Context

The idea for this project grew from the need to assess the temperature and humidity of my child’s bedroom. At the time, he was almost one year old and the house was pretty cold and humid. It was important to know the room temperature to evaluate the need to go there to check if he was properly covered, or, to turn the heat on, or even to remotely control the heater like a thermostat. With this in mind, I decided to create a device that could measure both the temperature and humidity and provide that data directly via a screen or remotely via a mobile app.

At the time I ended up leaving the project on the shelf after a quick breadboard prototype. At this moment, I decided to resume the project with some additions to the initial concept.

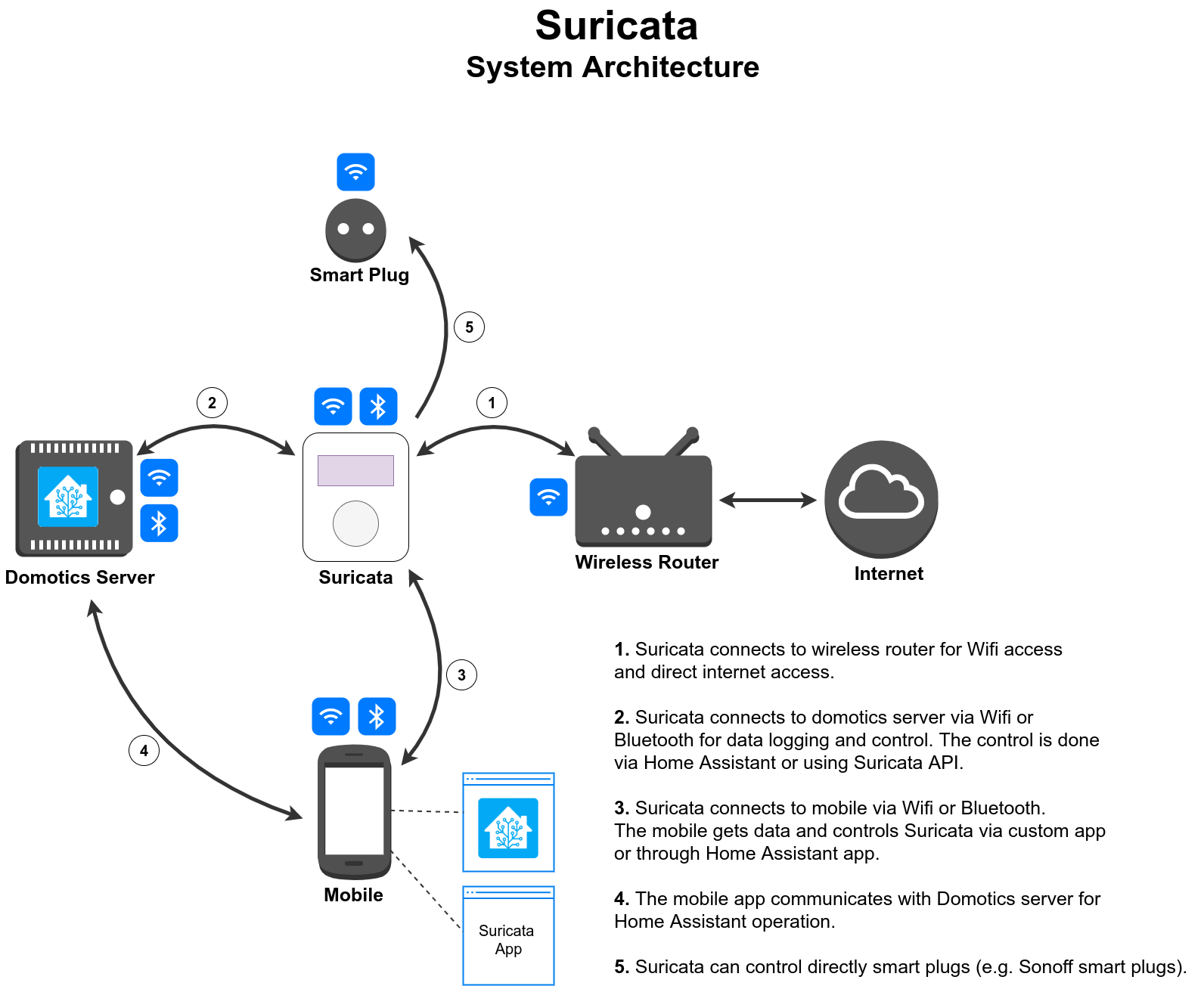

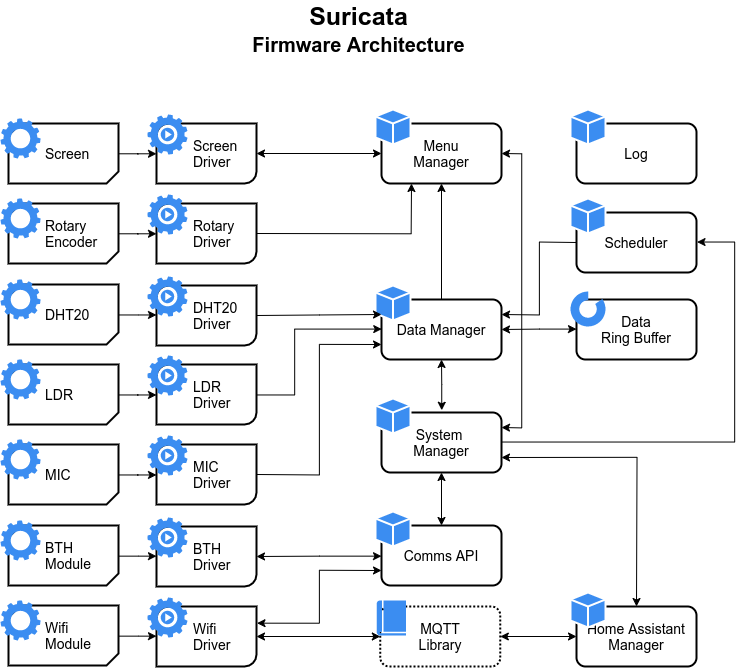

System Architecture

Goals & Milestones

Major Goals

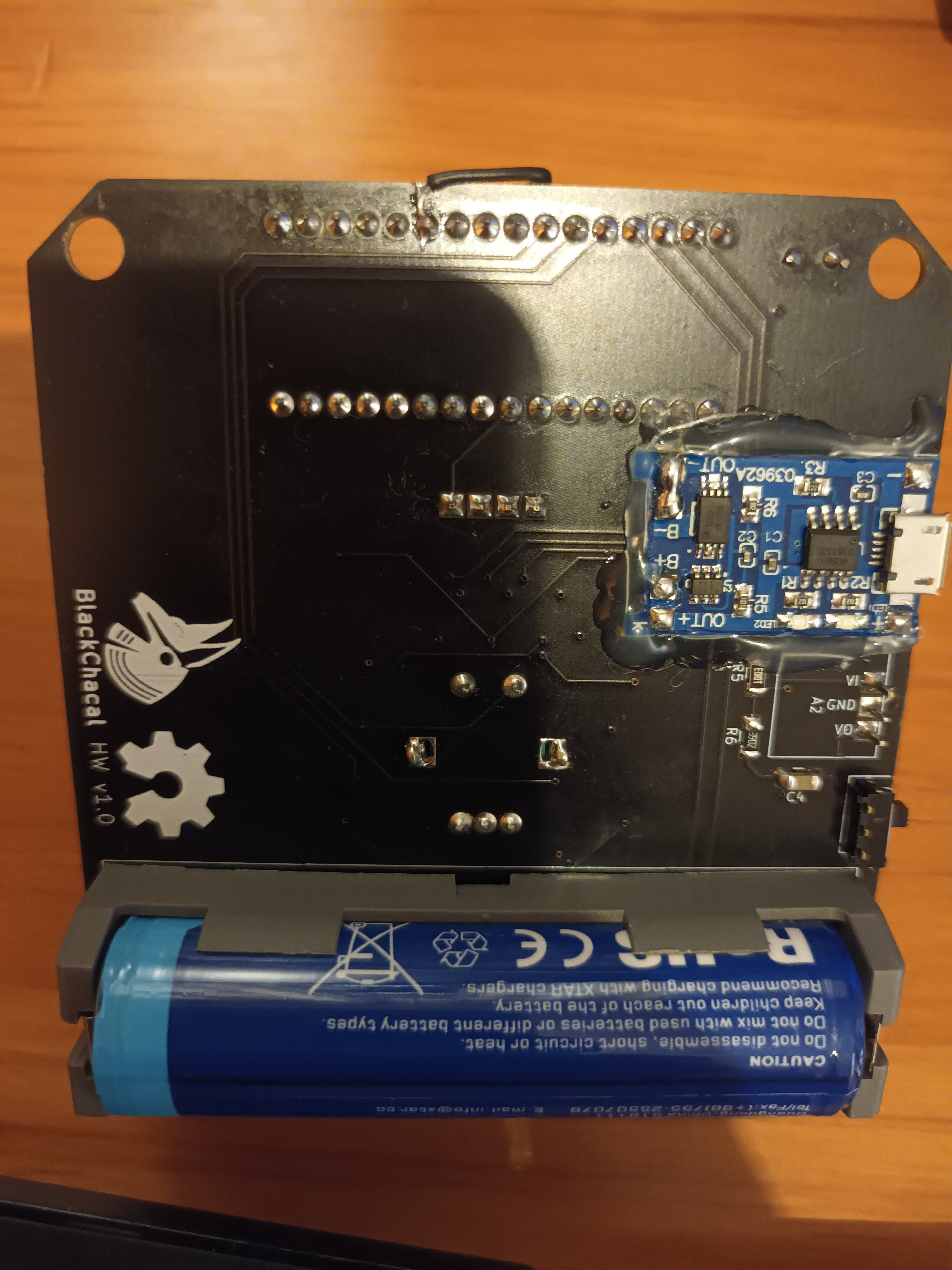

- Power: the device must be battery powered to allow an installation anywhere inside a room, and also to allow an easy relocation to a different place or room. However, there should also be an option for plugged power, via USB. The battery level should be measured and shown on the screen and mobile app.

- Temperature & Humidity assessment: the device must be able to measure the room temperature and relative humidity. The temperature resolution cannot be greater than 1 ºC. The relative humidity resolution must be less or equal to 5 %.

- Data acquisition: the data acquired should be sampled at regular intervals that can be configured by the user via the mobile app, within certain limits. When the user reads the data directly on the device, via button control, the data should be acquired at that moment.

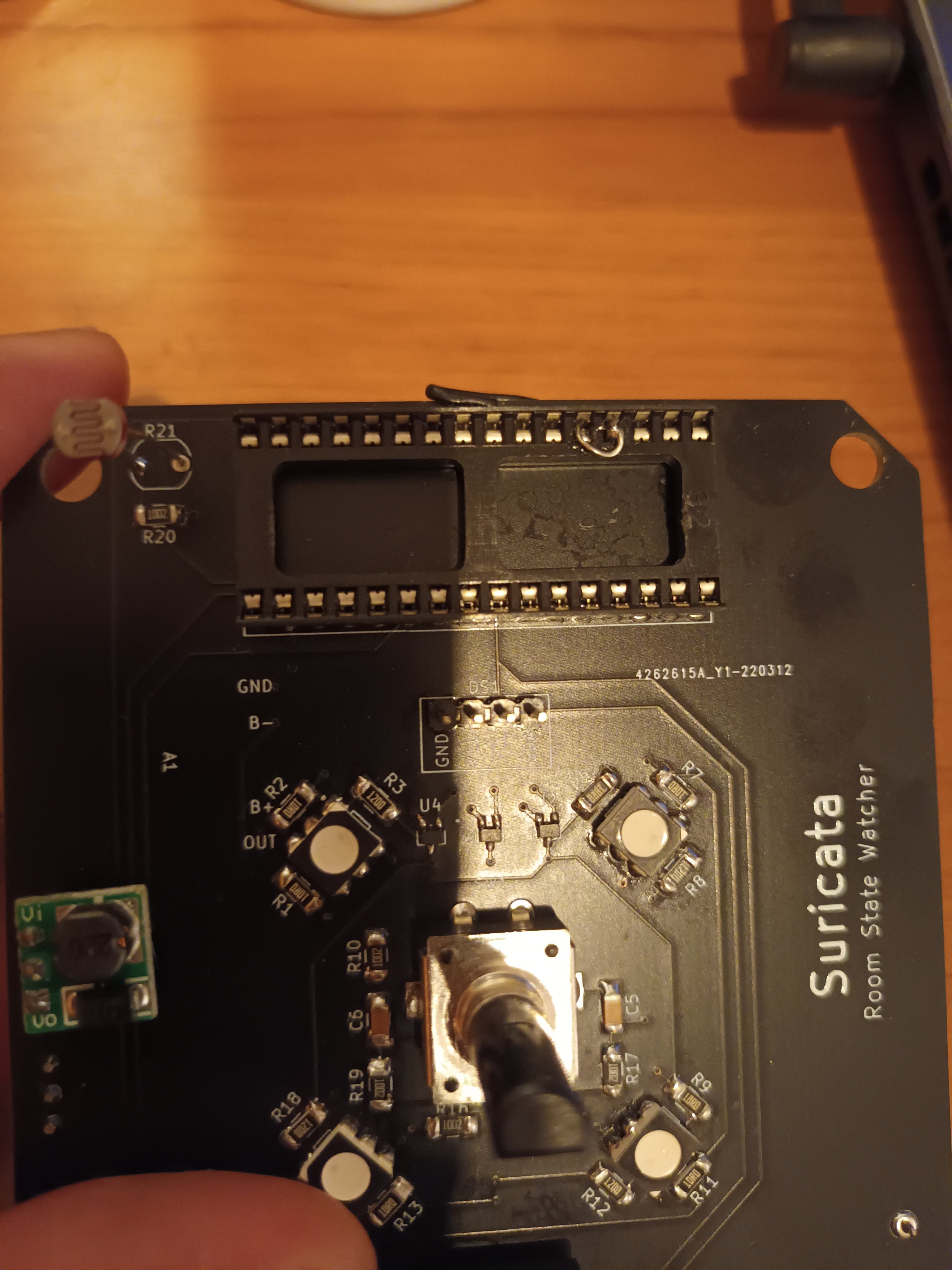

- User interaction: the device should have a screen to show the data and some buttons for device control. The screen should allow to draw small icons and text (be pixel-based), not like a normal LCD screen with lines and columns. It can be monochromatic.

- Communication: the device should be able to communicate via BLE and Wifi.

- Shape & Size: the device case should be small, allowing the device to be comfortably held with one hand. It should have supports to hang on a wall and also to stay on top of a table or furniture. The small size and weight should contribute to portability.

- Mobile app: the mobile app is used to control the device and should have the following features:

- Take a measurement;

- See sensor statistics reports for various periods: hour, day, week.

- Configure Wifi connection;

- Configure data acquisition rate;

- Configure SD card clean period;

- Read SD card stored data;

- Select weather forecast channels;

- Connect, register and control various devices at the same time;

- Show the battery level;

Minor Goals

- Data storage: the device should have internal data storage via a micro SD card. The data can be read via the mobile app or a central domotic unit. The user can configure the data duration on the card. When that duration passes the card is wiped out and new data is stored. If the card should fill up to maximum, a notification should be sent to the user that the card will be wiped after a certain time. This allows the user to download the data if it wants to.

- Light, audio and gas data assessment: the device should be able to measure the light intensity inside the room, differentiating between darkness and several levels of light. It does not need to measure LUX directly. It should also measure audio levels. It is not about recording the sound waves but the sound intensity. We do not need audio information, only dB information. If possible it would be nice to have also some form of gas measurement. Maybe CO2 levels, or stove gas presence. The inclusion will depend on the dramatically on the available sensors and price range.

- Weather forecast: when using the Wifi connection, the device can access some weather forecast channels to download the forecast for the current day. The weather channel used can be chosen on the mobile app, from a list of available services.

- Control AVAC devices: the device can turn on/off a heater, or control an AC system. The...

Ricardo Tonet

Ricardo Tonet

James Kissel

James Kissel

MyTeletouch

MyTeletouch

Olek

Olek