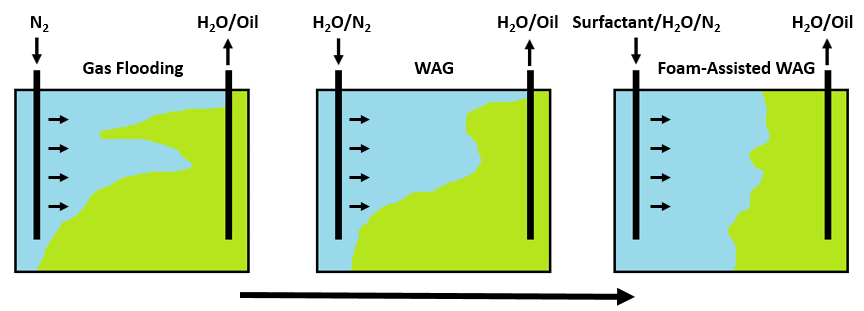

My project uses X-ray microfocus radiography to monitor the changing displacement patterns and saturations of Berea sandstone rock samples while undergoing water alternating gas injection coreflood experiments. Water alternating gas (WAG) injection is commonly conducted in enhanced oil recovery of partially depleted oil and gas reservoirs. Alternating slugs of water and gas are injected to displace remaining oil trapped in subsurface reservoir rock. However, gas flow often associates with fingering due to high gas mobility, which leaves a large portion of the reservoir unswept. Many mobility control agents have been proposed to curb the high gas mobility and hence improve the efficacy of the WAG technique (Fig. 1). The agents are aimed at decreasing the permeability and/or decreasing the apparent gas viscosity; examples include foams, polymers, and nanoparticles. My study primarily focuses on the use of foam as a mobility control agent for conformance improvement.

Fig. 1—Improved sweep efficiency, reduced effects of gravity segregation and heterogeneities in FAWAG

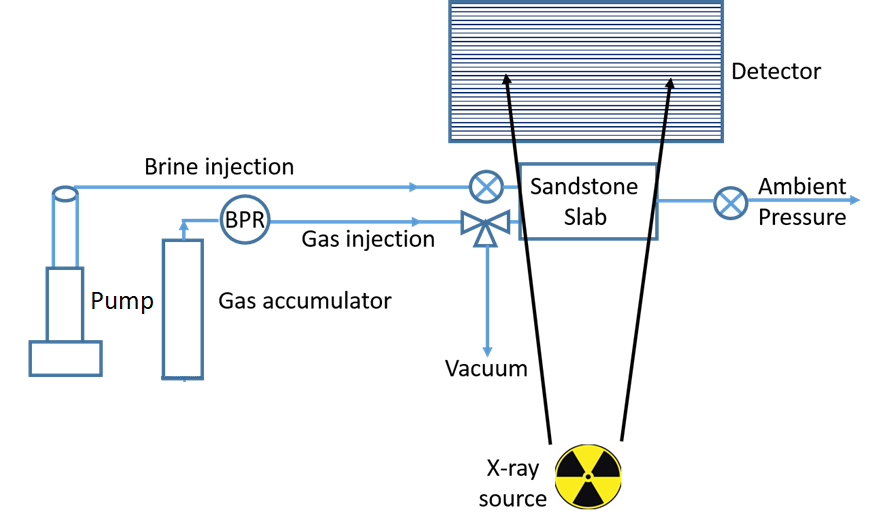

The experiments are conducted within the X-ray cabinet. X-rays are perpendicularly passed through the rock sample during the WAG coreflood experiments and images are taken (Fig. 2). Analysis and processing of these images will allow us to visualize the changing displacement patterns and saturations of the rock sample as alternating slugs of water and gas are injected. The X-ray machine itself is a shielded enclosure, providing a physical barrier between damaging radioactive X-rays and the outside environment. This means the X-ray cabinet is a self-contained and closed system. Any pumps or tools placed within the X-ray cabinet can only be powered from within the X-ray cabinet.

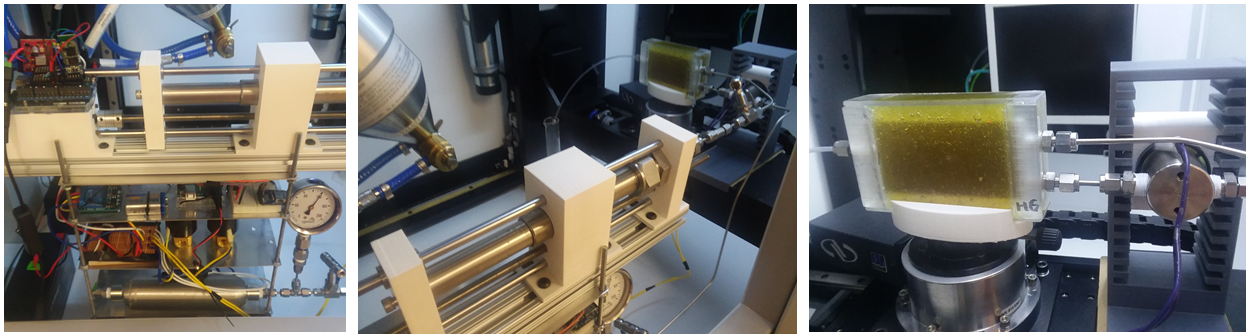

For our application, a 20V battery is used to power the injection syringe pump and is placed along with the rest of the fluid injection setup within the X-ray cabinet. Once the interlocks of the X-ray cabinet are secured, which is the only way for X-rays to be generated, we will not have access to the interior of the X-ray cabinet. Thus, the pump must also be able to be remotely controlled via Bluetooth. An android phone or computer is used to wirelessly operate the fluid injection apparatus via an Arduino Uno and HC-06 Bluetooth module. Pictures of the automated fluid injection setup along with the syringe pump is shown in Fig. 3. More pictures of the syringe pump is shown in Fig. 4.

Fig. 2—Fluid injection setup

Fig. 3—Flow automation setup with portable syringe pump placed within the X-ray cabinet

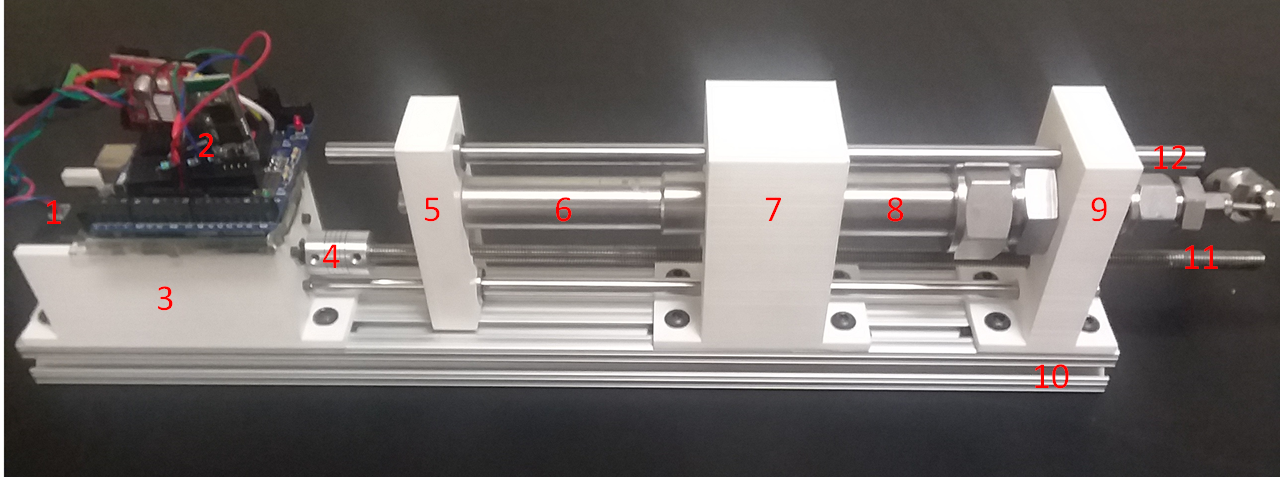

Fig. 4—Syringe pump with components (1) NEMA motor (2) electronics (3) motor mount (4) shaft coupler (5) syringe plunger mount (6) syringe plunger (7) syringe barrel holder (8) syringe barrel (9) syringe tip holder (10) mounting rail (11) M8 threaded rod (12) smooth rod

The syringe pump is able to inject at pressures as high as 100 psi and at flow rates as low as 1 cc/min. Total injection volume before having to disassembly the pump and refilling is approximately 100 mL. The components for the syringe pump are listed below:

- NEMA Motor: A NEMA 17 stepper motor with a gear ratio of 100:1 is used to achieve the required torque and speed. With a 48mm body and 1.68A rated current, the motor purchased from STEPPERONLINE is very suitable for an application that requires low speed and high torque.

- Electronics: The various electrical components achieve flow automation, data logging, and stepper motor control. For flow automation, an android phone or computer is used to wirelessly operate the fluid injection apparatus via an Arduino Uno and HC-06 Bluetooth module. For data logging, pressure and temperature monitoring is accomplished through a DS 3231 Real Time Clock module, ADA254 Adafruit Micro-SD Breakout Board, and 100 psi Autex pressure transducer. For stepper motor control, a separate Arduino Uno and HC-06 Bluetooth module are used, along with a Big Easy Driver. Electronics purchased from various vendors including Amazon, SparkFun, and Adafruit.

- Motor Mount: A 3D printed part to securely hold the NEMA motor in place. Printed in ABS (Acrylonitrile Butadiene Styrene) thermoplastic.

- Shaft Coupler: Purchased from STEPPERONLINE, the 8mm-8mm Flexible Coupling 18x25mm CNC Stepper Motor Shaft Coupler connects the stepper motor to the threaded rod.

- Syringe Plunger Mount: This 3D printed part with a M8 nut embedded inside is used to translate the rotational movement of the stepper motor and the attached M8 threaded rod to the translational, horizontal movement used to push or pull the syringe.

- Syringe Plunger: The stainless steel part of the syringe that pushes against the liquid residing in the syringe barrel.

- Syringe Barrel Holder: This 3D printed part holds the syringe barrel.

- Syringe Barrel: The stainless steel part of the syringe that holds the liquid.

- Syringe Tip Holder: This 3D printed part rests against the syringe tip. Only the syringe tip holder has to be unscrewed and removed in order to refill the syringe barrel.

- Mounting Rail: Components are mounted onto an 18-inch piece of 1"x2" 80/20 extruded aluminum rail, which makes the design modular and space-efficient.

- M8 Threaded Rod: Turns with the stepper motor.

- Smooth Rod: Two smooth rods hold the separate components in place.

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.