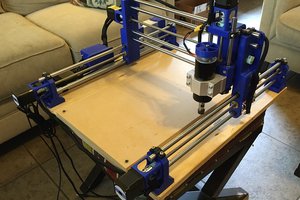

About a year ago I built myself a 3D printed CNC machine. Among other attachments I added a NEJE A40640 LED laser module to it that has a 10 watt optical output. I have been trying to get a handle on how the laser diode works. Recently I have been going over research papers trying to work out the relationship between laser power and cutting speed. I came across a few papers that seem to fit the bill.

if you dig into the papers and do a little simplification you get an equation like this that tells you approximately how deep a cut will be.

This says that increasing the laser power or the number of passes should increase the cut depth in a linear way. While increasing the velocity of the laser head or increasing the size of the laser spot will result in a decrease in cutting depth at a logarithmic rate. This falls out of the math easily enough, if we plug 1 in for all values but power then we end up with depth = x, while if we plug in 1 for all values but velocity we end up with depth=1/x. This equation is missing some constants that dial it in for each material type, so keep in mind this is an approximation.

We can pull out a part of this equation and call it energy per unit length or energy = power/velocity. For any given material type it can only take so much energy before being permanently damaged (burning) and that defines the optimal ratio between power and velocity. Say the material can only take 1 unit of energy before burning, then we can choose to run 1 unit of power at one unit of velocity, or 10 units of power at 10 units of velocity resulting in a faster cut, but we can't get any more depth out of the laser than this. We can try to run more passes to get more depth without adding more energy, but only up to a point.

Another interesting point here is that it is the focus spot size that dictates the ultimate depth of cut. If the spot size grew to 4x its smallest size then we would only have 25% of the energy to cut material. The way the laser focus spot works we end up with a 'waist' where the laser spot size is relatively unchanged, but outside of that area the laser light diverges rapidly. This means that as our cut depth increases past the depth of this waste we start to loose cutting power and eventually it gets to the point where no amount of extra passes, reduction in speed or energy can overcome the loss. Basically any laser, no matter how strong, will ultimately have a maximum depth of cut.

According to these equations there should be no difference between laser power or passes. That is a laser with power of 1 running 2 passes should be equivalent to a laser with a power of 2 running 1 pass. Also there is an inverse relationship between speed and power, so if you want to run at 2x the speed you need 2x the power or 2x the passes to cut the same depth. In practice there are small differences in each material that make power and passes not fully equivalent, and the above limitations are still in place and you can't keep cutting deeper and deeper by just increasing power or reducing speed. But as a rule if someone says they cut at high speed for many passes you can reduce the speed and passes at the same rate and get an equivalent cut

---

Here are some of the papers I used to derive this.

https://www.fpl.fs.fed.us/documnts/fplrp/fplrp250.pdf

http://alumni.media.mit.edu/~yarin/laser/physics.html

https://makezine.com/2019/03/04/a-deep-dive-into-laser-cutter-speed-and-power/

https://www.sciencedirect.com/topics/engineering/laser-power-density

---

In order to verify the above equation I wrote a test utility that can control my laser. This test is simple, I start the laser just off the edge of my material and...

Read more » David Tucker

David Tucker

Hari Wiguna

Hari Wiguna

michael Mayo

michael Mayo

Bill Weiler

Bill Weiler