This project log summarises the work in the Integration Report and the Testing Report. For more detail on any of the stuff in this log, check those reports out.

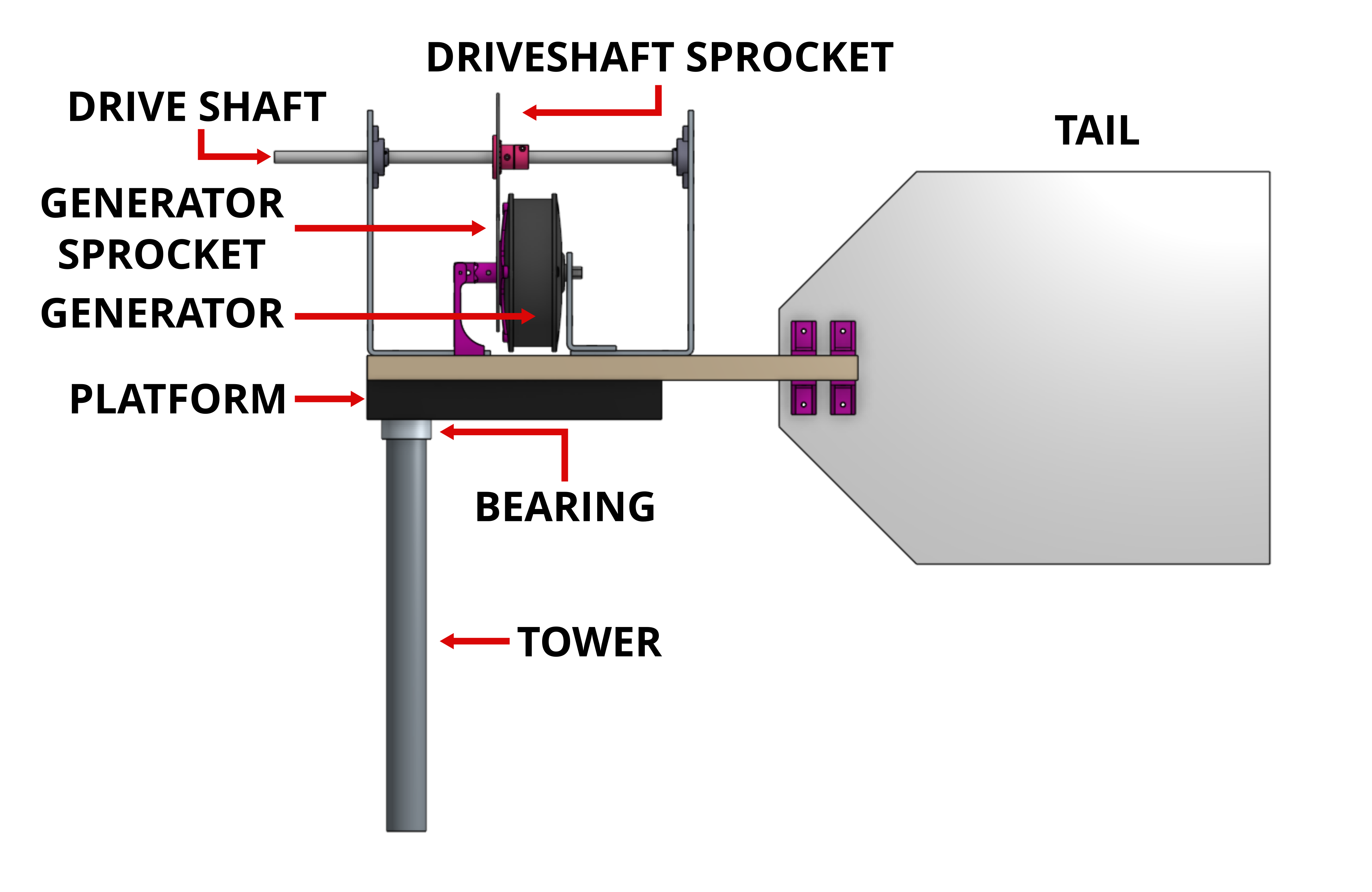

With a rotor design complete, it was time to work out how that rotor was going to be mounted to the fenceline, and how the drive shaft was to be linked to the generator. Figure 1 shows the CAD model of the nacelle and tower. This OnShape model is linked to on the main project page.

The rotor discussed in the previous log clamps onto the drive shaft. There are then two steel braces holding the driveshaft in place with two bearing blocks. These braces are bolted to a baseboard, which is connected to the main nacelle platform. This platform is a recycled scooter, with the main shaft of the scooter sliding into a steel tower pole that is firmly mounted to the fenceline. With this bearing sitting at the top of the pole, the turbine can be designed to have any desired range of motion, to allow for wind tracking.

In the video above, this setup can be seen. The rotor is connected to the driveshaft, and the nacelle is mounted in the tower post. As this was an initial test of the rotor there is no link between the driveshaft and the generator.

Rotor Velocity Testing

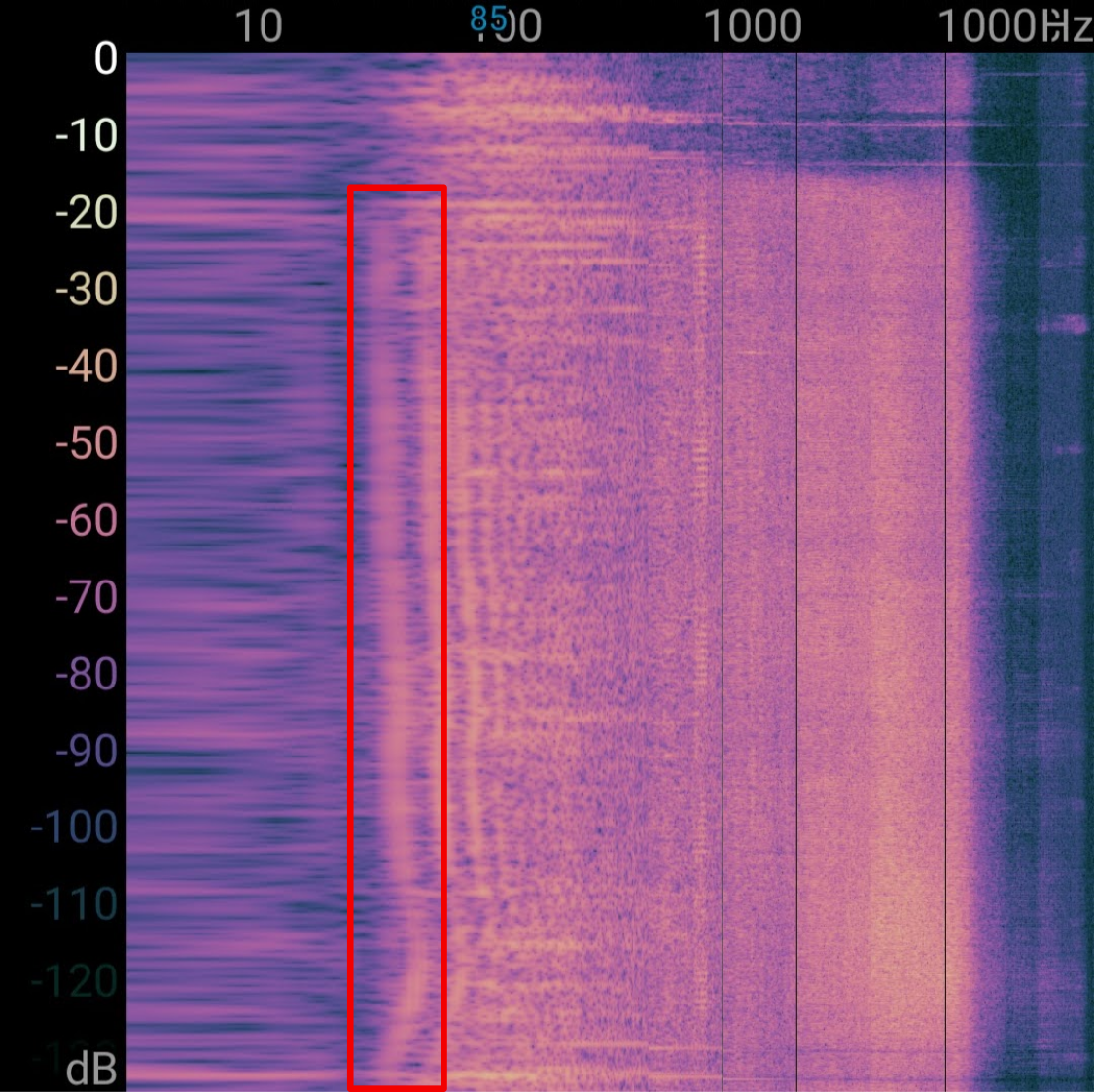

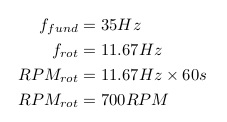

Calculations in the Blade Design Report indicated that for a tip speed ratio (TSR) of 7, in an average windspeed the rotor would operate at around 700RPM. Figure 2 shows an analysis of the audio spectrum of a rotor test. Highlighted in red is a major frequency band that was only present while the rotor was operational, and died off when the rotor was stopped.

Given three blades on the rotor, it is reasonable to imagine that this frequency will be three times the operational frequency of the rotor. With the band at approximately 35Hz, calculations shown in Figure 3 found the rotor RPM to be approximately 700RPM. Having this number align with the theoretical model was pretty exciting, it indicates that the blade development methodology has some weight behind it.

Generator Integration

Once the rotor was shown to effectively self start, and spin up to expected speeds, it was time to integrate the actual generator and look at whether power could be effectively extracted. A set of sprockets and used chains were obtained from a bike shop, and my plan was to use these to modify the startup torque required from the rotor, and the operational speed of the generator.

Figure 1 roughly shows how these were to be set up in relation to the rest of the setup.

Figure 4 gives a close up image of the developed gear train. A number of chains were developed to allow for testing of a range of sprocket configurations.

Testing & Results

Initial testing indicated that for a TSR of 7, the startup torque required was too high and could not be generated by any of the fabricated rotor configurations. There is detailed discussion in my Testing Report on this topic, but the result was a shift to a TSR of 5, and a wider root section. A lower TSR results in a lower operational speed (Approximately 500RPM) allowing for a lower gear ratio, and a wider root section will increase the generated starting torque.

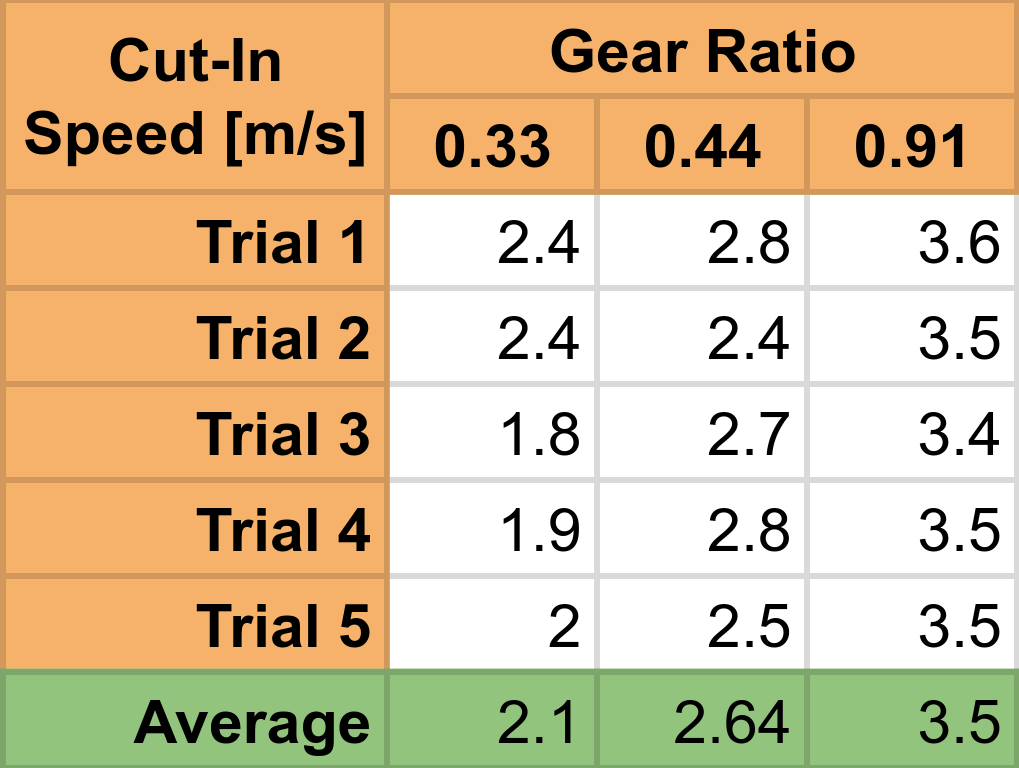

Testing then pivoted to analysing the impact of gear ratio on the cut in speed for this TSR 5 rotor configuration. Figure 5 shows the results of these tests. With a ratio of 0.44 or below, a cut in speed below 3m/s was achieved. This was important as the NIWA data obtained indicated that with a cut-in speed between 2 and 3m/s, 85% of the available wind could be effectively harnessed.

In terms of power output, there is detailed discussion on the small amount of power that was produced in the report. In summary, it wasn't much. At most the rectifier output 5.8V, producing between 0.2W and 0.6W. This is obviously far from ideal, given that the maximum power available in the wind is theoretically 145W.

Work From Here

The rotor works, and works pretty well. However, the generator poses some serious problems. Future work coul potentially look into either gearing the generator differently to provide a lower startup torque, and a high operating speed to ensure high output power. Alternatively, this work could look into stripping the copper wire and permanent magnets from the scooter motor, and winding a custom generator. This could allow a custom generator design that operates optimally at 500RPM, or even 700RPM. This could also be a good opportunity to remove the gear train entirely, resulting in a smaller nacelle and less complicated mechanics, which could minimise maintenance reuirements.

Additioanlly, future work needs to look into electronic control systems for electronic braking, and maximum power point trackin systems.

Sam Griffen

Sam Griffen

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.