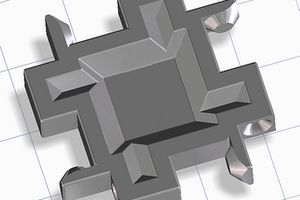

This is a holder for the bottom of a drinks or soda can that turns it into a tray. You cut off the bottom of a can and push it into the slot, the concave shape can then be used as a small parts tray or holder.

There's a recess in the print that allows you to push in a 10mm x 3mm magnet which then holds magnetic parts in the tray. This is optional.

I put adhesive felt material on the base of mine.

The can bottoms are a nice rounded shape that holds the items but also allows you to easily get them out again, unlike a square vertical edged container.

Mark Langford

Mark Langford

mclien

mclien

Andrey Kalmatskiy

Andrey Kalmatskiy