Specifications for Designed Size

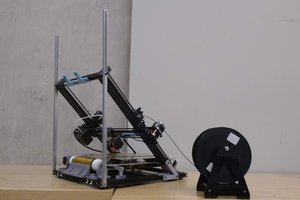

- Frame footprint – 500X520X750

- Print volume – 310X310X300

- Weight ~45Kg

- Option to print high-temp materials 300+

Join our Discord Server for all updates

Valkyrie Main Features

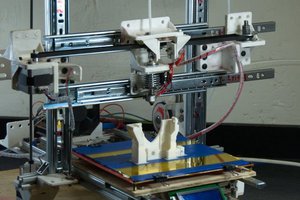

- Advanced Kinematics with independent triple Z axis

- Fully automated bed leveling

- Inverted CoreXY for minimal friction

- XUV Triple Z True Bed Leveling with Maxwell Coupling Criteria

- Stall-detection homing on all 2+3 – XY+ZUV axis

- Light tool-head riding on carbon X with MGN9h

- ABZUV stepper motors all located in the cold zone

- Temperature Controlled Heated Chamber <80C

- Engineered insulation options for high level of safety and minimal thermal loss

- High end ACM Outer Paneling

- Double glazed window for inside viewing and good insulation

- Integrated Temperature Controlled Heated Dry-box

- Filament weight control by load-cell

- Dry-box temp control <70C

- Dry-box humidity sensor

- Advanced Firmware add-ons

- Chamber temp controls and display

- Dry-box temp control and display

- Dry-box humidity display

- Filament weight display

- Extruder motor temp sensor and display

- Water-cooled hotend

- Option to water-cool extruder stepper motor

General Requirements

Product Choice

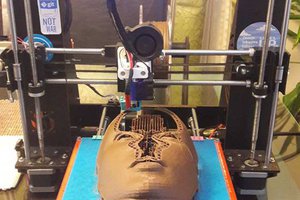

The aim is to develop a Premium DIY FDM 3d printer for the DIY 3d printer community

- Safety features must be very high

- Fully automated bed leveling

- Engineered advanced Z lift with kinematic coupling

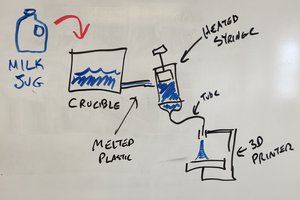

- Integrated dry-box filament container

- We want to be able to print high temp materials

- The project will be open source

- Size should be scalable < 500

- Standard alu profiles. 2040 or 3030

- Belted Z drive

- Advanced Firmware options

- Enclosed chamber with engineered insulation for <80C Chamber temp

Function Choices

The machine should have all the functions needed for a trouble-free user experience. The goal is to implement all basic functions plus any feature that is making an advanced high temp premium 3d printer

Competition

- Ratrig V-Core 3

- Hevort

- Voron

- BLV MGN Cube

- VZBot

The Development Team

Roy Berntsen – Norway – Lead Engineering Designer

Mark Bridgewater – New Zealand – Mechatronics Design

Cris Lombardi – USA – Firmware, Design and Advanced features

Roy Berntsen

Roy Berntsen

Swaleh Owais

Swaleh Owais

Eric Cantrell

Eric Cantrell

Mateo Miličević

Mateo Miličević

Jonathan Irwin

Jonathan Irwin