In this log we will cover

- the temperature concern... is your hotend ok for PET?

- the slicer parameters

- how to protect your bed

PET printing temperature

PET, which stands for polyethylene terephthalate, it is a form of polyester (just like the clothing fabric).

PET is a polymer of ethylene glycol and terephthalic acid. Pellets of PET resin are heated to a molten liquid, which can be easily extruded or molded into almost any shape.

PET is a crystalline resin, a specific gravity of about 1.4, a melting point of 245 ℃, the molding temperature between about 290 ~ 315 ℃.

For Pullstruding the best "printing temperature" has been tested to be above 265°C and not more 270°C.

These temperatures are very high compared to PLA filament (190-220°C). If you do not want to destroy your printer you should verify that it is able to handle such a temperature.

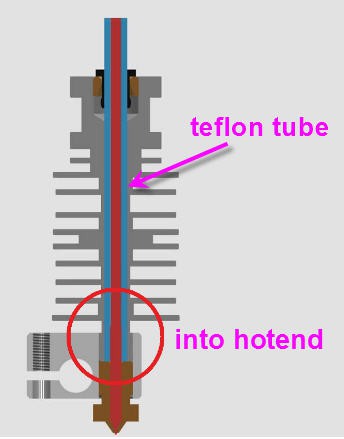

Issue will occur with cheap devices where a PFTE tube is inserted down into the hotend

In this configuration the tip of the teflon tube will heat and start to produce toxic fumes... It may clog the hotend and it is unsafe for your health.

DO NOT PRINT PET filament with cheap hotends...

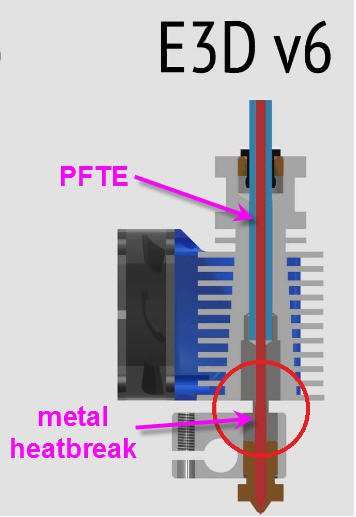

On the other hand, full metal hotends have a metal heatbreak so that the PFTE which is cooled by the top fan will never reach these high temperatures. These fullmetal hotends are safe to be used for PET printing.

This was the case for my Prusa i3 MK2S printer (and all Prusa's printers). It is equiped with a EV-3DV6 full metal hotend (I was lucky !)

Slicer parameters

Nozzle

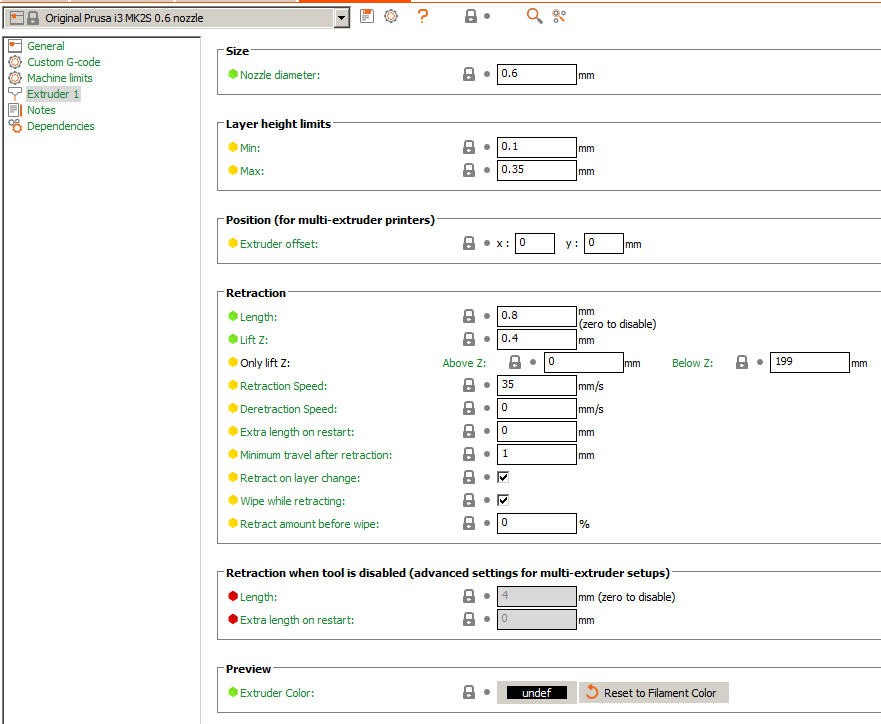

Let's start by the nozzle. I do use an old .4mm nozzle which is totally worn out. So that its diameter is now .6mm!

My advice is to print this PET filament with a real .6mm nozzle as it will help to print faster but also to be tolerant to slight variations of the filament diameter and thus will prevent clogging your hotend.

The settings under PrusaSlicer are the regular ones. No modification ...

filament settings

Your PET filament has not exactly the nice 1.75mm dameter of a perfect circle... It has rather the shape of a "C".

But don't worry, provided that you used a 1.5mm hole on the PullStruder side, then you can safely assume that it is 1.75mm filament.

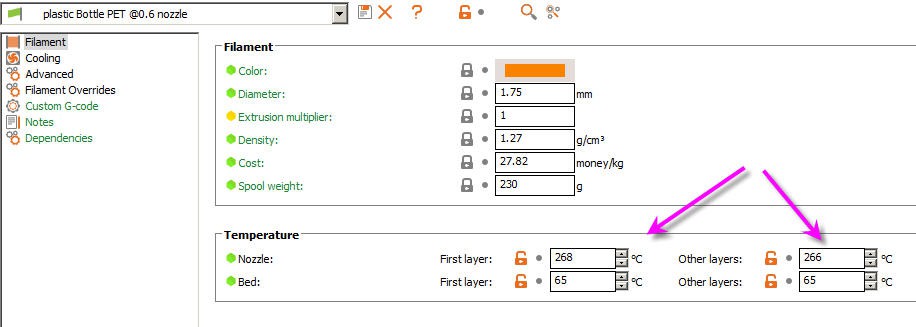

Start with all the settings of a regular 1.75mm PETG filament and modify these parameters.

You just have to change the temperatures (hotend and bed) as follows :

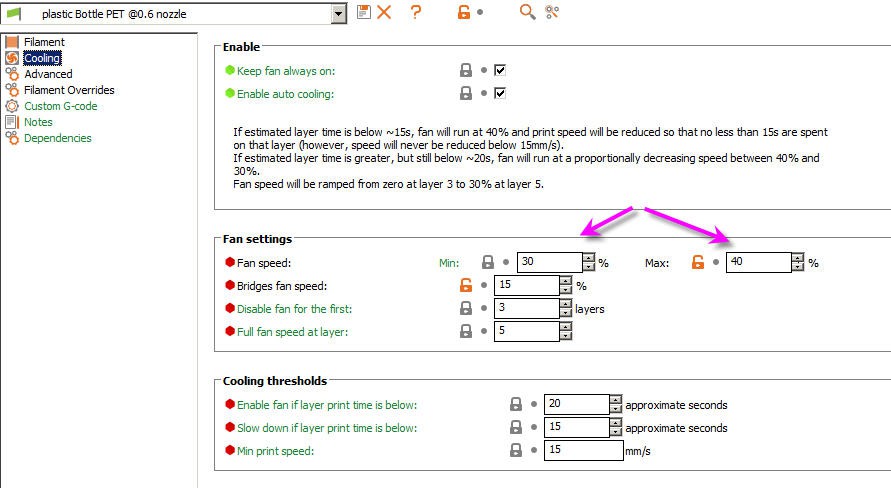

Now go into the cooling section and decrease the fan speed accordingly. These slow values prevent the "temperature runaway" error that may otherwise occur if the fan is blowing too much air on the nozzle...

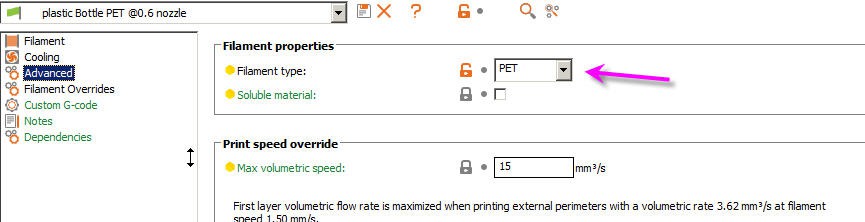

Now go into the "advanced" tab and just precise that you are using PET filament. Don't change the other parameters.

Print Settings

You can do pretty much what you prefer into this tab.

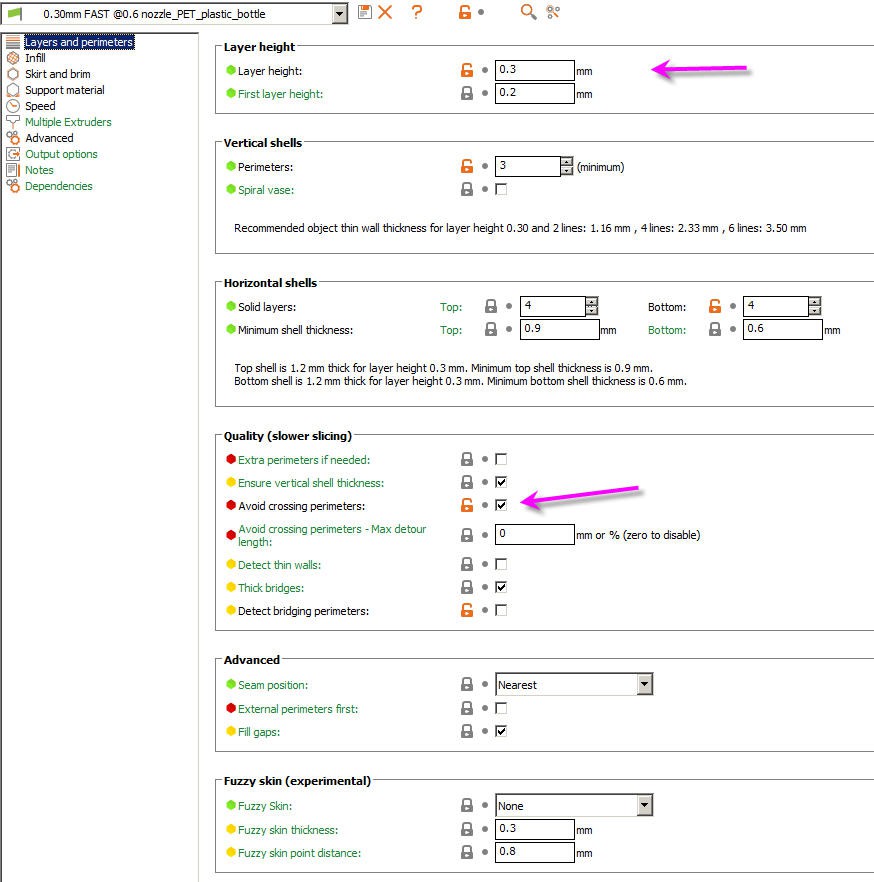

I did configure my printing to "fast 0.3mm" but you can of course stay to the standard .2mm.

More important, IMHO, is to tick the box "avoid crossing perimeters" it helps a lot to "hide" oozing and stringing into the printed parts !

Apart for this you can safely leave the other parameters unchanged from the PETG filament settings.

How to protect your bed

Do not try to print directly on a PEI sheet, the adherence will be too strong and you might destroy your PEI when removing the part.

Rather use Painter tape that you will stick on yor bed.

Happy printing with PET

JP Gleyzes

JP Gleyzes

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.