[17 Jan] Right now, the tool steel bed costs around £60 and the honeycomb mesh would probably cost another £60 if I could find one in the size I need. I did some research on r/lasercutting and the reasons for the honeycomb is so that the air stream has somewhere to go and the laser beam doesn't reflect back onto the cut material, allegedly. I also looked at the typical beds for top-down SLA's and it does seem that resin prints can tolerate quite large holes.

I'm thinking that a sensor will be needed to detect if the bed was able to move down to the max; this would indicate if it was able to push the boltheads through the holes in the bed or if a part or fixture stopped it. It could be as simple as a second endstop or as detailed as a load cell force sensor.

Anyway, I found this video that shows that charring of the bottom side of the laser cut workpiece can be eliminated if the sheet is elevated. A commentor suggested ball bearings as a possible object too.

Due to having tofirst layer cleaning, moving bed mass, auto ejecting and preventing laser reflections, it really seems that a bed surface with a large air:material ratio is the ideal bed choice for my application. Additionally, I was wondering how I was going to mount traditional PCBs for any PnP operations, and the holes would allow for a straightforward solution.

Ideally, the hole spacing would be equal to the mounting holes of the MGN9 rail, allowing me to actually mount the rail directly to the bed underside. M3 bolts seem common enough, and their bolt heads can usually pass though a 6mm hole, so this measurement will be the minimum size. I feel like >=8mm would be ideal, allowing for some of the bolts to be misaligned.

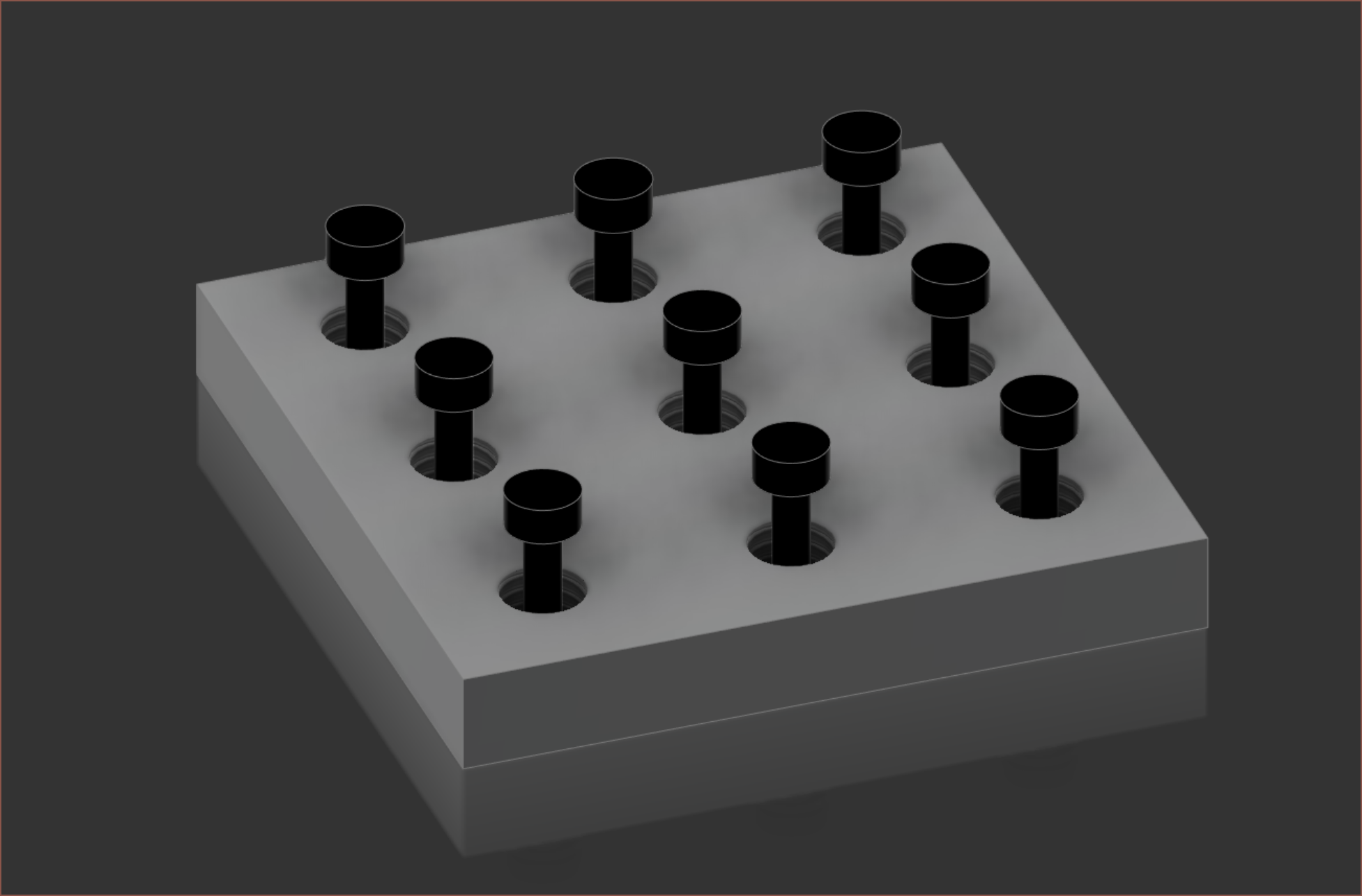

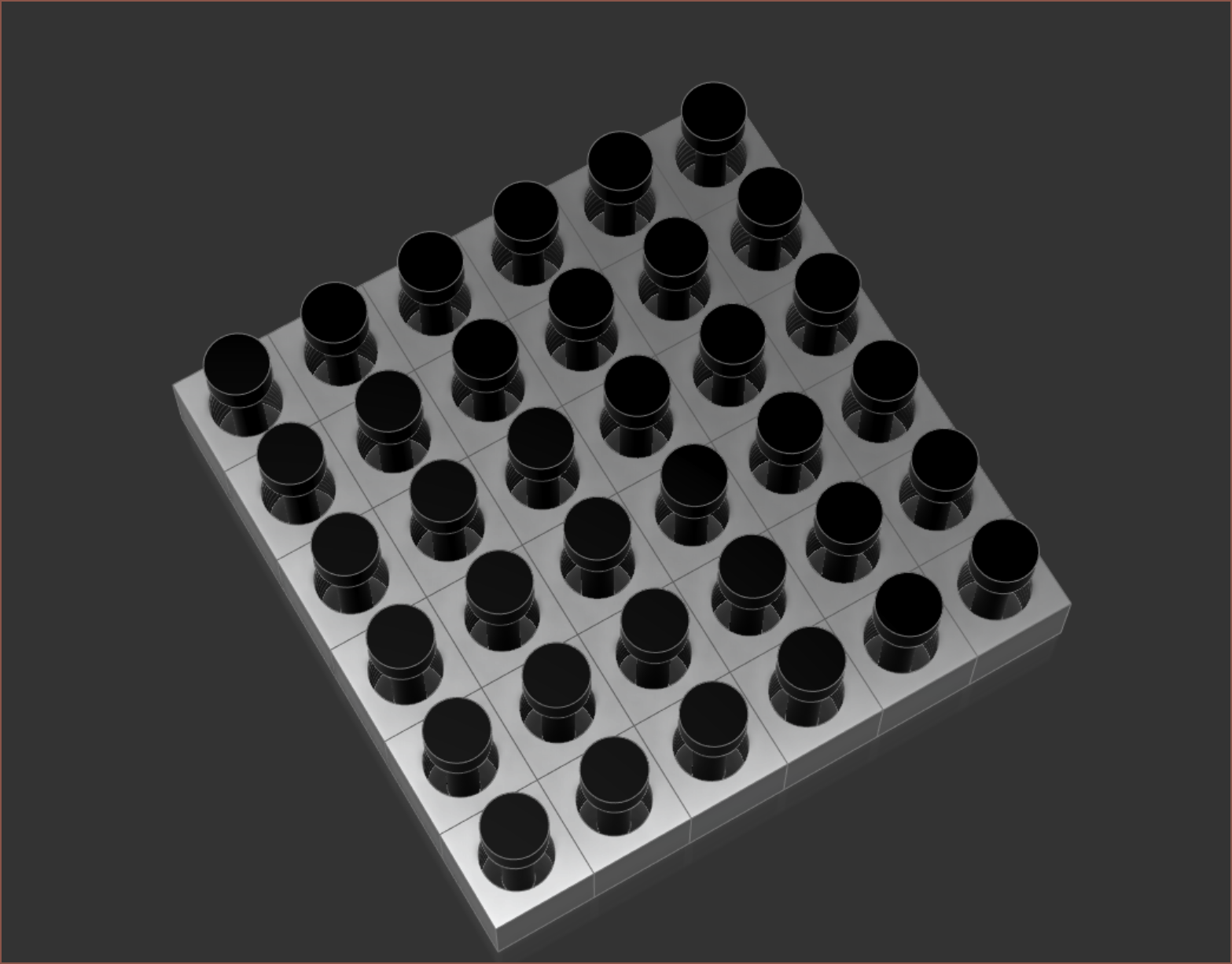

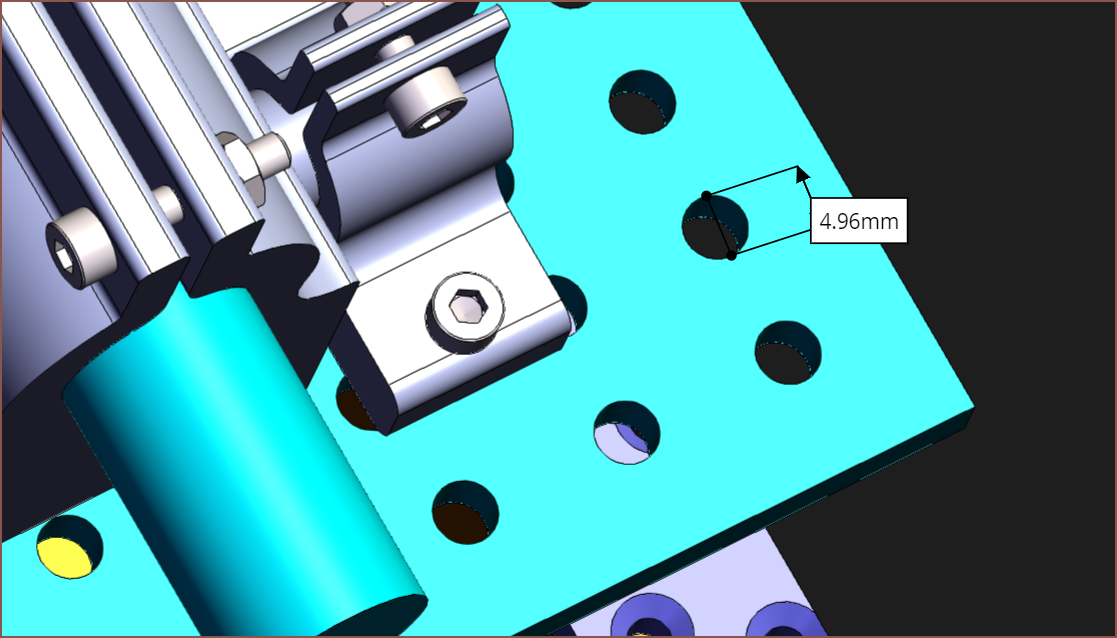

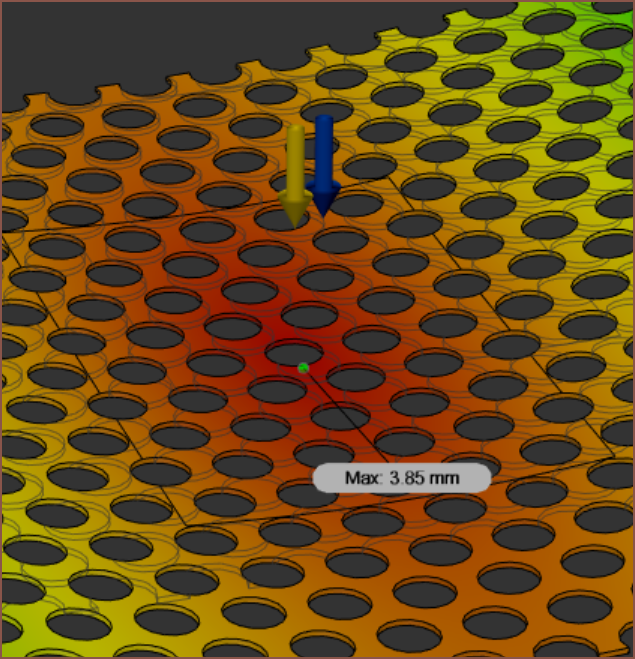

Here are M8 threaded holes spaced 20mm apart in an 8mm plate. There are M3 bolts on the very bottom of the Z axis travel such that when the bed goes all the way down, the bolts stick up through the bed and push off whatever is ontop. I can already see that there's still loads of surface area, so a more extreme 10mm spacing could be used:

Here are M8 threaded holes spaced 20mm apart in an 8mm plate. There are M3 bolts on the very bottom of the Z axis travel such that when the bed goes all the way down, the bolts stick up through the bed and push off whatever is ontop. I can already see that there's still loads of surface area, so a more extreme 10mm spacing could be used:

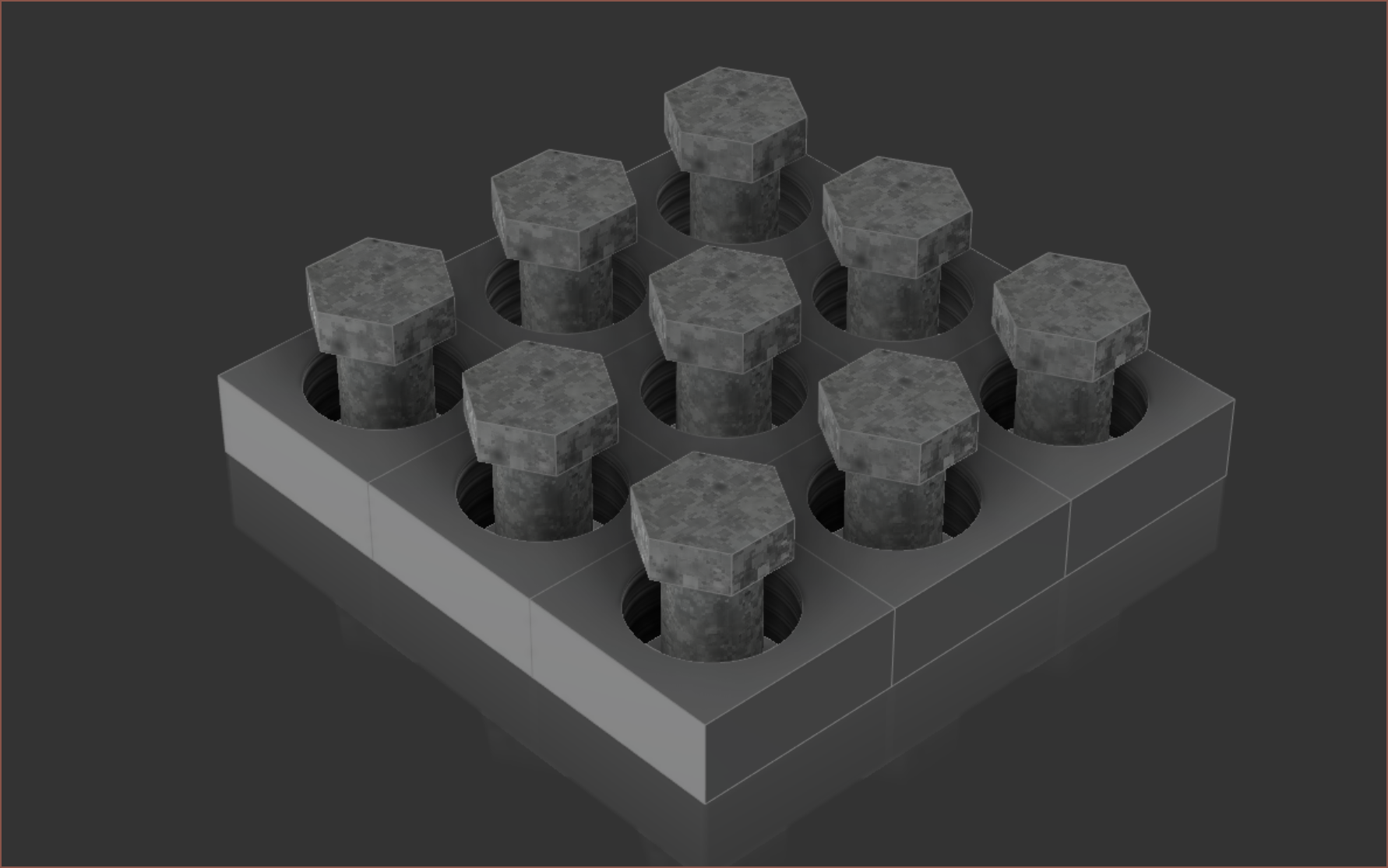

Alternatively, ths could be an excuse to use the hundreds of M8 bolts I bought that were planned for #SecSavr Sublime [gd0036]:

Alternatively, ths could be an excuse to use the hundreds of M8 bolts I bought that were planned for #SecSavr Sublime [gd0036]: In any case, I'd rather not have to manually drill 528 16mm holes into an expensive...

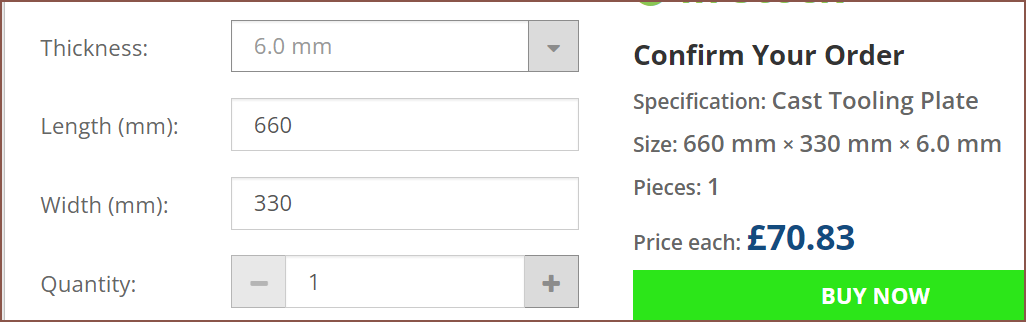

In any case, I'd rather not have to manually drill 528 16mm holes into an expensive... oh right. The bed is larger now than when I last got prices. I probably should resimulate too, now that I think about it.

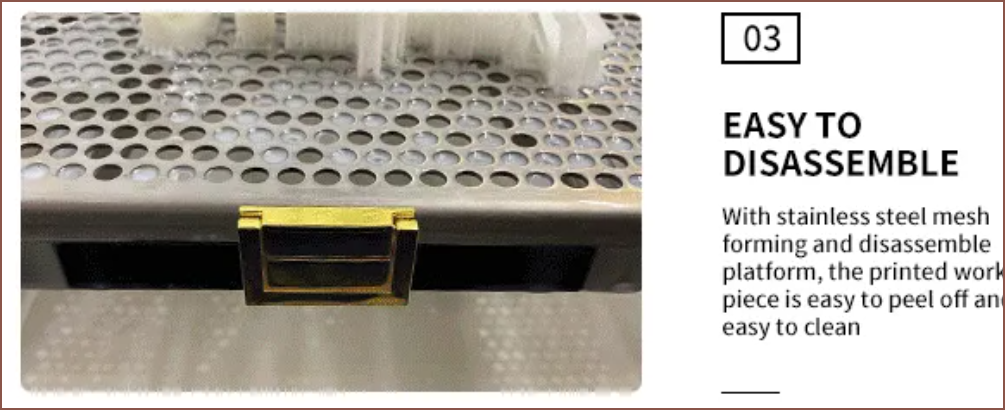

oh right. The bed is larger now than when I last got prices. I probably should resimulate too, now that I think about it.Anyway, that number could be even higher if I can't find some industrial printer somewhere that actually can get away with holes so large. I found this model which uses 5mm holes, so an 8mm hole is probably in the realm of possibility.

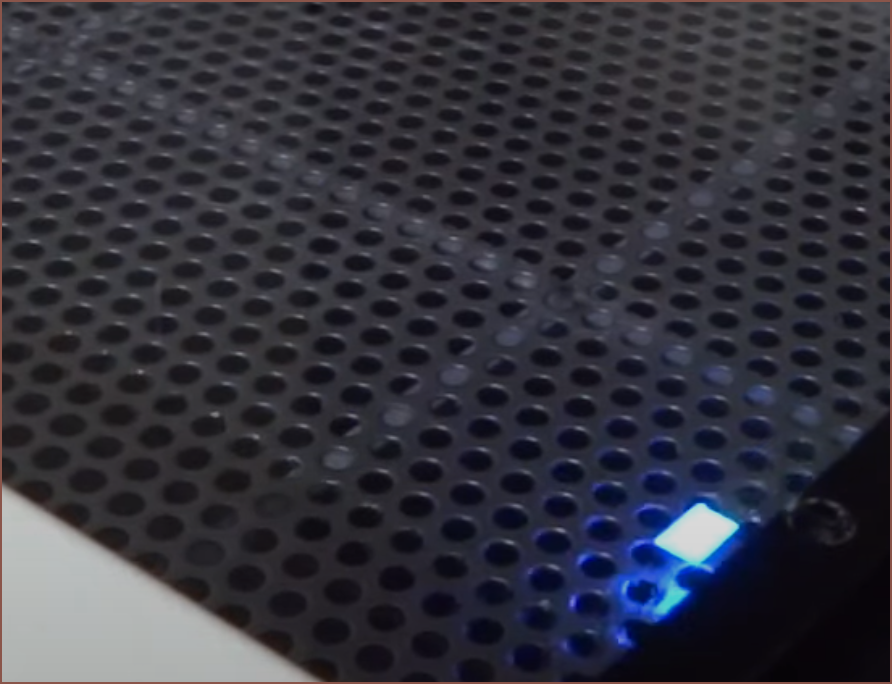

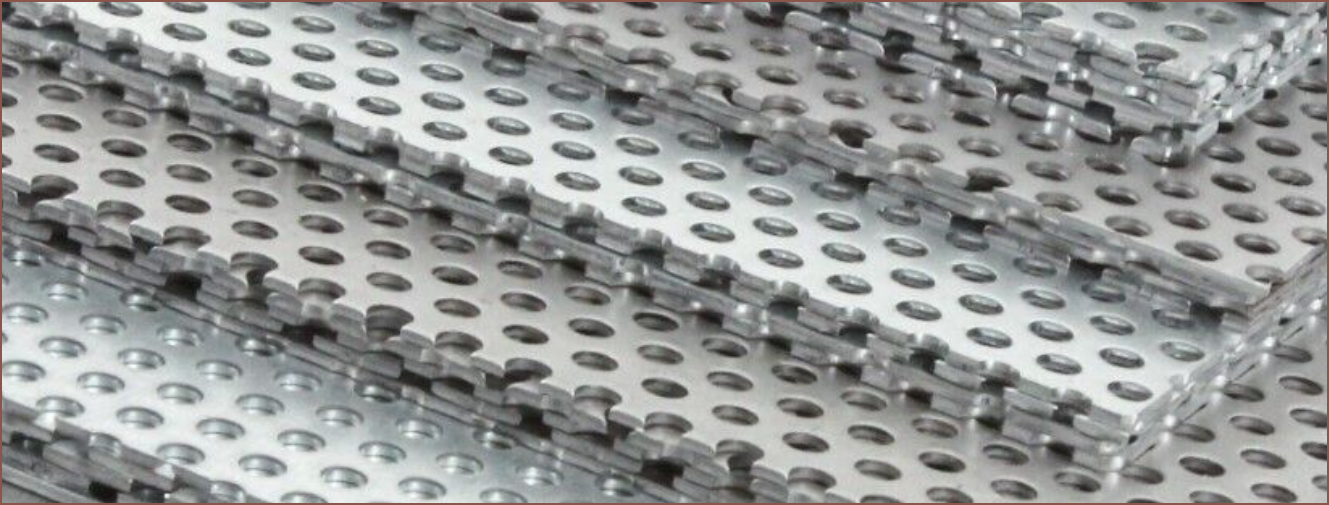

The holes in beds I can find on google images seem massive:

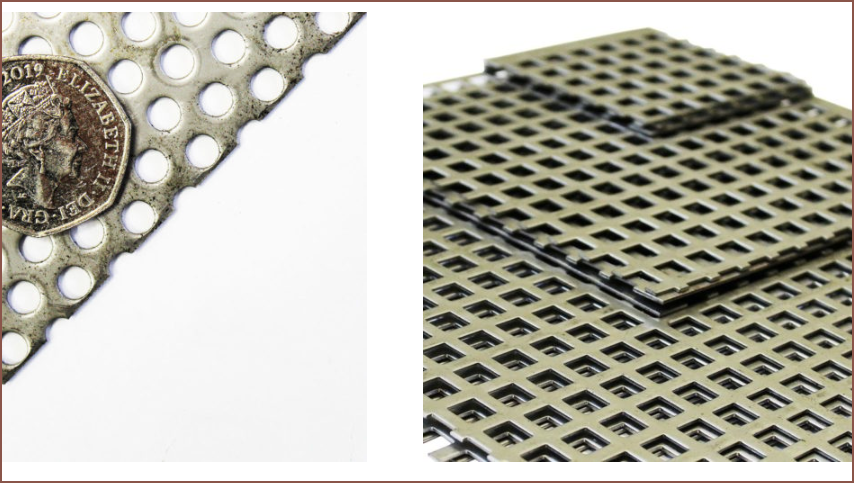

The holes in beds I can find on google images seem massive: And is it me or are they getting away with just a perforated sheet of metal?

And is it me or are they getting away with just a perforated sheet of metal? Ooo you can even get it in squares. It's a shame I can't seem to find some spare bed listing or something that indicates what sla beds are made like.

Ooo you can even get it in squares. It's a shame I can't seem to find some spare bed listing or something that indicates what sla beds are made like. Idunno about you but that looks A LOT like a perforated sheet with some backing grid. And every industrial printer is using it like it's the standard.

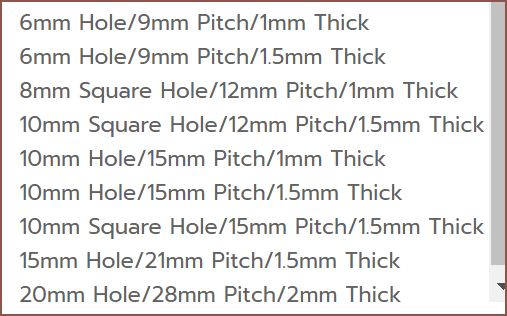

Idunno about you but that looks A LOT like a perforated sheet with some backing grid. And every industrial printer is using it like it's the standard. For some, unexplained reason, 10mm and 20mm pitch just get skipped.

For some, unexplained reason, 10mm and 20mm pitch just get skipped. Thanks Alibaba for telling me what this material is. It's 100% + verified + blue checkmark + no ratio stainless steel.

Thanks Alibaba for telling me what this material is. It's 100% + verified + blue checkmark + no ratio stainless steel.I can't seem to find anything against using this as a bed material for laser cutting. Only issue I can see so far is that it's only 2mm thick max (and the ones I like are 1.5mm). How am I supposed to thread that? The good news though is that stainless steel should be 3x as stiff as aluminium, so theoretically a 2mm perforated sheet should be as stiff as 6mm of aluminium, right?

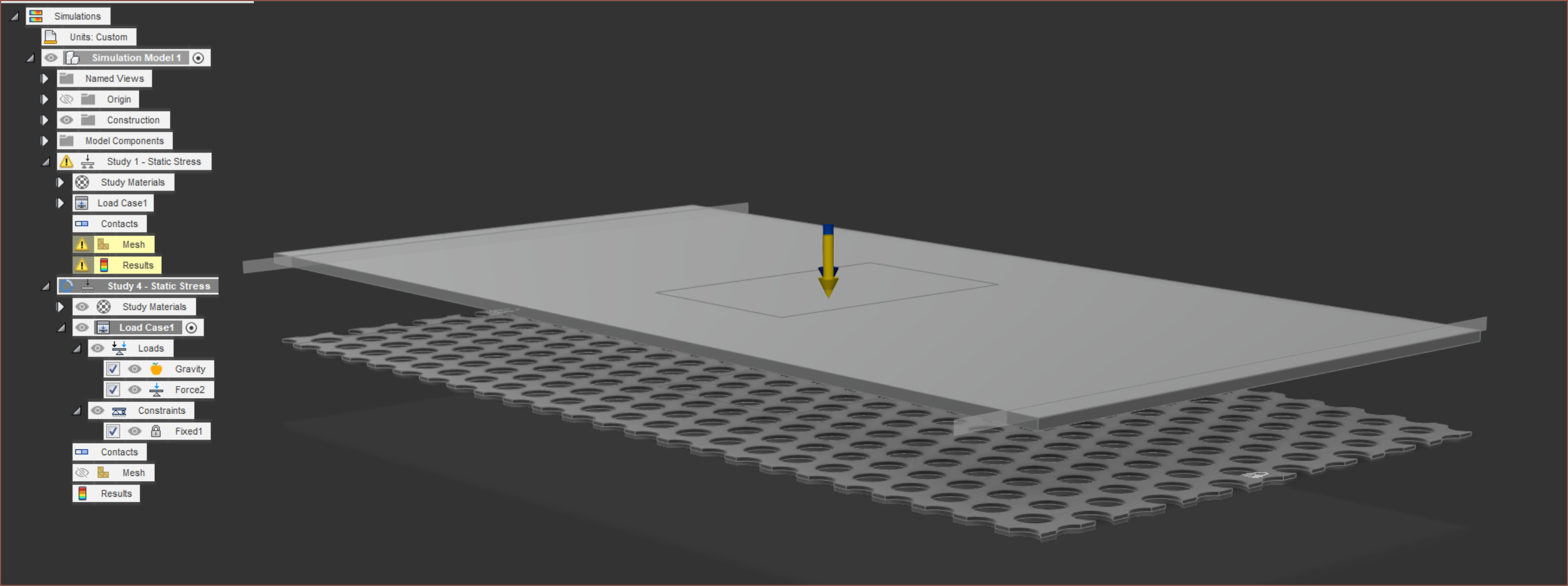

I have no idea if this is going to work, but it turns out that "simplify" applies to all studies so I can't just remove the unsimulated bed.

nope. Ok let's try "suppressing features" on the remove instances in the simplify

okay...

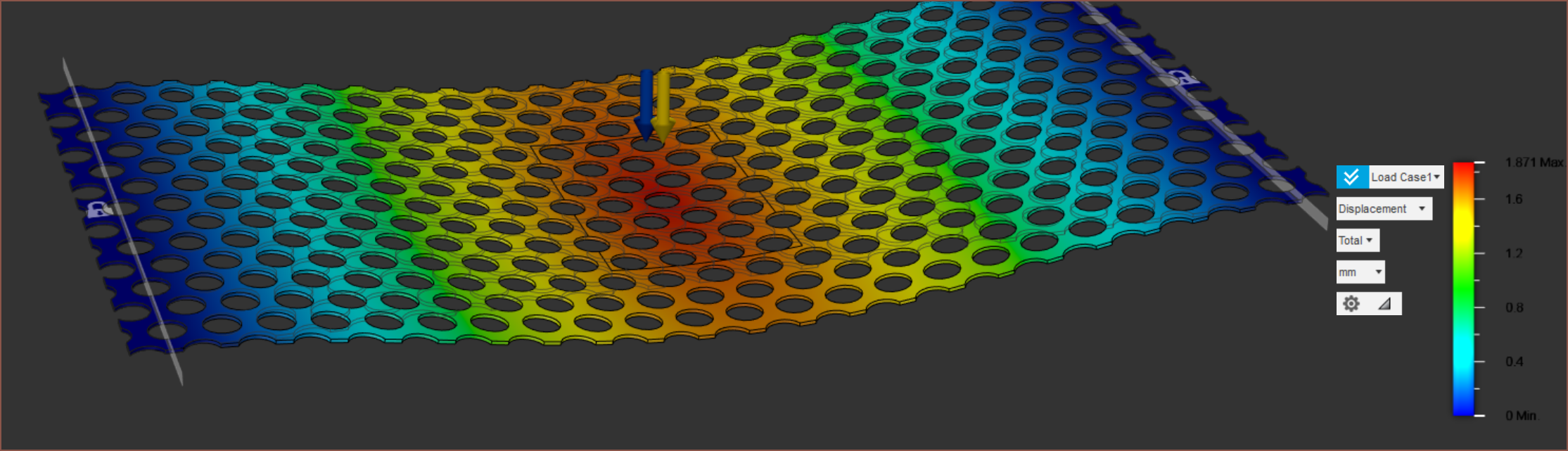

okay... So for a 2kg load, I'm down almost 2mm.

So for a 2kg load, I'm down almost 2mm.Perhaps the simulation only works if I send 1 to the cloud at a time.

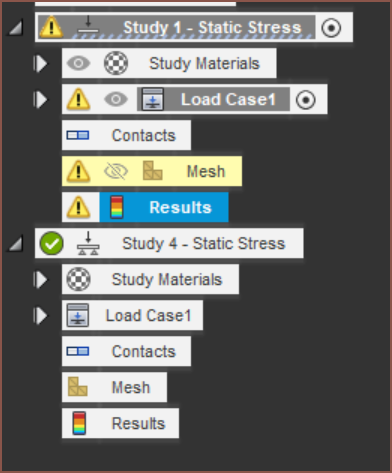

Yeah uh that's a big difference.

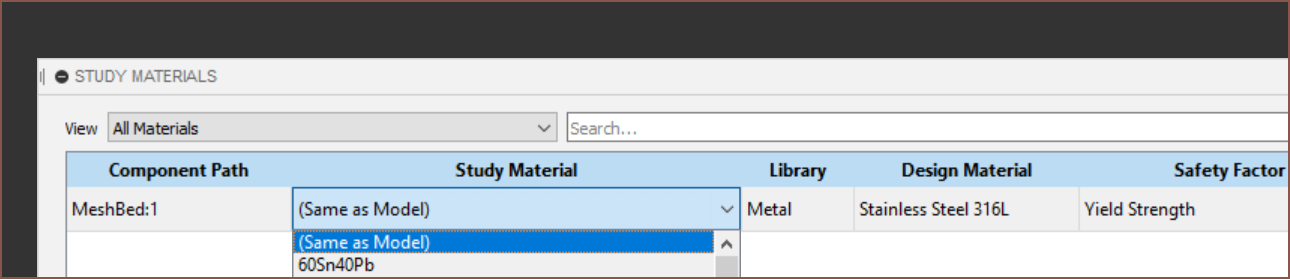

Yeah uh that's a big difference. I do wonder if this has anything to do with it.

I do wonder if this has anything to do with it. Okay so the holes certainly do something to the stiffness alright. I still feel like it's salvagable by just adding rods underneath like what the industrial printers do.

Okay so the holes certainly do something to the stiffness alright. I still feel like it's salvagable by just adding rods underneath like what the industrial printers do.

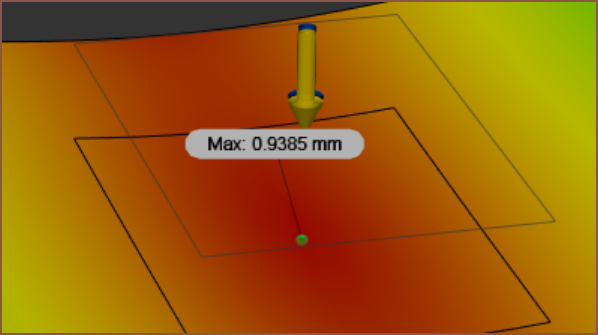

Youch if I thought the 2mm one was problematic, the 1.5mm thick sheet is a no go zone.

But I feel like I'm still on the right track here... again, the entire, MASSIVE, industrial, £££££ printer market seems to have confidence in this material. A 2KG load in a 110x164mm area is also kind of unrealistic. It's just what Me In The Past already had set up.

But I feel like I'm still on the right track here... again, the entire, MASSIVE, industrial, £££££ printer market seems to have confidence in this material. A 2KG load in a 110x164mm area is also kind of unrealistic. It's just what Me In The Past already had set up.[19 Jan]

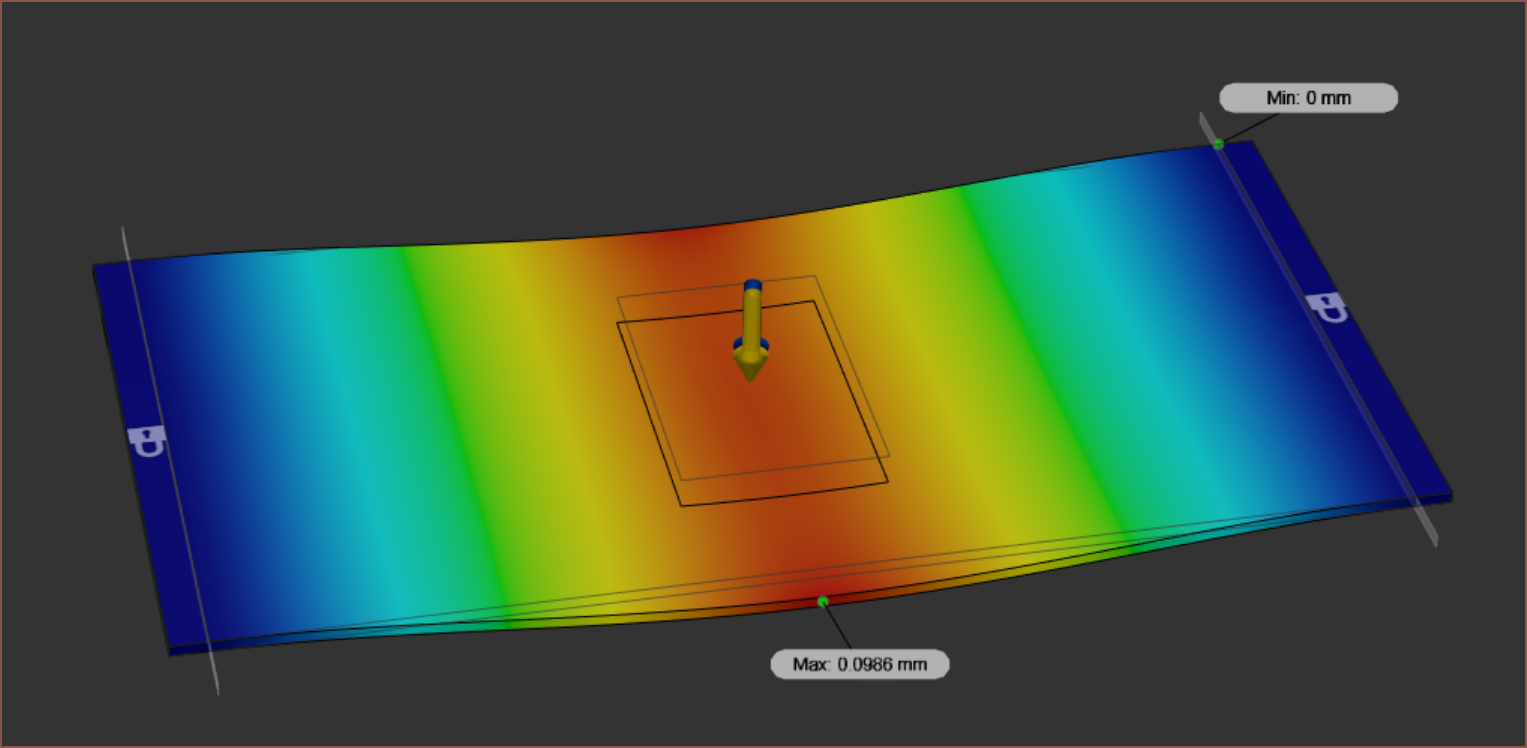

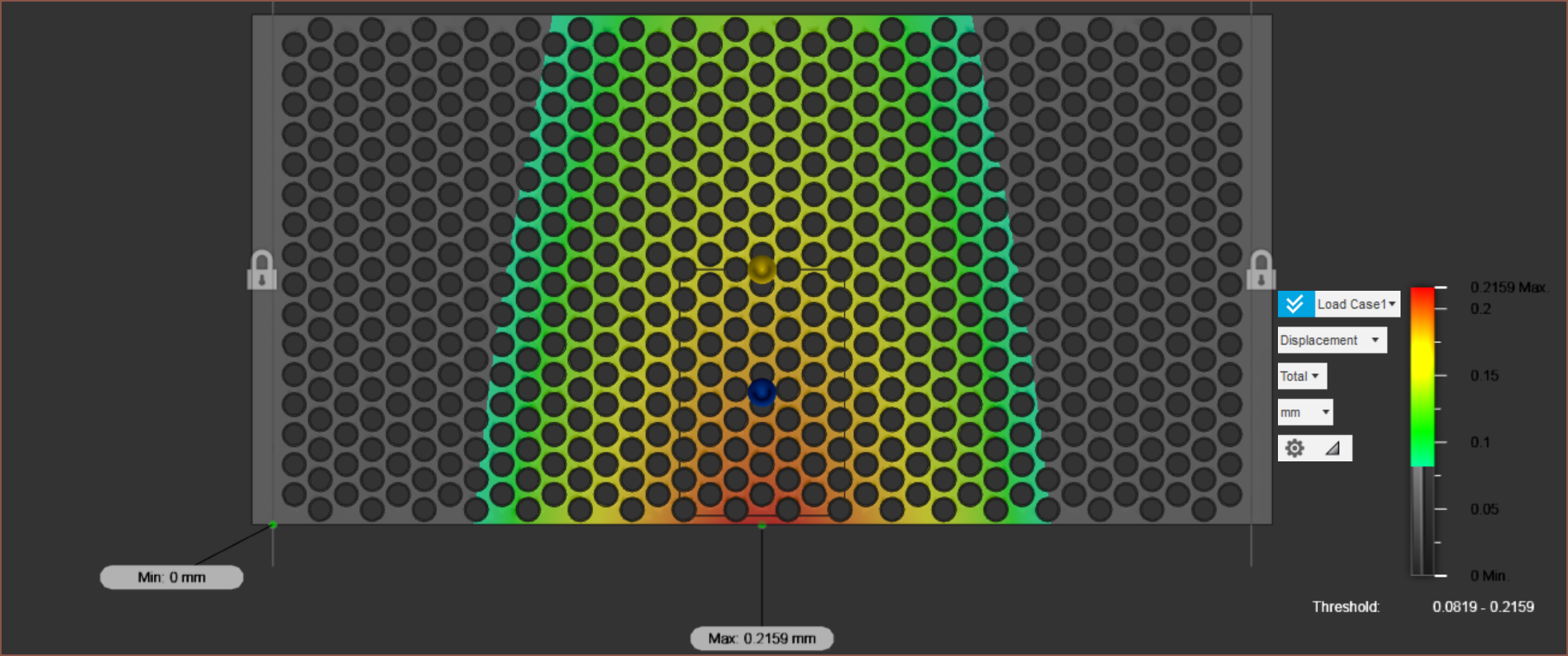

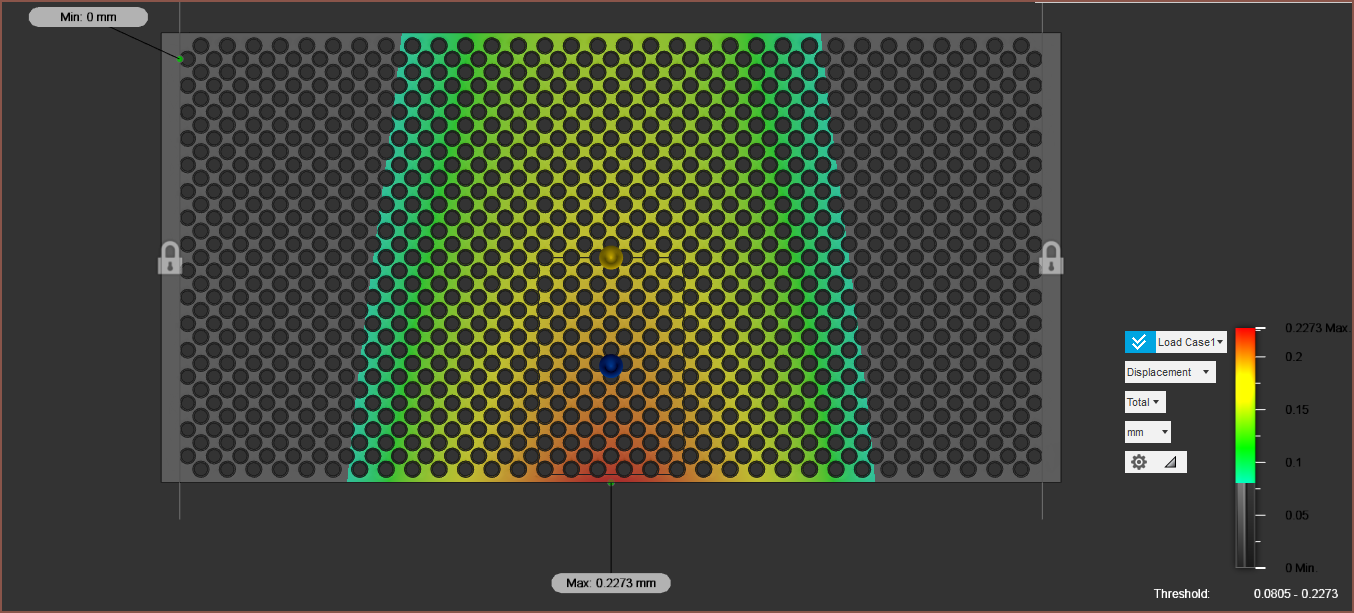

I've done a simulation of a 10N load on one side of a custom tooling plate filled with 610 M16 holes. This is really testing for the possible displacement when the part is pushing against the PET film, but since I have no actual force data, I just thought 10N would be a bit more standardised going forward.

I've done a simulation of a 10N load on one side of a custom tooling plate filled with 610 M16 holes. This is really testing for the possible displacement when the part is pushing against the PET film, but since I have no actual force data, I just thought 10N would be a bit more standardised going forward.Unfortunately, the size of an M8 bolt is less than a millimetre smaller than the size of an M16 thread, so I'd need to aquire smaller bolts. Obviously, that's nowhere near as tedious as drilling 610 holes into a 680x340mm bed. I predict that it'll be some 8 hour process. Hopefully I only have to do it once because it'll be £100 a bed after VAT + shipping.

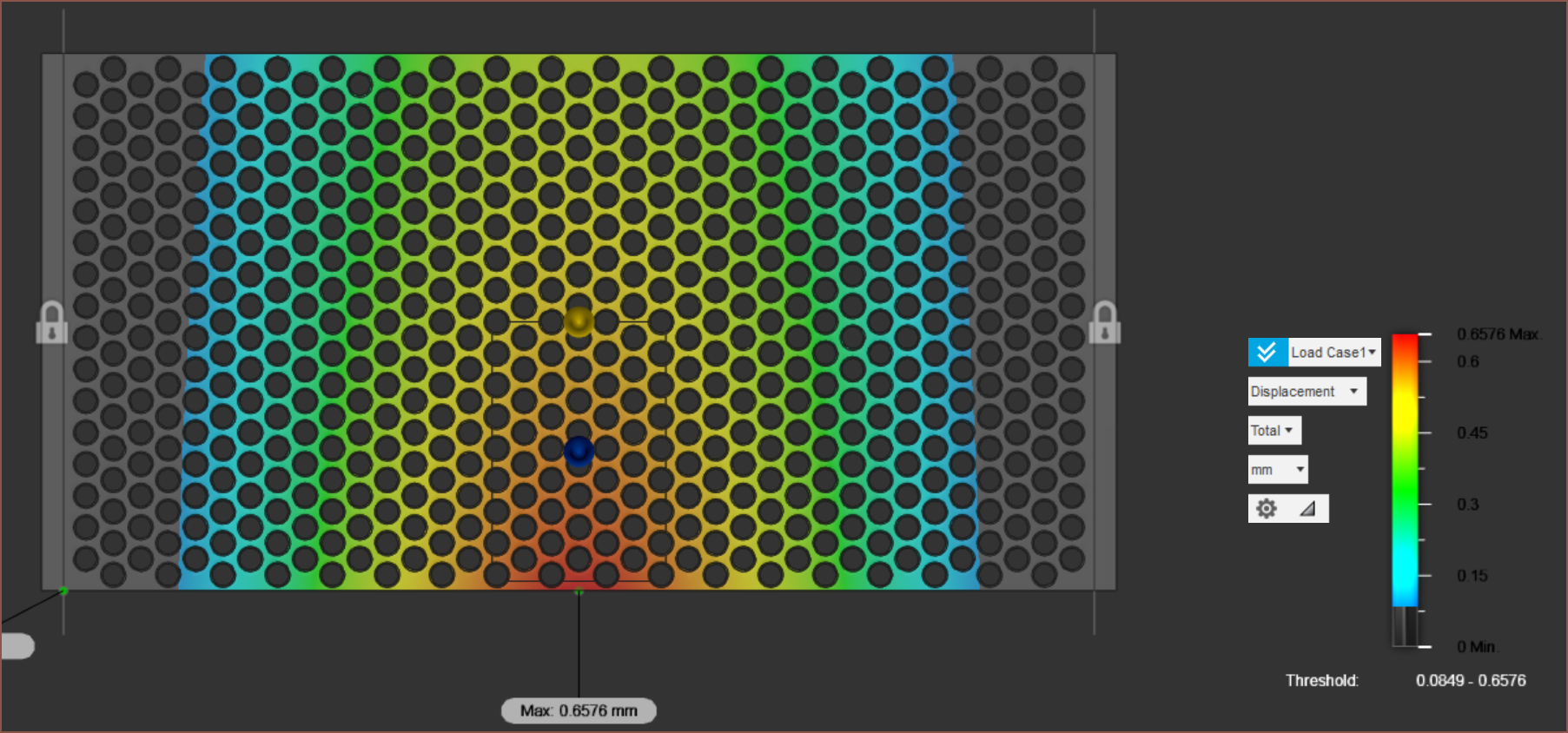

This is what the same design would be in 3mm 304 stainless:

For both I've set the threshold to start from approx 80um, or 1 standard layer height (for this printer).

For both I've set the threshold to start from approx 80um, or 1 standard layer height (for this printer).[22 Jan]

I've also tried the pattern seen on CNC fixing plates. Half of the holes are 10mm and the other half are M12 threads. Similar displacement, the holes are spaced out the same 20mm in X and Y, and the hole count is over 1000. There's slighty less surface area with this one, but the minimum thickness between holes is now a narrow 2mm, compared to almost 4mm for the M16 bed.

I might be able to use the CNC mill or waterjet my university just so happens to have, but if not I'd have a lot of holes to drill either way.

kelvinA

kelvinA

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.