Since the very beginning of this project in may, things have evolved a lot. I am now extremely honored to be one of the finalists of Hackaday Prize 2022.

Consequently the project has followed its own track and is now significantly "bigger" than in spring!

My advice, not to be lost into the various pages and logs, would be to read the whole description (this long page!) and then jump into the logs.

Alternatively here is a Table of Content that you can follow to directly access specific topic into logs.

Table of Content

building the frame

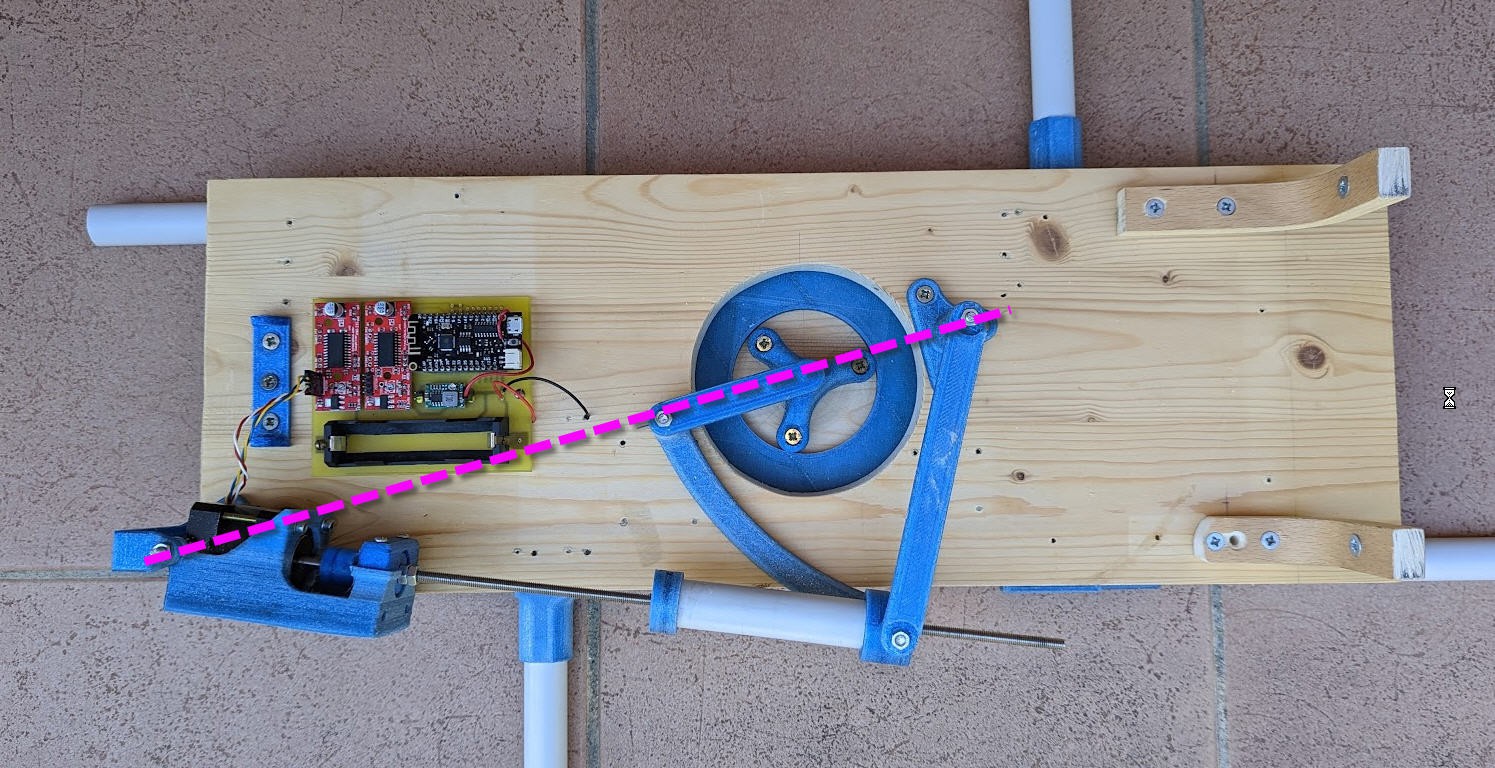

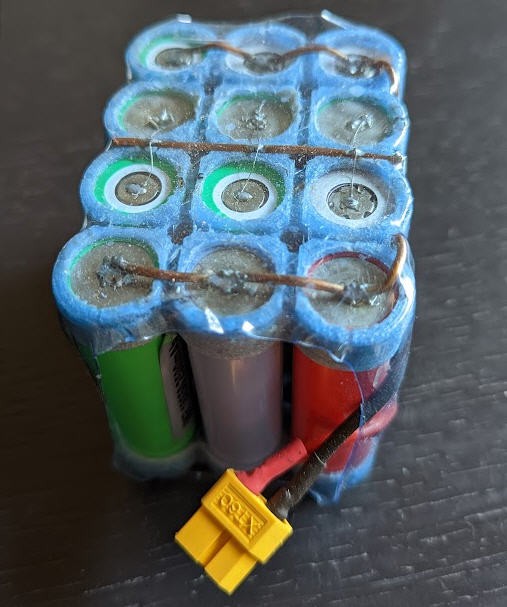

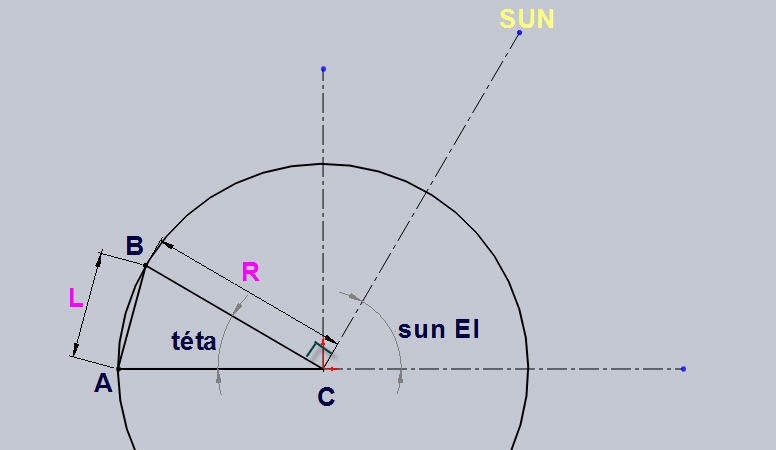

building the Solar Tracker

- mechanics

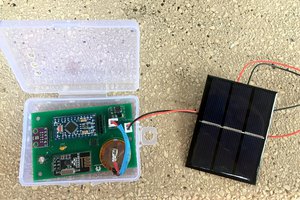

- electronics

- pcb

- calibrating the solar tracker (version with worm gear on Azimut axis)

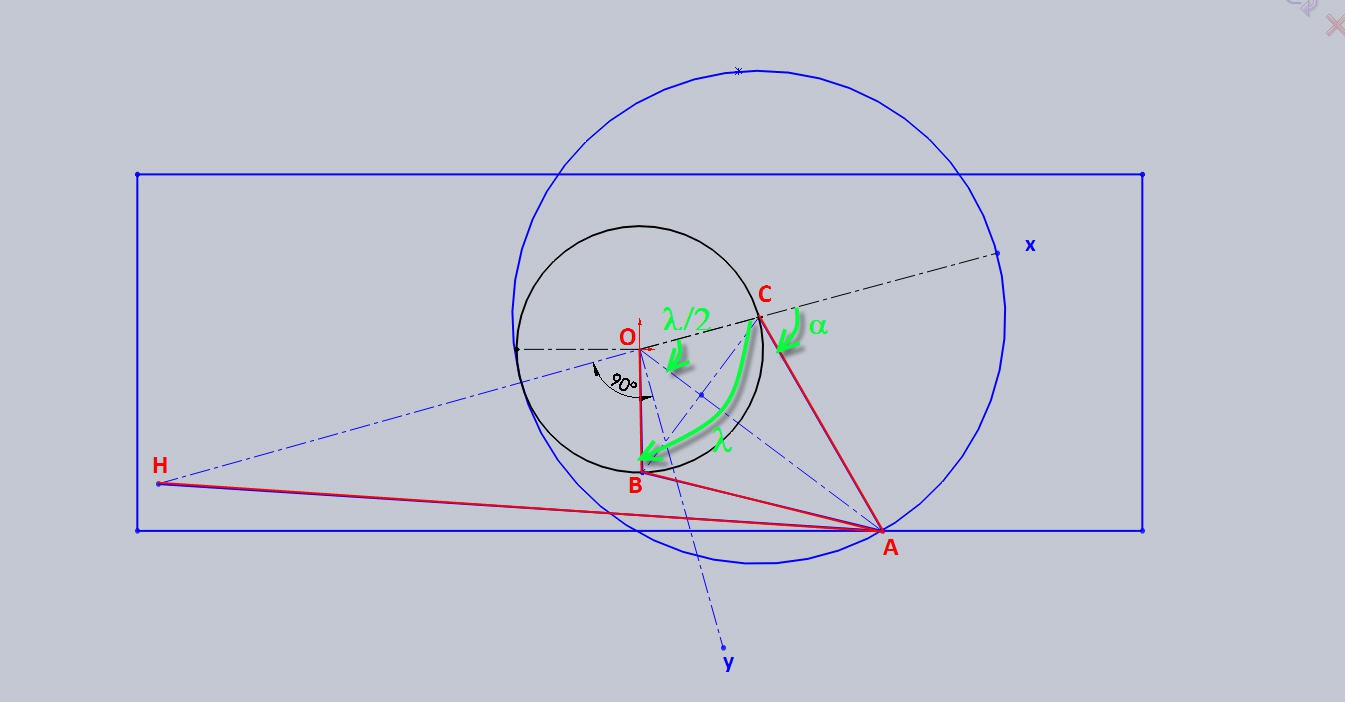

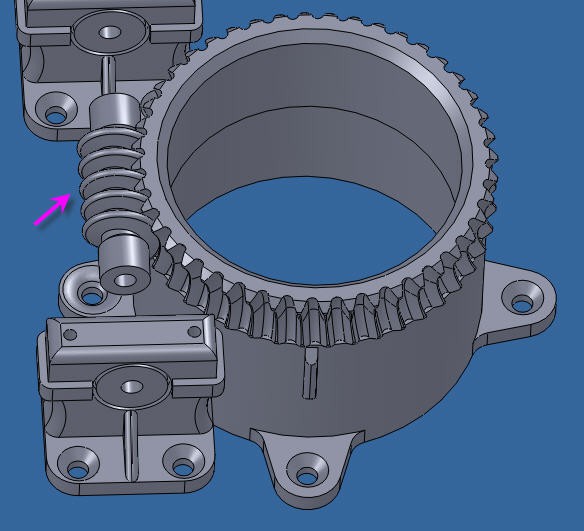

- equations of motion (version with worm gear on Azimut axis)

- firmware lite version

- Android App panel orientation lite version (version with worm gear on Azimut axis)

- Automating the Solar tracker initialization (version with worm gear on Azimut axis)

- V2 source code for firmware and Android panel Orientation App

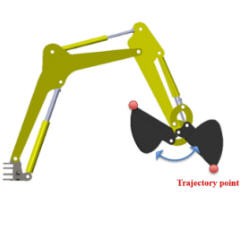

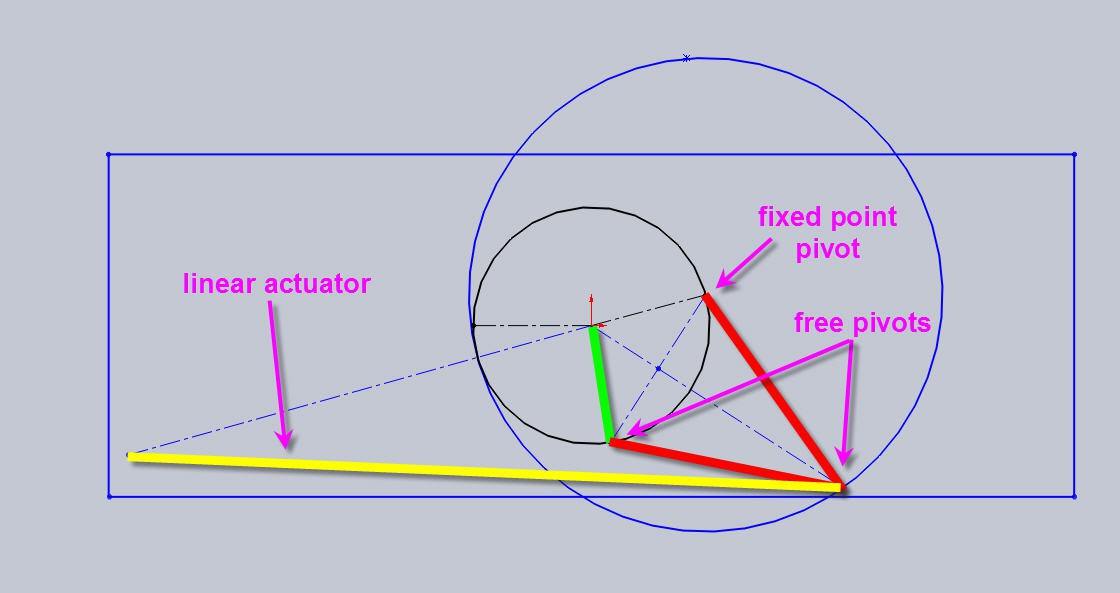

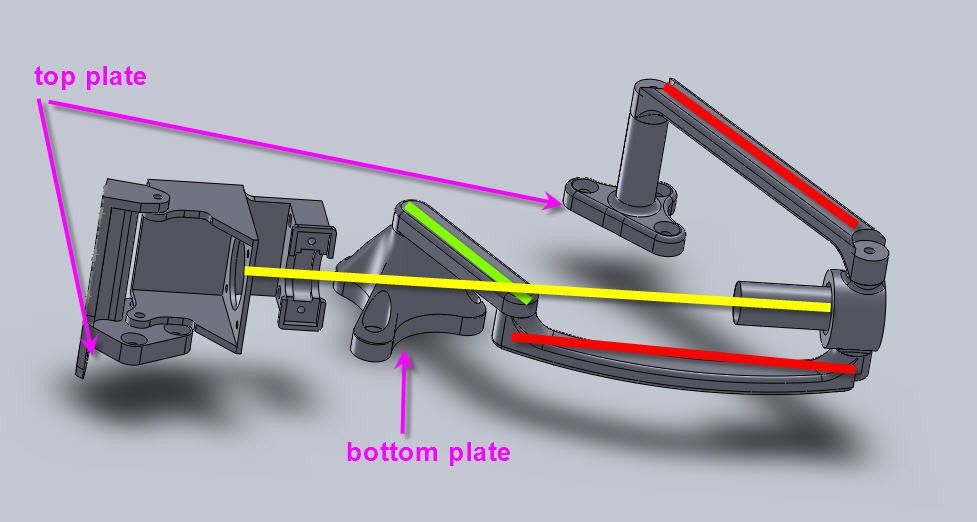

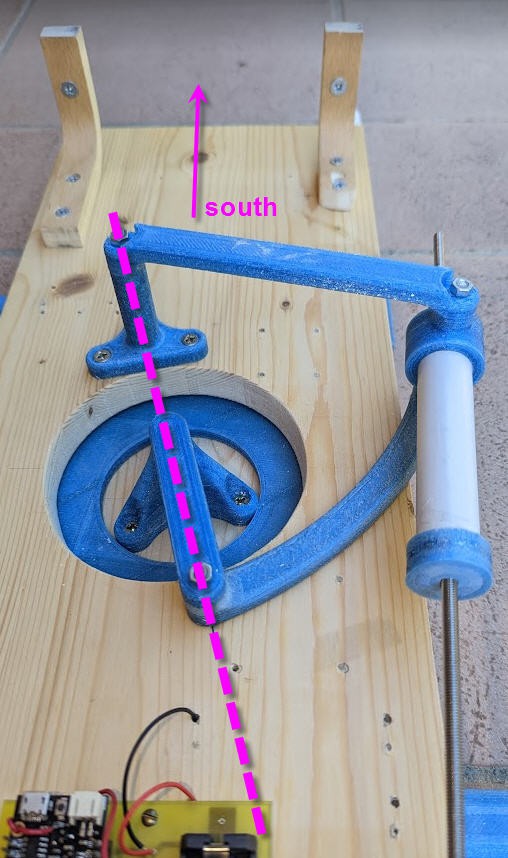

- a fully new Azimut axis mechanics

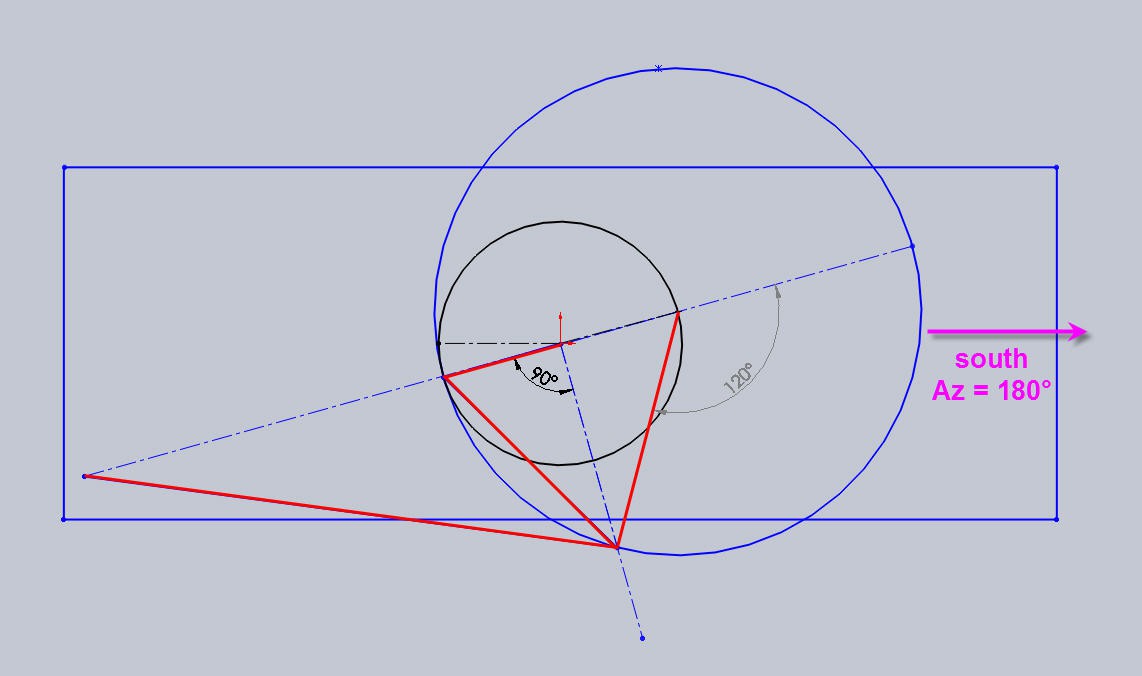

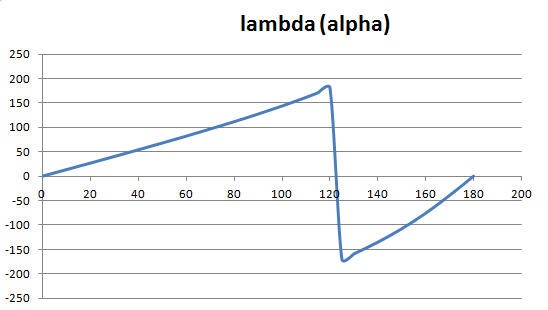

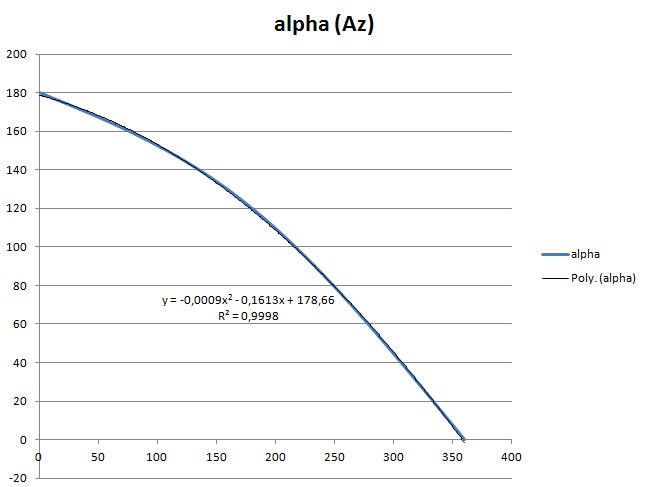

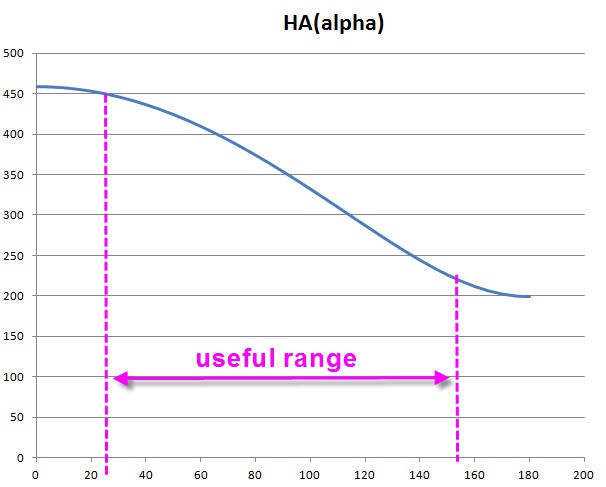

- new Azimut: equations of motion

- a new auto calibration procedure (version with linear actuator on Azimut axis)

- publishing v3 source code for firmware and android app (version with linear actuator on Azimut axis + 4 hours timelapse video)

building the MPPT Controller

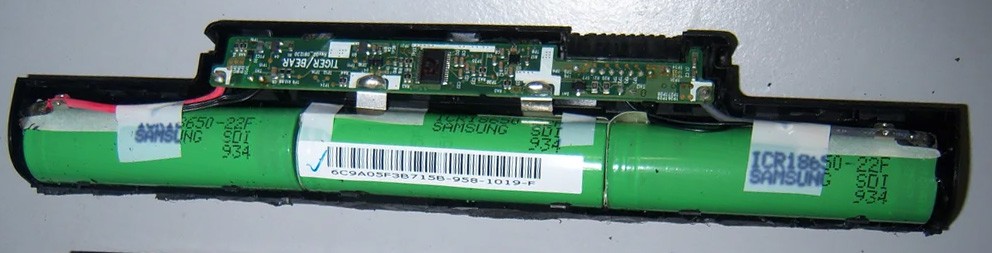

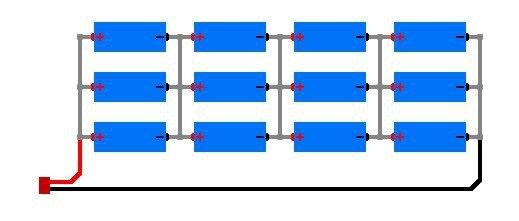

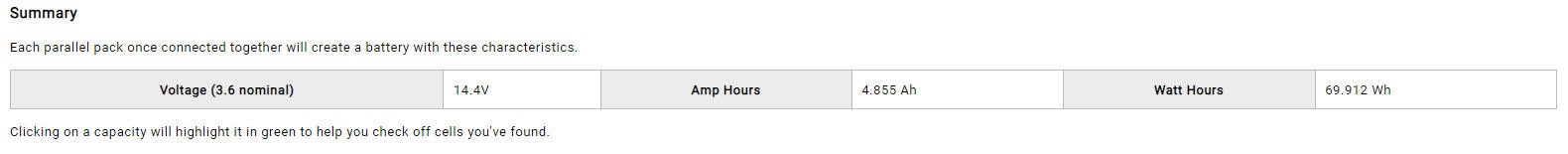

adding power storage

using the system

going further

The true story

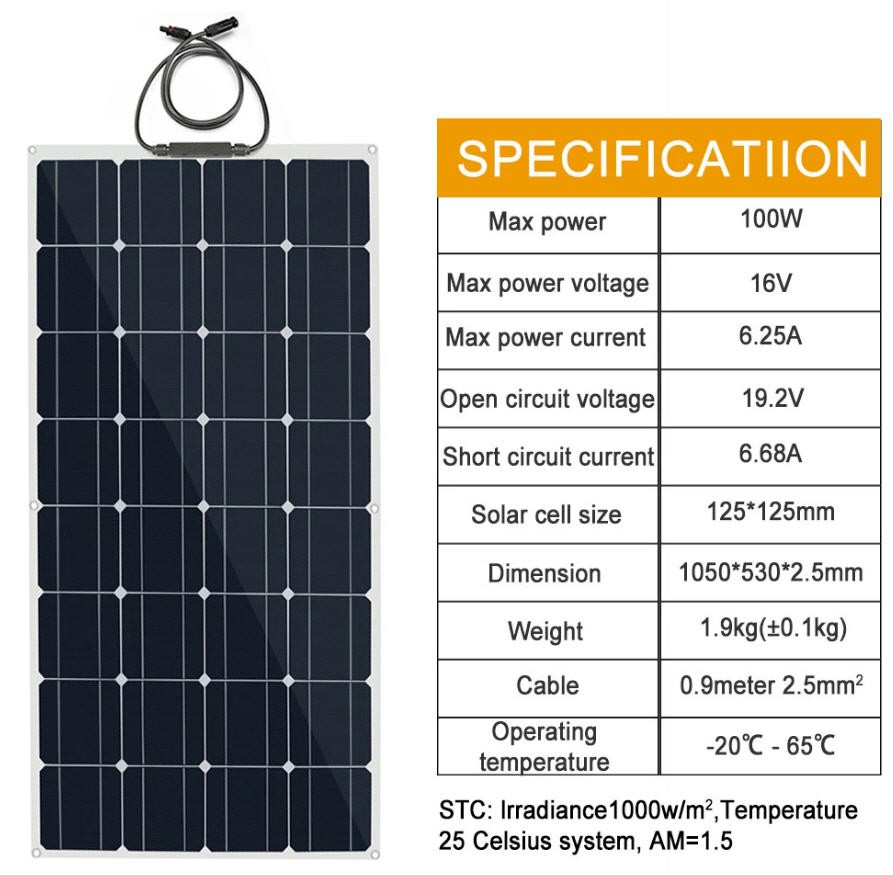

I started this project after buying this 100W flexible solar panel during BlackFriday last october.

These panels are quite cheap and are very light (less than 2kg). They are thus well positioned to design a portable system.

Here in Europe it was the beginning of the winter season and I very soon discovered that a solar panel rated at 100W never produces such a power in winter times...

So I started to imagine a system to harvest the most possible power from this solar panel while preserving two main objectives that I fixed to myself :

- keep it as cheap as possible (as it was for me a hobby and a way to discover real problems with PV panels before thinking to equip my house with a Pro installation)

- keep it portable, ready to go, easy to operate and light (I wanted to be able to carry this panel in the fields to recharge my Parrot Disco flying wing batteries or to use it in a camper van !)

Finally, to be honest, this project wasn't intended to participate to the Hackaday's contest.... But when I received the reminder mail (two days before the deadline) and read the objectives of this contest... I frankly believed that with no effort I was completly inline with the Planet-Friendly Power themes :

"Build a hardware solution that lowers the cost of clean energy, through energy harvesting and/or storage efficiency improvements."

In the following sections I will cover the design of

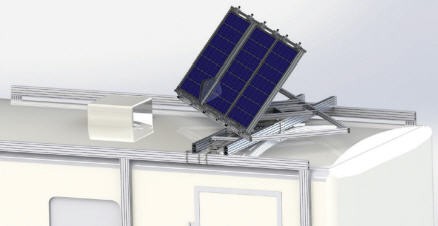

- the frame for the PV panel

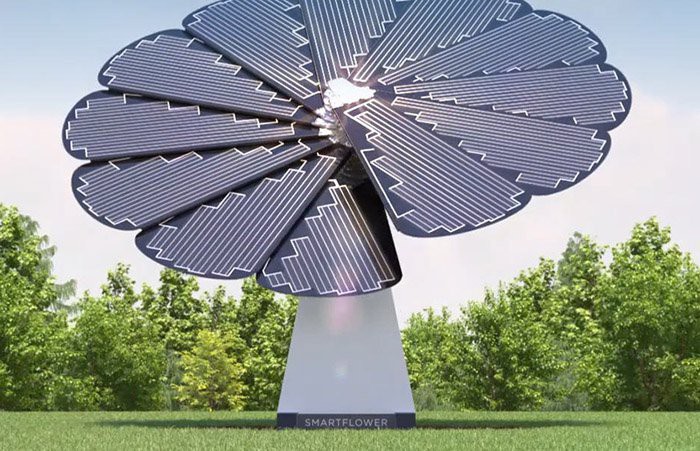

- the solar tracker system

- the MPPT controller

- adding battery pack

And you will soon see how my design lowers the costs while improving efficiency of energy harvesting with solar panels !

Everything wil be open source either hardware or software, so you will be able to build your own whenever you want !

Currently (may 22) I do have a working prototype, but even if a lot has already been done, there is still a lot of job to clean the code and to improve the operations. Stay tuned !

The frame

Adding a frame to a flexible panel was an absolute necessity !

Furthermore this frame should be "scalable" to be reused for the solar tracker system

I wanted the frame to be light and cheap, so I forgot using metal and jumped to a "full plastic" solution.

Considering the low cost approach I decided to build it around cheap 20mm PVC pipes used for electrical...

Read more » JP Gleyzes

JP Gleyzes

Tobias

Tobias

Dan Julio

Dan Julio

Gos

Gos

Amazing work! I can't wait for the parts to arrive from China so I can replicate your invention.