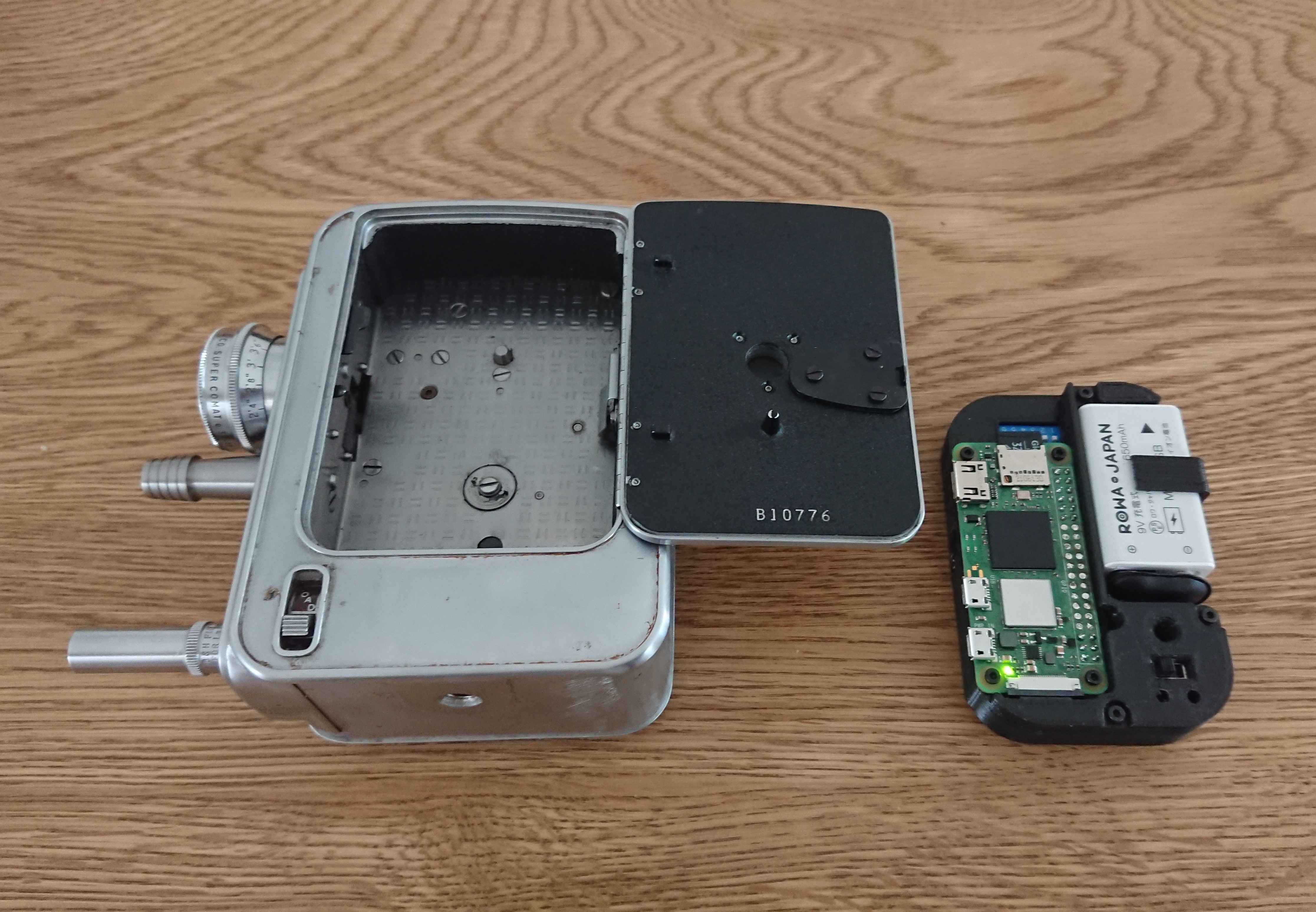

This camera modified for this project is a Bell & Howell Model 172 magazine-loading 8mm camera manufactured in the 1950s. The film standard is double 8, but it is set in a special magazine.

As a magazine-loading 8mm film, super8 was widely used.

I have found several projects to modding Super 8 film magazines into Digital, but this camera is even older than those.

This may be the first project to digitize a spring-driven camera!

The film feed and shutter are powered by a mainspring, and when the spring is wound up, the camera can shoot for about 35 seconds at 16 fps. It can also shoot back and forth on a single roll of film, recording approximately 100 seconds per side.

There is no single item that can be automatically controlled; aperture and focus are controlled by the lens, and exposure time is fixed in conjunction with the frame rate.

The preview is not visible and the viewfinder is very small, so it takes some technique to get the image you want.

I have never shot with 8mm film, but my goal was to recreate the fun of the surprise box-like experience of not knowing the result until the film is developed.

Why not revive this delightful heritage buried in the depths of our garage drawers?

=====================================================

After completing the production

The goal of this project was to preserve the original mechanism as much as possible.

As a result, all mechanisms remain original except for the film, which has been replaced by an image sensor.

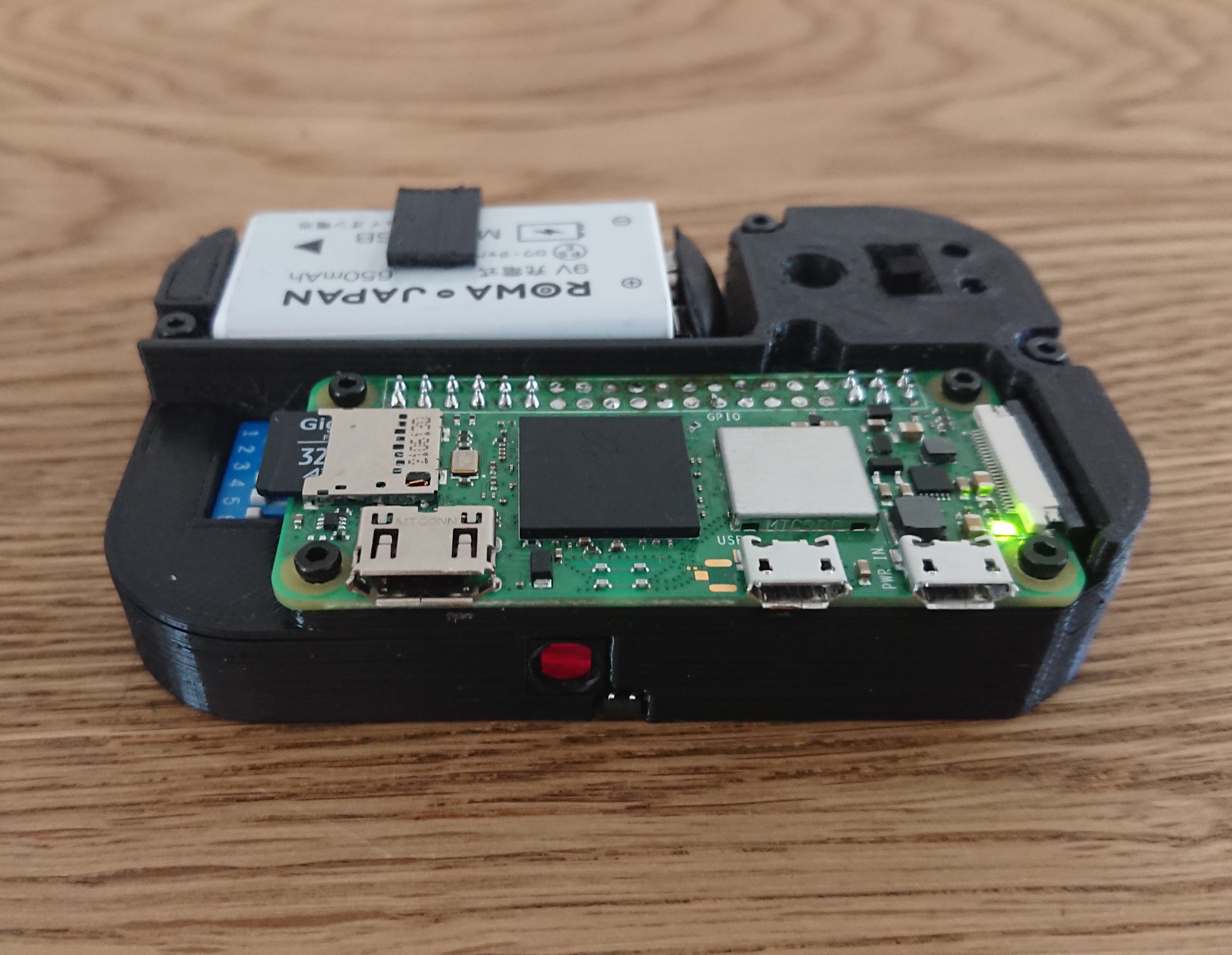

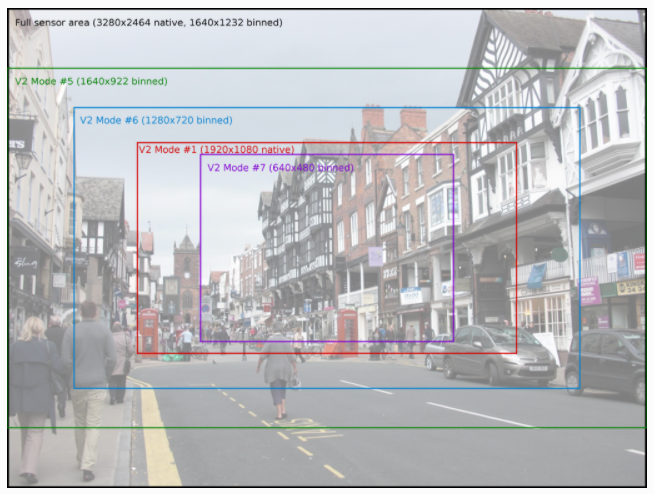

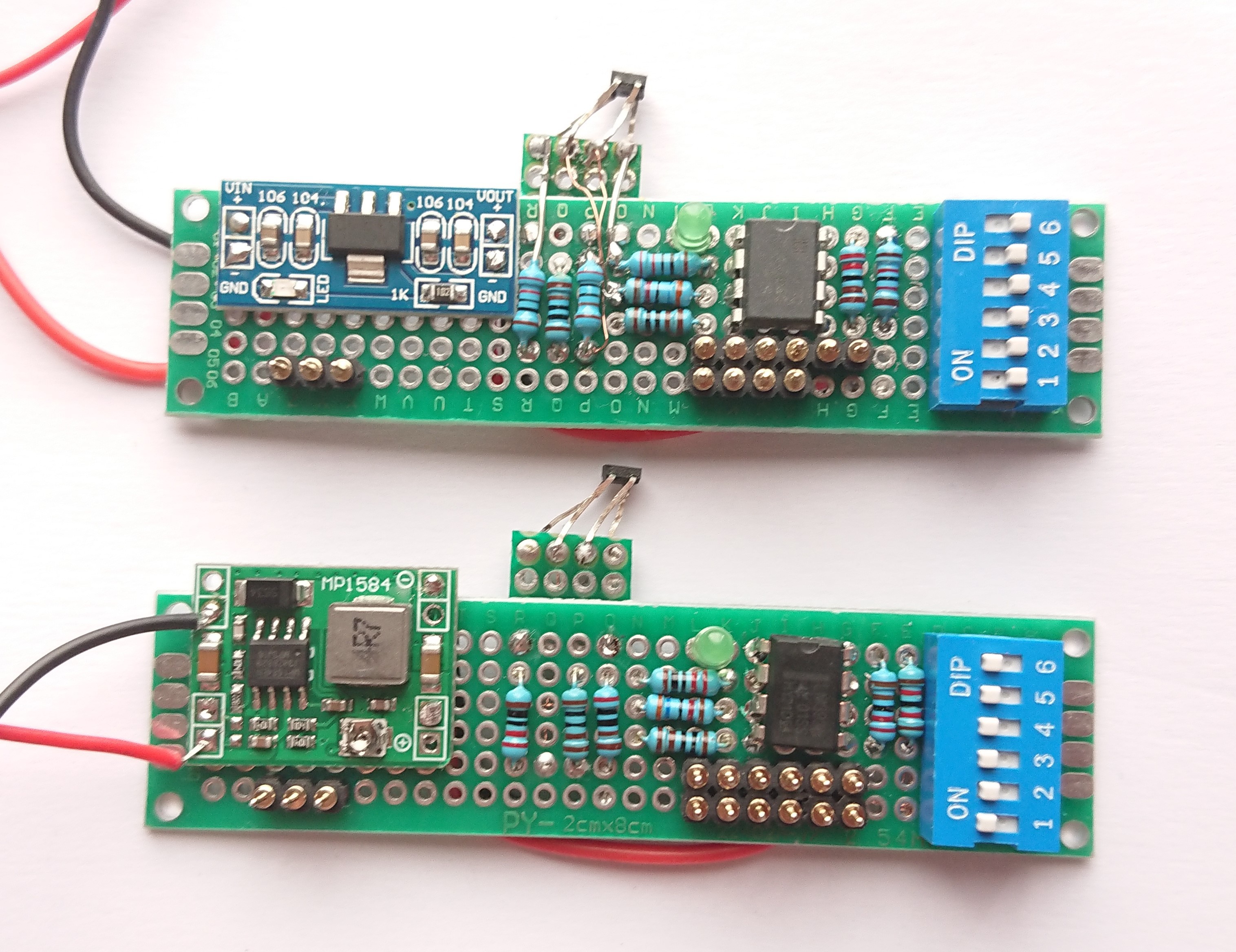

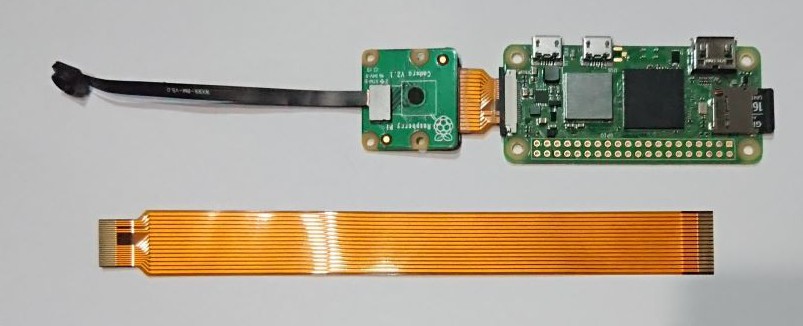

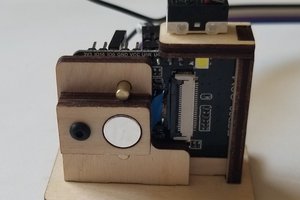

This camera was originally configured to shoot on an 8mm film magazine. The digital photography module we created is exactly the same size as this film magazine and contains an image sensor, shutter-sensing sensor, battery, Raspberry Pi, indicator lamp, dip switches for configuration, and main board.

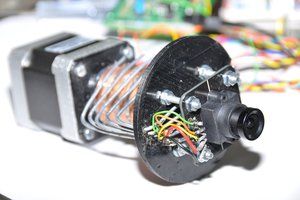

Because this camera is spring driven, the shutter timing is unstable and does not provide an electrical timing signal. Therefore, to obtain proper shutter timing, a mechanism to adjust the shutter timing with a photo reflector is incorporated.

In addition, since the Raspberry Pi Zero2 is a power-saving device, it can be powered by a 006P type rechargeable battery.

The minimum settings required for digital photography, such as film sensitivity and white balance, can be set using dip switches.

It was a bit of a challenge to miniaturize the entire system to the size of a film magazine, but in the end we were able to complete a compact digital back system.

These innovations have allowed us to create a very attractive system for utilizing past assets.

When recoding video, this module is set inside the camera. You only have access to the interface originally equipped on the film camera.

However, there is no problem. The digital module senses the movement of the shutter and records video in synchronization with the timing of the shutter opening.

It can be operated in exactly the same way as the original spring drive camera.

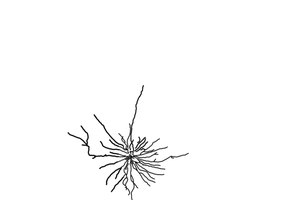

Although I did not specifically aim for this, the video I was able to capture was very nostalgic. I don't want to ruin the atmosphere, which I think was caused by the low frame rate, low contrast, and white balance, so I decided not to tune the camera any further.

====================================================

Wow!!

I was able to capture very atmospheric images.

AIRPOCKET

AIRPOCKET

Dave Ehnebuske

Dave Ehnebuske

Such a wonderful project - Thanks for sharing. :-)