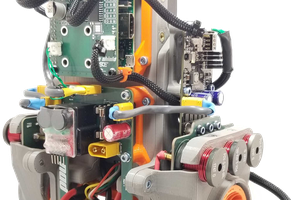

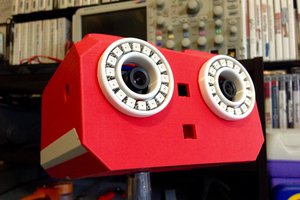

To build a new Upkie from scratch, expect to spend around $3,000 in components, 60+ hours in 3D printing, and more hours of your work assembling and testing the beast. Check out the step-by-step build instructions for details, and head over to GitHub for community support on both hardware and software.

Upkie wheeled biped robots

Wheeled biped robots that can balance, go around and more. Upkies are fully open source, both hardware and software.

Upkie Zero

Upkie Zero

Mike Moore

Mike Moore

ThunderSqueak

ThunderSqueak

jdelbe

jdelbe

Kevin Harrington

Kevin Harrington

hello,Can it achieve biped walking in the future?