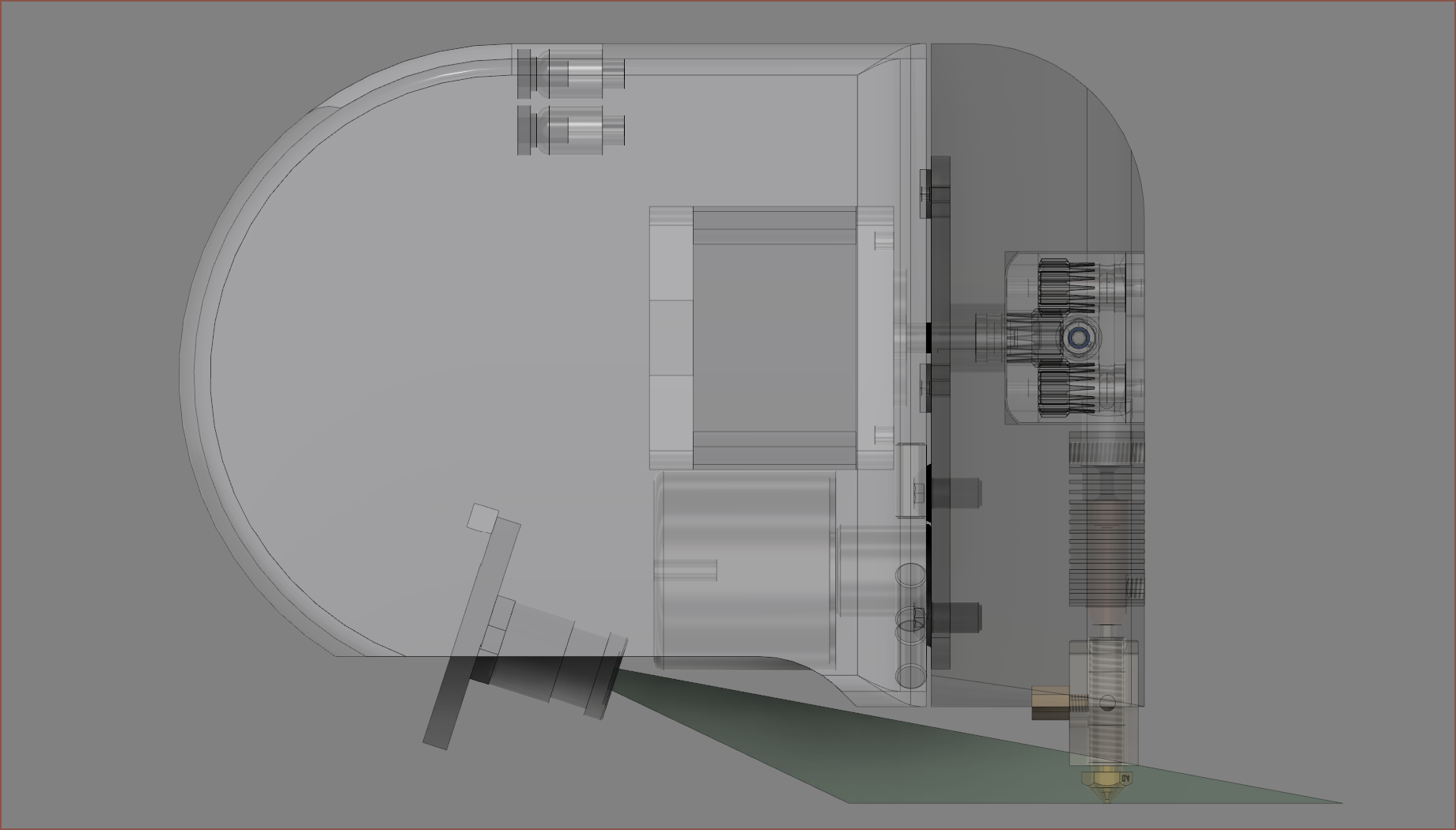

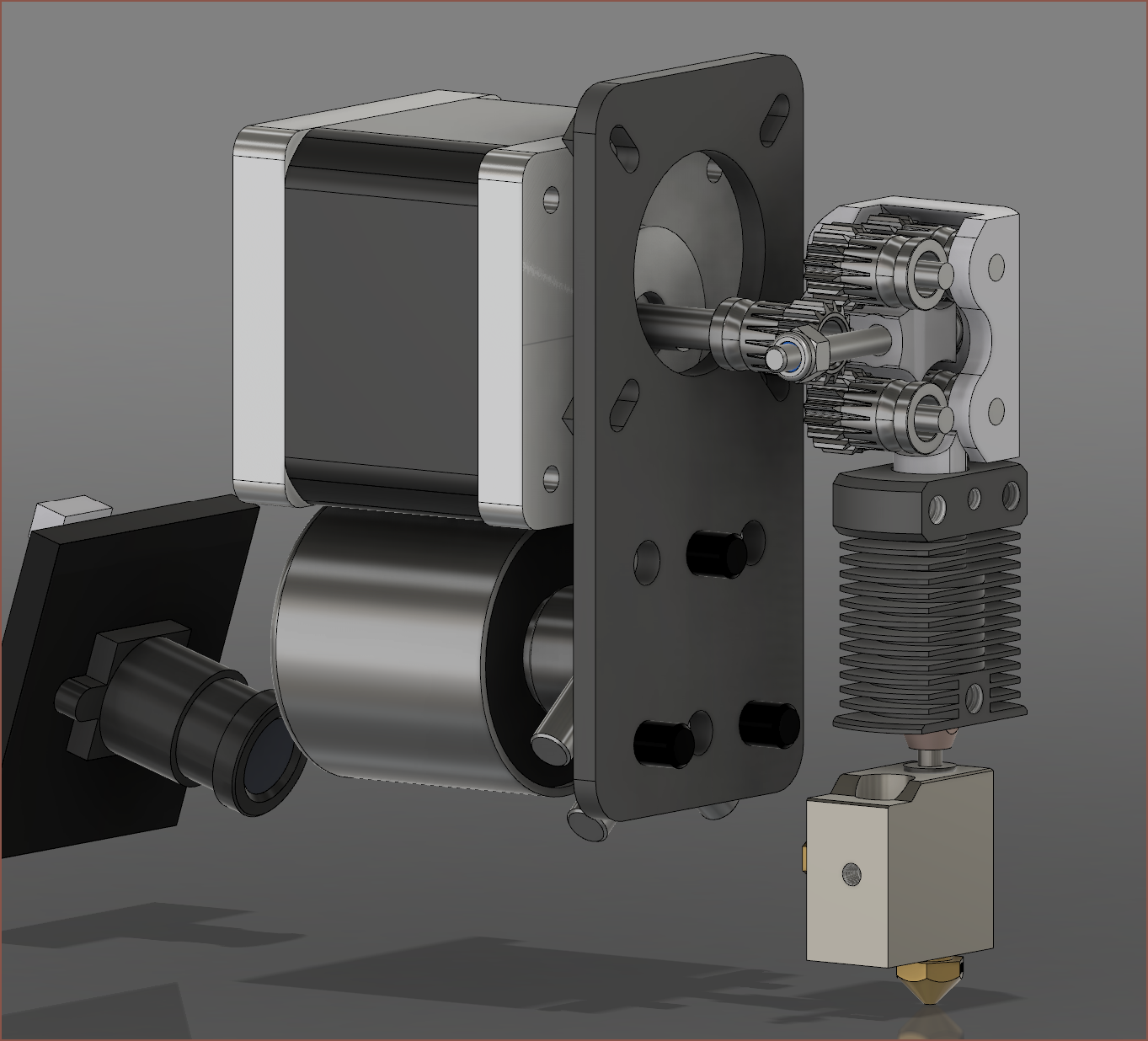

So I woke up today and thought "Do you think there's enough space to rotate the tool plate 180 degrees?". The reason I've been considering it is because:

So I woke up today and thought "Do you think there's enough space to rotate the tool plate 180 degrees?". The reason I've been considering it is because:- The fixing location is closer to the end position of the tool, wether that be the nozzle of the extruder tool or the drill bit of the milling tool.

- The gear of the extruder is likely to be used for things in other tools like lifting or lowering tools in the milling tool or connected to a plunger for the chocolate tool, and the mechanical force is expected to be on the top section of the tool.

- The extruder is probably heavier than the degaussing electromagnet, so having that higher up means that the centre of mass is closer to the axis rail.

Modelling a concept

Yeah it's going to be close alright. It looked promising though so I kept going.

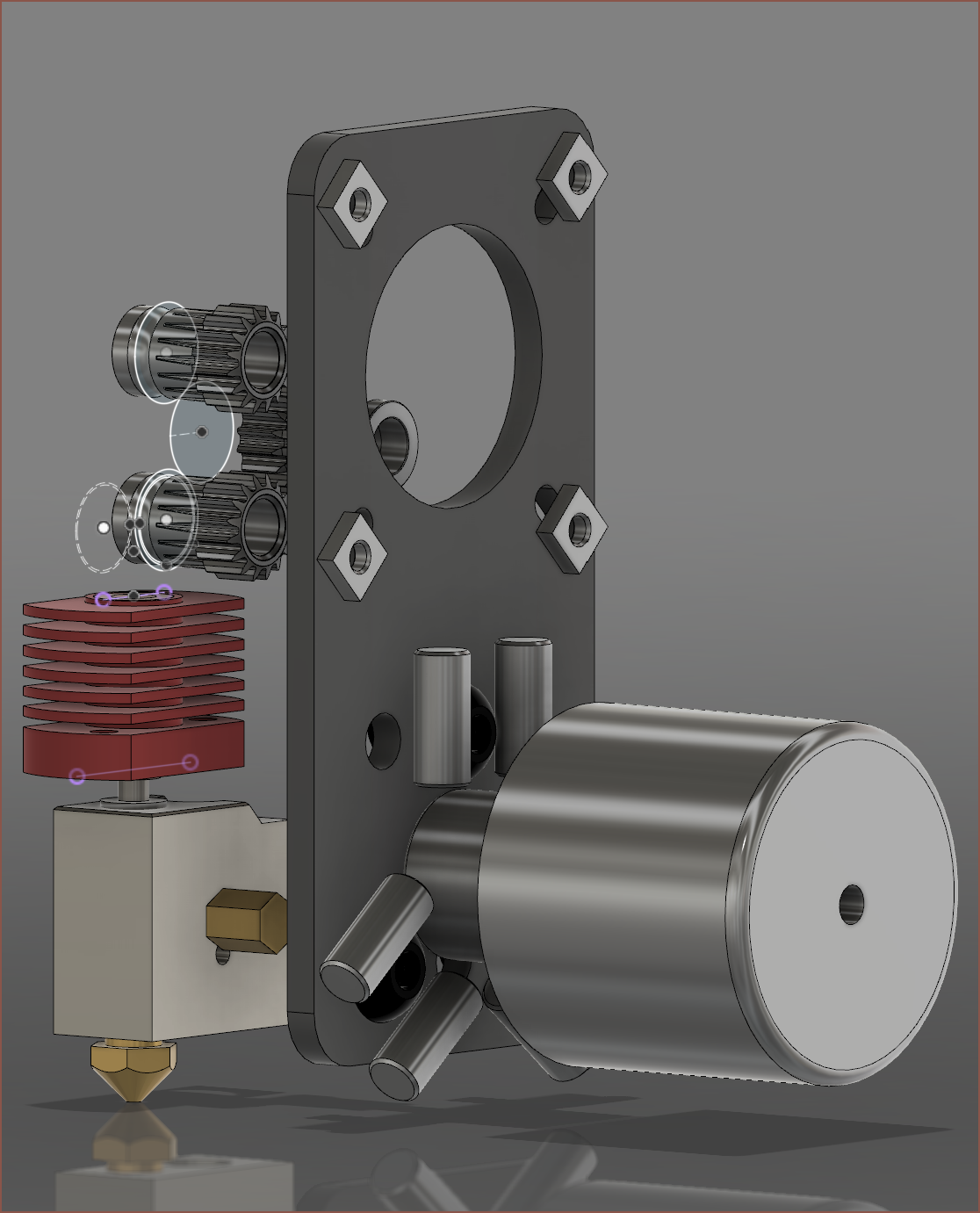

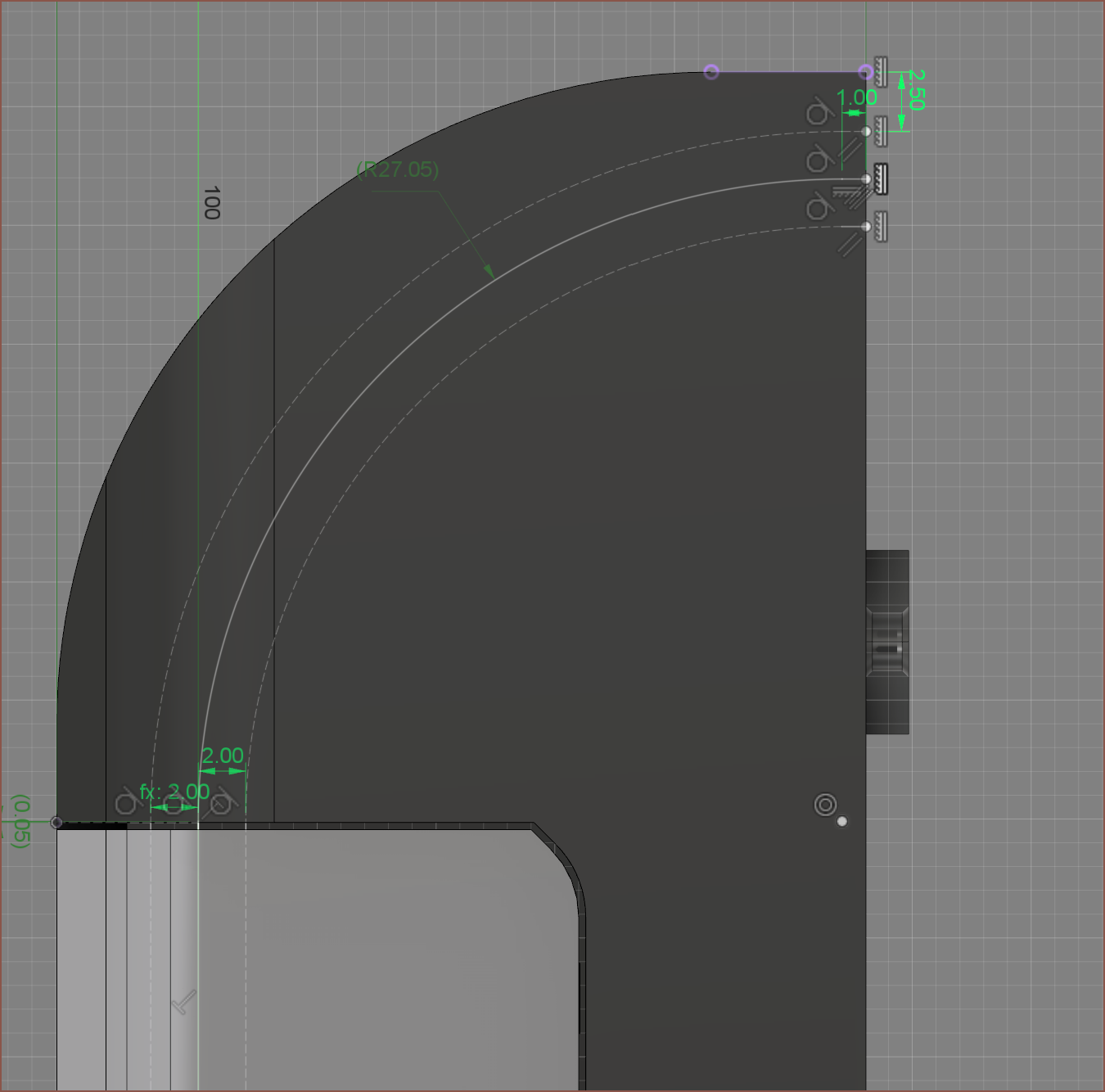

Yeah it's going to be close alright. It looked promising though so I kept going. What else can I say expcept "Barely (TM)"? There is just about enough space for the filament to curve around the 90 degree bend.

What else can I say expcept "Barely (TM)"? There is just about enough space for the filament to curve around the 90 degree bend.Increasing length for the camera

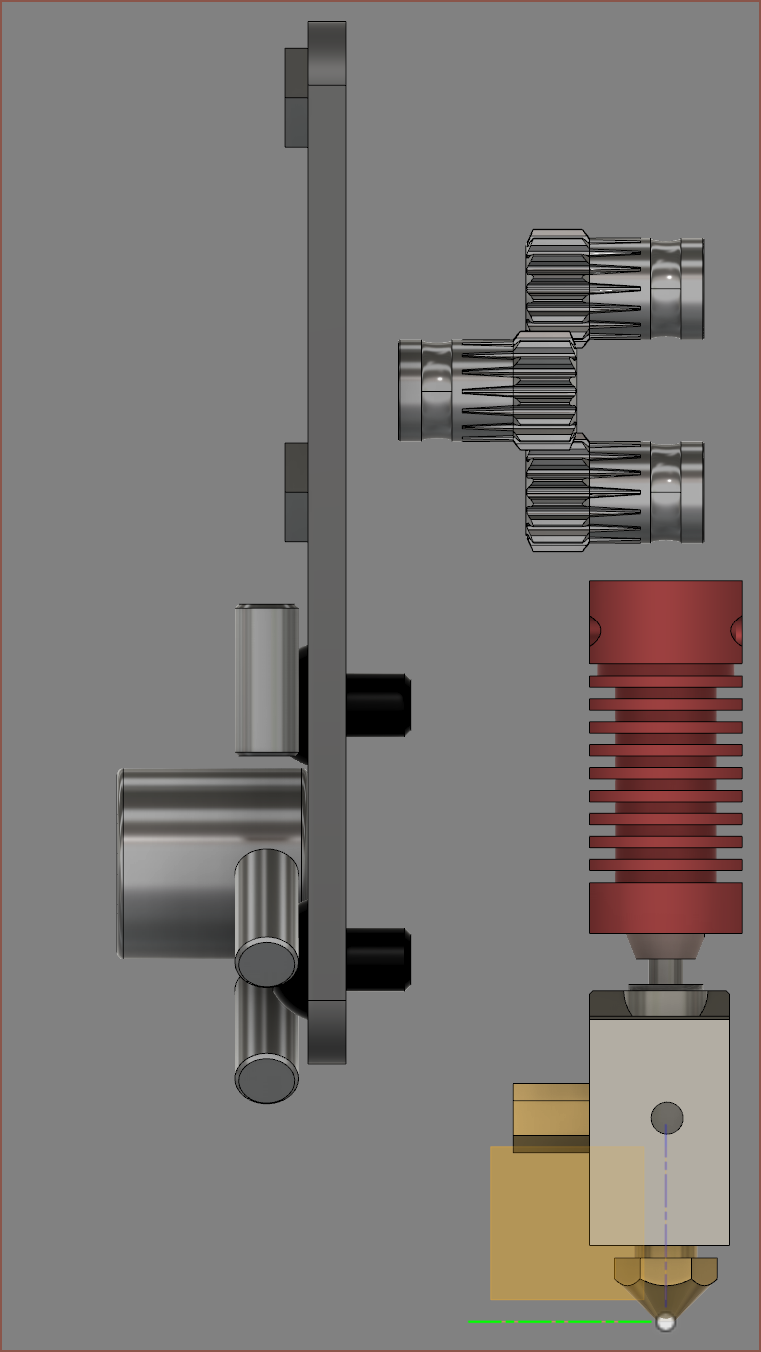

I then updated the Slime file and the bottom of the hotend was too close to the bottom of the Slime. I guess that's a nice problem to have, because I increased the length of the hotend assembly so much that I don't even have to cut the CR10 heatsink anymore.

I went on AliExpress to do some searching on my hotend options again, and found this hotend from LERDGE.

I went on AliExpress to do some searching on my hotend options again, and found this hotend from LERDGE. It's a tad more expensive than the CR10, but it comes with advantages:

It's a tad more expensive than the CR10, but it comes with advantages:- Easier to add a filament guide as it uses a grub screw instead of an M10 thread for the bowden coupler

- Uses an M4 grub screw instead of M3 for the heatbreak, meaning that there's a lower chance of stripping the screw.

- More material around the mounting holes, which I intend to tap in some M4 threads.

- It's black, increasing both aesthetics and matte black objects emit radiation the best.

I got to modelling and uploaded it on GrabCAD. Lastly, I modelled the filament guide and fixed the SecSavr Slime model.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.