DC-motor-speed-control-circuit-using-IC555-TIP122

Pulse Width Modulation PWM controller. PWM is a technique in which the amount of current going in a circuit can be controlled by

chopping the Direct current using a gate or transistor that is changing its duty cycle( on-off time) you should see this article flashing of LED using 555 IC.

This article is about how you can control the speed of a DC motor using PWM motor controller

This PWM circuit can be easily found in our daily life equipment like mobile chargers, laptop adapters, inverters

the power supply of desktop pcs, and in many other types of equipment in which steady low voltage is required.

We use DC motors like DC fans in many systems in our daily life. For example, to cool the system, in power supply, etc. Most of the time we have to control its speed according to the requirement.

There are many ways to do it. For example by inserting a series resistor to limit the current and hence limit the speed.

But this is not a good way because in doing so, much of the power is wasted in the form of heat.

If we use any microcontroller, then this is an expensive method that is not affordable and suitable for small motors.

That’s why we use PWM which has high efficiency and accuracy.

COMPONENT USED

555 Timer IC

TIP122 NPN transistor (You can also use MOSFET IRFZ44N)

1N4007 diodes (3no)

5-mm LED

1k 0.25-watt Resistors (3no)

10k 0.25-watt Resistors (1no)

100k Potentiometer (1no)

100nF Capacitor (C2) (1no)

10nF Capacitor (C1) (1no)

Connectors

Custom PCB

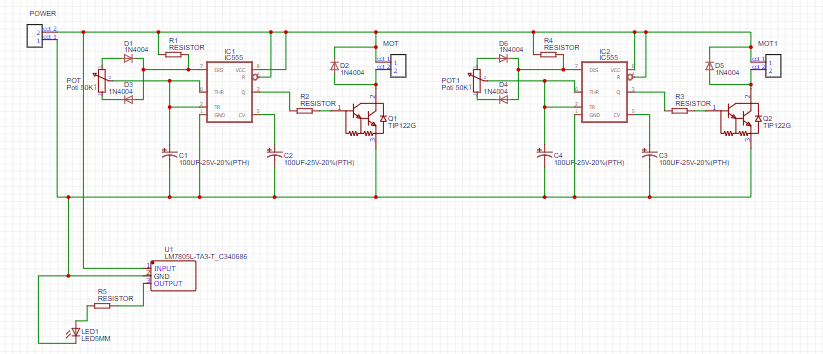

CIRCUIT DRAWING

To control the speed of the motor, we have to control certain electrical parameters that directly affect its speed. Obviously, we have to adjust the voltage and current supplied to it.

One way is that at constant supply voltage, you might want to put a variable resistor(potentiometer) in series with the motor to adjust/limit the current that it draws during operation. The bad thing about this method is that by limiting the current flow changes the value of the series resistor which also changes the voltage across the motor. When the motor is loaded, it draws a significantly large amount of current thus increasing the power across the series resistor. The power across the resistor will just be converted into wasted heat.

Another way is to use a Common emitter bjt transistor configuration with the motor as the load to adjust the current through the motor by changing the supply voltage at the base-emitter junction of the transistor. However, this is harder to predict since the relationship between the Vbe and Ic of the transistor is exponential. Aside from additional transistor concepts that you have to keep in mind, the transistor itself dissipates additional power as heat.

Another alternative and probably the most popular among speed control methods is the pulse width modulation. This method generates a pulse signal of voltage or current switching from on(HIGH) and off(LOW) with definite intervals on each state and a defined constant frequency overall. Note that this kind of voltage signal would still look like a constant DC voltage as seen by the motor. If you supply a DC motor with a 9V source and a switch but you constantly press the switch between On and Off reduces the average voltage supply as seen by the motor thus reducing its speed.

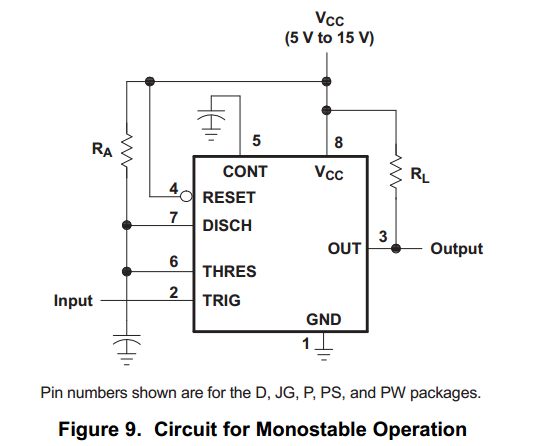

The 555 timer IC is a monolithic timing circuit that produces accurate timing delays and oscillations in a form of a square wave signal. This small IC has a lot of applications such as in oscillators, tachometers, waveform generators, control systems etc. Some features of 555 timer ICs are:

-It operates from a wide range of power supplies ranging from + 5 Volts to + 18 Volts supply voltage.

-Sinking or sourcing 200 mA of load current.

-The external components should be selected properly so that the timing intervals can be made into several minutes along with the frequencies exceeding several hundred kilo hertz.

-The output of a 555 timer can drive a transistor-transistor logic (TTL) due to its high current output.

The astable mode functions just like an oscillator which outputs a square wave with frequency, pulse width and duty cycle dependent on the values of the external resistors and the capacitor. This oscillation shall go on forever unless... if you cut the power supply of course. The pulse width, duty cycle and the frequency can be calculated as follows:

pulse width(t high) = 0.693(Ra + Rb)C

t low = 0.693(Rb)C

period = 0.693(Ra + 2Rb)C

frequency = 1 / period

duty cycle = [t high / period] x 100>#/p###

CUSTOM PCB FOR SPEED CONTROL

I have ordered PCB from JLCPCB

This is the link of PCB editable file

If you seriously need quality PCB quickly in your hand then you must have to try JLCPCB PCB manufacturing service. They have Special offer of $2 for 1-4 Layer PCBs, free SMT assembly monthly.

SMT Assembly service of JLCPCB.com is cherry on top now get your PCB fully assembled and save your time and money Select components for your PCB from there Parts Library of 200k+ in-stock components they are offering $27 valued New User coupons & $24 SMT coupons every month $8.00 setup fee, and $0.0017 per joint

Now no need to order components separately for you PCB and get free from stress of soldering them on PCB just try PCB SMT assembly service and get you PCB with components pre assembled and ready for the project

👉 Try PCBA service of JLCPCB.com and save your time and money, get PCB ready for project, 200K+ components in library of JLCPCB.com as well as 3rd party parts to choose from. Assembly will support 10M+ parts from Digikey, mouser

👉 $27 valued New User coupons

👉 $24 SMT coupons every month

For more details & offers please visit JLCPCB.com

Click here to visit JLCPCB.com

HOW TO ORDER PCB FROM JLCPCB.com

Mrinnovative

Mrinnovative