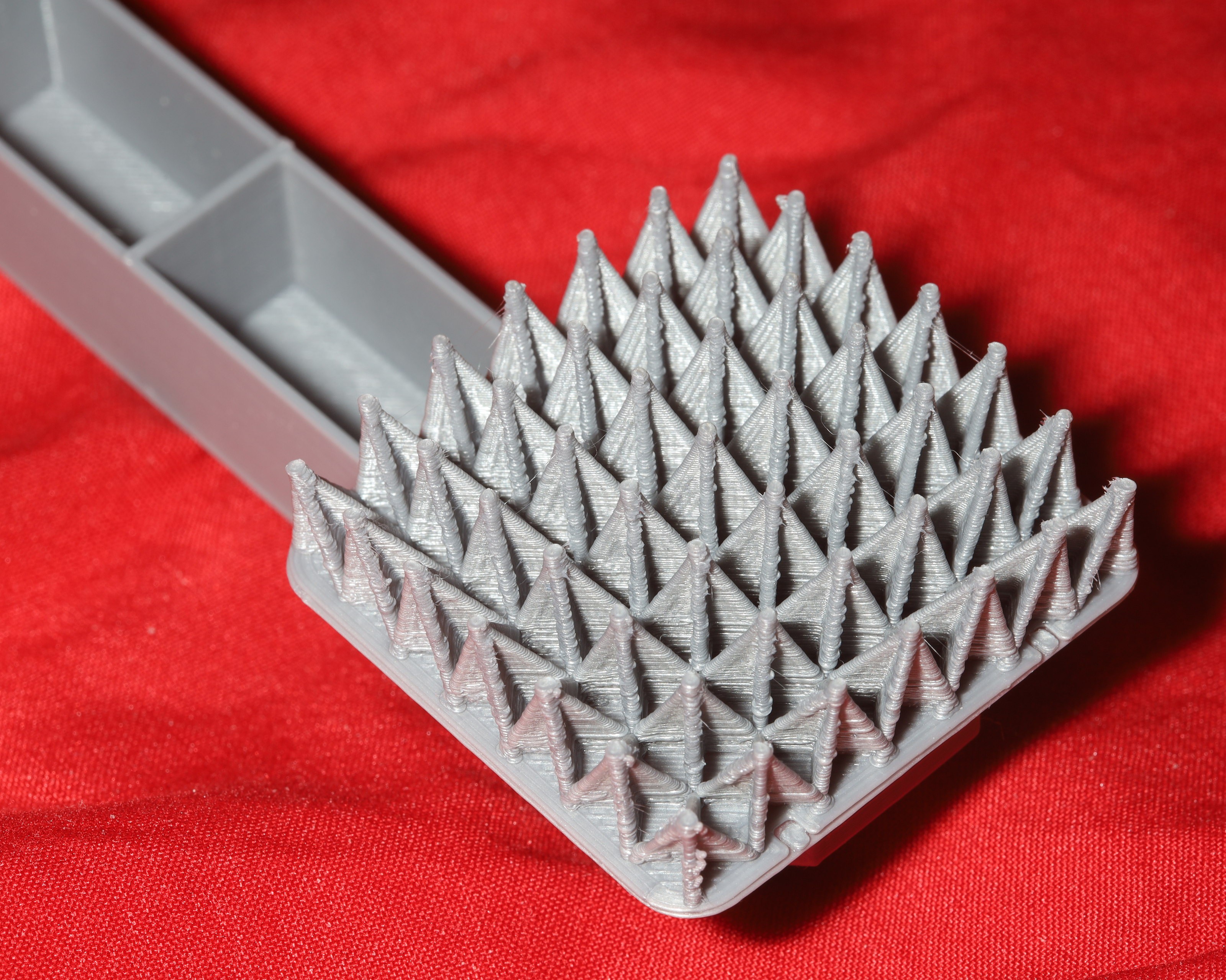

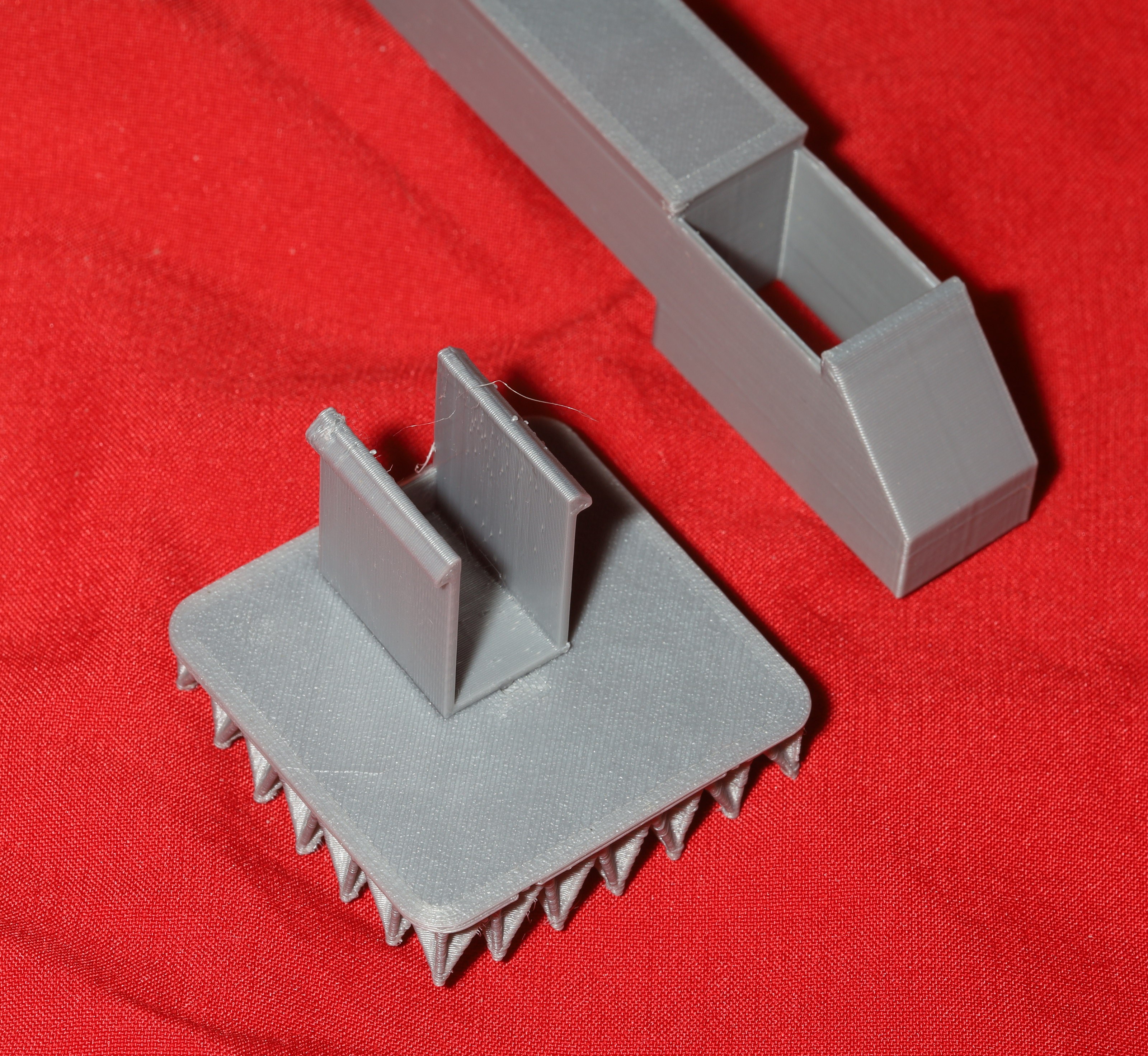

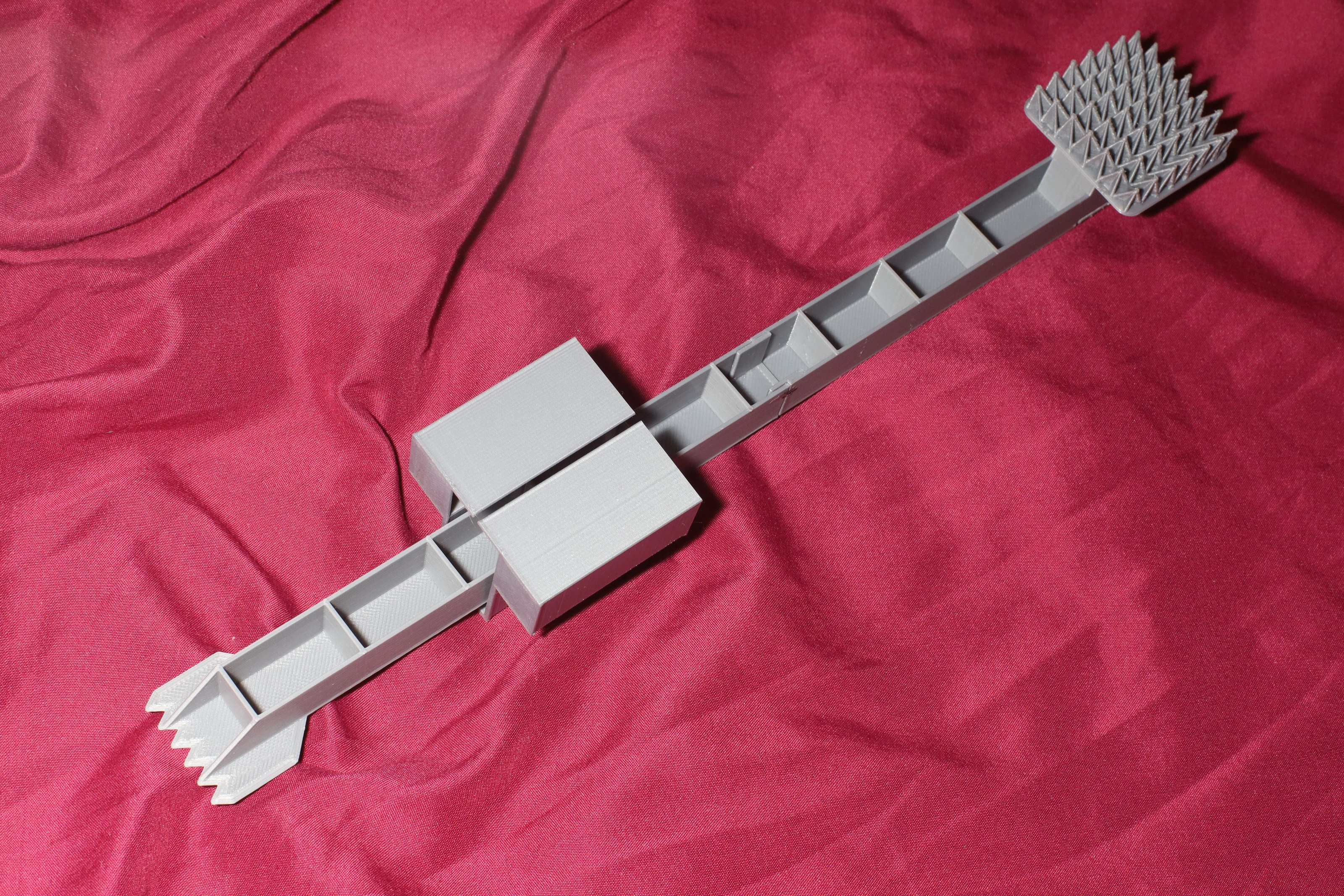

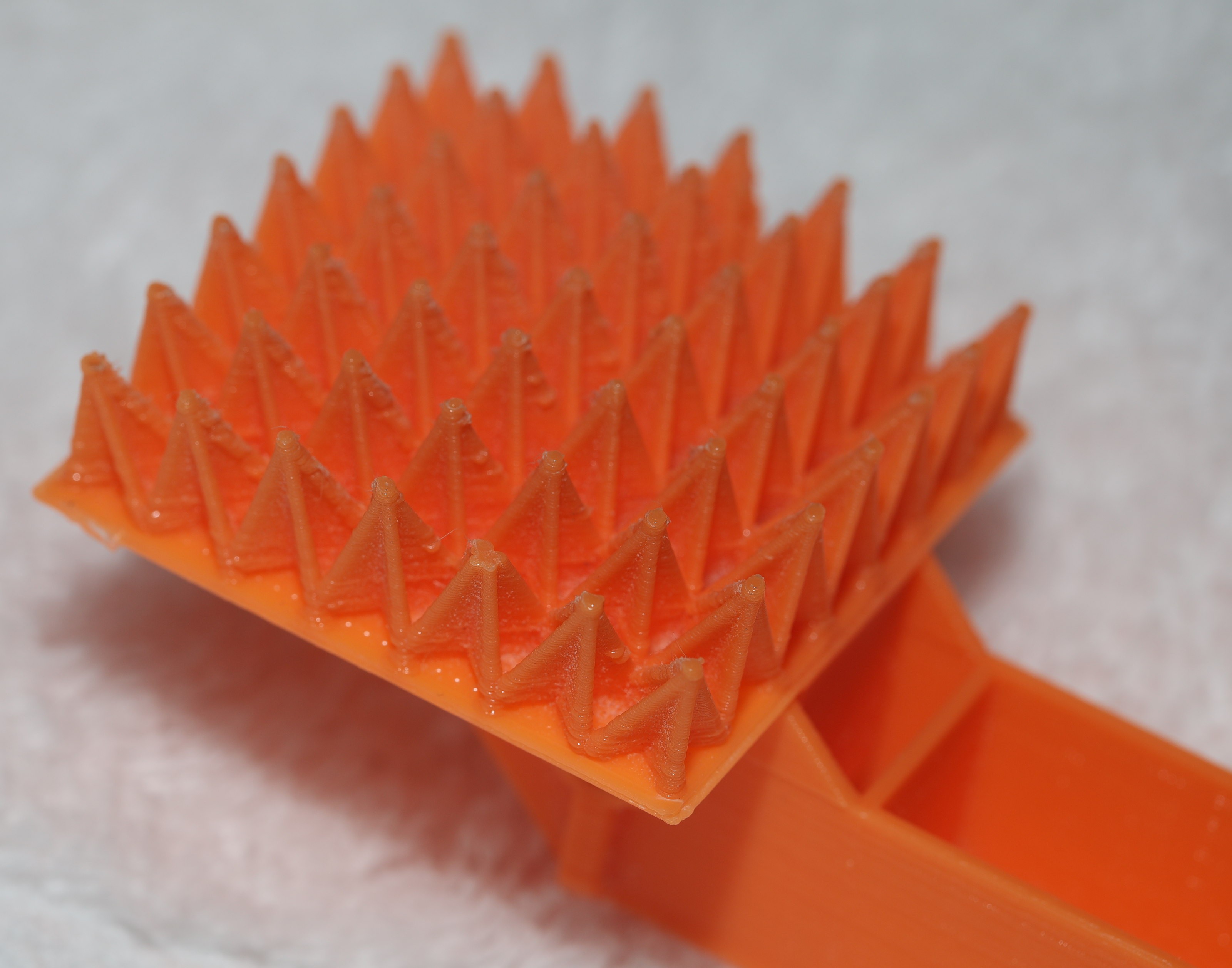

The key feature was interchangeable spikes, since printing a handle is expensive. The ideal head so far has diagonal crosses on a square panel.

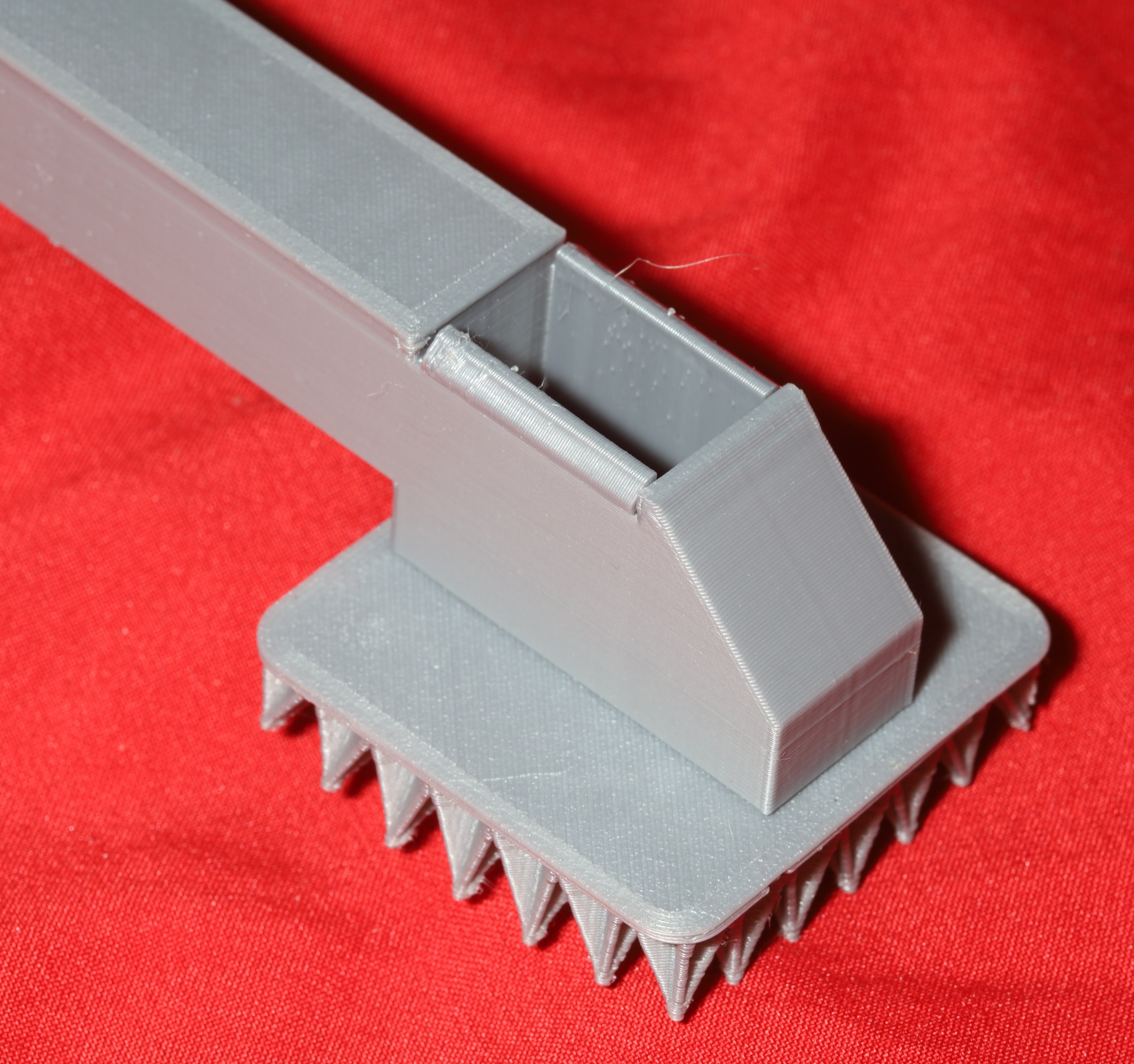

The cross shaped spike, rotated 45 deg, forces skin into a corner before it can pass. The layers have to be parallel to the plane to get the most abrasive surface. The spikes have to be tall enough so they do the scratching instead of the edge of the panel.

PLA is much more abrasive than wood, so this can cause injury if abused. A few light brushes are all it takes to cure all itches.

A diamond panel was less effective because it presents a narrower line of spikes in the direction of travel.

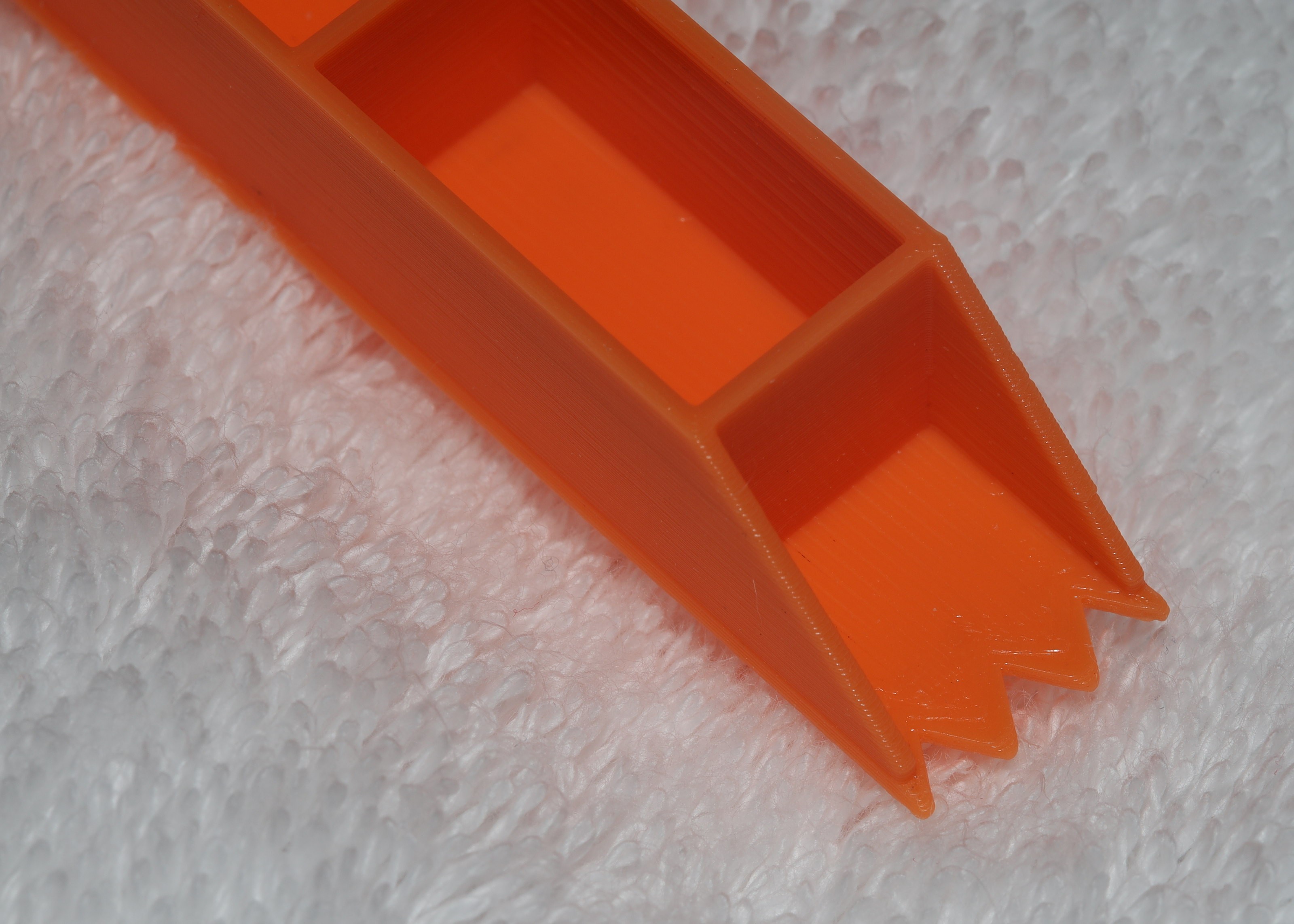

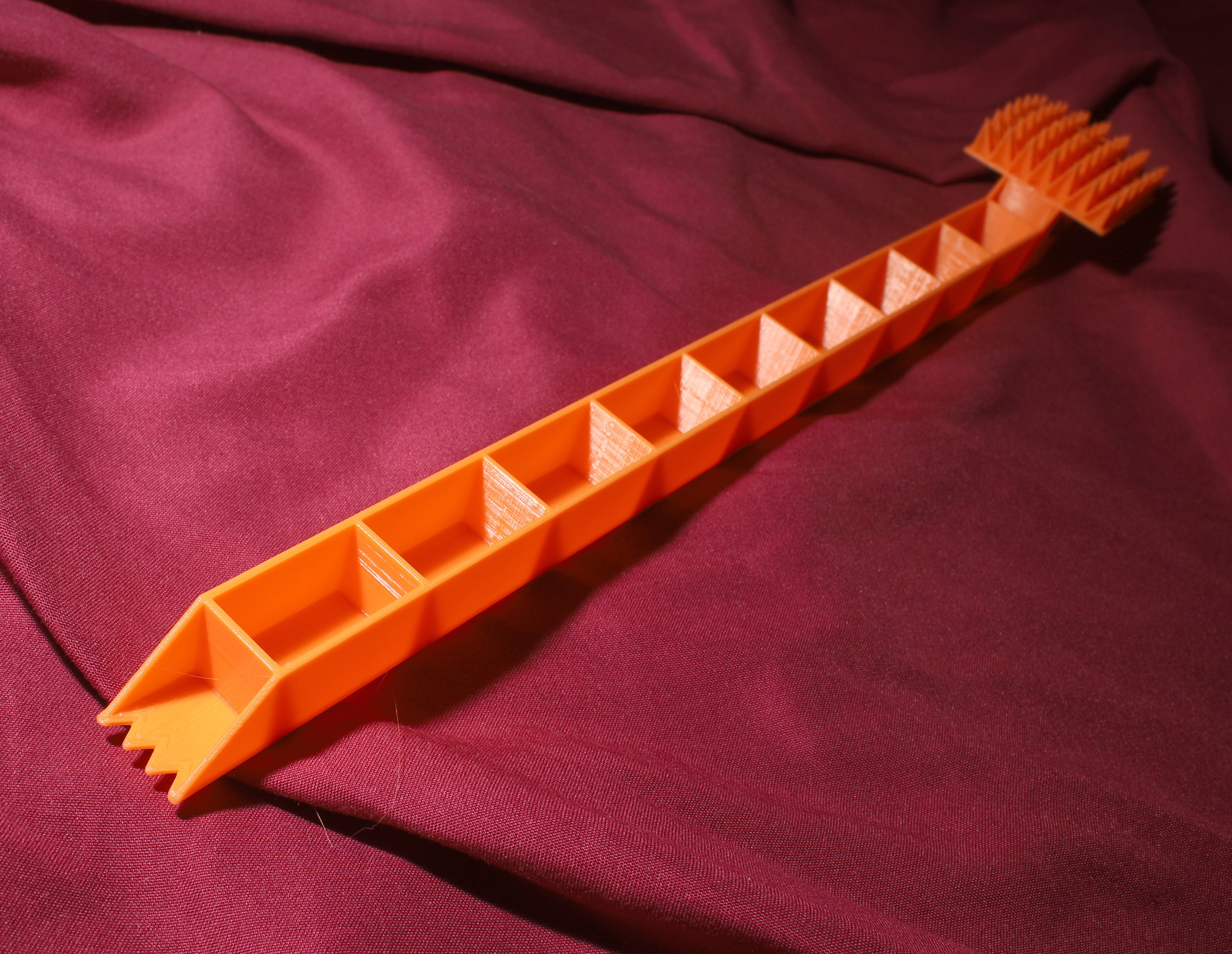

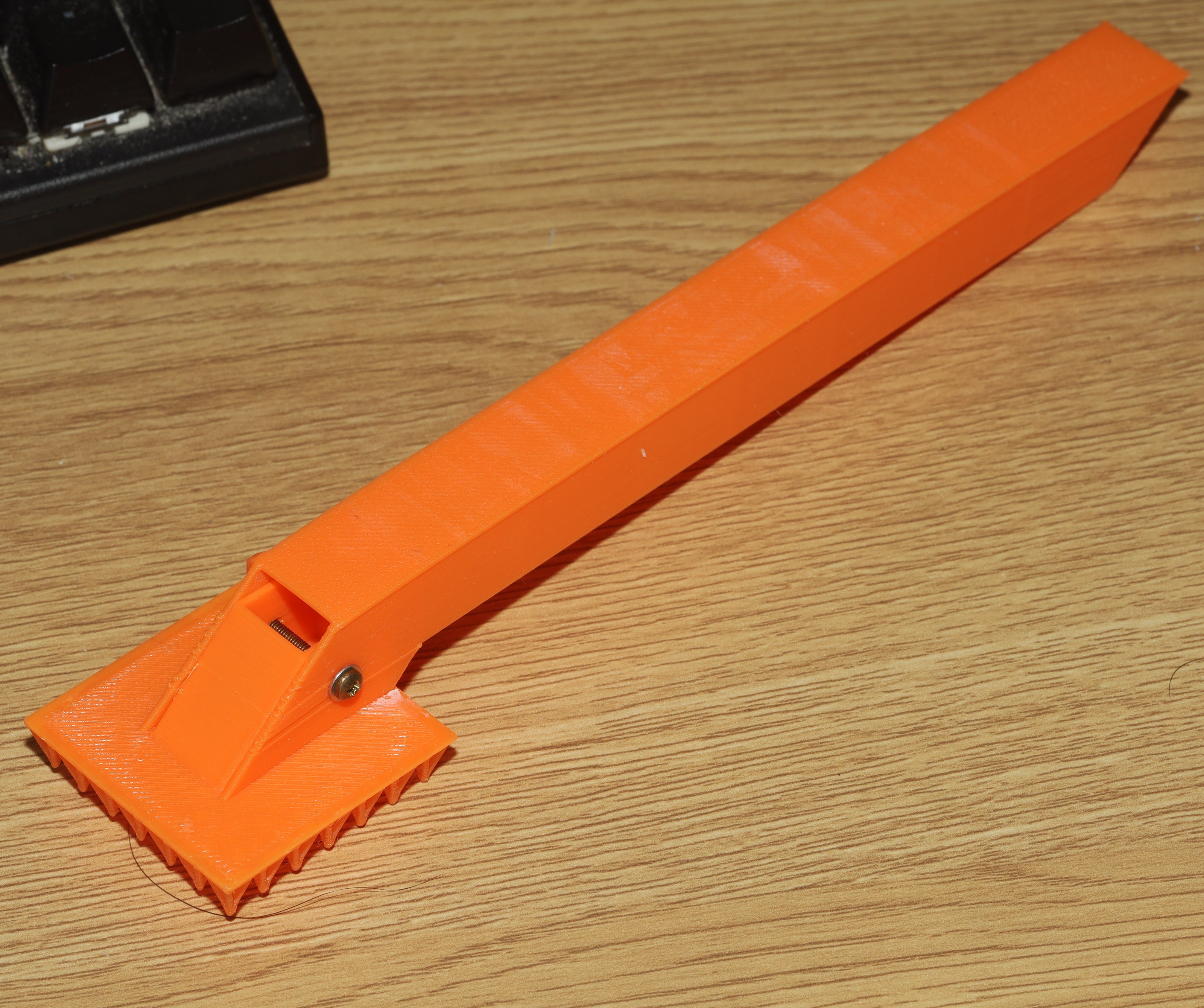

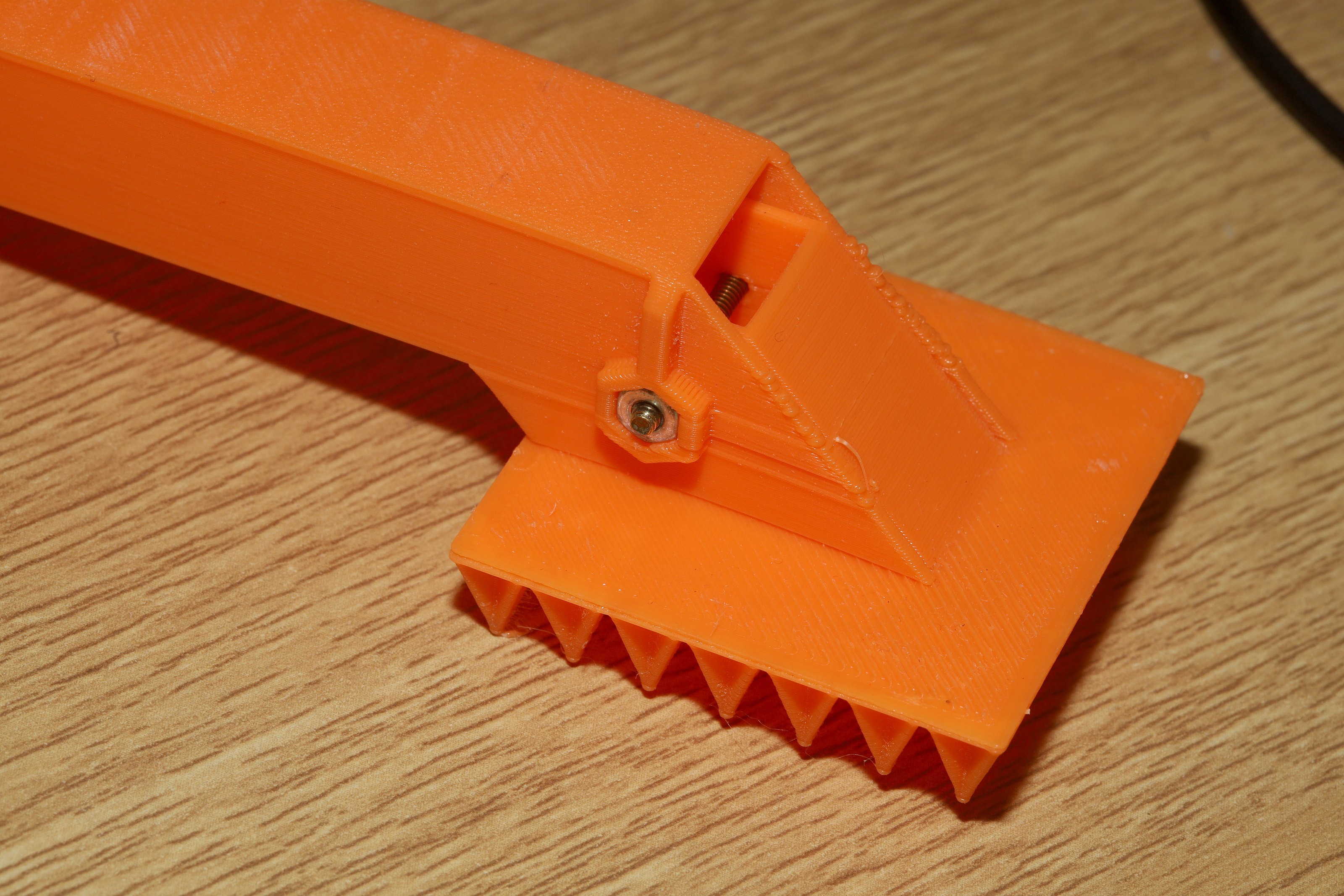

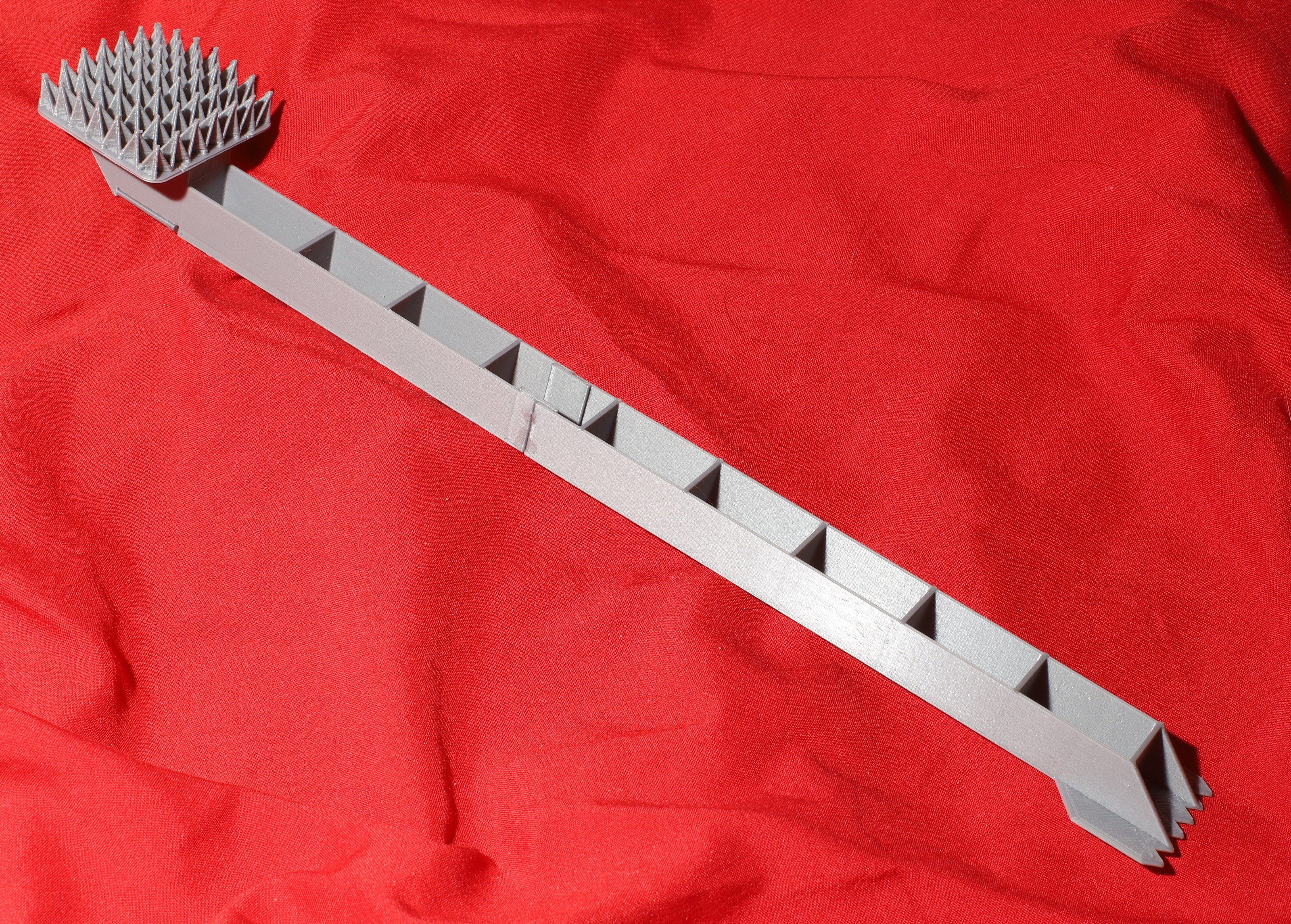

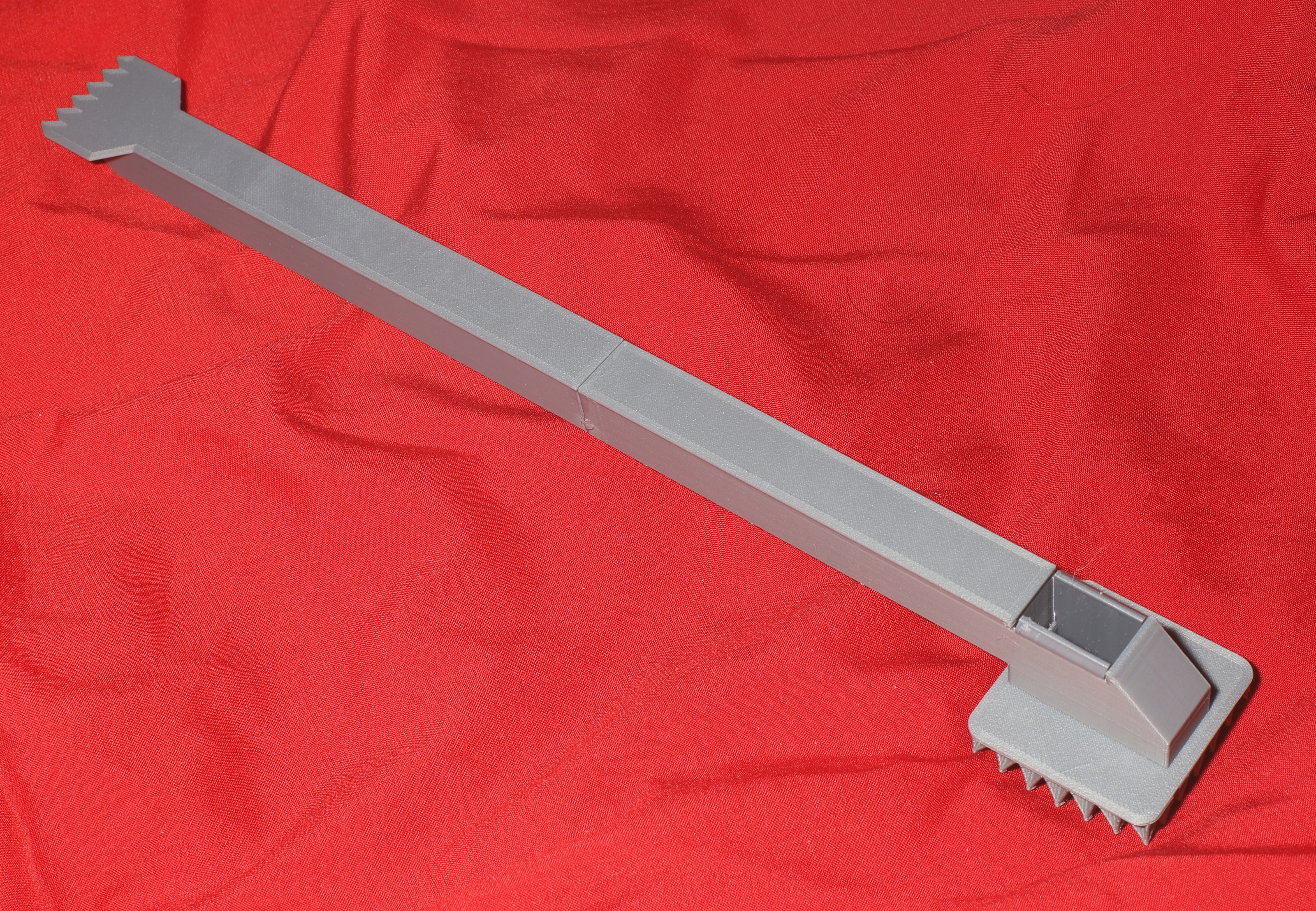

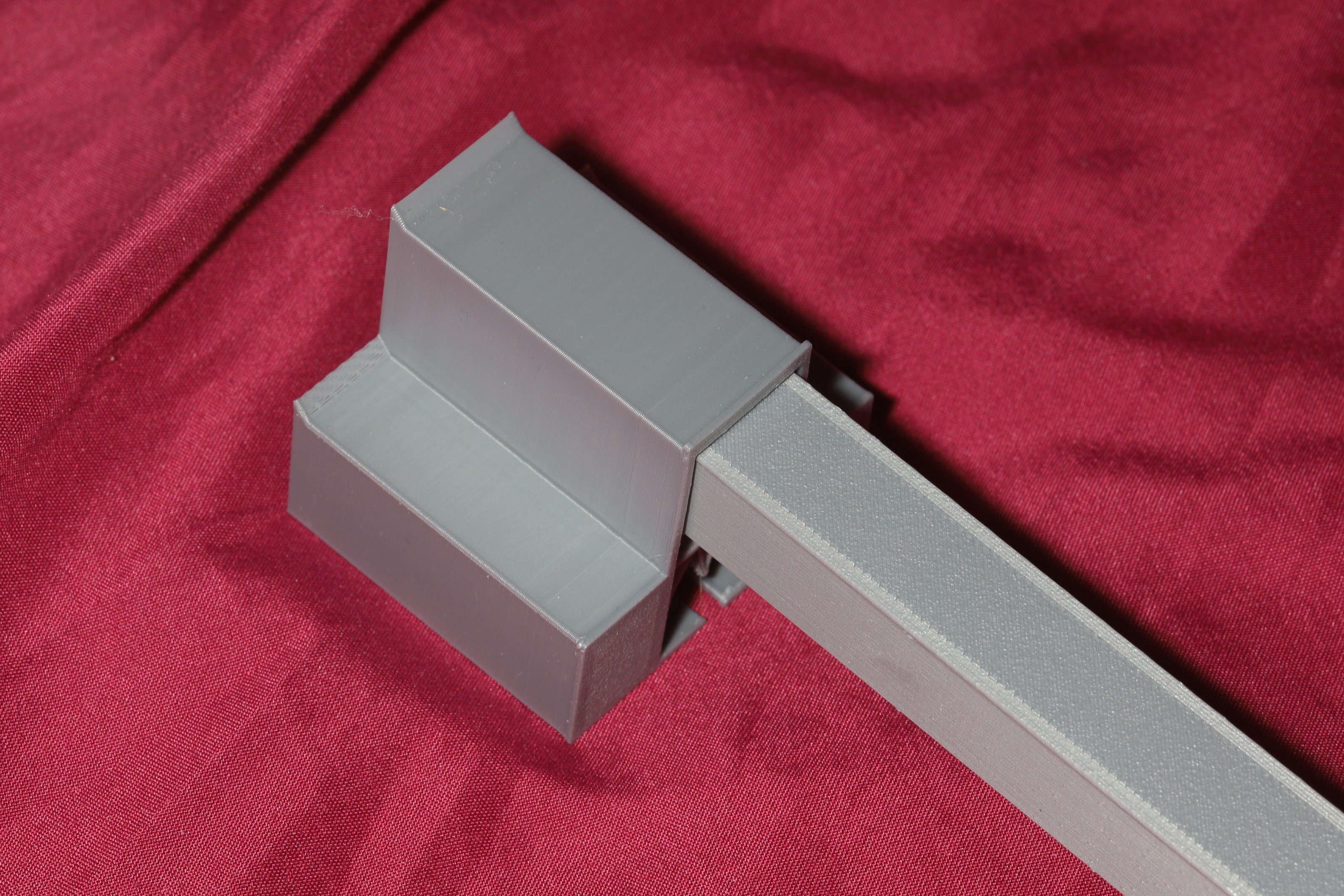

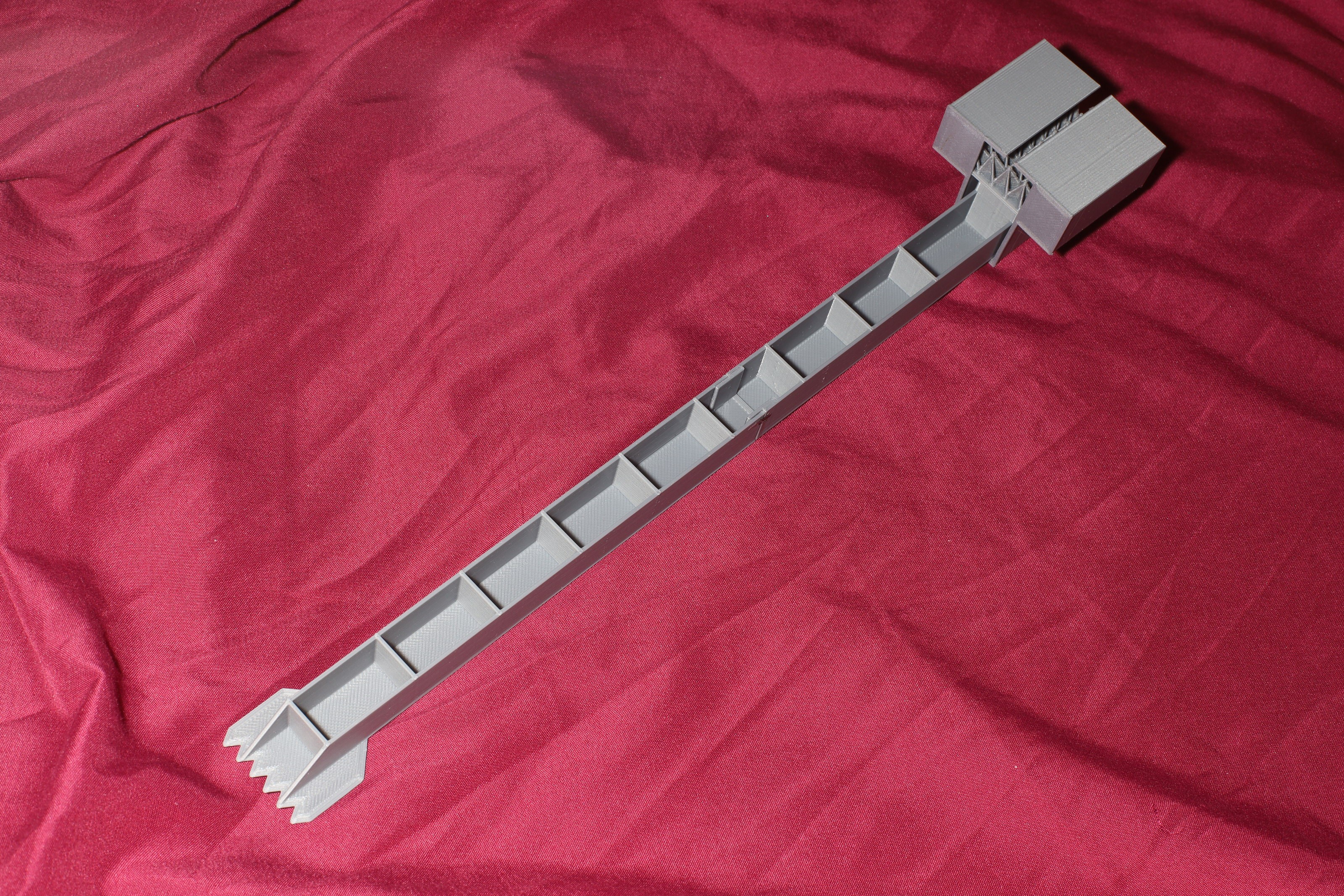

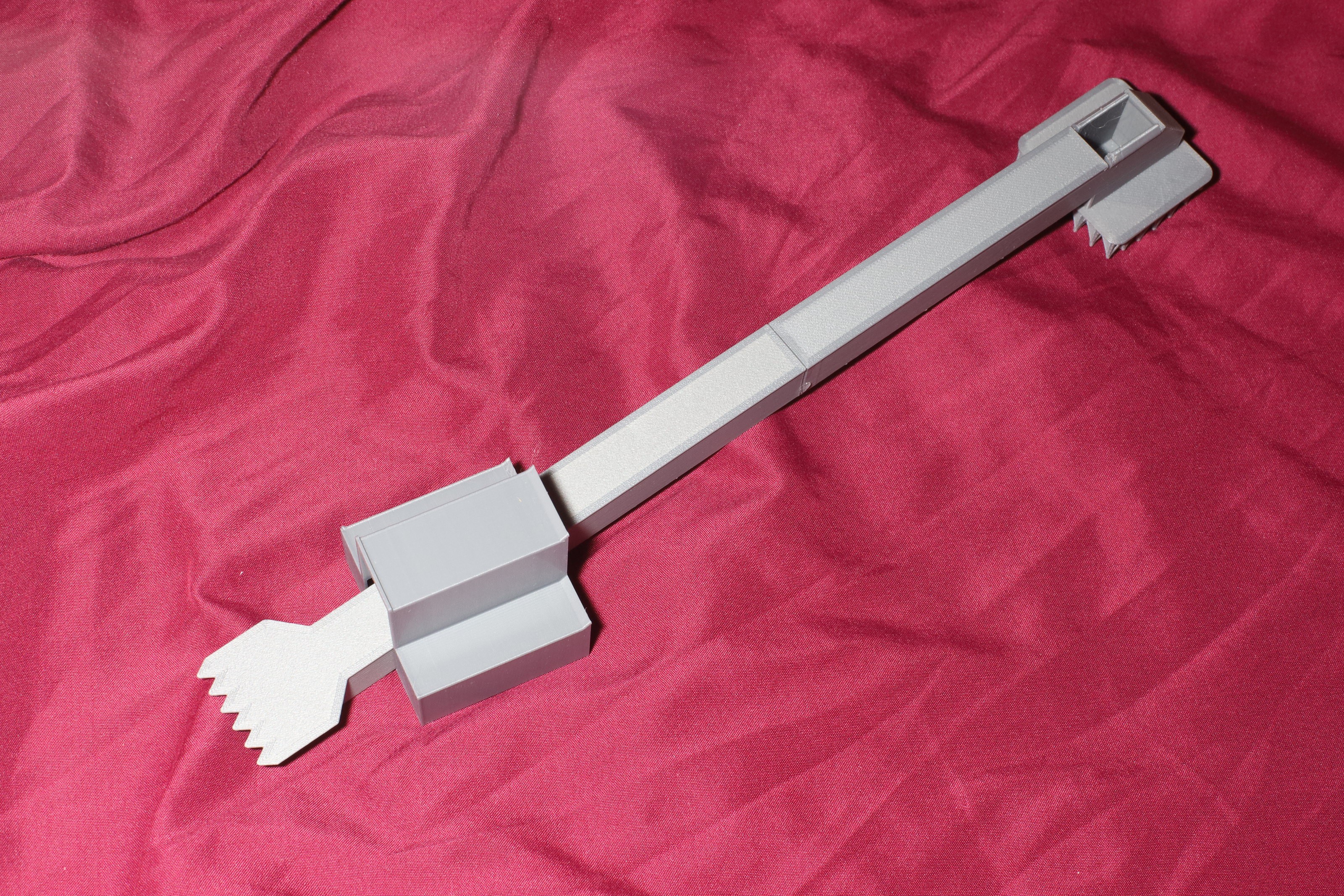

The handle is too short, but it was all lions could afford. Other back scratchers bolt on to a wood dowel, but the lion kingdom figured bolting onto wood wouldn't be as stiff as a single piece of plastic. It has a sharp end for scratching other areas not best served by the spikes.

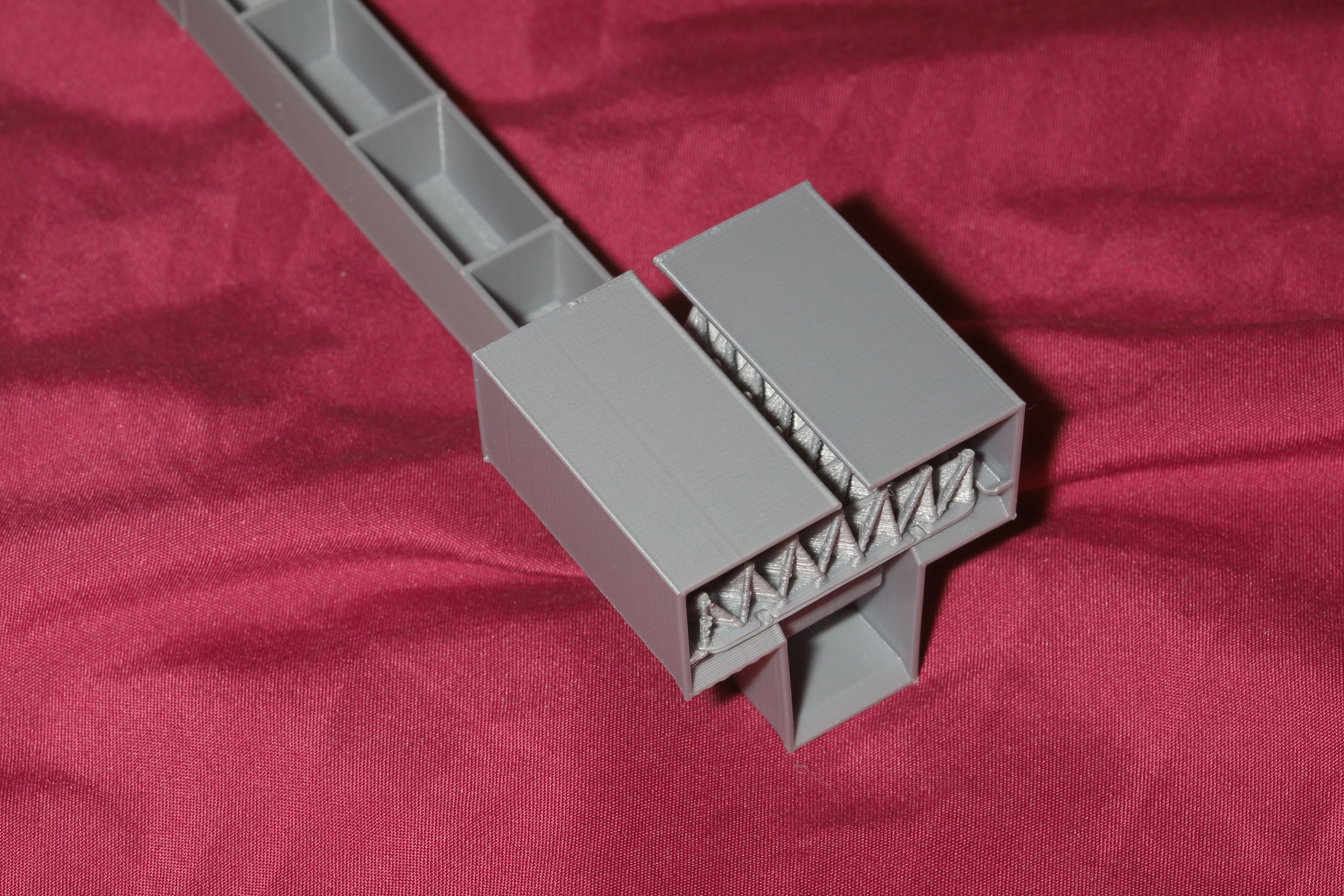

The ever important captive nut farstens the scratcher.

lion mclionhead

lion mclionhead

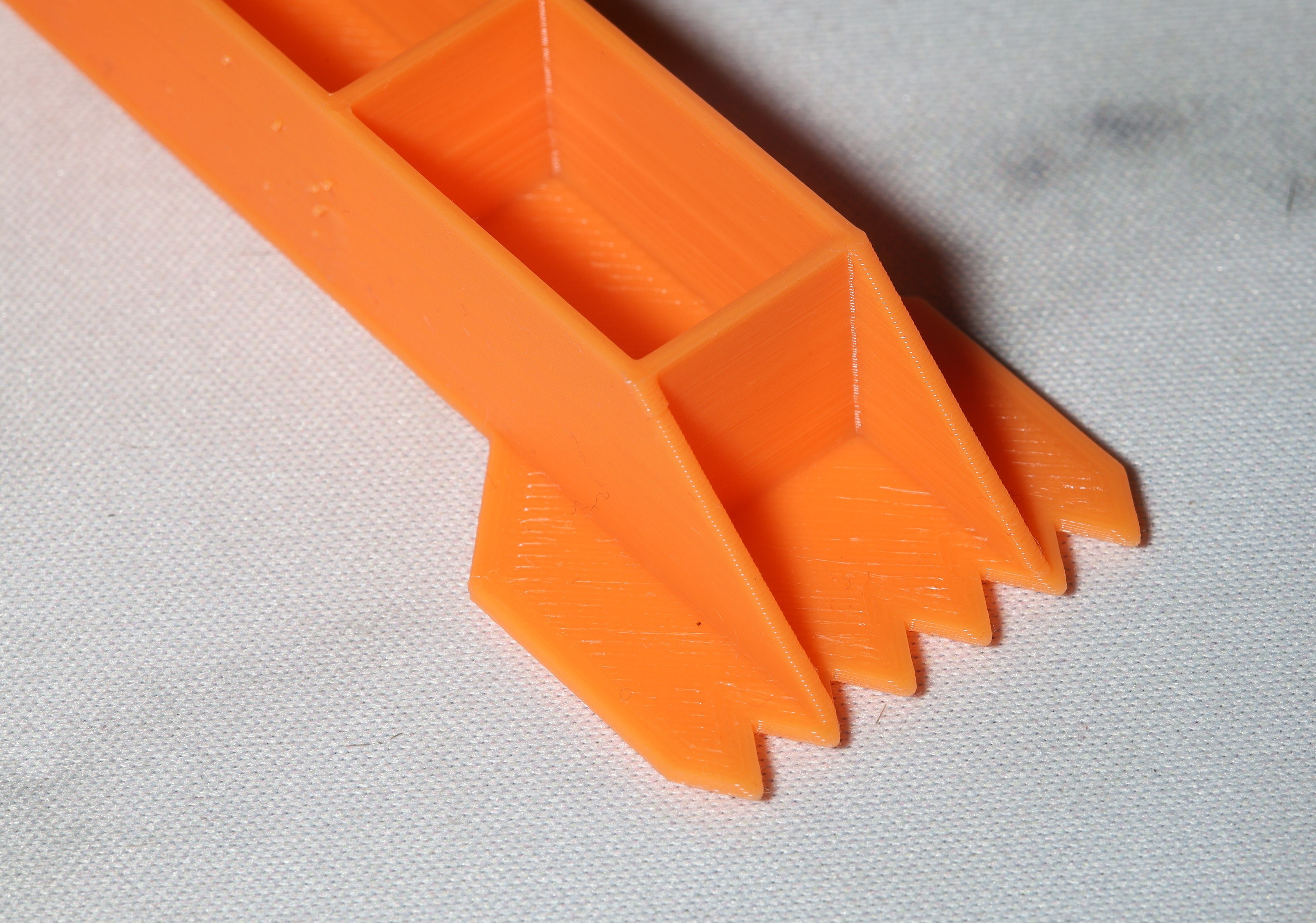

Then the handle's pointy end got slightly more aggressive.

Then the handle's pointy end got slightly more aggressive.