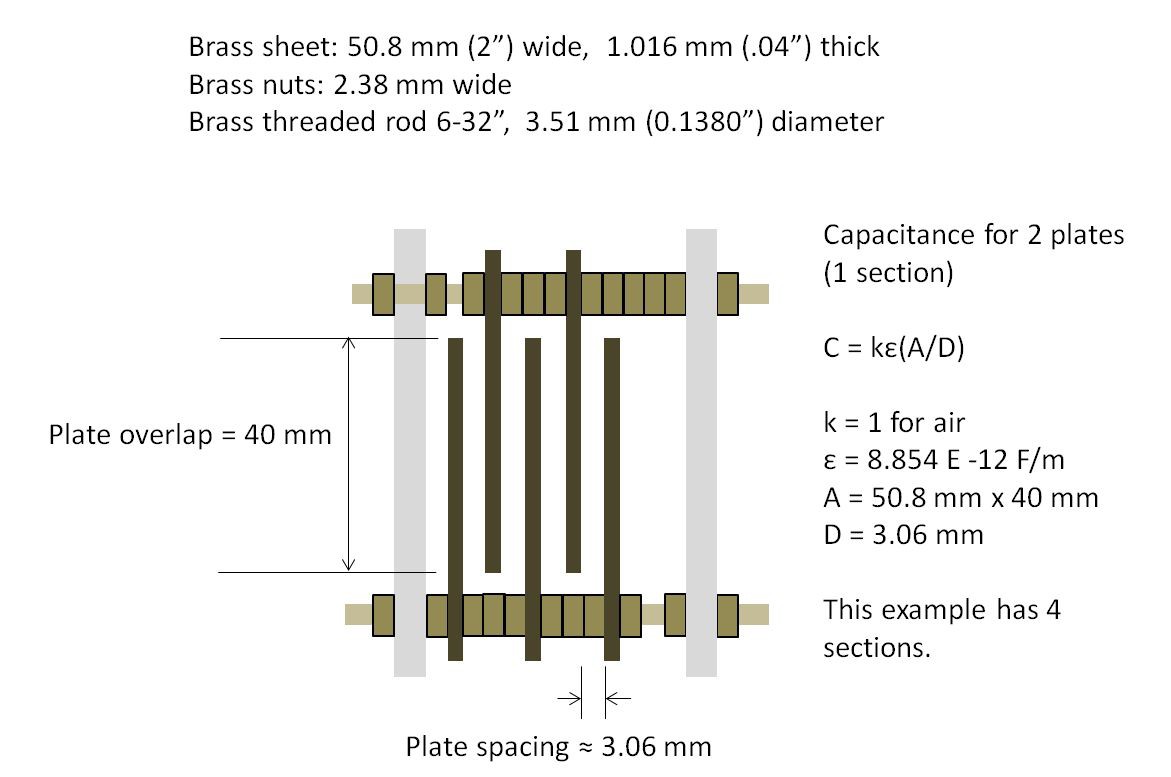

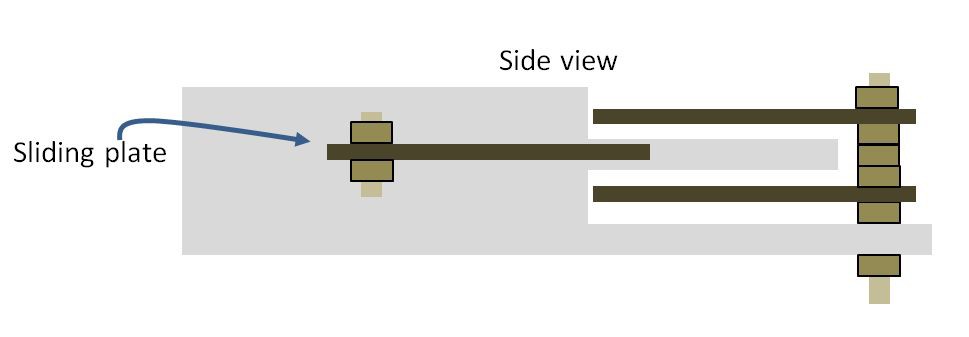

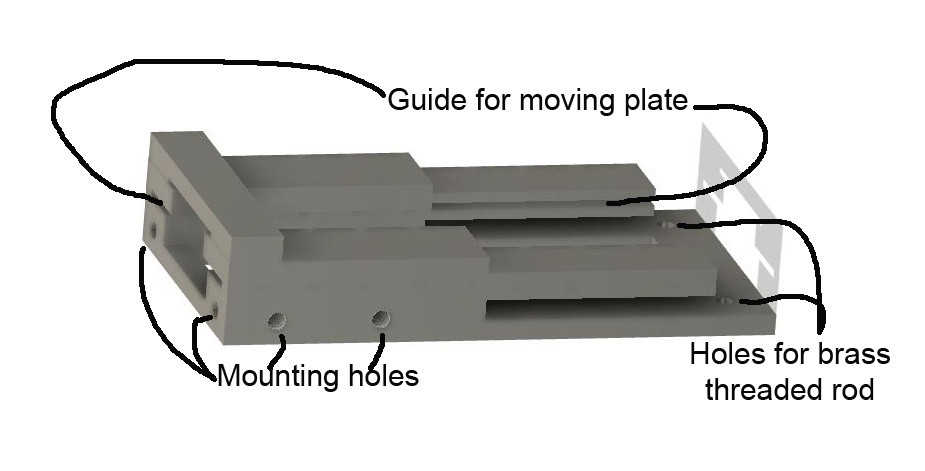

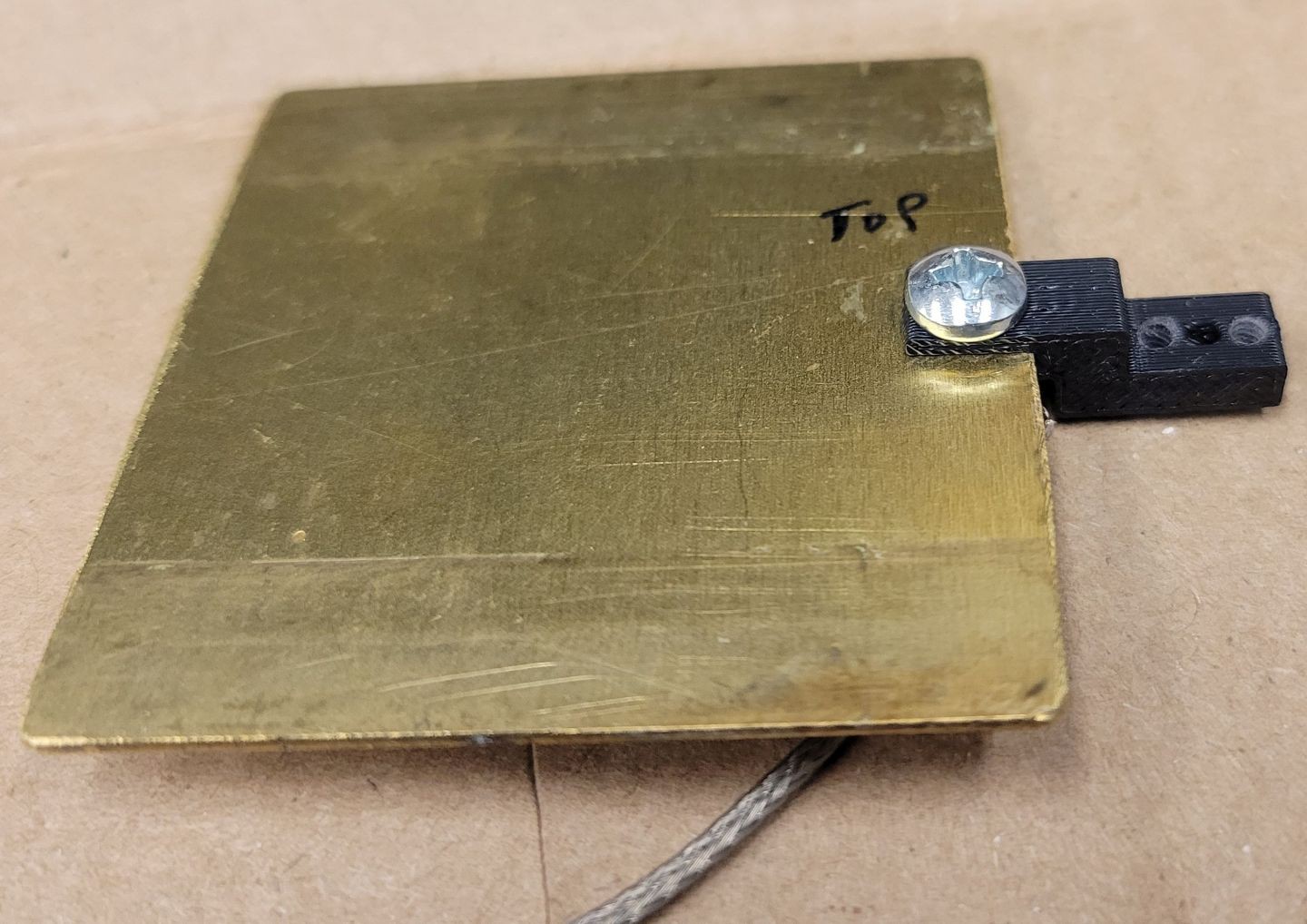

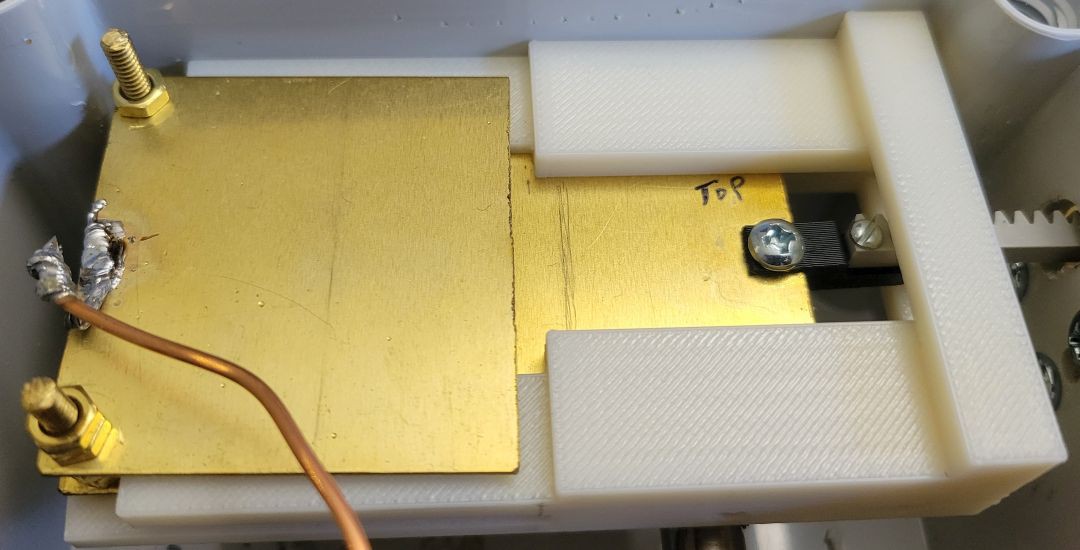

The main part of this project is a very simple home made variable capacitor. You can design it for a wide range of capacitance and voltage values. I give an example for a 15 pF capacitor that will tolerate over 3500 volts. It requires one 3D printed part and the rest is easy peasy.

The remainder of the project is testing and some more advanced stuff, like remote tuning with a DC motor and an Arduino.

Andrew Mitz

Andrew Mitz

Ignacio Acosta Pineda

Ignacio Acosta Pineda

Fabian

Fabian

Tobias

Tobias

Josh Cole

Josh Cole