Earlier today, I was looking at spindle motors to see what was available on AliExpress, and I found a 200W 24V motor for about £16. "It's cheaper than a CHC Pro so, worst case scenario, I have 1 motor per bit. Wait..."

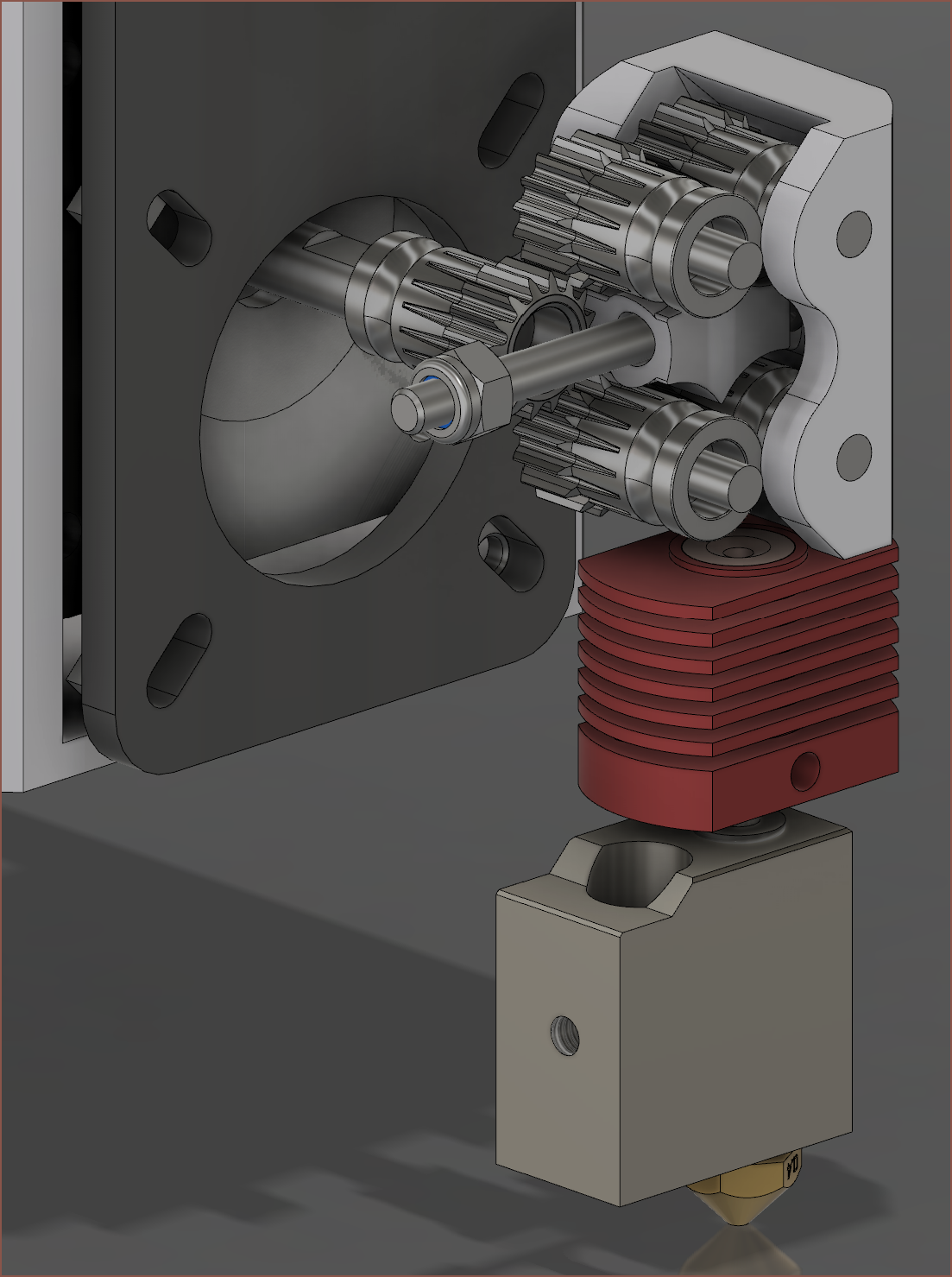

Earlier today, I was looking at spindle motors to see what was available on AliExpress, and I found a 200W 24V motor for about £16. "It's cheaper than a CHC Pro so, worst case scenario, I have 1 motor per bit. Wait..."Thus I went around to see what my options were. My first find was the copper Volcano V2 block (modelled above) where I could get 10 for £15, followed a little later by an Ender 3 high temperature kit that comes with a copper plated nozzle as well as the heatsink and bimetal heatbreak.

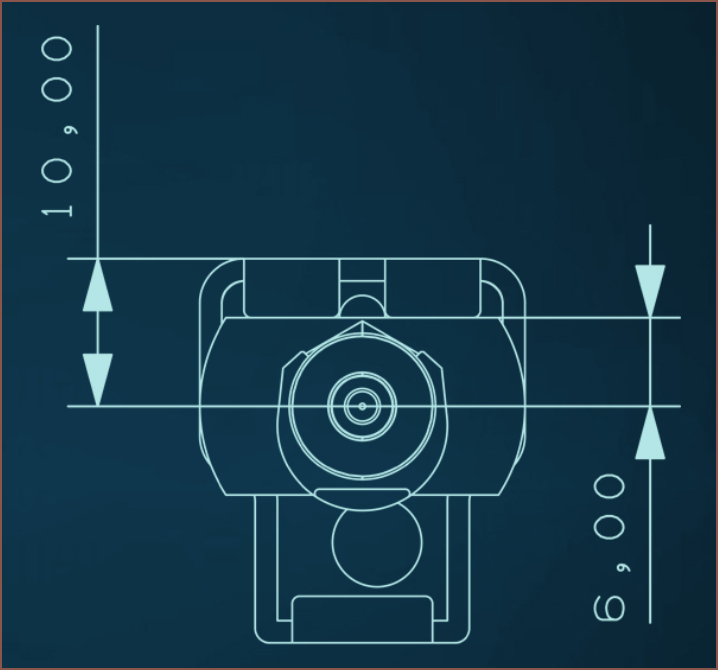

While the second find looked cooler, my first concern was the centre to edge distance. The longer this is, the higher a print feature would need to be before the Slime could reach it at a 90 degree angle without hitting the bed.

While the second find looked cooler, my first concern was the centre to edge distance. The longer this is, the higher a print feature would need to be before the Slime could reach it at a 90 degree angle without hitting the bed. On this block, it's 10mm (including sock) wheras the CHC is 6mm. Speaking of silicone socks, I just found out that the max temperature of them is around 300C these days; I thought that it was 260C.

On this block, it's 10mm (including sock) wheras the CHC is 6mm. Speaking of silicone socks, I just found out that the max temperature of them is around 300C these days; I thought that it was 260C.

What I like about the "Volcano V2" (VV2) was that it finally eliminated those annoying 2 screws that clamp the heater cartridge. I've never been able to get them off, but more importantly, they increase the distance between the orifice and the edge. My main concern was that 300C thermistors don't usually come in beads, but conviniently, there are M3 versions.

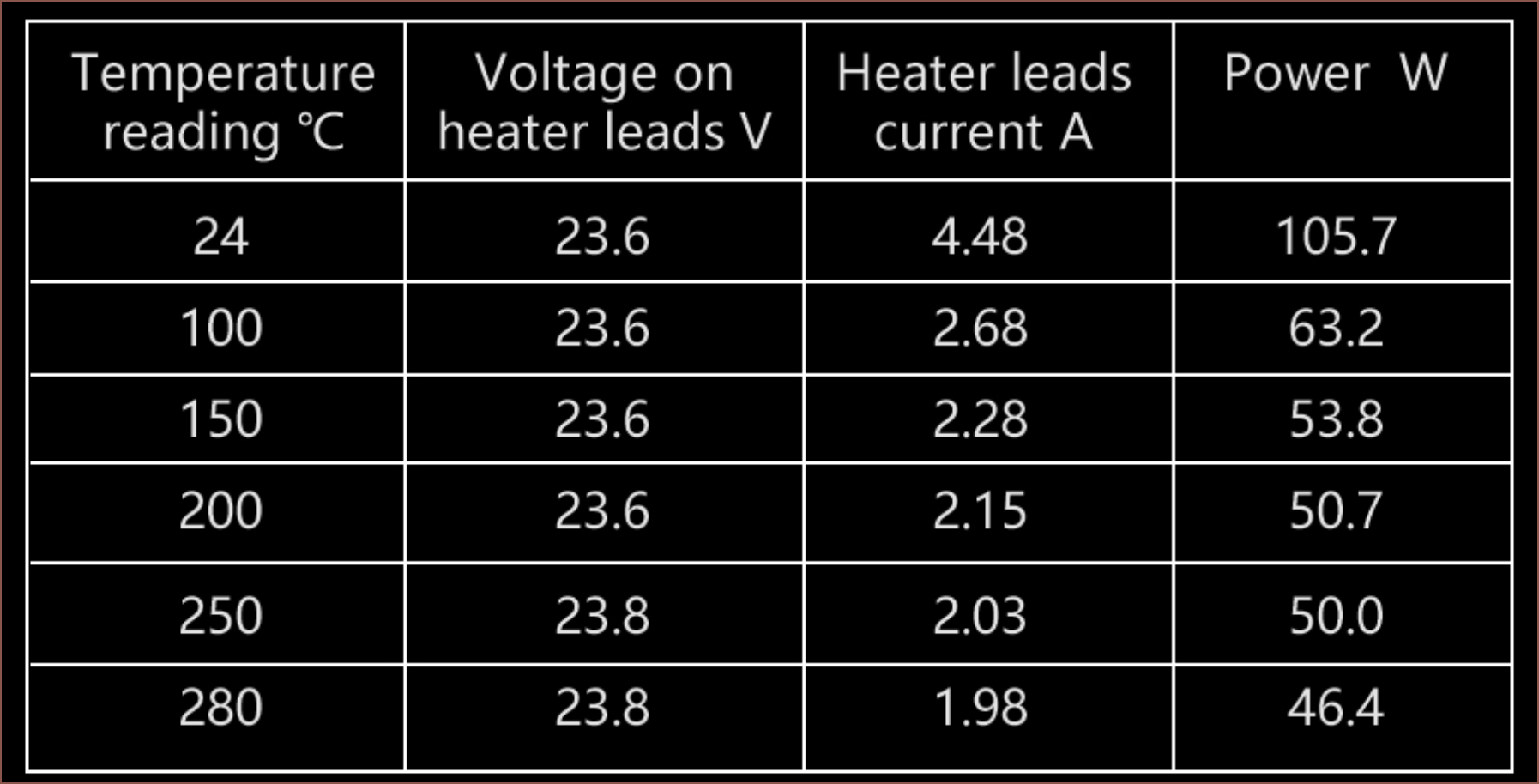

I also did some research into thermocouples, PT100/1000 and the D500 thermistor, but apparently polycarbonate doesn't usually need over 300C to print so I cancelled that research tangent.

I also did some research into thermocouples, PT100/1000 and the D500 thermistor, but apparently polycarbonate doesn't usually need over 300C to print so I cancelled that research tangent.

Lastly, one other benefit over the CHC is that there should be more cross sectional area between the block and the melt zone extenders.

Lastly, one other benefit over the CHC is that there should be more cross sectional area between the block and the melt zone extenders.

- CHC Pro + Heatsink + Bimetal: £209.43

- HT Kit + Cartridge Heater + Cartridge Thermistor - Copper Nozzle (estimated value of £5.50): £127.91

- VV2 + Cartridge Heater + Cartridge Thermistor + Heatsink + Bimetal: £80.59

The CHC is nearly £129 more expensive than the VV2, and I'd need around 18 (8 and a spare for each of the two SecSavr's), so an extrapolated difference would be £232. That saving could go towards the Milling Tool, BTT's fancy new Mantra M8P I'm probably going to use if the price is right or another project, and I'm fine with using a melt zone extender if I really need to get a higher angle for non-planar printing. Thus I quickly got to work modelling the changes needed and it took probably an hour.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.