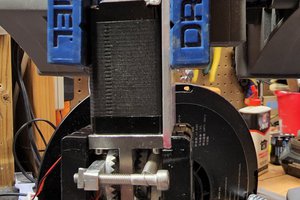

Ok, after taking literally a couple months of working time mostly working on various revisions of this roots blower mechanism, for the openERV.org project, I had to abandon the approach. Ultimately the mechanism is just too expensive, probably.

However, it works marvelously well and might be useful for something else. Maybe a silent pc, or a super quiet ventilation fan.

The point of using it rather than a fan is that it can give a silent airflow even at significant pressure differential. I haven't tested it exactly, but I think you could get it to operate at less than 0.3 sone at about 500 rpm, which it gives 0.65 liters per rotation, so that would be like 4.5 liters per second or something, 10 cfm, and maybe 20 mm of h2o air pressure. It is actually possible to make a centrifugal fan that can do that, but meh no one has published a design for it yet.

If you wanted a truly silent flow at more than about a mm of h20 pressure, you could reduce the rpm still further, and then this would be the only way to get that. Any fan will produce noise because of turbulence at the blade tips, at the rpm needed to produce that much pressure.

So it does have a small window of operating parameters where it can do something nothing else can do.

It is made to last a very long time, just like a brushless fan.

However, you still need a silent motor to make this happen. I have found some, they are a certain variety of 32 mm diameter gimbal motor, used in camera gimbals. They can be had for about $3 USD each on ali express (including shipping). There are several manufacturer's. They have a hollow shaft, are black and have 3 wires. Not all gimbal motors will work, and these ones are bigger and more powerful than most of the little gimbal motors out there, and they are non-cogging which helps a lot to make them silent.

Then, you can get a so called sine wave motor controller, or a Field oriented control (FOC) driver for it. Sine wave controllers are reasonably easy to get although they are at least $15 each, they are available for drones. Make sure it says sine wave control. A square wave one might actually work ok, though, I don't know.

For my experiments I used a servo motor that is of a type that is common on the used market, but they make noise on their own so there isn't much point any more. However, if search 12 volt servo motor with encoder on ebay or ali express you will find several suppliers. You can match them to the picture. They are old and used and some of them are siezed. They are available on Amazon, too, and not much more expensive there.

I implemented a PID controller to control motor speed, but that's really not necessary. You can just give the motors a PWM signal and they will exert a certain torque, and thus end up going a certain speed. The pwm regulates torque, not speed.

The roots blower has several rubber parts that need to be printed in TPU. I used 85(A?) shore durometer ninjaflex, the softest TPU I could get. Harder TPU might not work very well to isolate the vibrations.

The cushions on the shaft just make it easier to print and assemble, because you can get a tight fit without precise printing, they don't help much with the noise.

The cushions that the bearings go into help a bit, because they prevent the bearings from creaking around, mostly. Also rolling element bearings produce a bit of noise naturally, which you can't hear unless it's coupled into a nearby object. The cushion prevents that coupling. The cushions are super glued or epoxied into place.

The motor shaft cushion and rubber mounting washers are the most useful.

I used 3 mm hex cap screws for everything, they are easy to get.

The cad file is a bit of a mess, but I tried to make it show how things work. The bigger of the two motor mounting plates isn't as good. The smaller one...

OpenERV

OpenERV

Andrew Mayhall

Andrew Mayhall

Brian Brocken

Brian Brocken

Jeroen Delcour

Jeroen Delcour