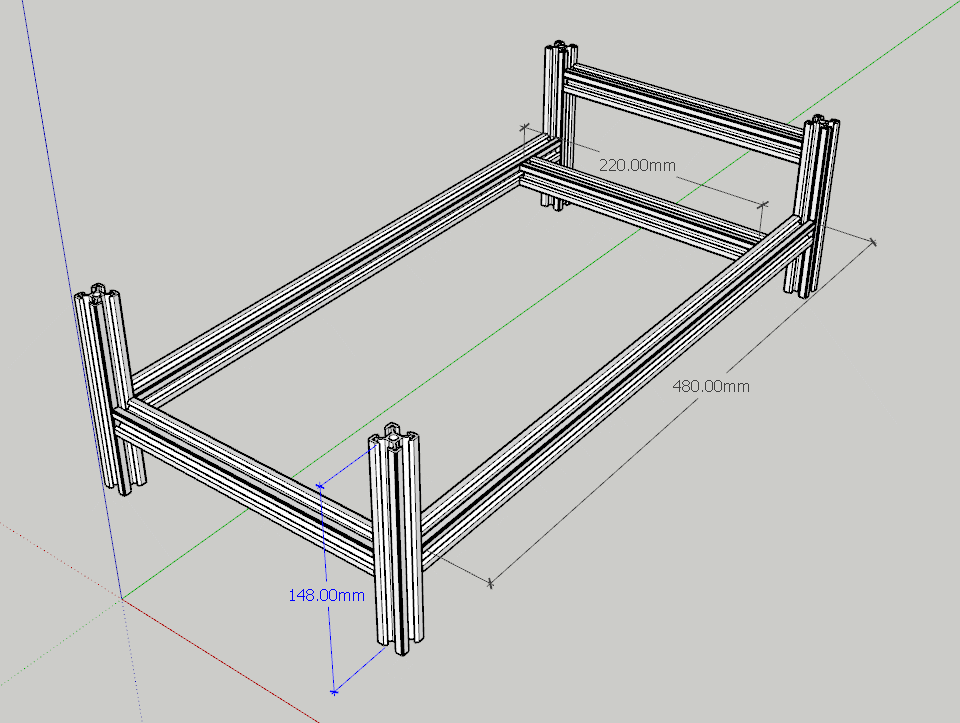

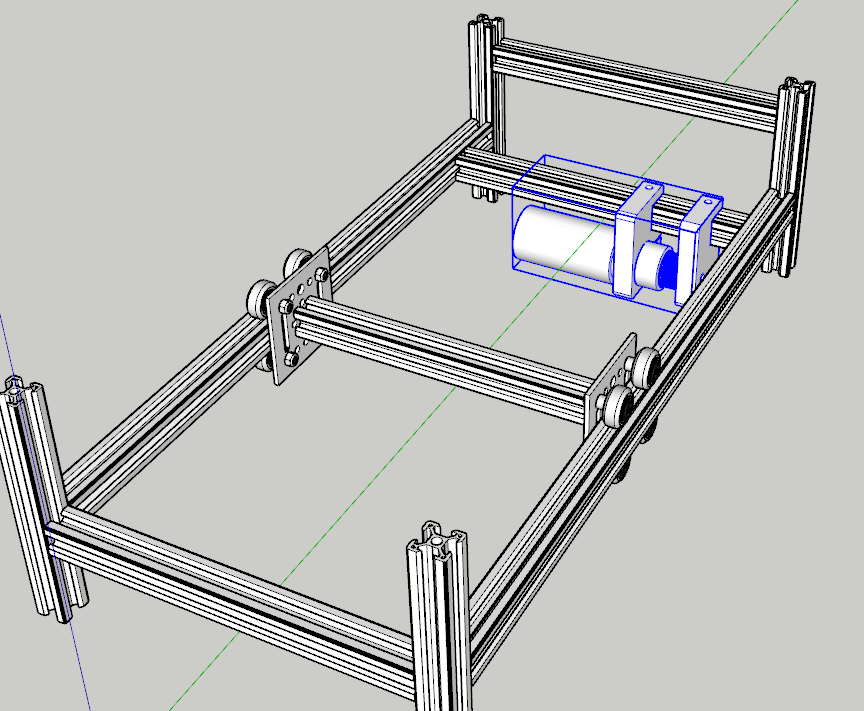

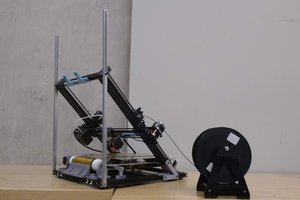

General Specs

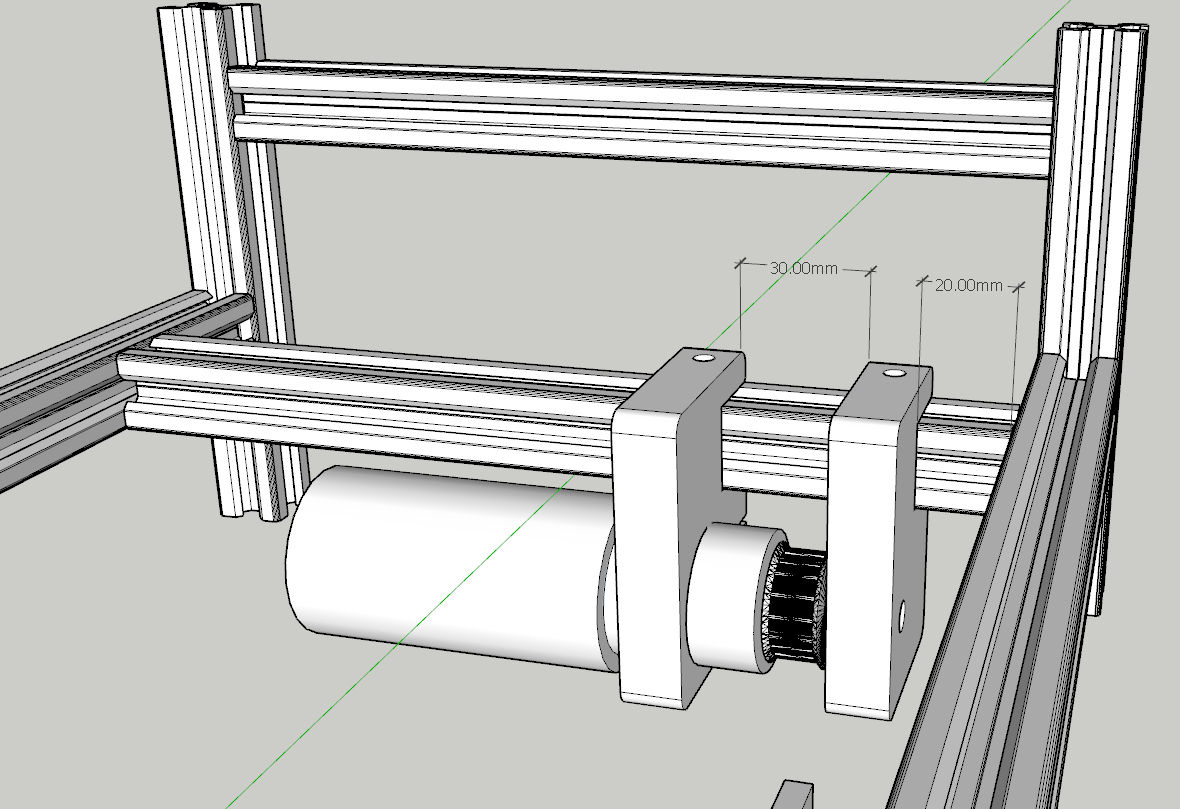

Pitch axis:

Range = 10 inches

Max force = 8 lbs

Roll axis:

Range = 180 deg

Max force = 4 lbs

_______________________________________________________________________________

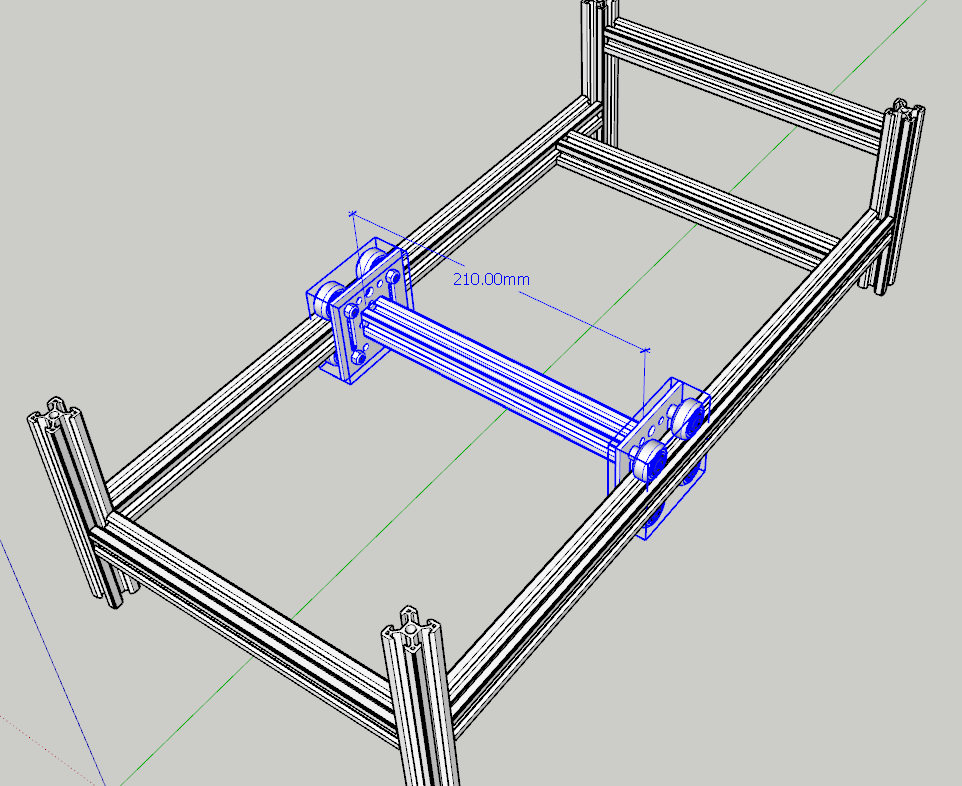

The prototype is already built and generally working with X-Plane although refinements continue.

Demonstration of auto homing

Demonstration of positioning to X-Plane

Demonstration feedback from X-Plane

The build instructions and related documentation are work in progress. I hope to complete them by mid to end May 2022.

The build instructions will not specify each and every fasteners (screws, washers, nuts, etc) needed to mount components. I recommended buying a kit of assorted length M5 fasteners like this one:

https://www.amazon.com/dp/B08HXLQ7K5?psc=1&ref=ppx_yo2ov_dt_b_product_details

I will call out specially fasteners in the instructions.

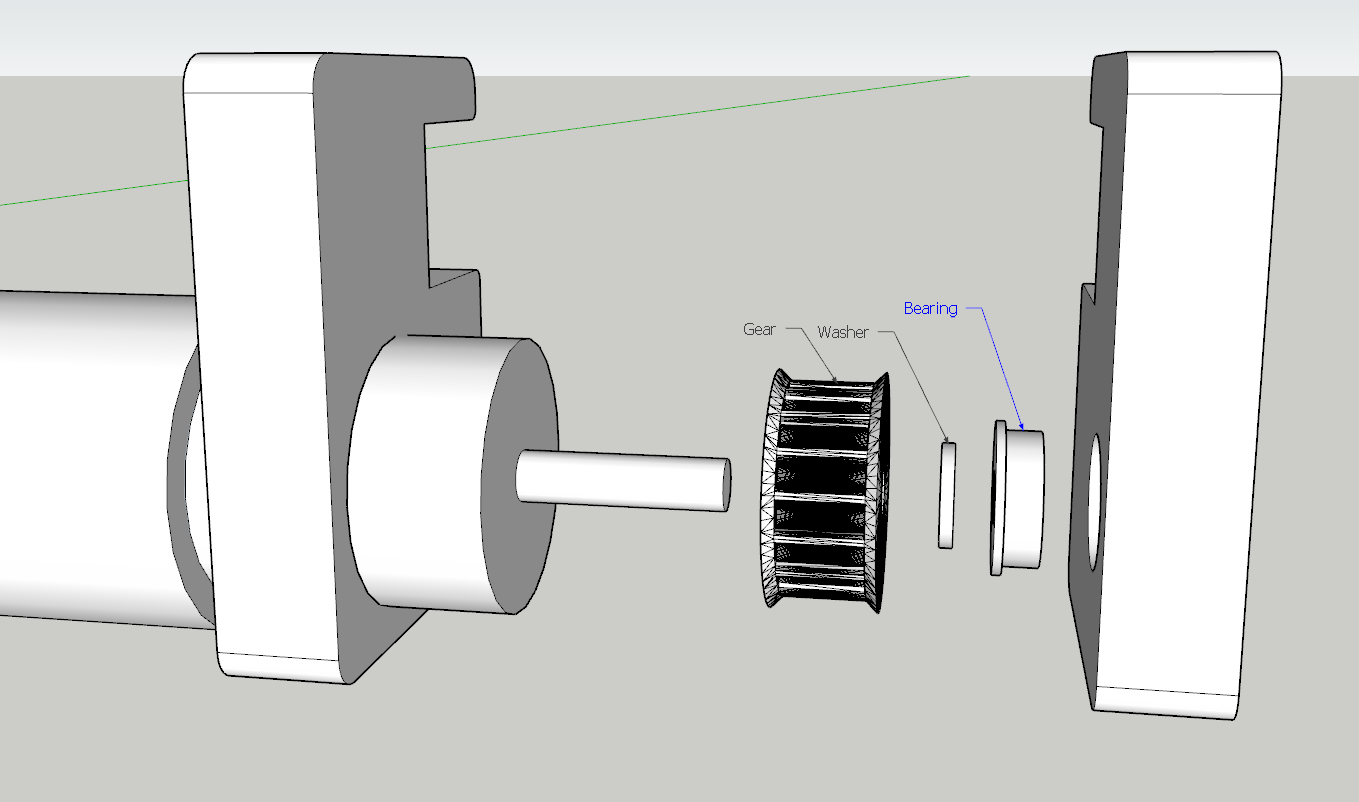

3D printed objects: The dimensional tolerance for these parts needs to be about +/- 250um (.25mm). If your printer cannot achieve that, I would recommend using a print service than can.

Know the material shrinkage for your printer and apply it to the print objects to achieve the best dimensional accuracy. For example, I know that objects shrink by about 2% after they cool on my printer, so I scale all objects by +2% (X, Y and Z) before printing. The STL files I am providing are NOT scaled.

I recommend ABS material, not PLA.

I designed the parts to require as little "support" material as possible, however some parts will require it. Make sure you are orienting the object correctly on your print bed to limit support material.

Tim

Tim

setCREATE

setCREATE

Swaleh Owais

Swaleh Owais

Matteo Borri

Matteo Borri

Lutetium

Lutetium

pardon my mistakes I am new to all of this. I ment to say I don't understand the pin descriptions