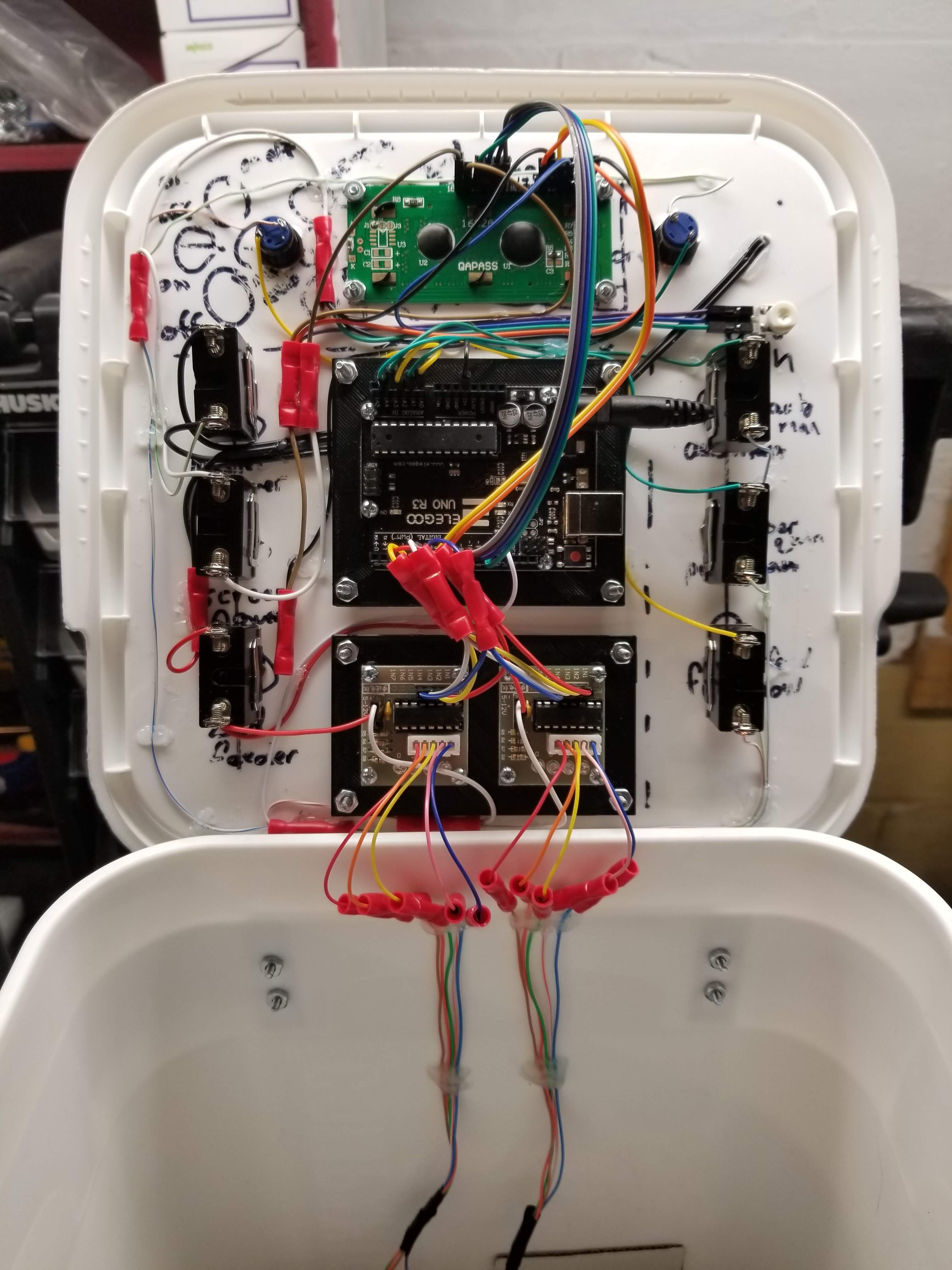

Many moons ago, I made a dual-cat feeder, using stepper motors and an Arduino. It had a lot of flaws.

- It was made out of a repurposed cat-litter container and was therefore very ugly.

- The cats discovered that if they picked it up with their claws and dropped it, they could shake food out of it.

- I knew very little about design, so it was very difficult to assemble and maintain.

- I knew very little about power, so it would shut itself off after each feeding, probably because of a overpower situation.

- I knew very little about components, so I used the suboptimal ones in many cases, like giant butt splices instead of solder sleeves.

- Most seriously, the stepper motors would melt and fail after a few days of operation, presumably due to poor quality controllers or incorrect implementation on my part.

I scrapped the project before a big move, but have been wanting to apply the lessons learned from that project to a new and improved cat feeder.

The requirements for this cat feeder are as follows:

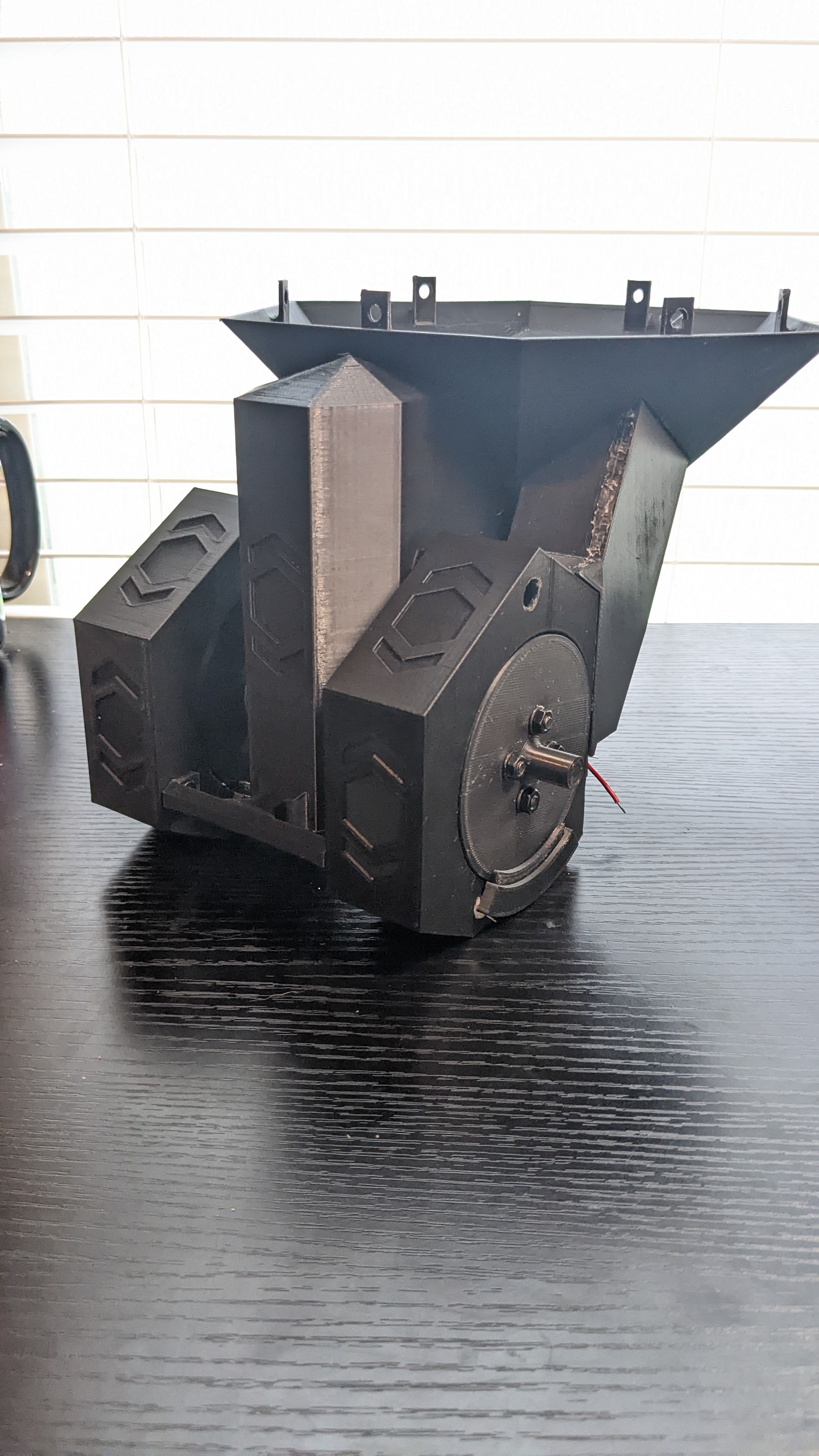

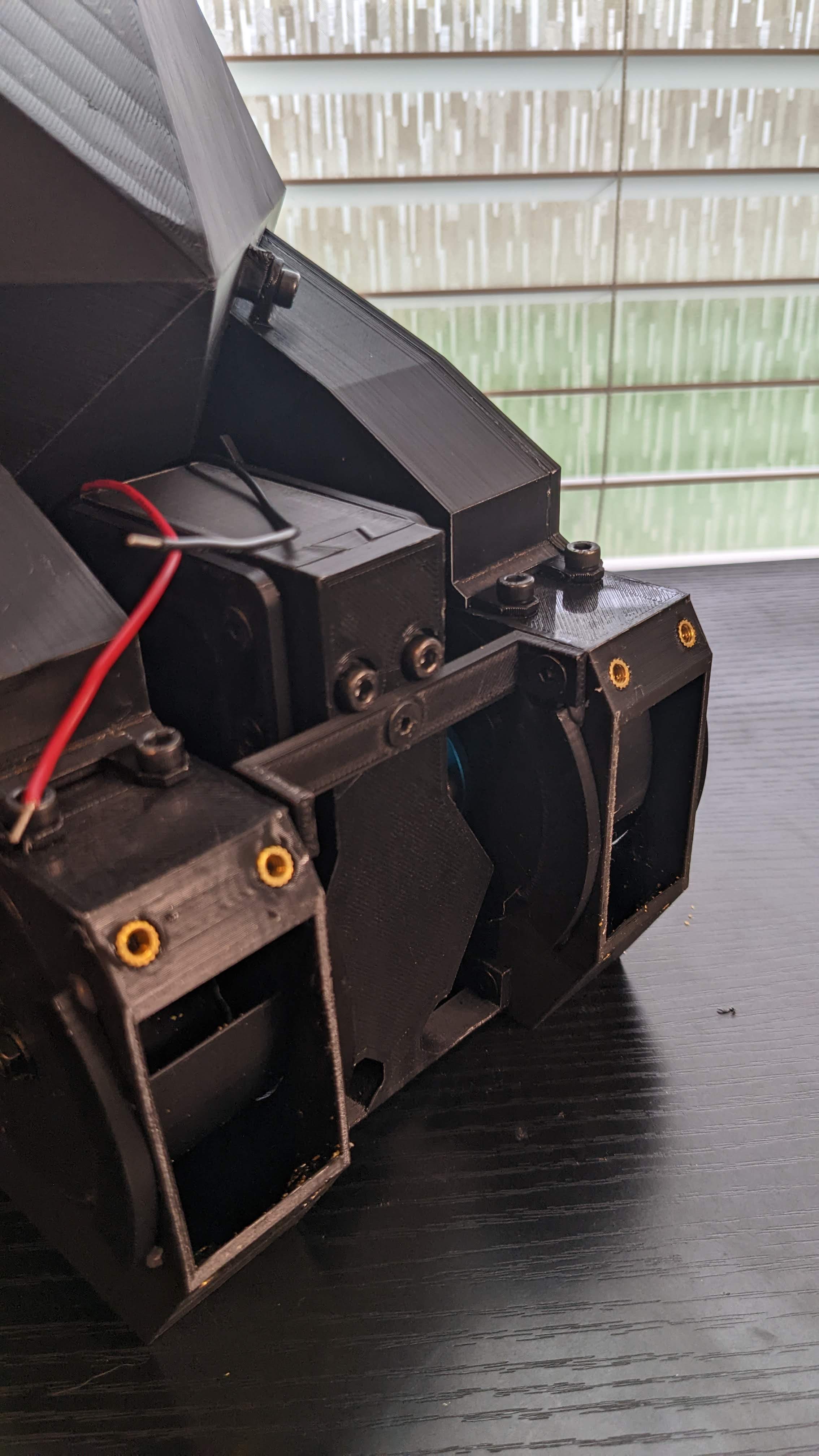

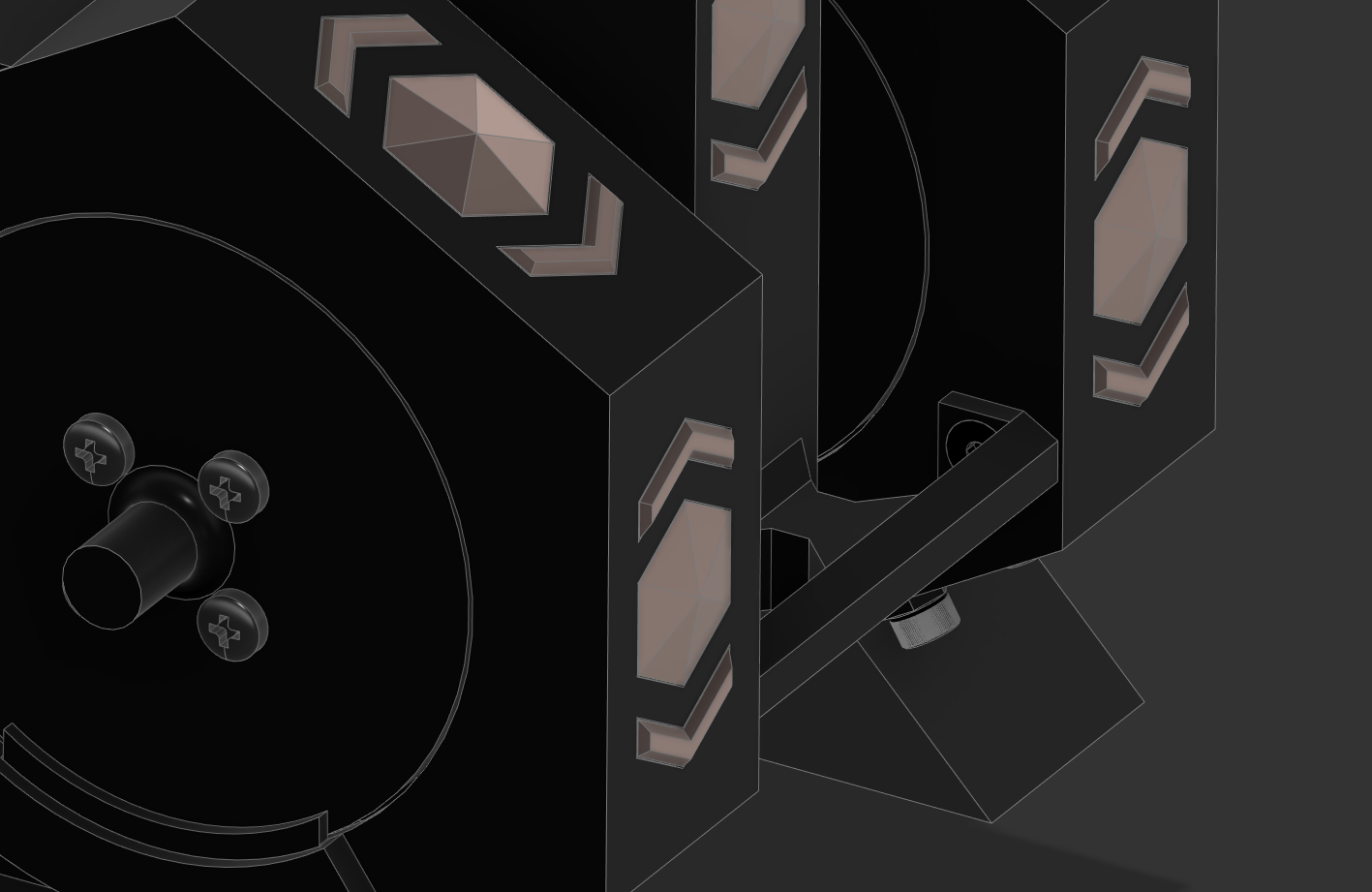

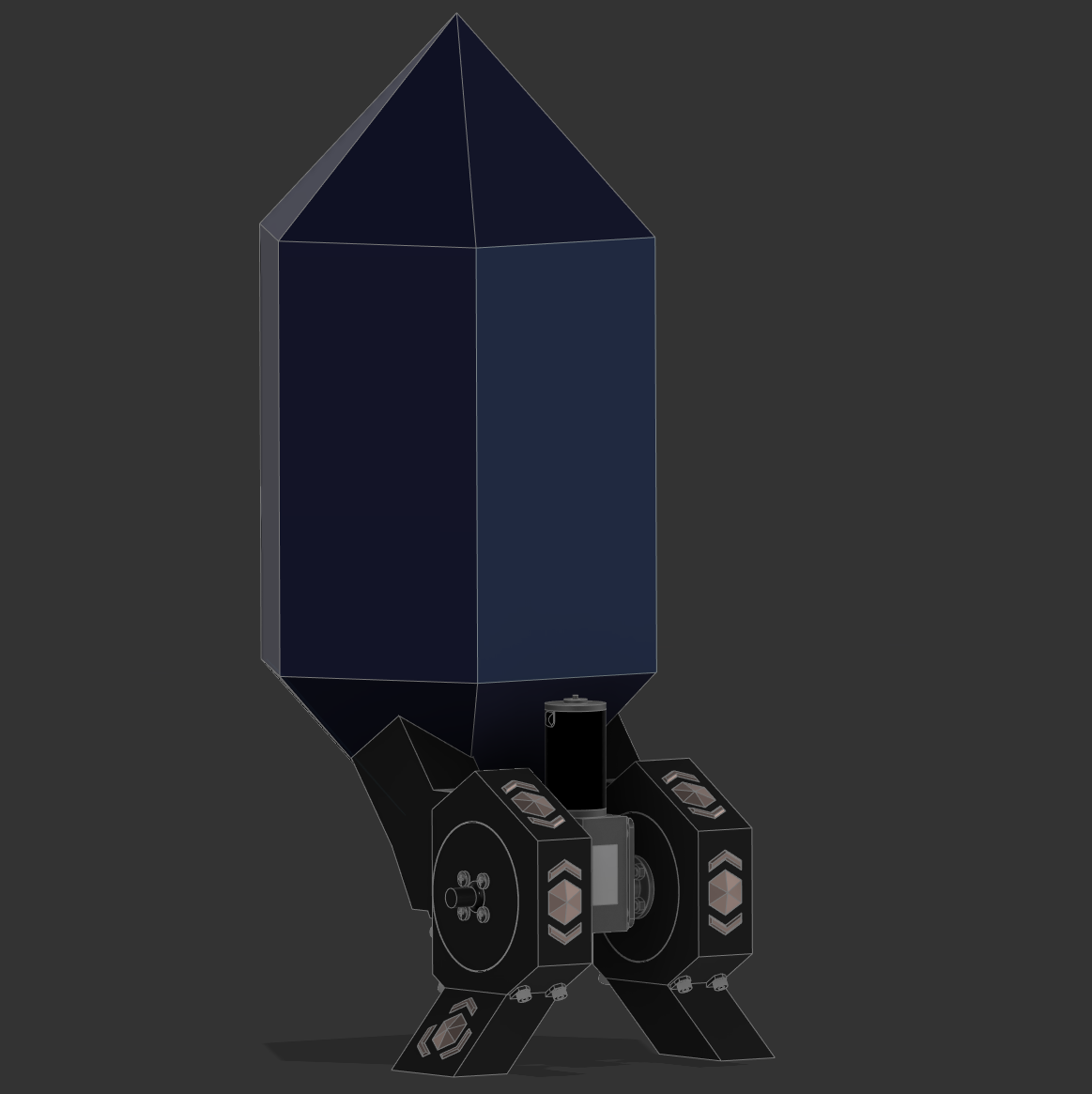

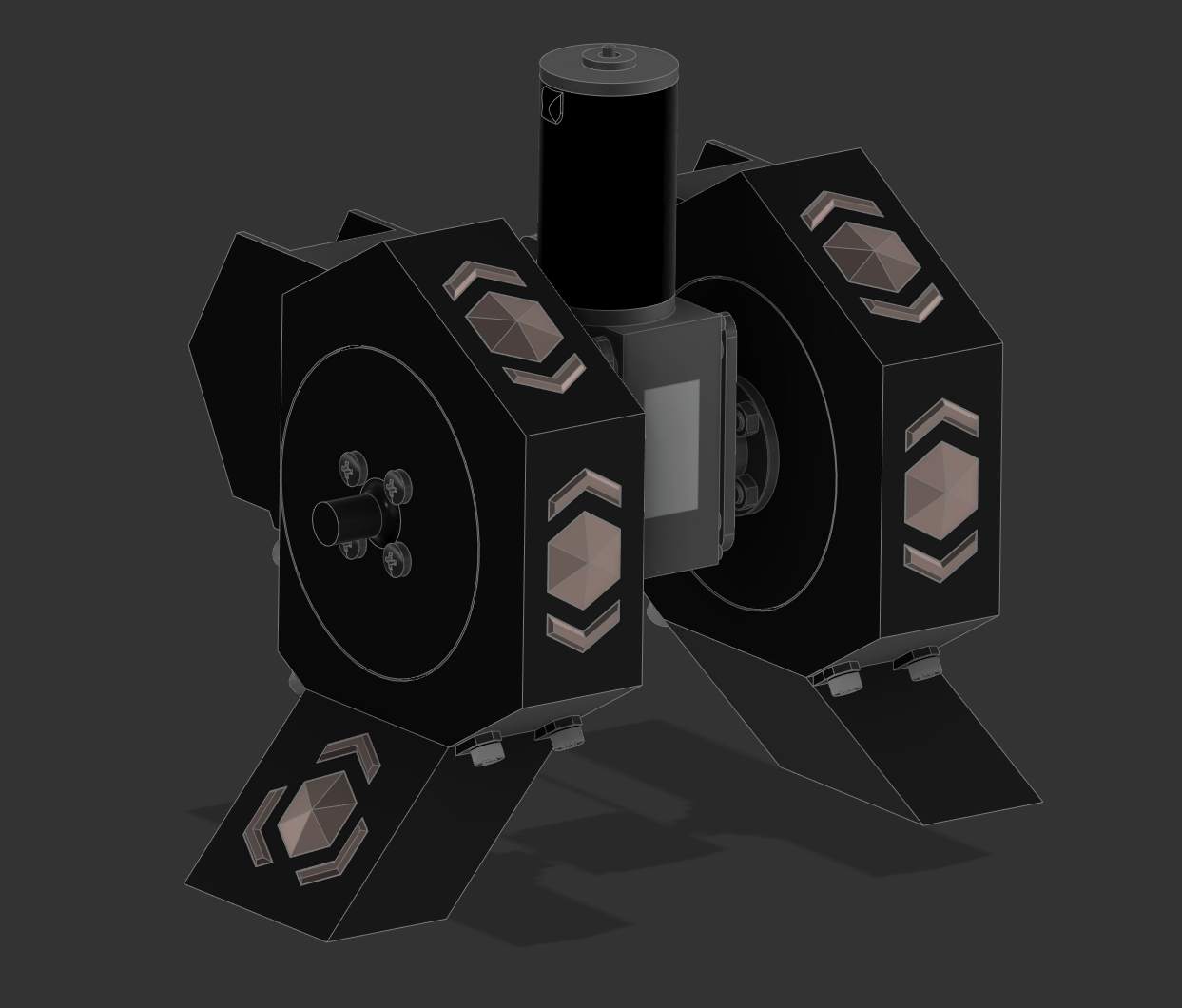

- Aesthetically pleasing

- Secure - not vulnerable to my cats robbing it anytime they want a snack

- Configurable remotely via network (Wifi)

- Solid construction

- Ease of maintenance

- Low food warning

- Food capacity for two weeks or more

- Painless food refilling process

- High reliability

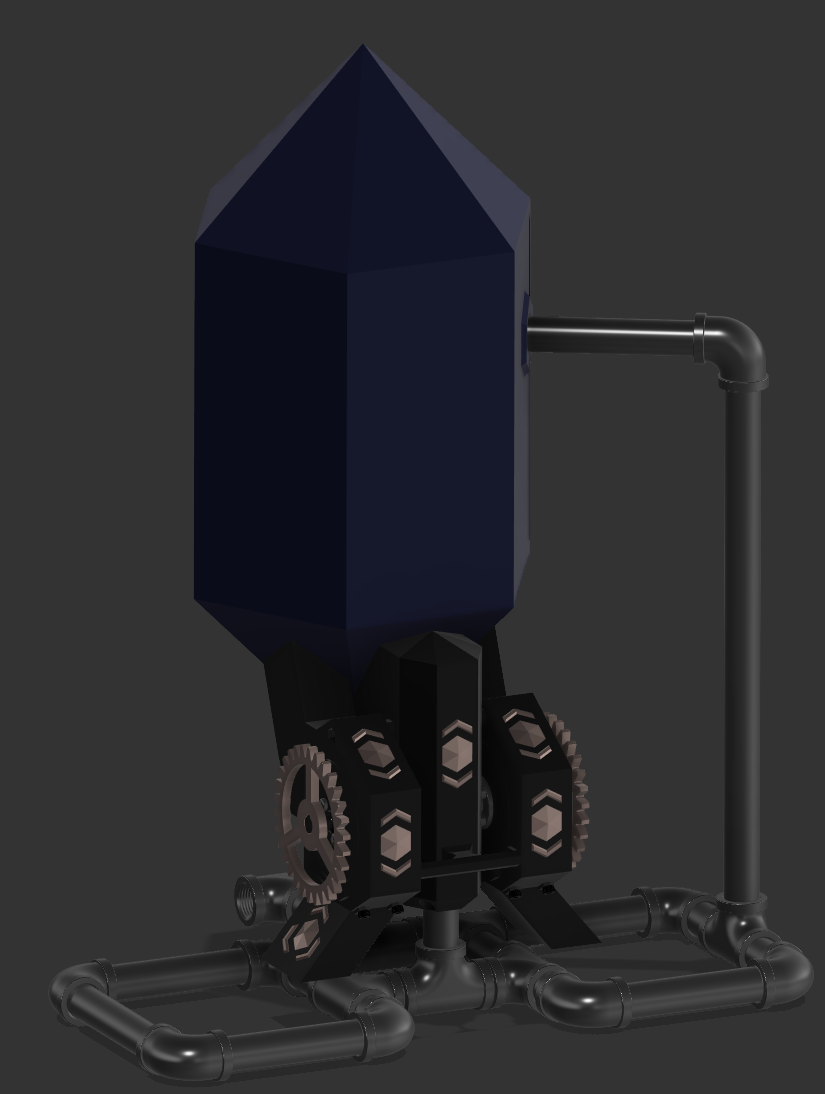

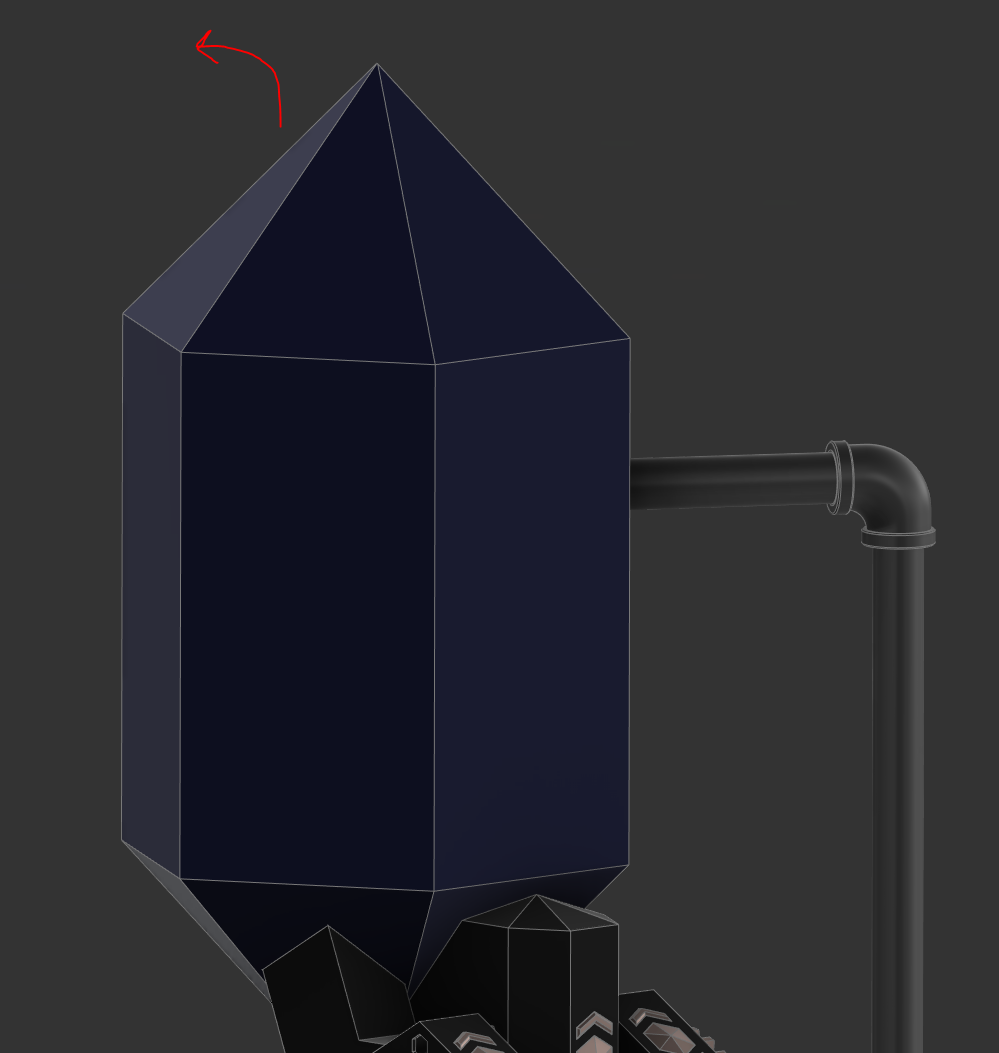

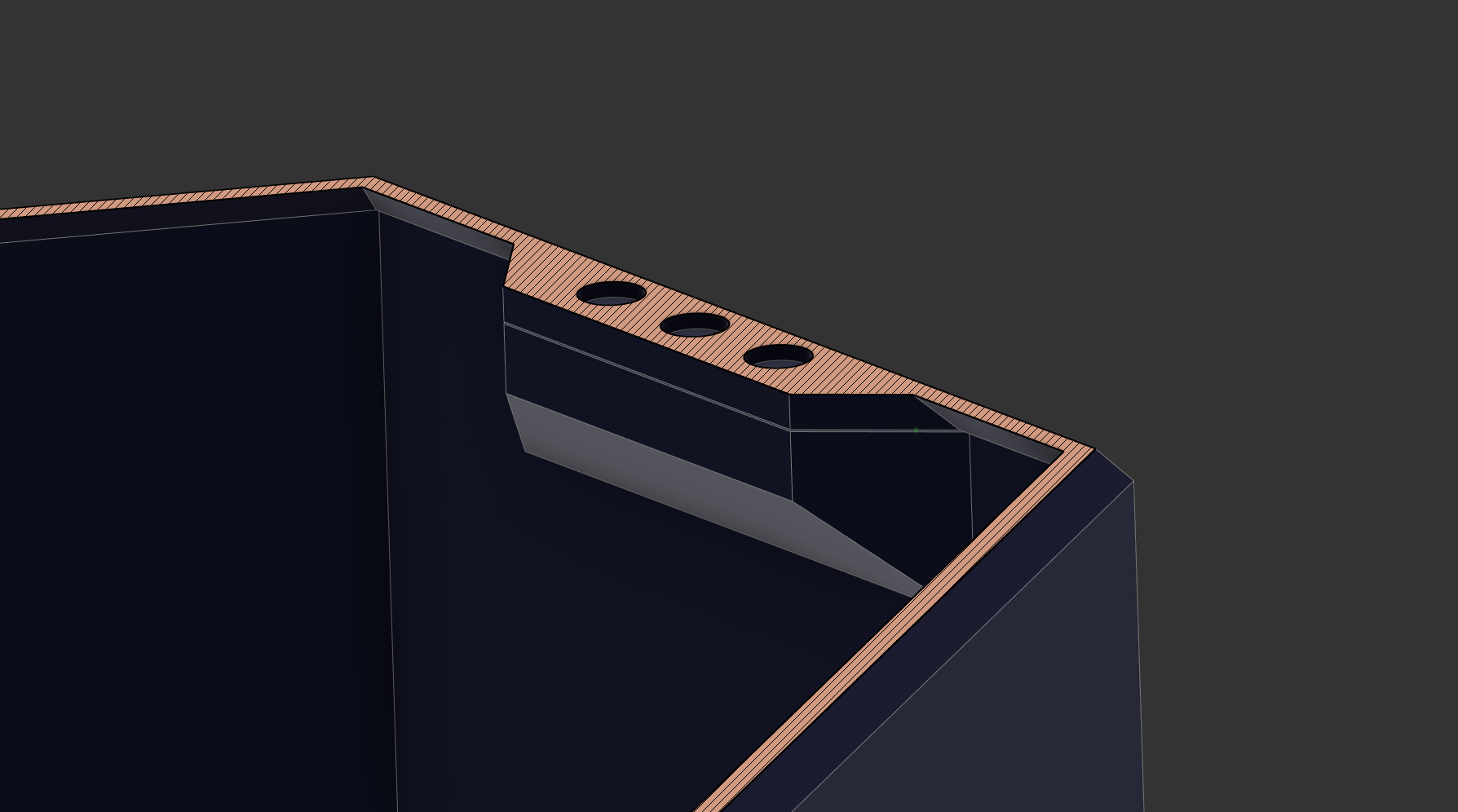

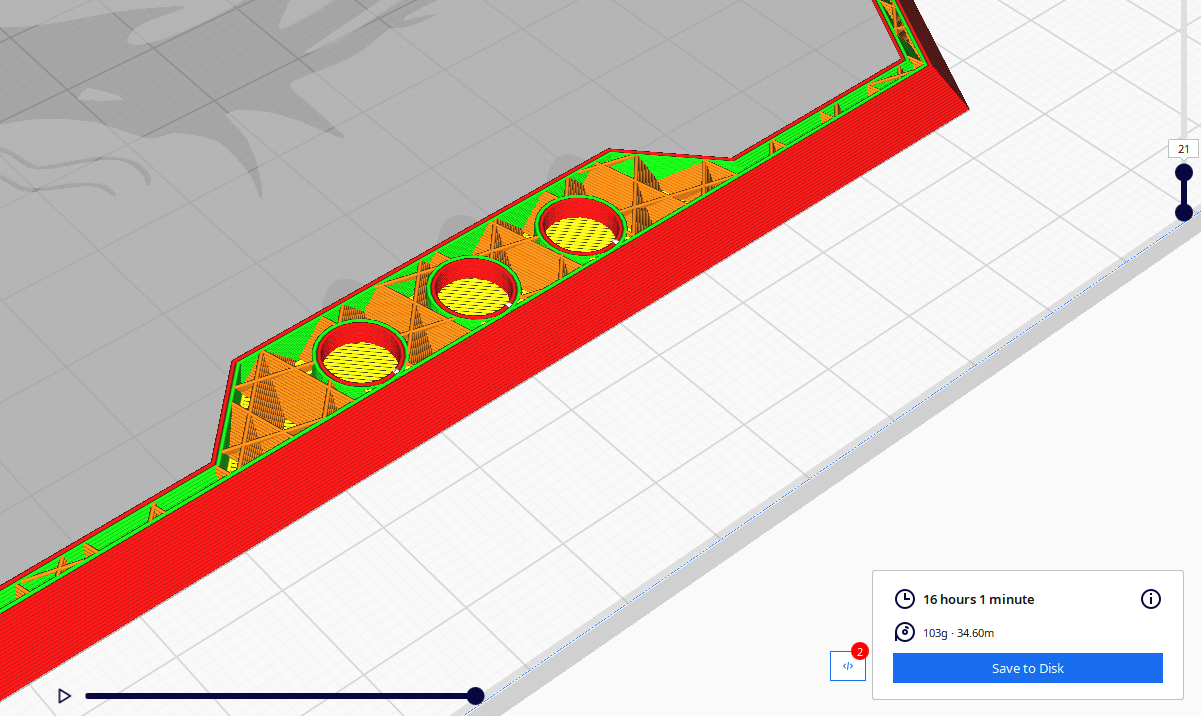

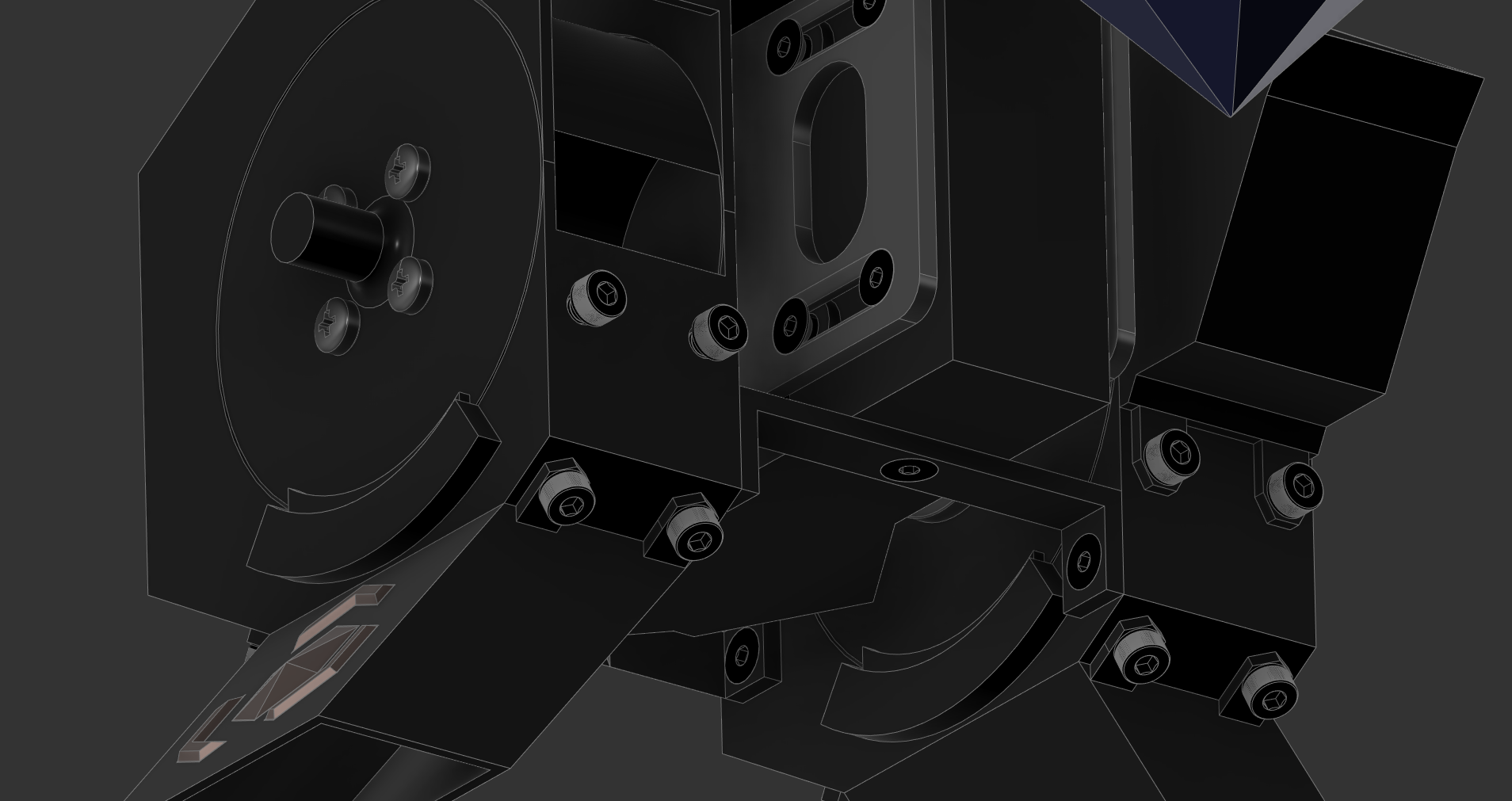

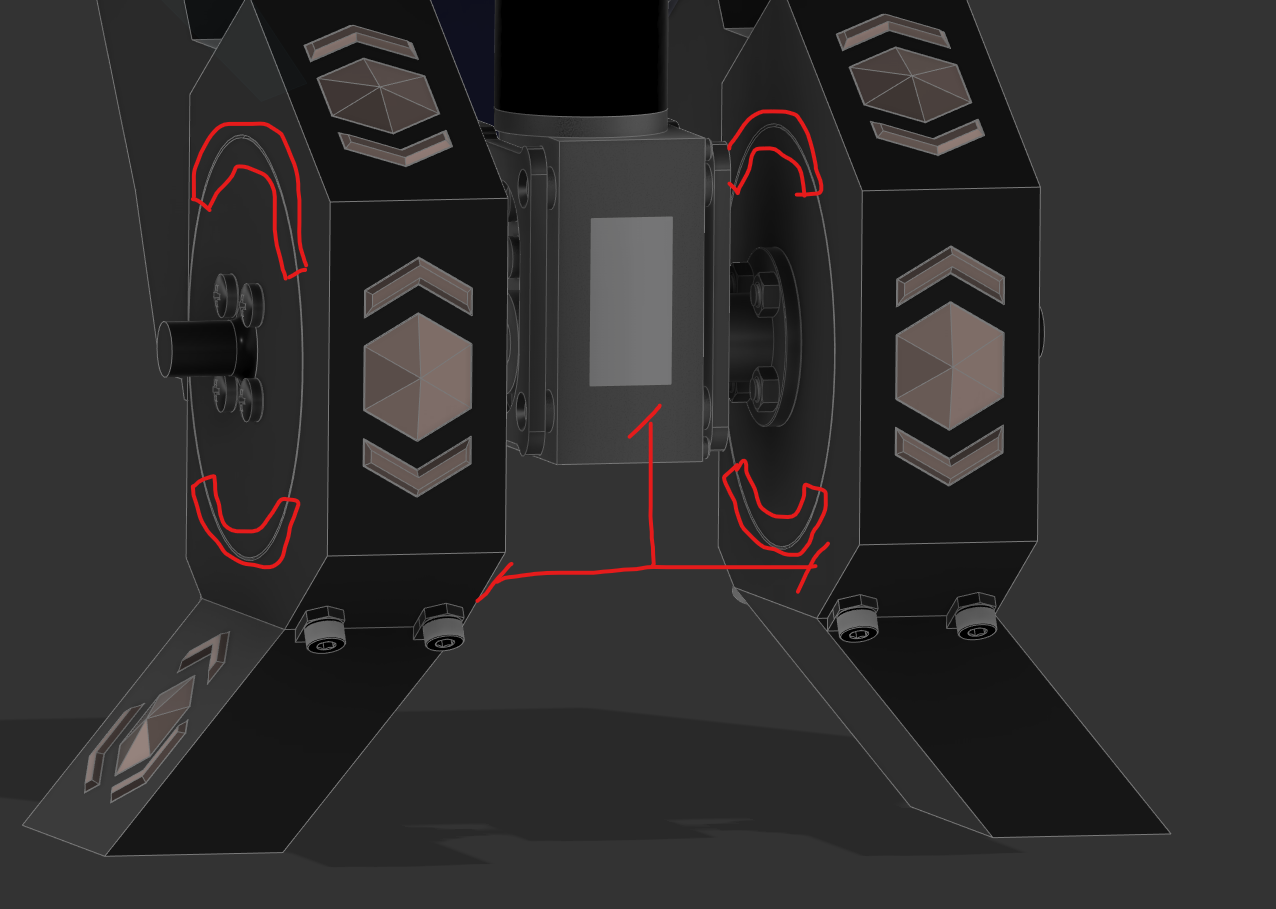

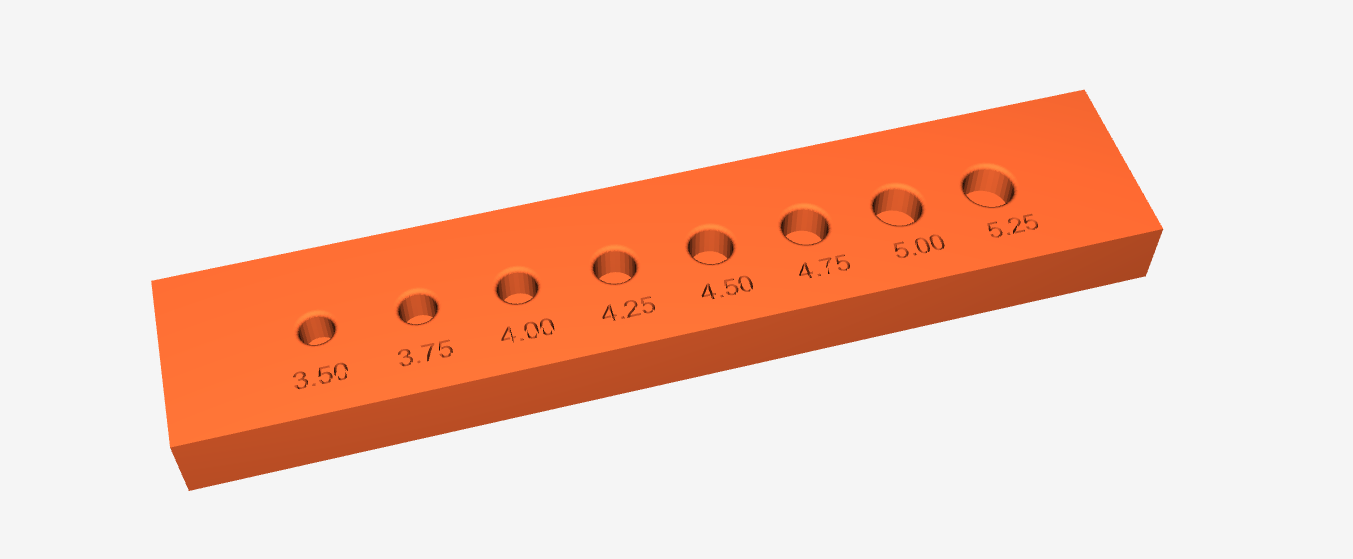

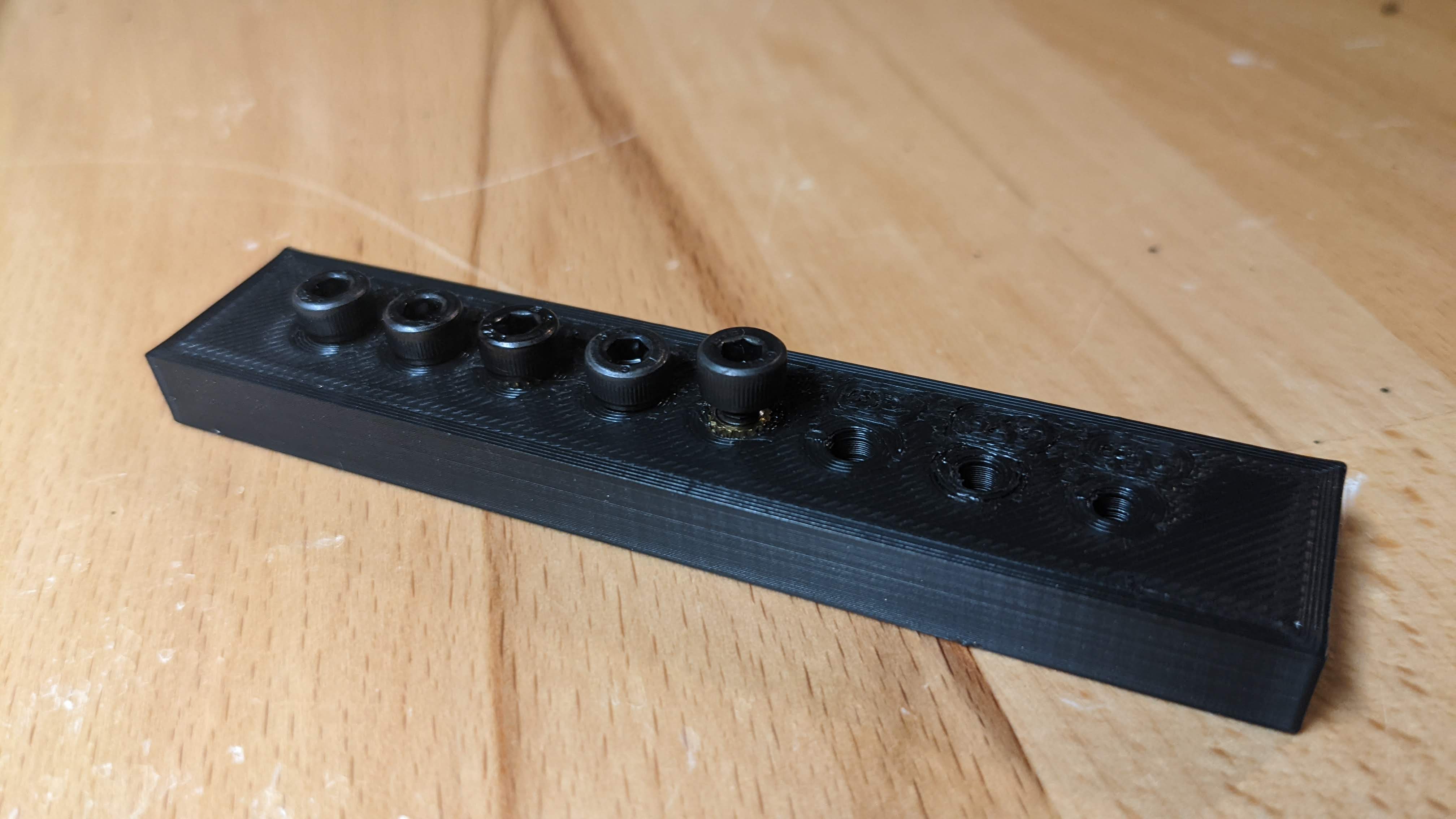

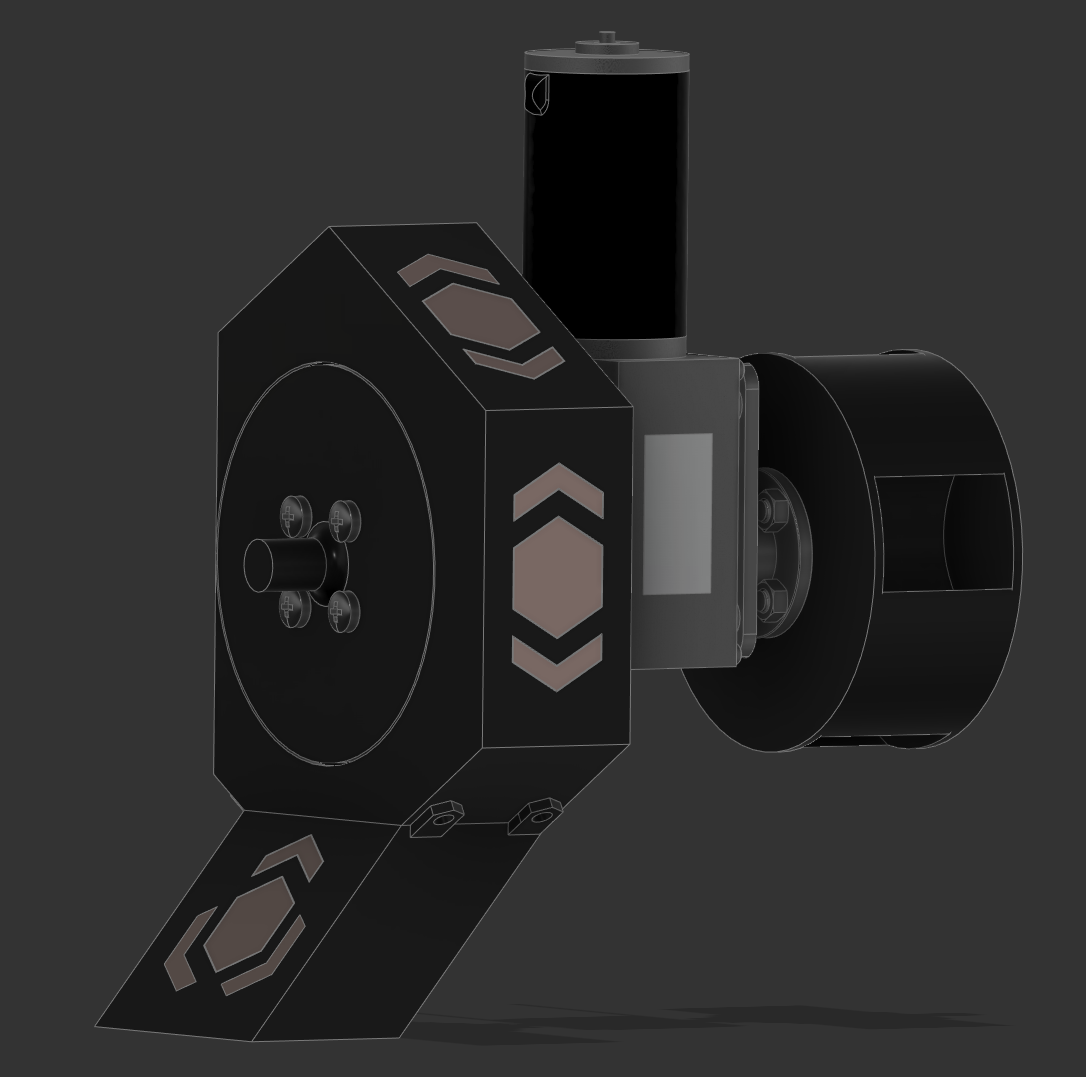

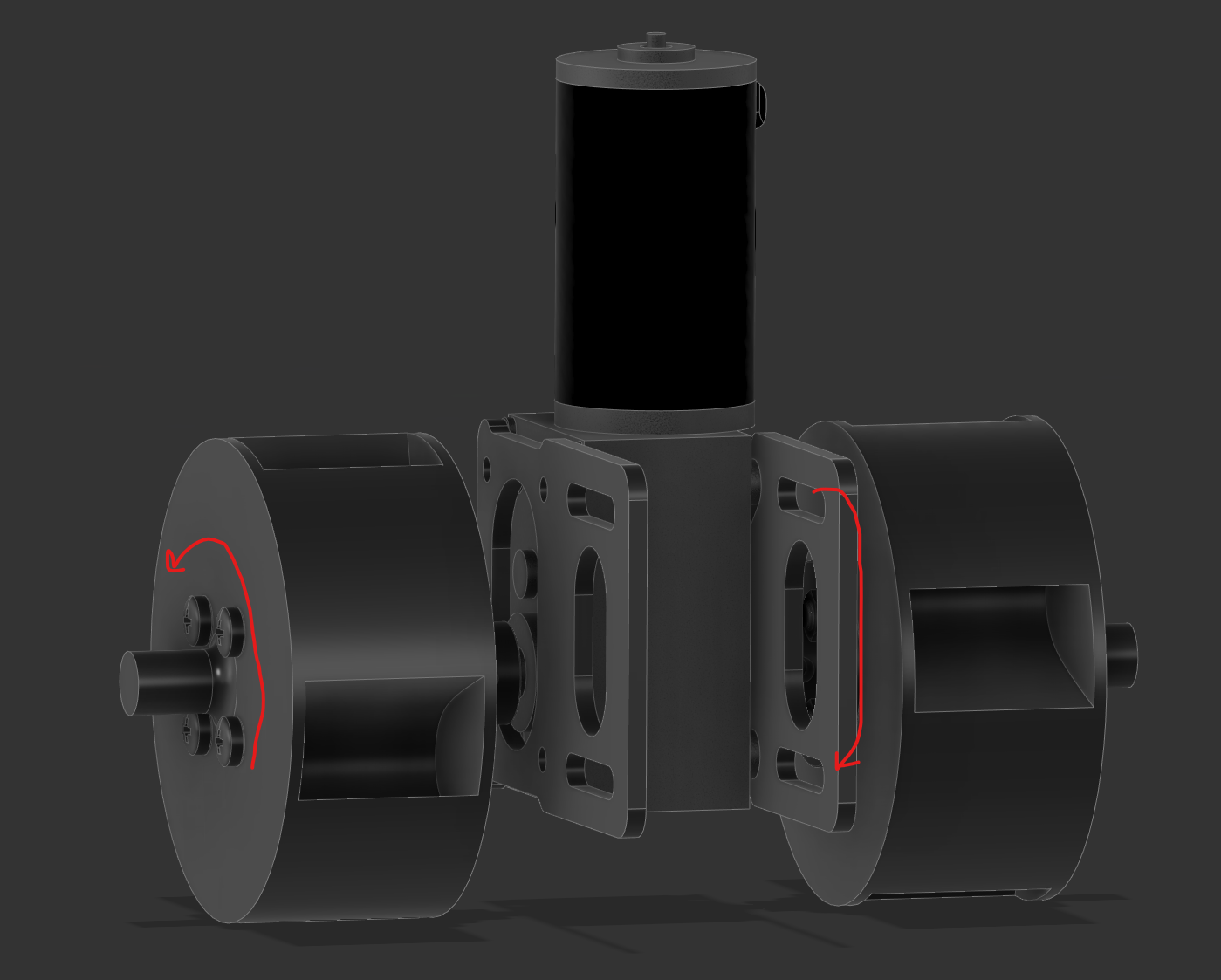

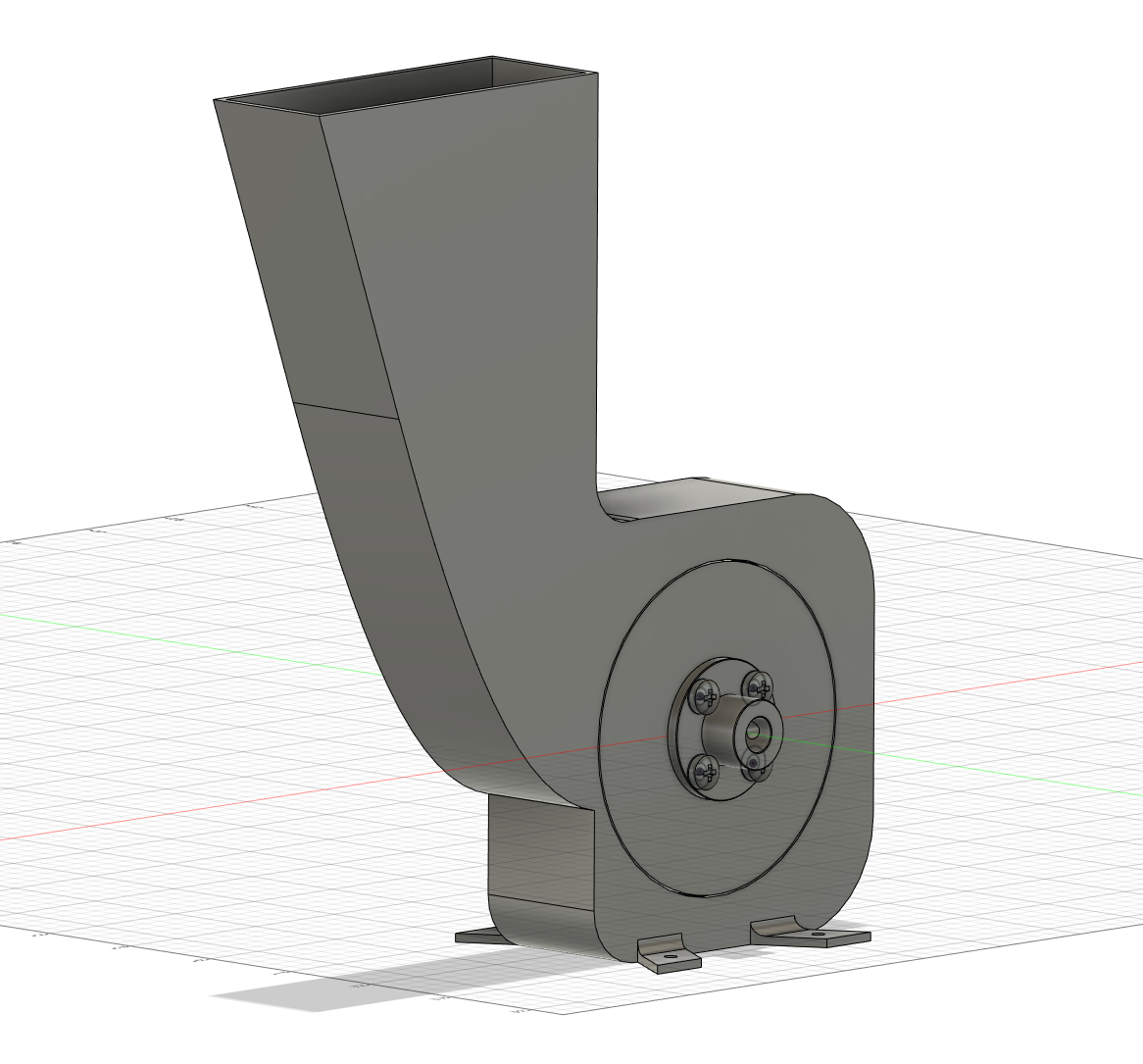

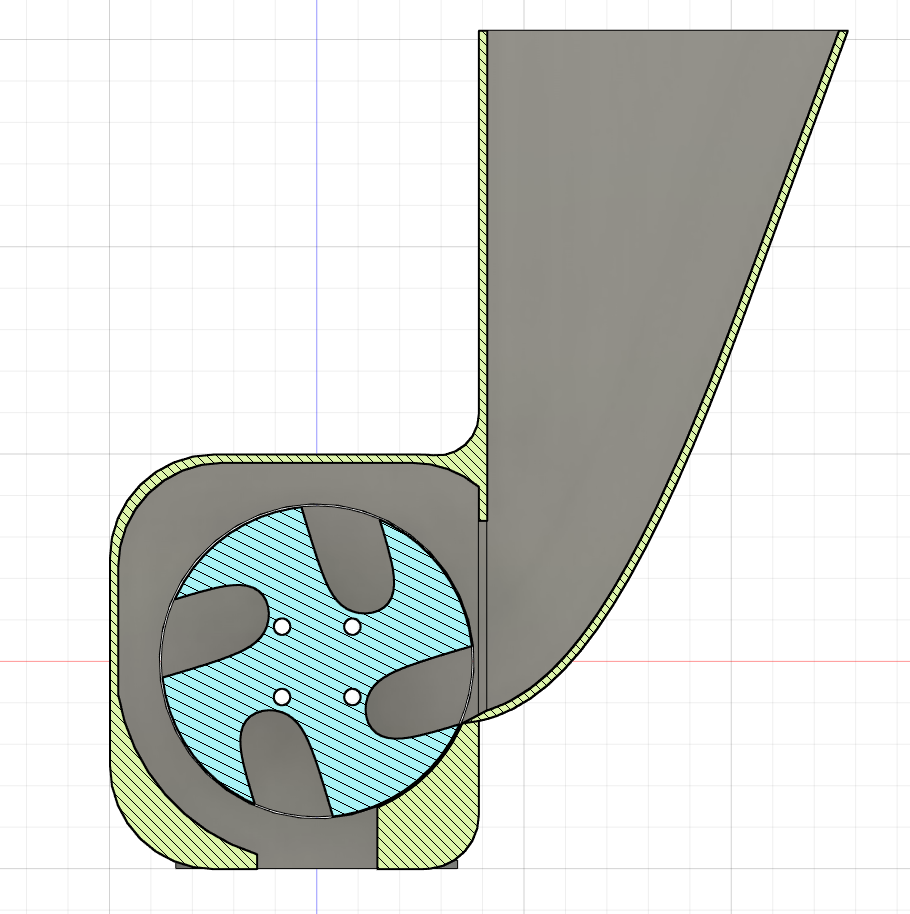

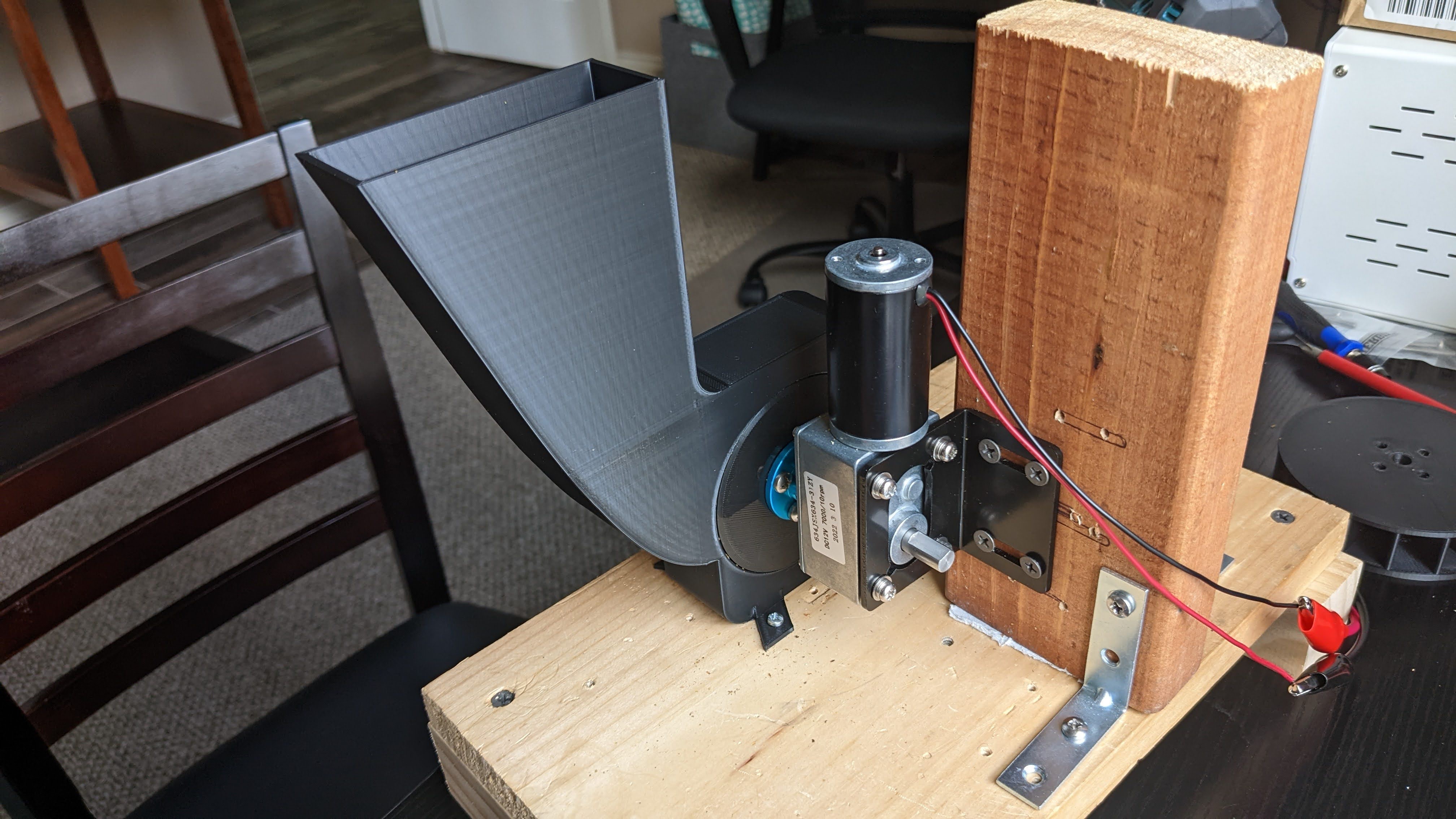

Here's what that might look like:

Joseph Marlin

Joseph Marlin

Paul Crouch

Paul Crouch

Kenneth Zaborny

Kenneth Zaborny

Will F.

Will F.

Fabian

Fabian

When dealing with a large volume or variable sized food pieces, you will likely find yourself better off using an auger screw design. The torque required for the stepper motor as well as the likelihood for jamming make this and the other horizontal wheel designs result in binding and failure, as well as can leave voids where old food can hide out.