Media

Music I mentally associate with this project

Ashton Edminster - Something Different:

Mainly the "Something different, don't know what to call it" line because this printer isn't a conventional FFF printer and this project was just called "SecSavr" for most of its lifetime because I couldn't think of a name for this printer specifically. "SecSavr" is a non-existant 3D printer brand name I thought up, so this situation is like Sony coming out and announcing that their new product is "The Sony".

Navigation

The title tag system is explained here, and the table is updated when a change occurs. Notable logs have bold L# text.

Preface

[2022 - May 18] (and tweaked 2024 - Jan 14)

Short for SecondSavr (as in, saving seconds of time), this...

Read more » kelvinA

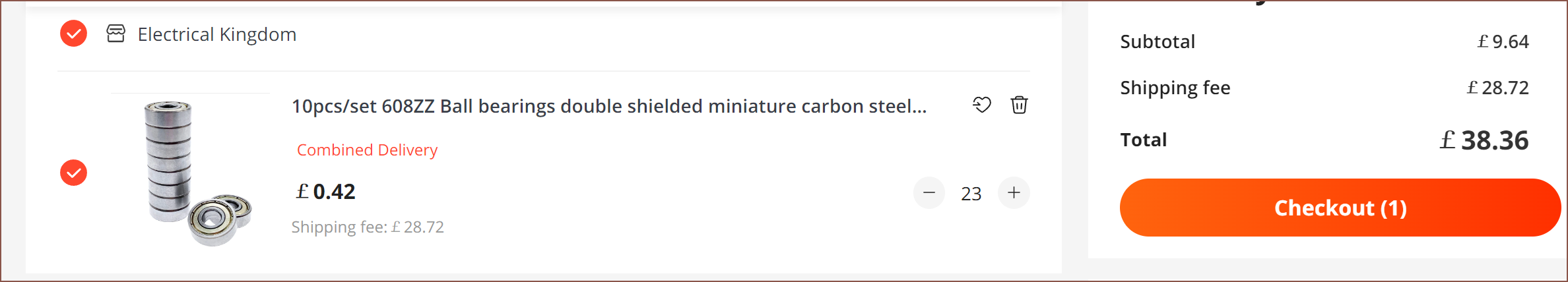

kelvinA So I was able to get on the limited edition CB1 drop ($10 price) and, looking at the order speeds in the first hour, I seemed to be the only one that was treating this like a GPU stock drop. I went in with the minimum to grab being 2 (for each Sublime) and 4 ideally (Suspense and a spare) but there was a 1 per customer blockade. I bought 1 immediately, tossed and turned for maybe 20 minutes, and made a second AliExpress account to get another one. Sometime (maybe a day) later I was just scrolling around and the $10 CB1 was back in stock. Strange. There's 2 of them though. And I can check out with both of them? Ok then!

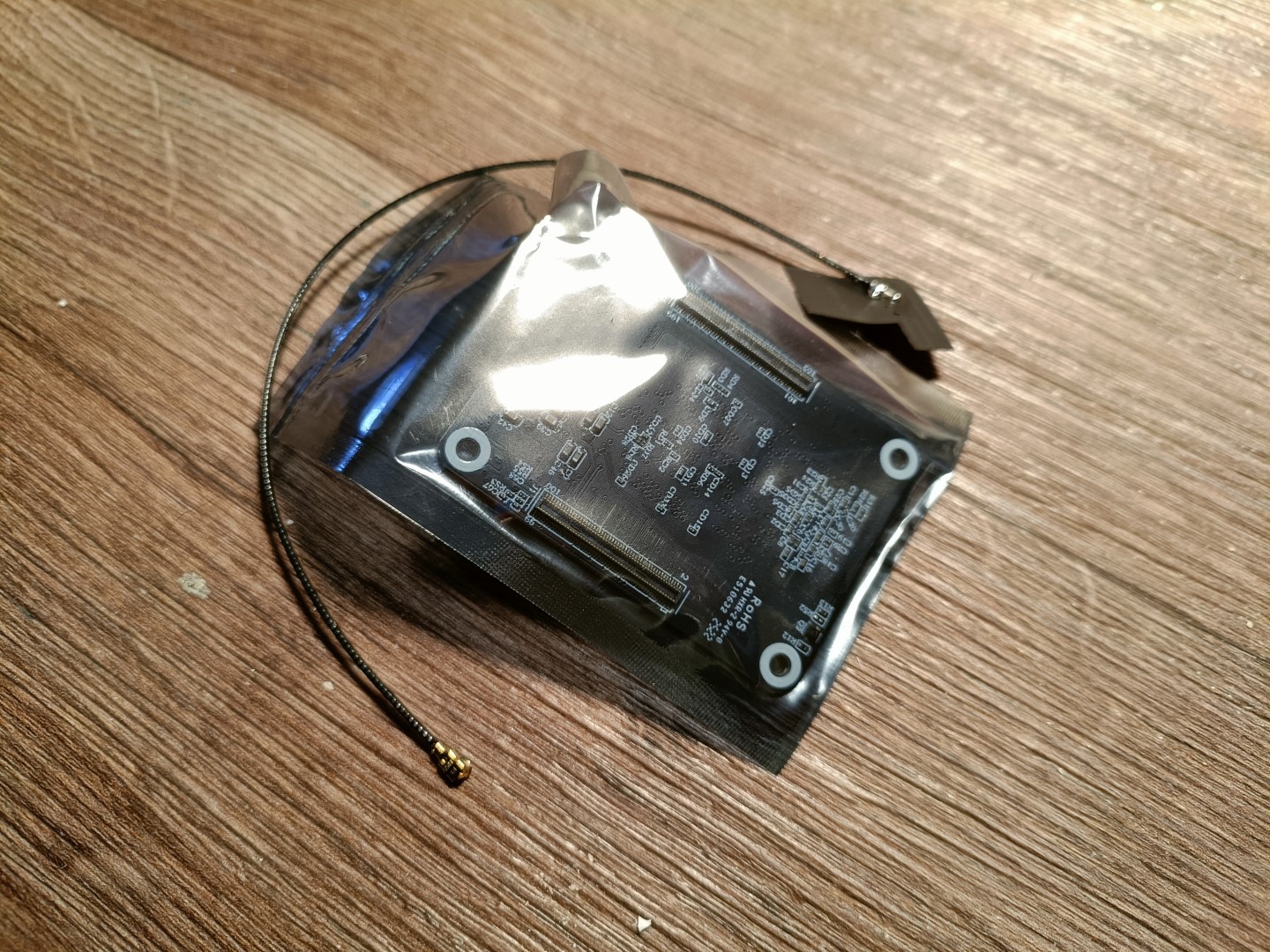

So I was able to get on the limited edition CB1 drop ($10 price) and, looking at the order speeds in the first hour, I seemed to be the only one that was treating this like a GPU stock drop. I went in with the minimum to grab being 2 (for each Sublime) and 4 ideally (Suspense and a spare) but there was a 1 per customer blockade. I bought 1 immediately, tossed and turned for maybe 20 minutes, and made a second AliExpress account to get another one. Sometime (maybe a day) later I was just scrolling around and the $10 CB1 was back in stock. Strange. There's 2 of them though. And I can check out with both of them? Ok then! Wow this board is TINY. Seems to also come with an antenna with adhesive.

Wow this board is TINY. Seems to also come with an antenna with adhesive. I wasn't expecting them to be this small. £23.50 is an expected price considering it's like a CB4 version of the Orange Pi Zero 2, but I'd like to imagine how versatile this could've been if their $19.90 (£17.47) lesser early bird price was the consistent price. What about $15??

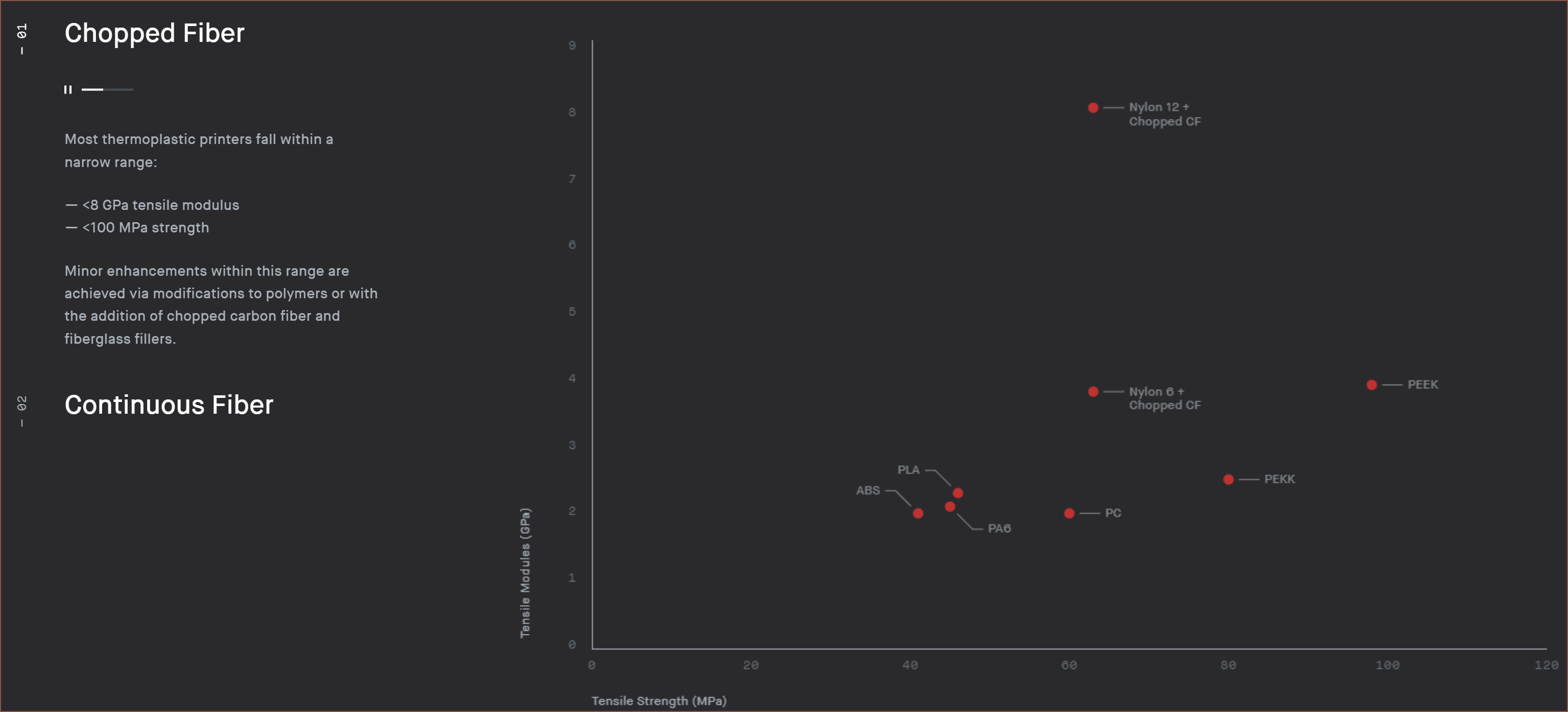

I wasn't expecting them to be this small. £23.50 is an expected price considering it's like a CB4 version of the Orange Pi Zero 2, but I'd like to imagine how versatile this could've been if their $19.90 (£17.47) lesser early bird price was the consistent price. What about $15?? While scrolling around, reading what industrial 3d printing companies have been getting up to, I found out that there's some rivalry between Desktop Metal and Markforged, and that Desktop Metal was making a continuous fibre 3D printer that could compete with Markforged's offering.

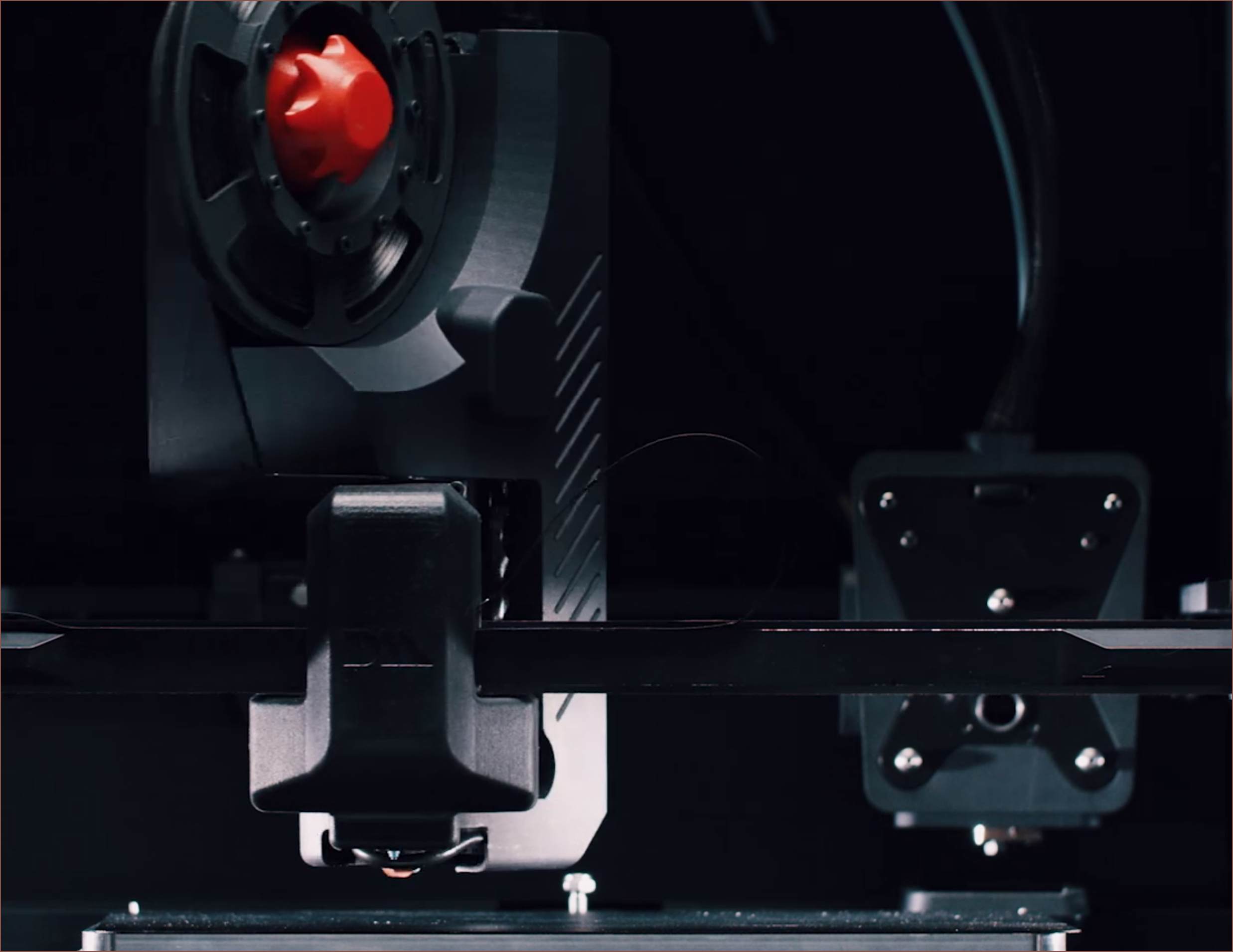

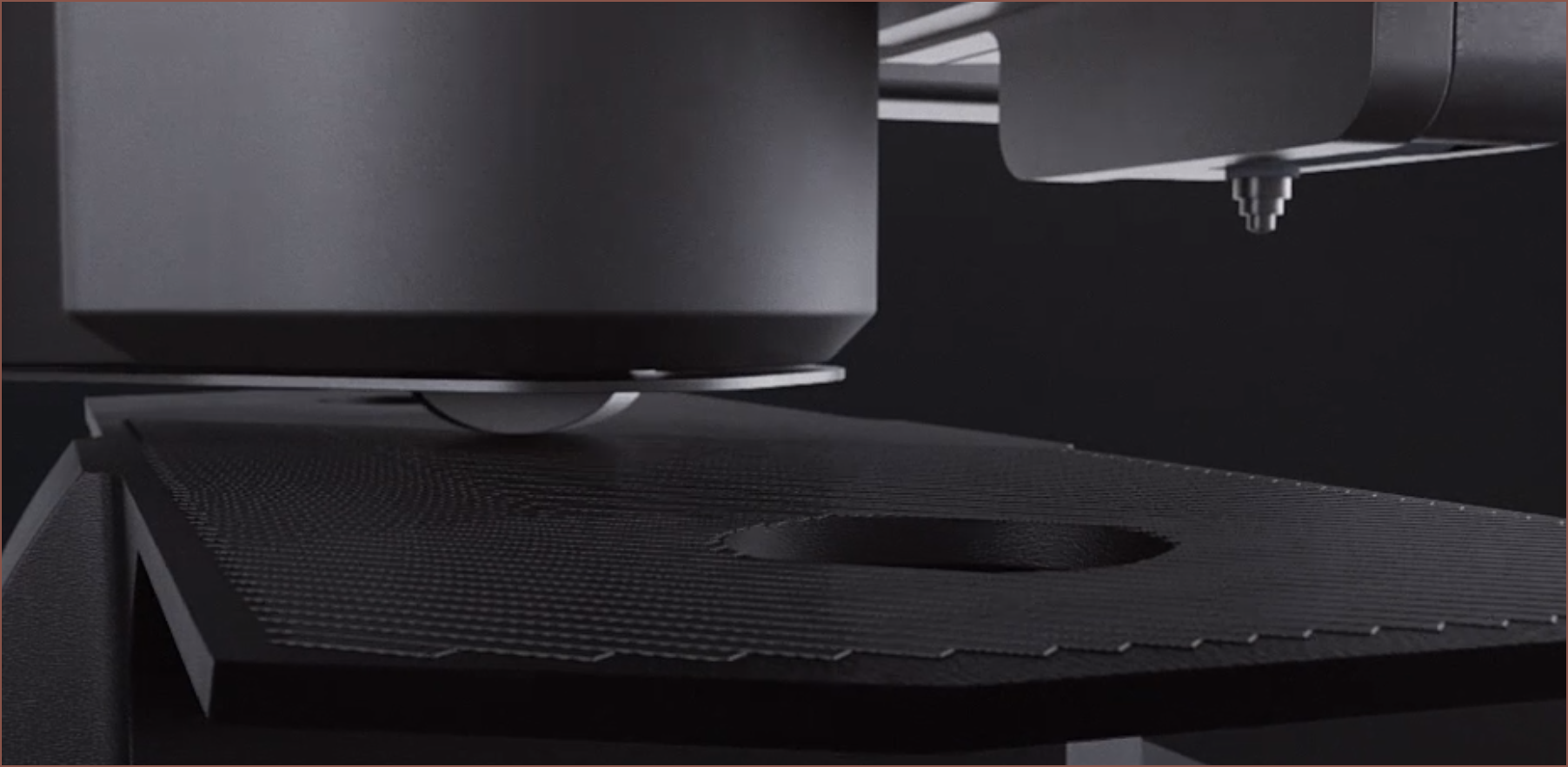

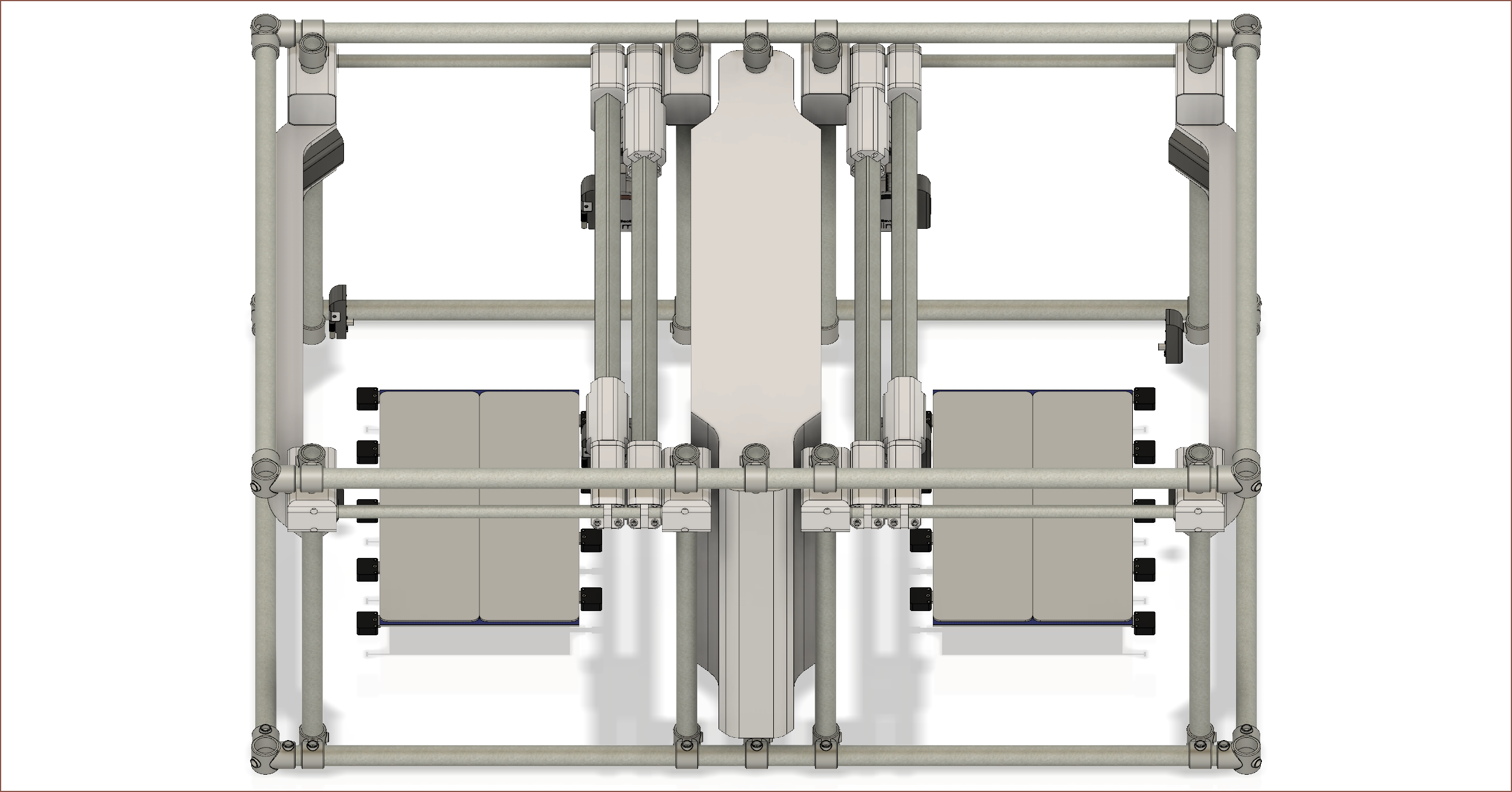

While scrolling around, reading what industrial 3d printing companies have been getting up to, I found out that there's some rivalry between Desktop Metal and Markforged, and that Desktop Metal was making a continuous fibre 3D printer that could compete with Markforged's offering. It very much seems to be a 2 tool toolchanger with the fibre tool being able to rotate 90 degrees, which would be able to get the fibre in any orientation. This reminds me of the rotating nozzle I found earlier.

It very much seems to be a 2 tool toolchanger with the fibre tool being able to rotate 90 degrees, which would be able to get the fibre in any orientation. This reminds me of the rotating nozzle I found earlier. It likely uses a heated roller (that seems spring loaded in the animation) to apply the continuous fibre.

It likely uses a heated roller (that seems spring loaded in the animation) to apply the continuous fibre.

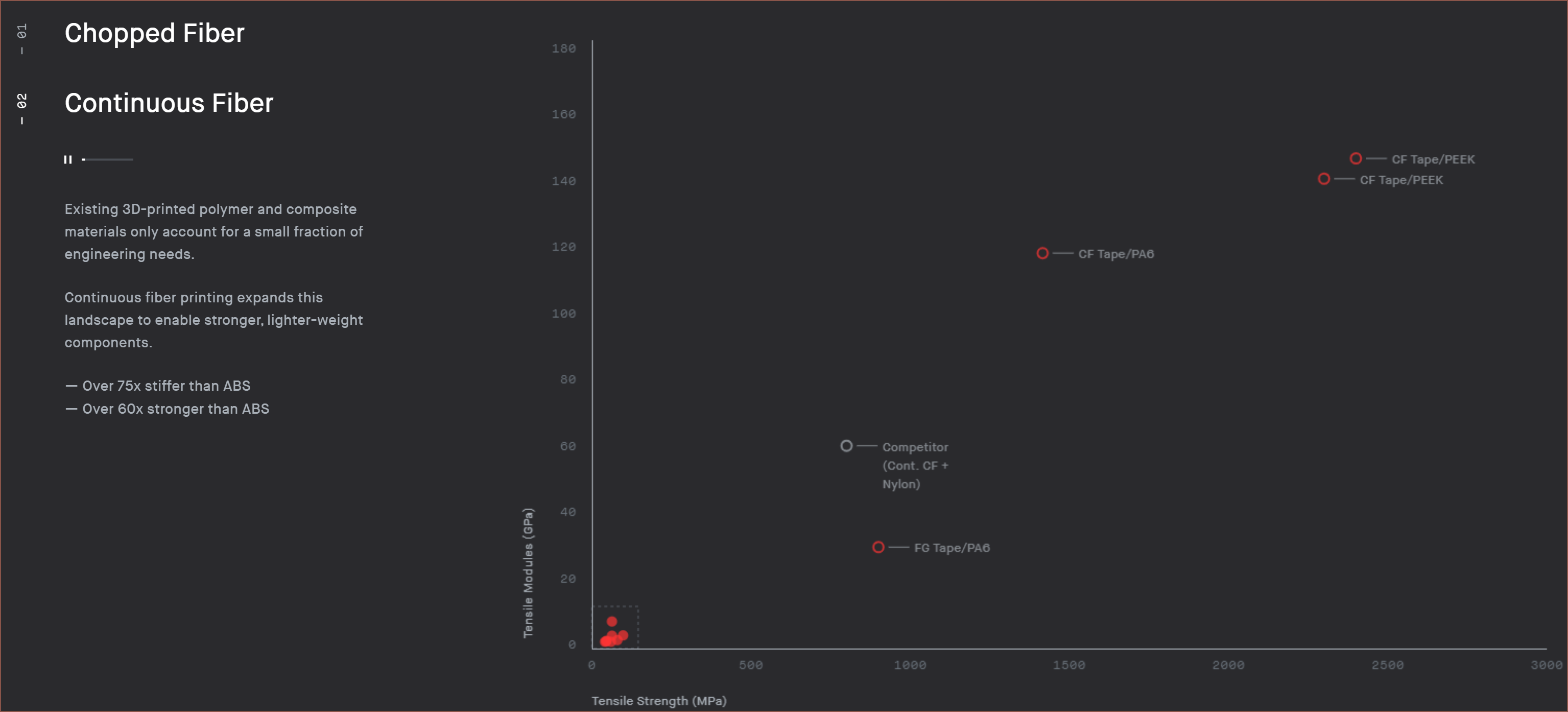

The grey dot is likely Markforge's flagship continuous carbon fibre:

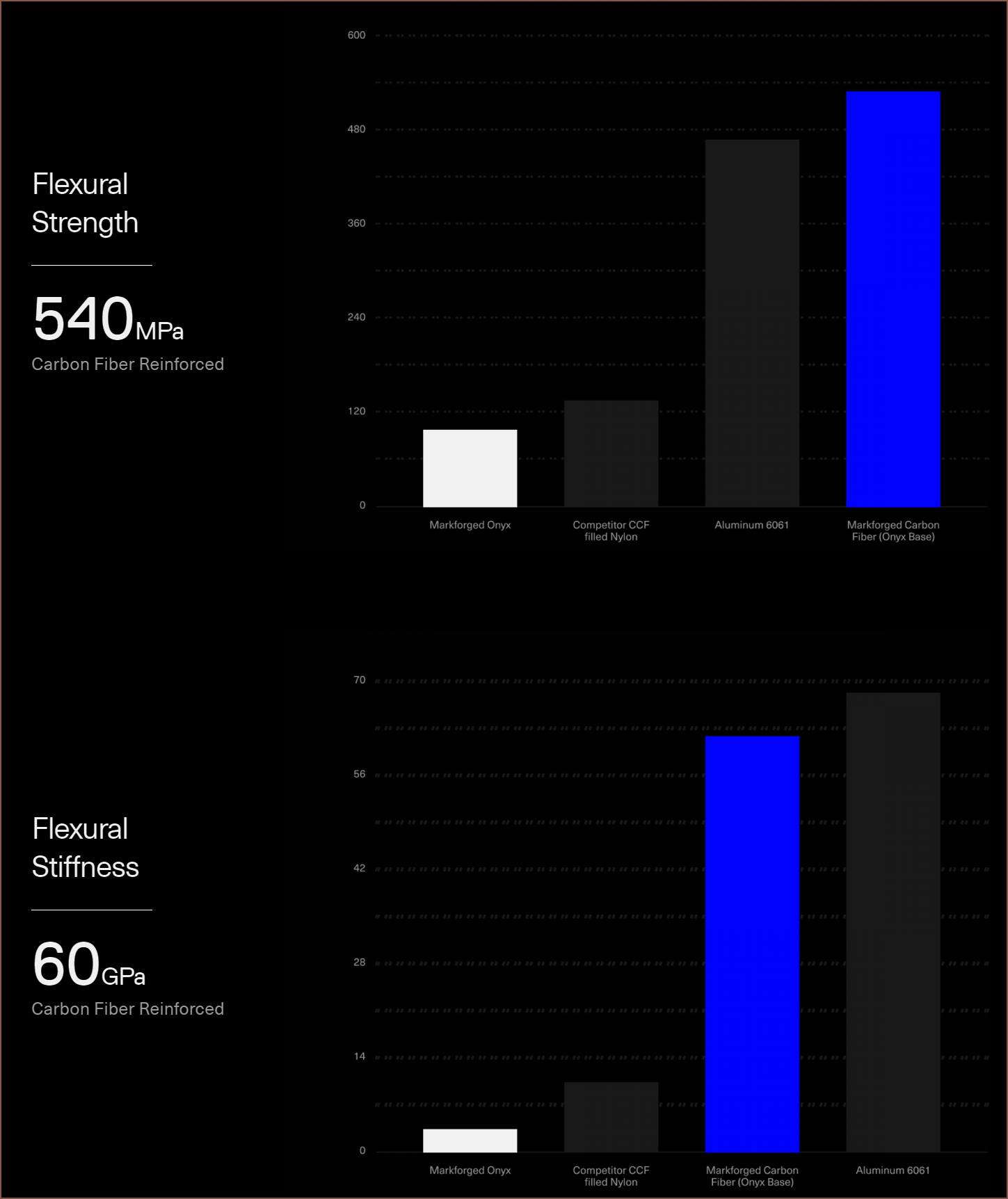

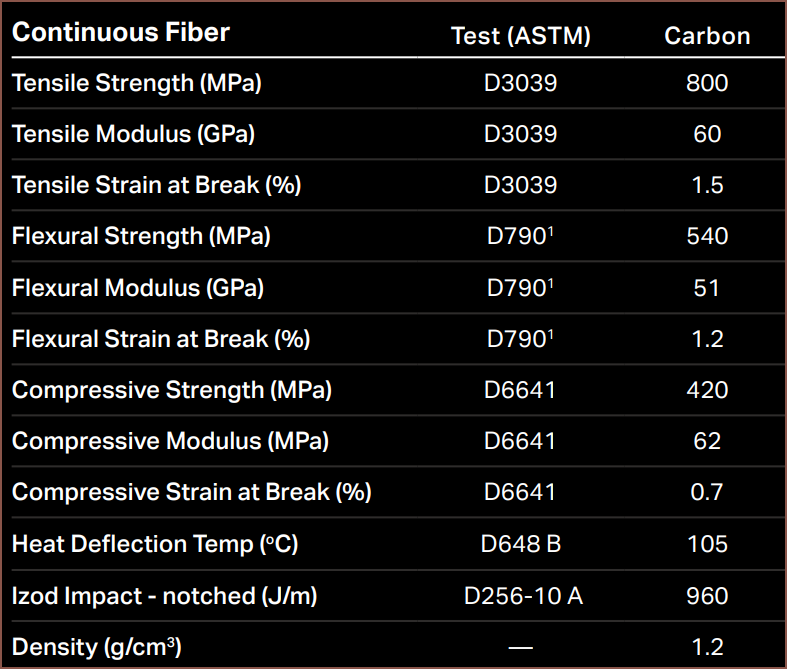

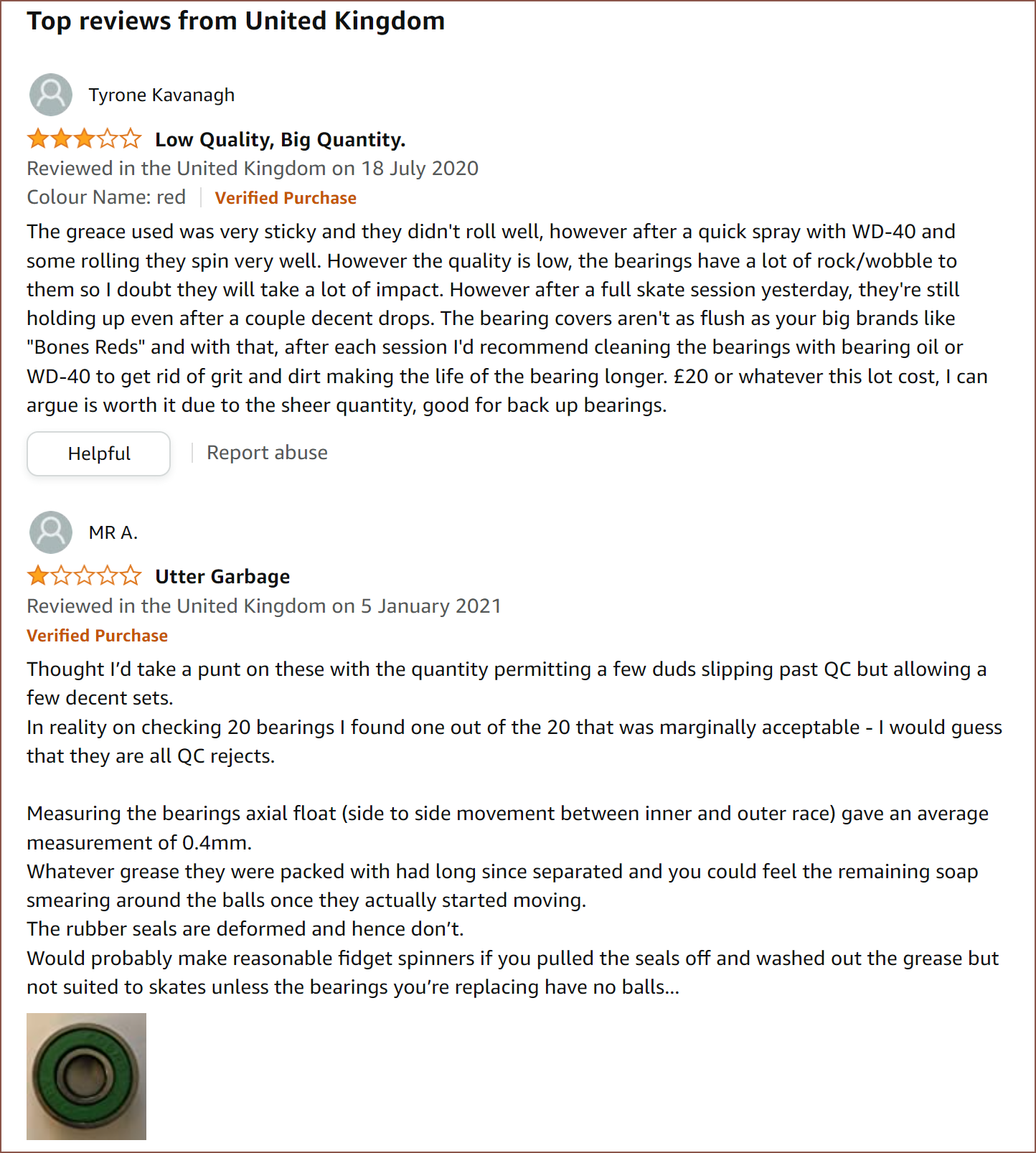

The grey dot is likely Markforge's flagship continuous carbon fibre: The carbon fibre tape is nearly 2x the tensile strength and is 2x the modulus. I'm more interested in the cheaper glass fibre tape (for which basalt should be a bit better). 30GPa modulus and a strength inbetween 800 and 1000MPa, according to Markforge's datasheet:

The carbon fibre tape is nearly 2x the tensile strength and is 2x the modulus. I'm more interested in the cheaper glass fibre tape (for which basalt should be a bit better). 30GPa modulus and a strength inbetween 800 and 1000MPa, according to Markforge's datasheet: I just hope that I can just press the basalt fibre into a printed channel similar to using a soldering iron to embed steel wire into a print. If that plan fails, I'd imagine extruding a thin bead of filament on one side of the fibre for a stronger bond between the fibre and the bottom of the channel could provide a solution.

I just hope that I can just press the basalt fibre into a printed channel similar to using a soldering iron to embed steel wire into a print. If that plan fails, I'd imagine extruding a thin bead of filament on one side of the fibre for a stronger bond between the fibre and the bottom of the channel could provide a solution.

Due to

Due to

e of h

e of h