It's hard to say, but I had to abandon the development of prototype 3. Don't worry, I'm not going to abandon this project, in fact, today I am in a much more advanced step than what I am going to describe in this Log.

The main reasons that supported the design of prototype 3 were precisely related to the characteristics of the selected generator. Let us remember that it was a BLDC motor, recovered from a DJI M600 Drone. This type of motor, as explained in the measurements made to it in a previous Log, is capable of producing one volt for approximately every 130 RPM. To get 10V the propellers had to turn at 1300 RPM, very fast for normal wind conditions. In order to obtain those RPM in the generator (electric motor) but for the propellers to turn at lower RPM and taking advantage of the torque of the new designed propellers, prototype 3 includes belts and pulleys. Here the problems begin, this design requires at least three bearings, two GT2-type pulleys and two custom-designed axles, in addition to the remaining bits and pieces from previous prototypes. It also turned out to be very large and heavy. The structures that would support it would also have to be larger and that would also lead to more weight. Too complicated and expensive for my taste! I inadvertently fell into the trap of looking for complicated redesign paths.

I know many people hate Stepper Motors as generators and to a certain extent I understand them (they are inefficient and quite heavy), but believe me that in wind generation devices as small as this project, it is very difficult to beat at low RPM. That is why my first build (Prototype 1) used a Stepper Motor.

Prototype 1 turned out to be well accepted and today I am proud to receive feedback from users of this platform who have already replicated it and are getting their own performance and application experiences. It has been used as a power source for automatic chicken coop doors, even as an electrical power source for remote sensors that measure humidity, temperature, wind speed, etc.

Prototype 1 proved to be feasible, but there is certainly room for improvement and I have been on that path for a few months now.

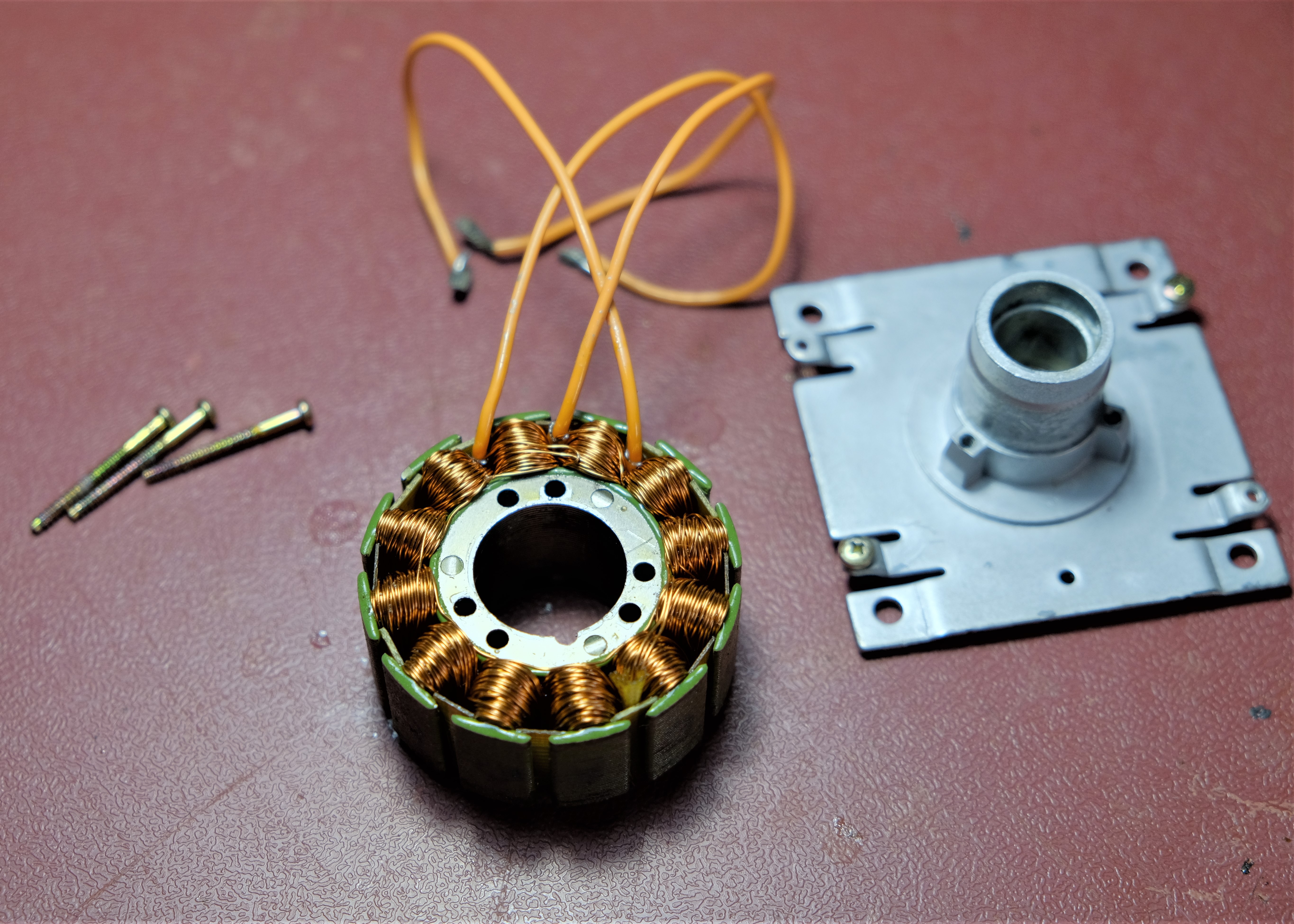

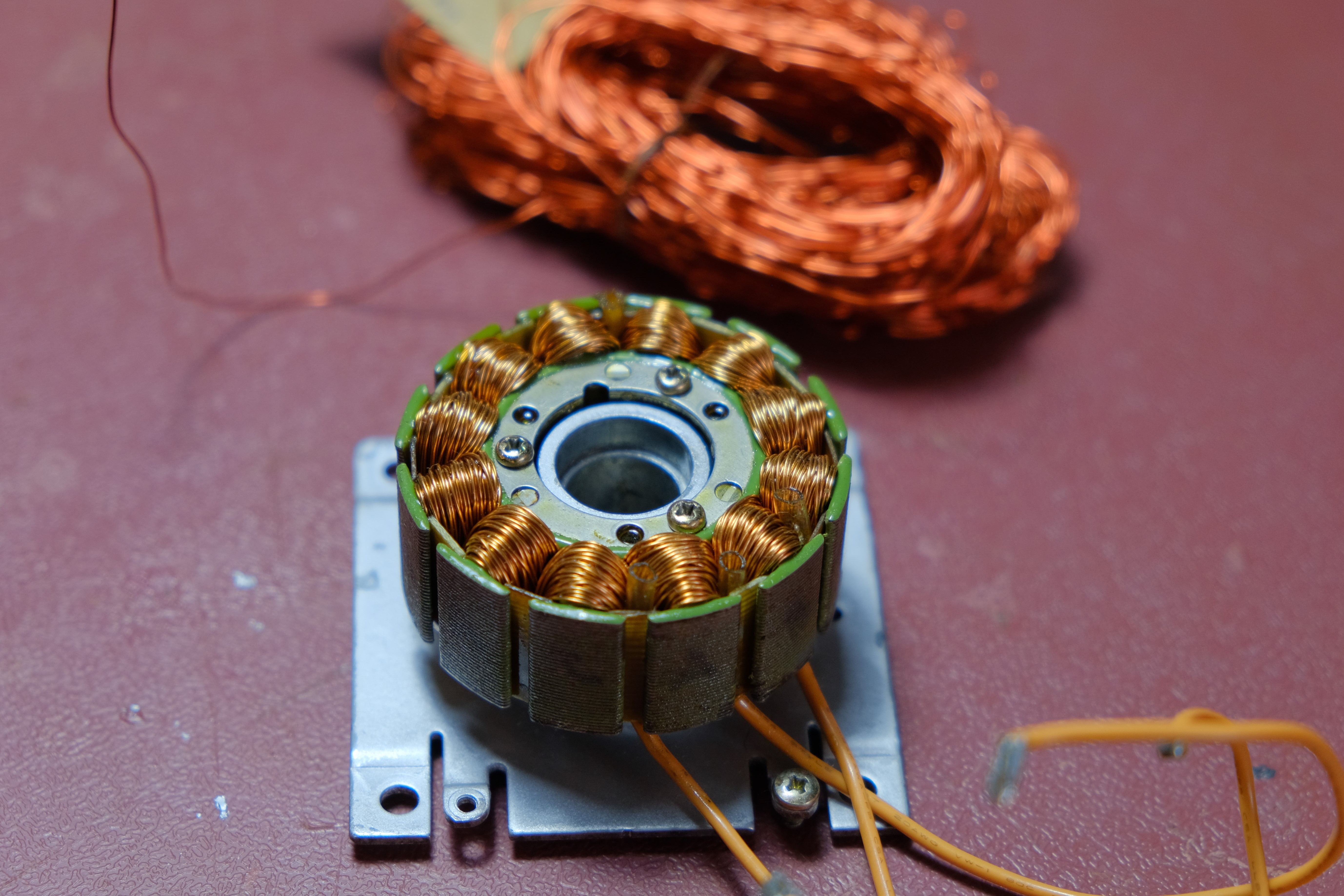

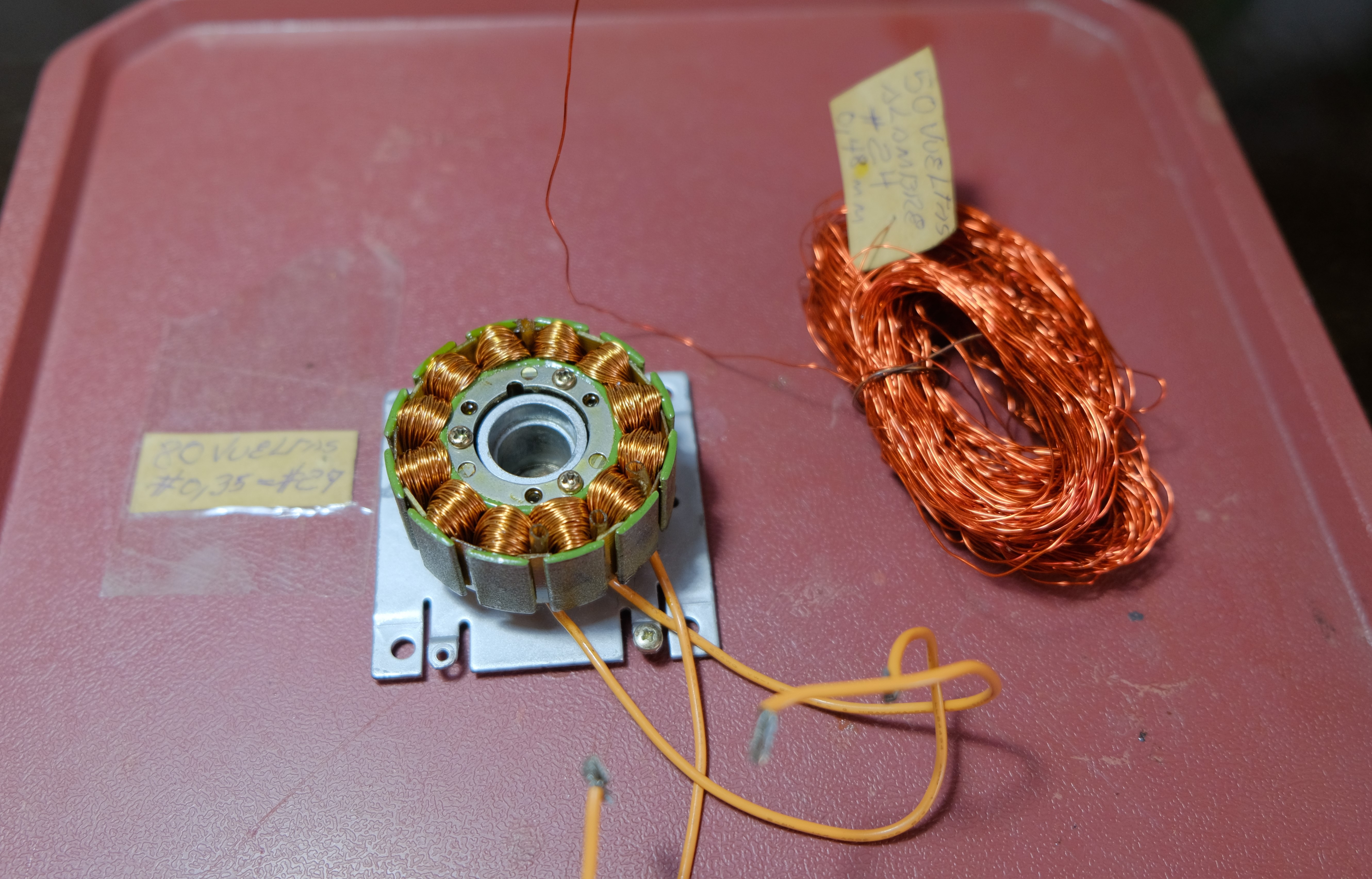

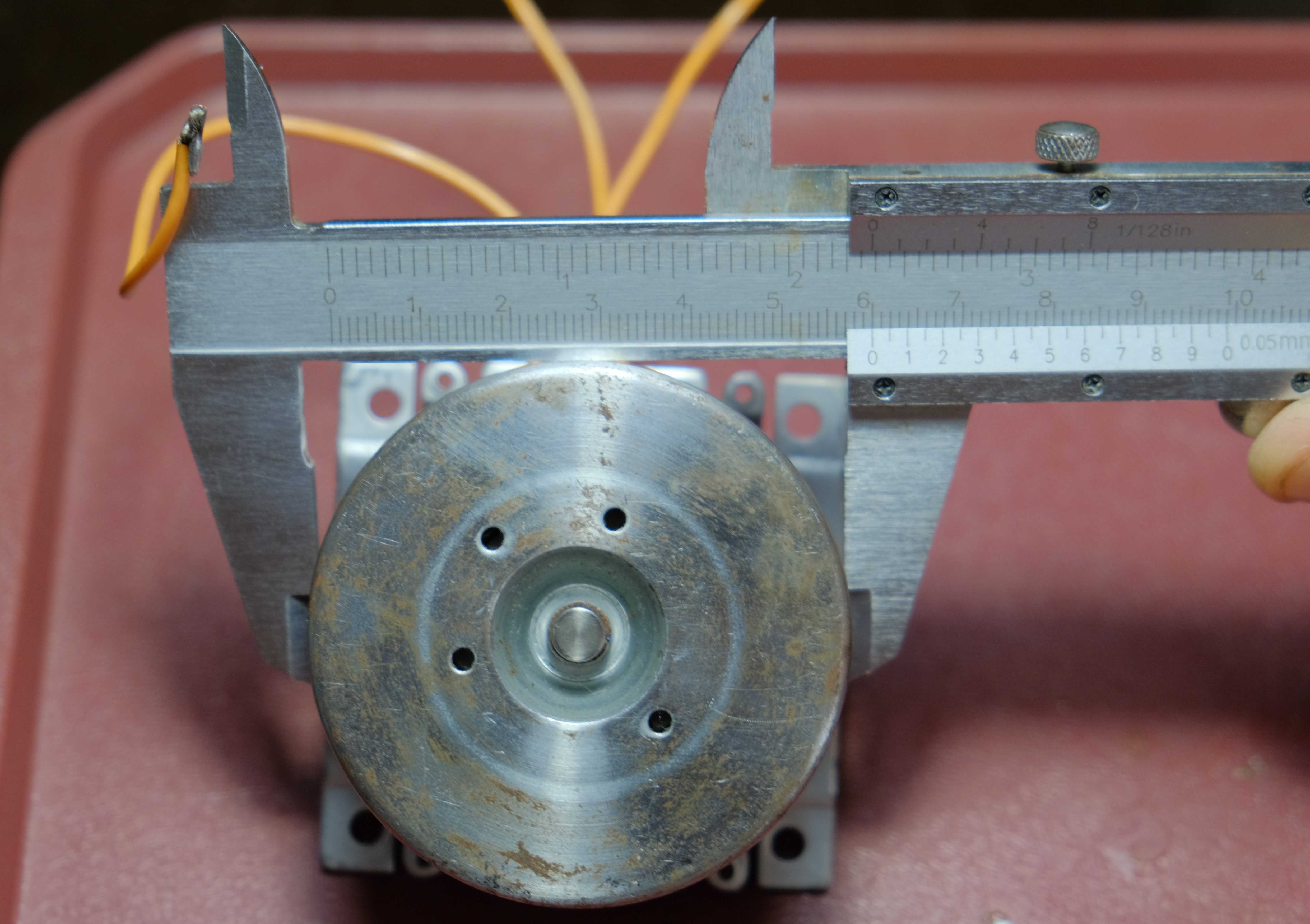

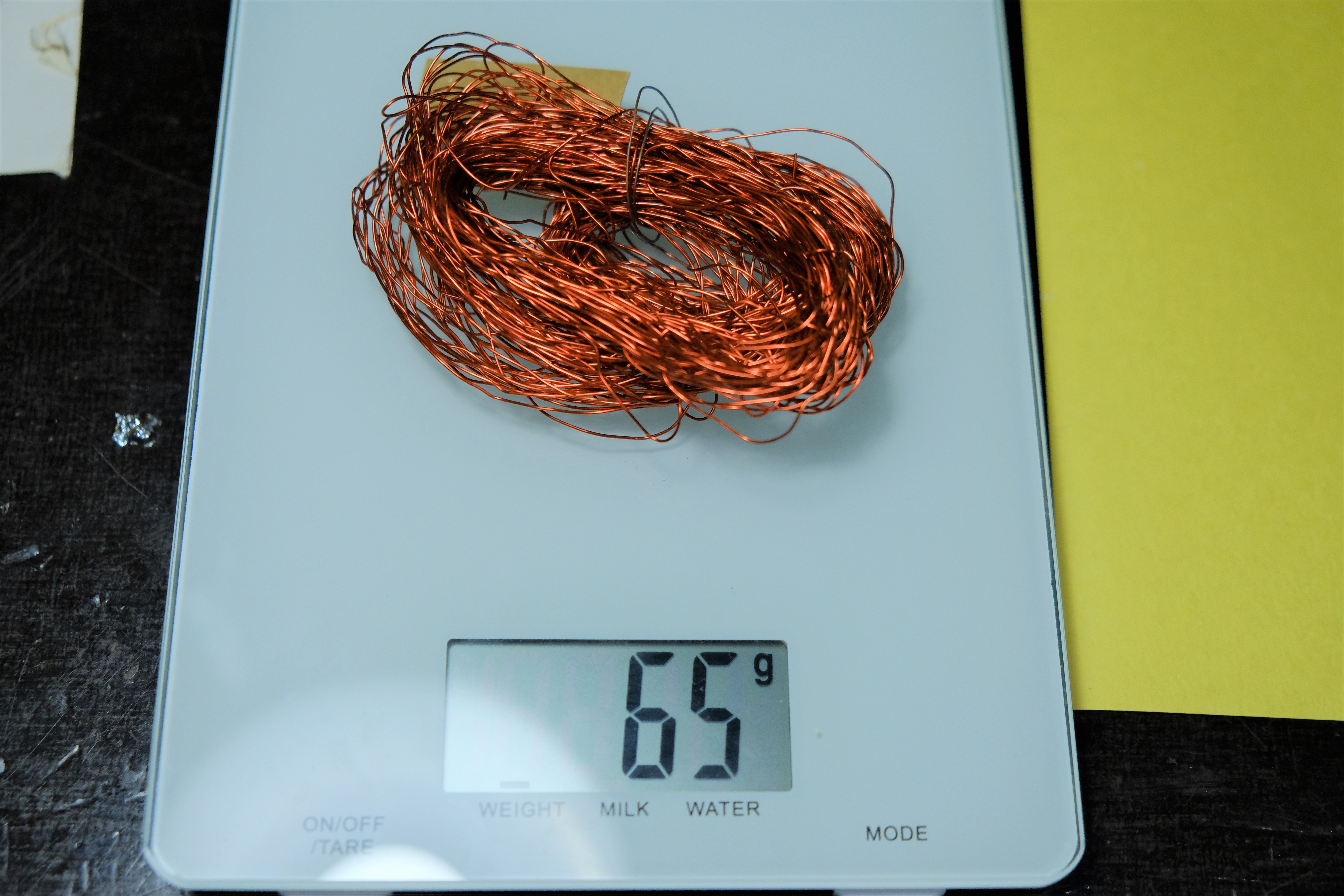

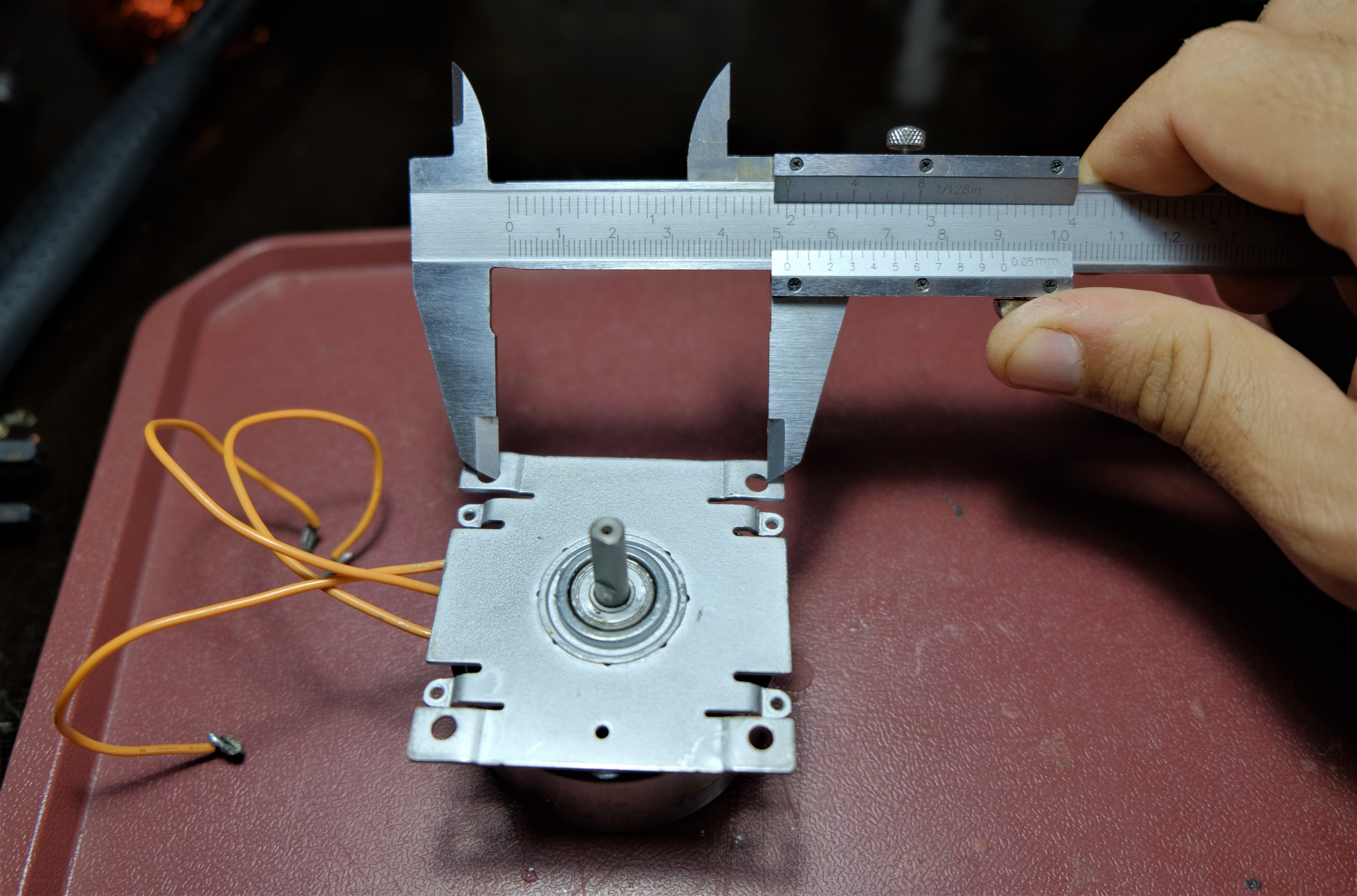

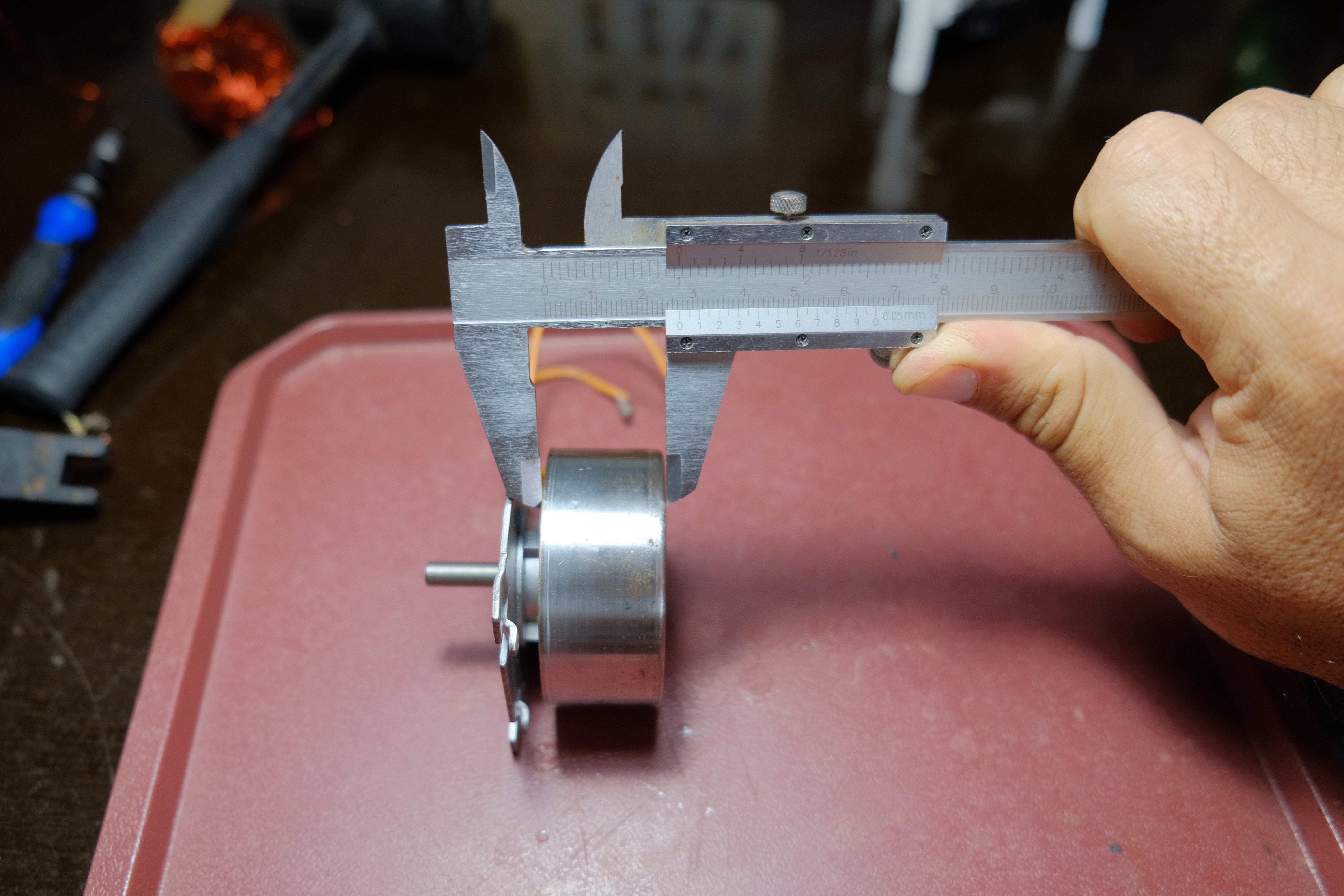

Prototype 4 has already been designed and features a modified BLDC motor as a generator. The same motor I once rewound from 35 turns per pole to 50 turns today is 80 turns per pole (12 Poles in total) using a thinner wire gauge (0.35mm diameter) and improving my winding skills lol. It was connected in a star configuration with three phases. In the next log I will explain its electrical performance, but let me tell you that due to the previous tests that I have been able to carry out, it perfectly meets expectations and exceeds the stepper motor of Prototype 1 in generation.

I leave you some photos of the process and a small demonstration. Thanks for reading. You guys are all amazing. See you in the next Log!!!

adriancubas

adriancubas

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.