Teaching programming is hard. And it's not made any easier by the fact that before you even start teaching, you have to first do the ungrateful job of an IT support worker and get your students through all the hoops of installing all the necessary software and libraries on their computers. And when you finish, the programs they have written only works on their own computers, unless they go through all the same (and possibly some additional) hoops.

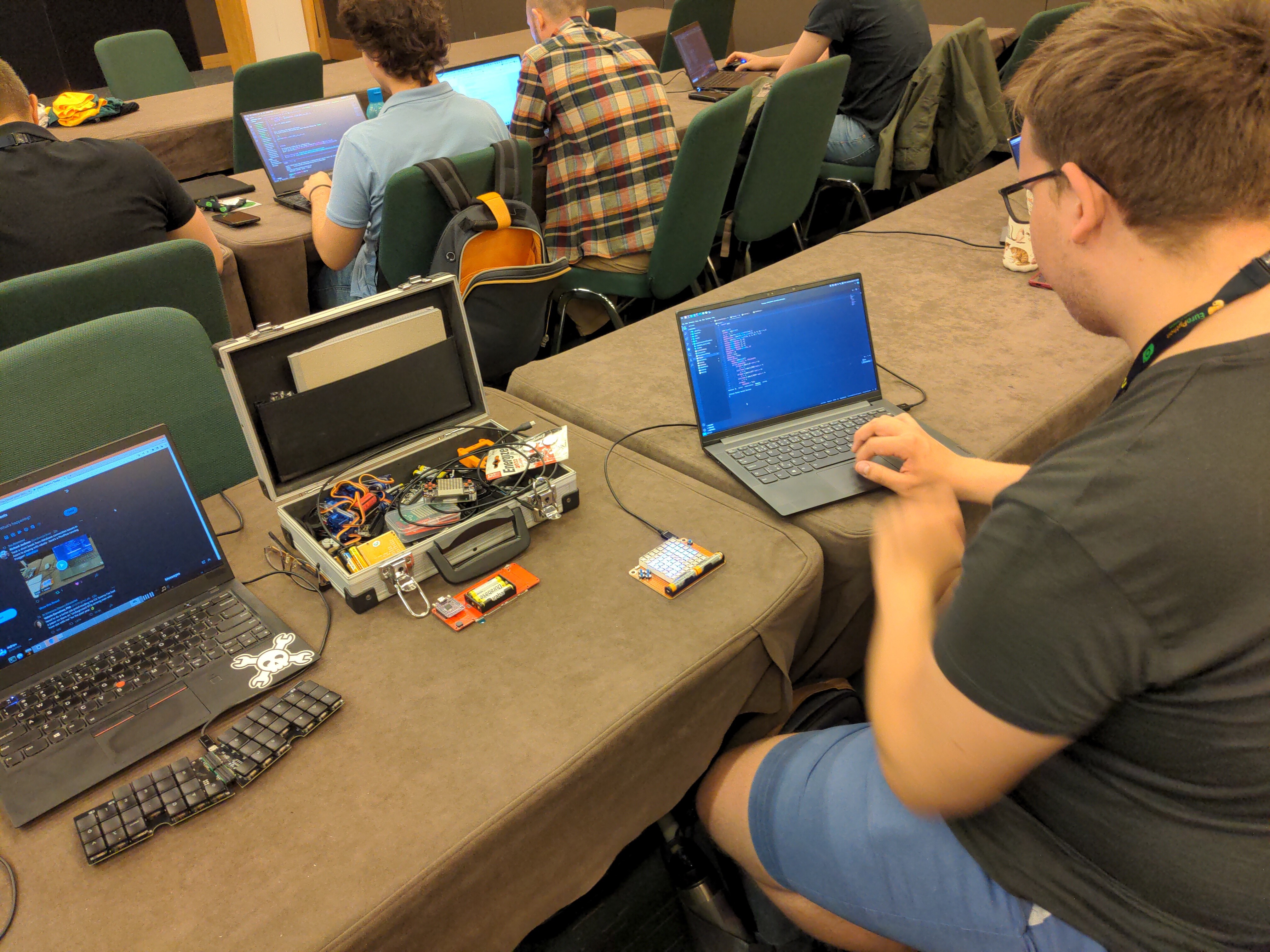

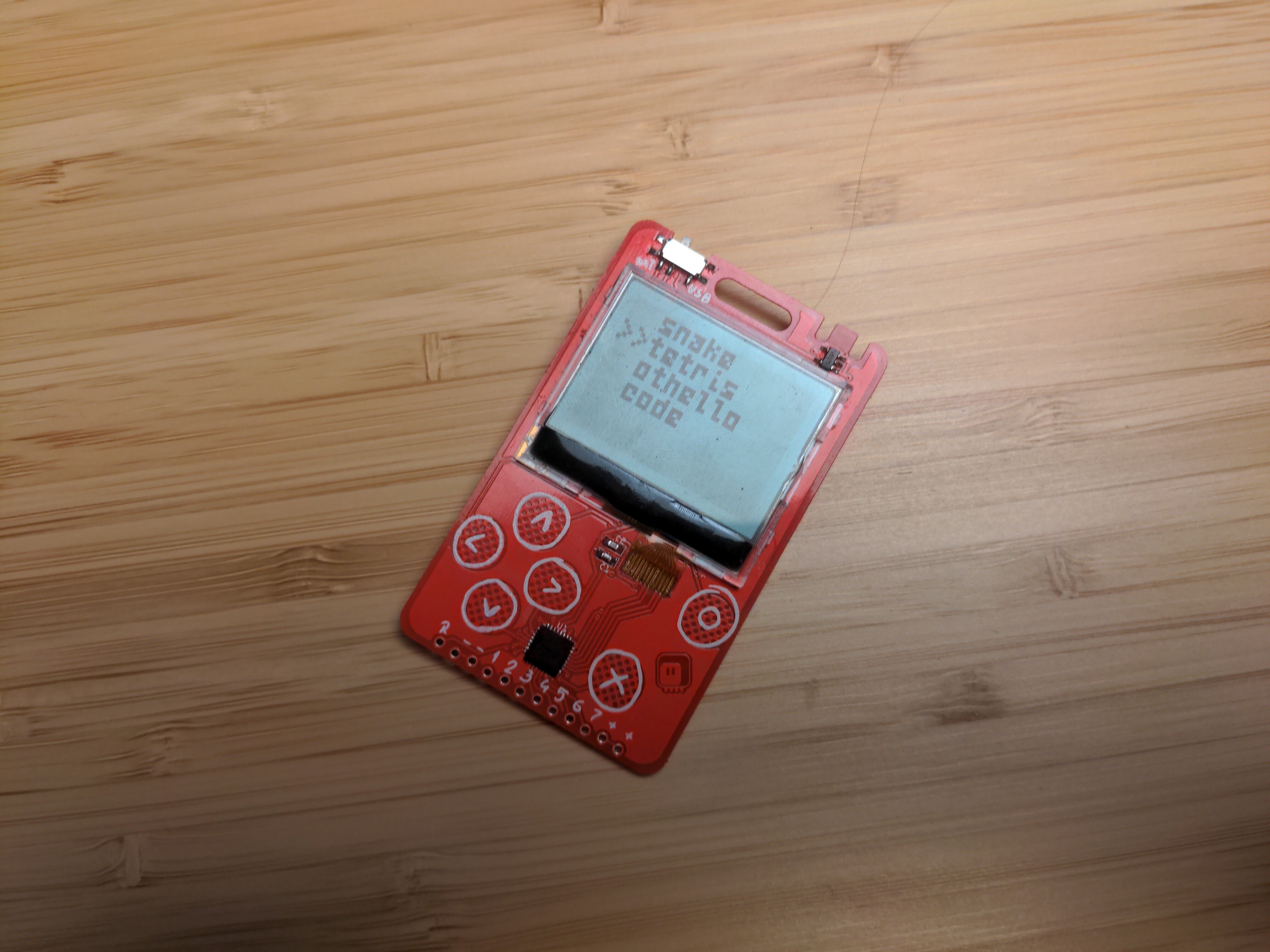

The PewPew family of devices is one possible answer to this. They are designed with one main goal in mind – to remove as many obstacles between your students and the game they want to create, as possible. To achieve that goal, the device itself has Python running on it – a version of Python designed for microcontrollers, called CircuitPython – so all you have to do is edit the files on it, using any text editor, to write your programs. As soon as you save, the device restarts and runs your code. In addition, if you want to show your game to other people, or enjoy it on the bus, you can simply put it into your pocket.

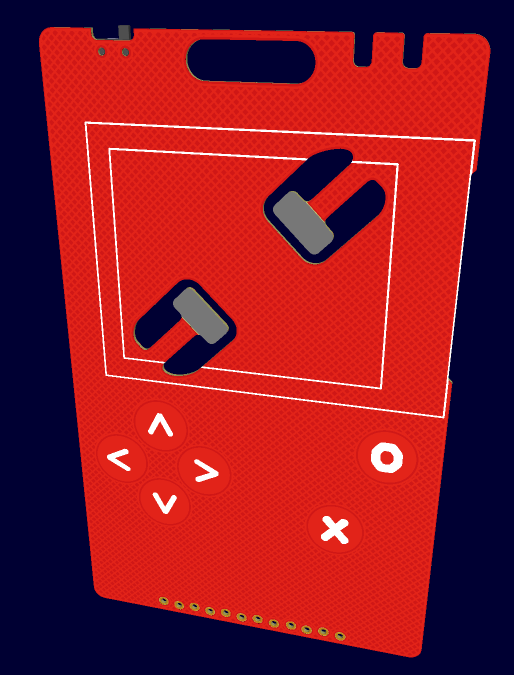

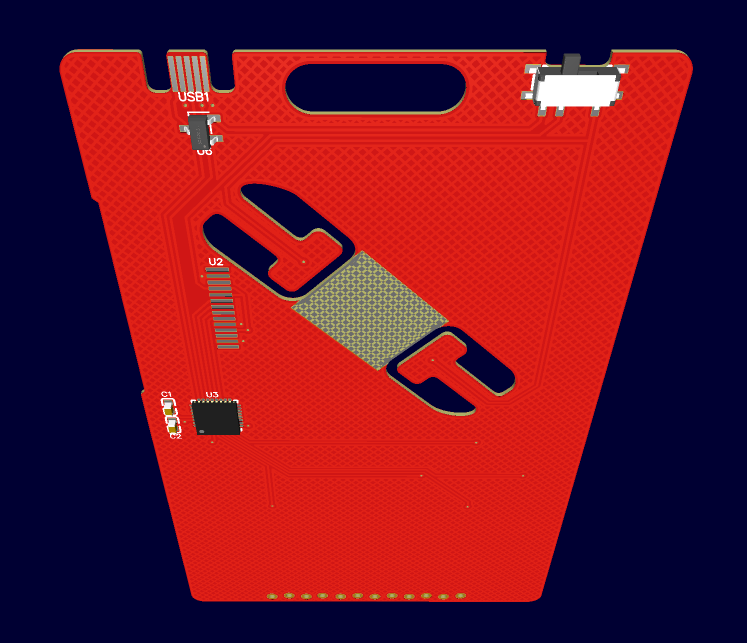

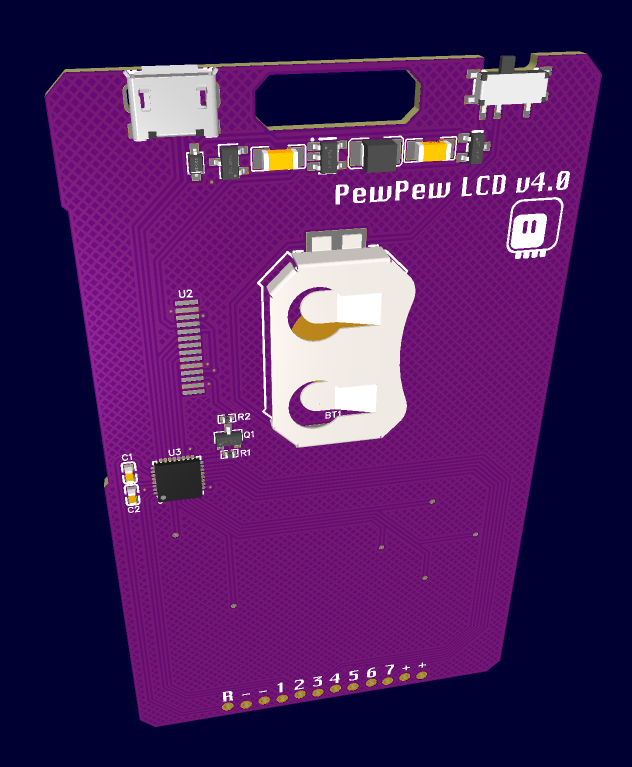

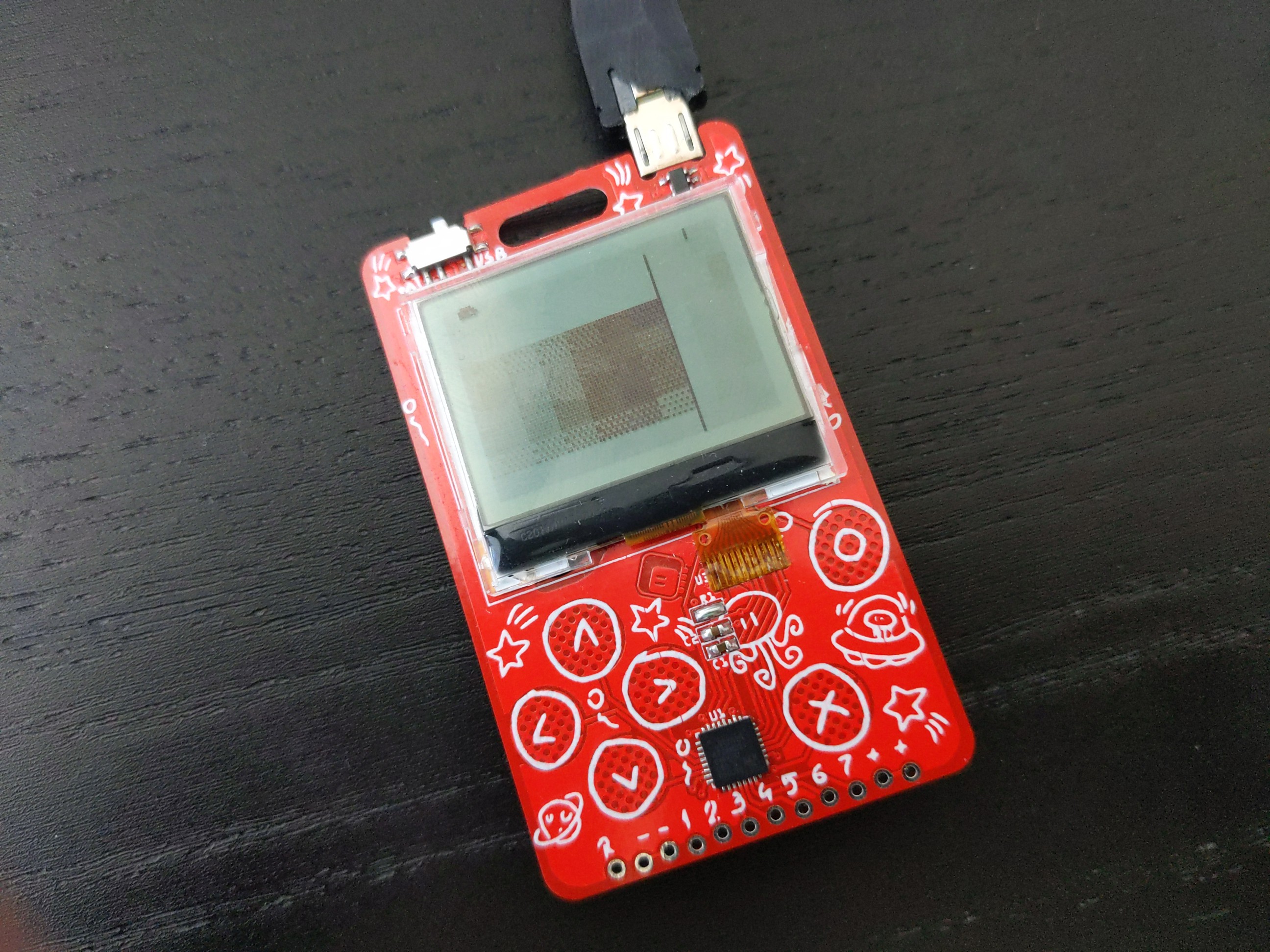

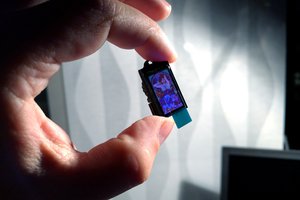

This is one of many devices in the family – I started with #PewPew FeatherWing and as I tried it in different workshops, I refined the design with #PewPew Standalone, #PewPew M4, #PewPew Slim, #PewPew S2 and #PewPew OLED. So far the standalone version has been the most successful, being simple and affordable, but later experimenting showed me that there is room for improvement.

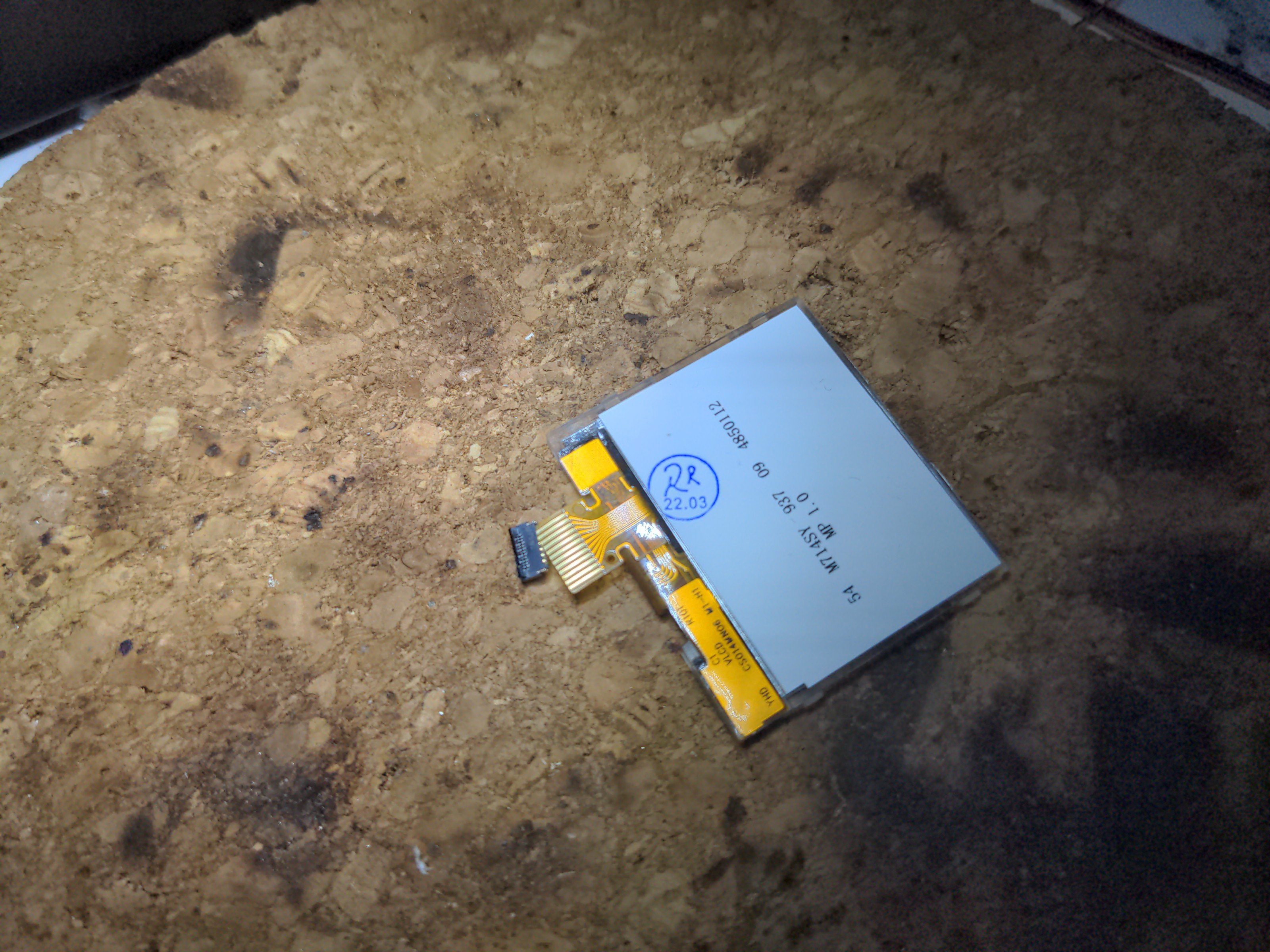

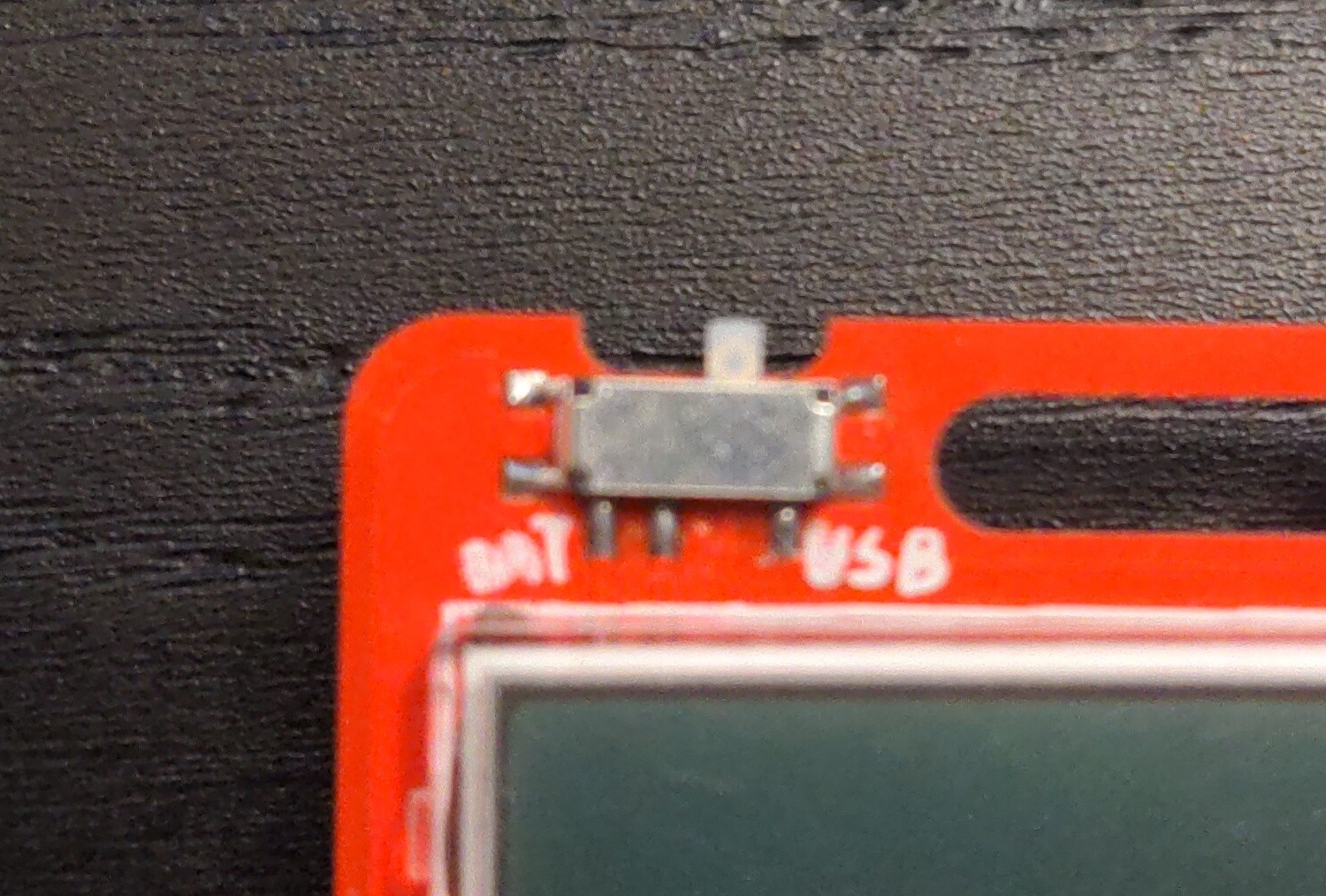

This time I want to design a device that is even simpler and cheaper than any previous one, while at the same time being more convenient to use, and maybe helping us find a use for some of the old electronic spare parts that lie around.

deʃhipu

deʃhipu

Well done, shows your high professional level