I was originally thinking that I was going to have the tool rack connected to the Z axis, but since the gantry is so large and the Z axis is doing overtime compared to a standard 3D printer, some weight saving decisions were in order. If I assume each SecSavr Slight is 200g and there's 10 tools installed, that's 2kg of mass to move that doesn't need to be coupled with the Z axis. Hmm, now that I write this, perhaps I can use a "flying extruder" type installation instead of using even more steppers to drive the tool axis. Anyway, couple that mass with the weight of printed parts and it could be 3kg of mass that needs to be moved excessively. I'm no penny pincher when it comes to saving 10g here or 60g there, but 3000g is a different ball park.

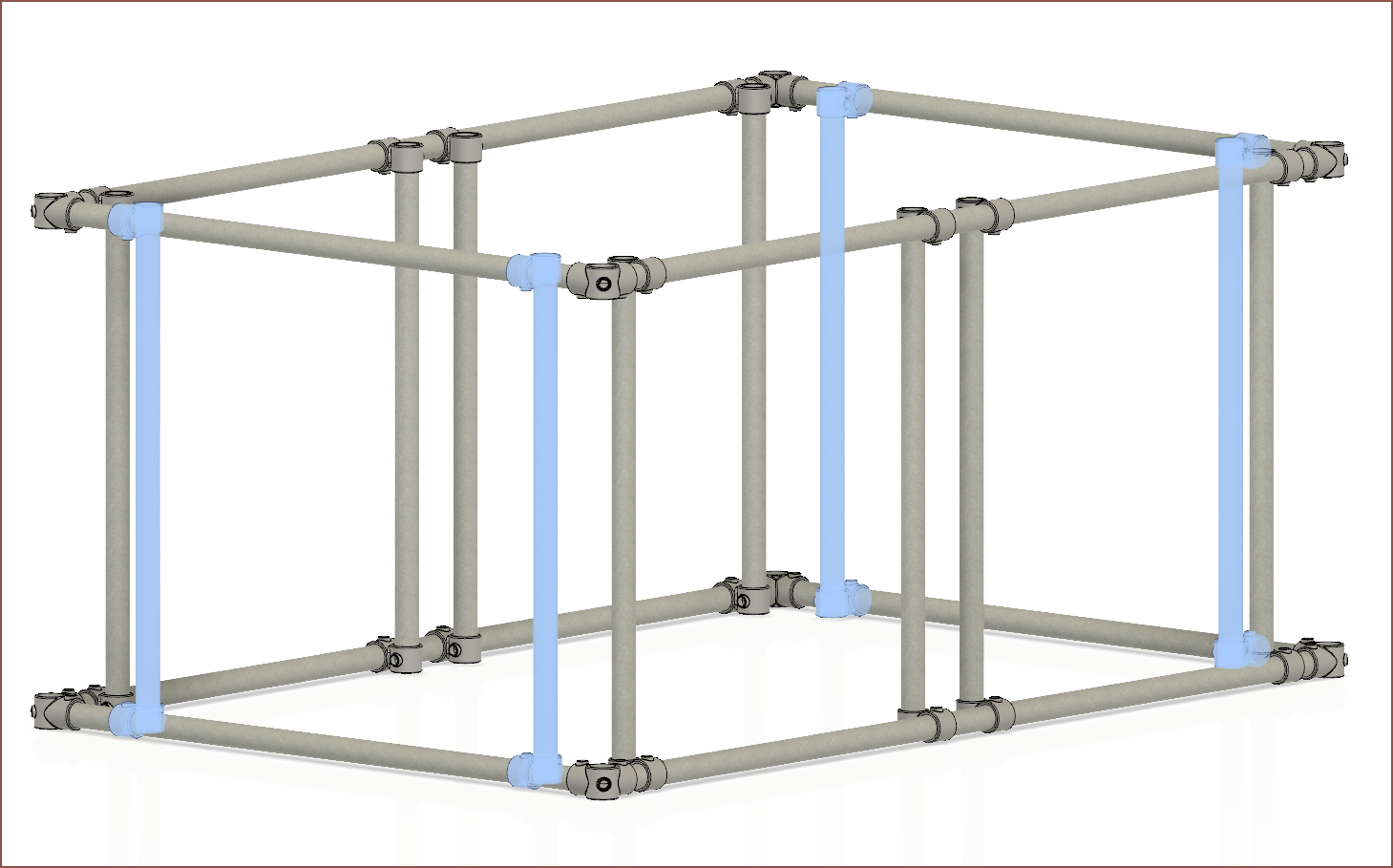

I was originally thinking that I was going to have the tool rack connected to the Z axis, but since the gantry is so large and the Z axis is doing overtime compared to a standard 3D printer, some weight saving decisions were in order. If I assume each SecSavr Slight is 200g and there's 10 tools installed, that's 2kg of mass to move that doesn't need to be coupled with the Z axis. Hmm, now that I write this, perhaps I can use a "flying extruder" type installation instead of using even more steppers to drive the tool axis. Anyway, couple that mass with the weight of printed parts and it could be 3kg of mass that needs to be moved excessively. I'm no penny pincher when it comes to saving 10g here or 60g there, but 3000g is a different ball park.There's no such thing as a 42.4 to 33.7mm version of the 161 clamp, so they're the same thickness as the rest of the frame, even if it could be considered overspecked for this use case.

Modelling time: About 40 mins

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.