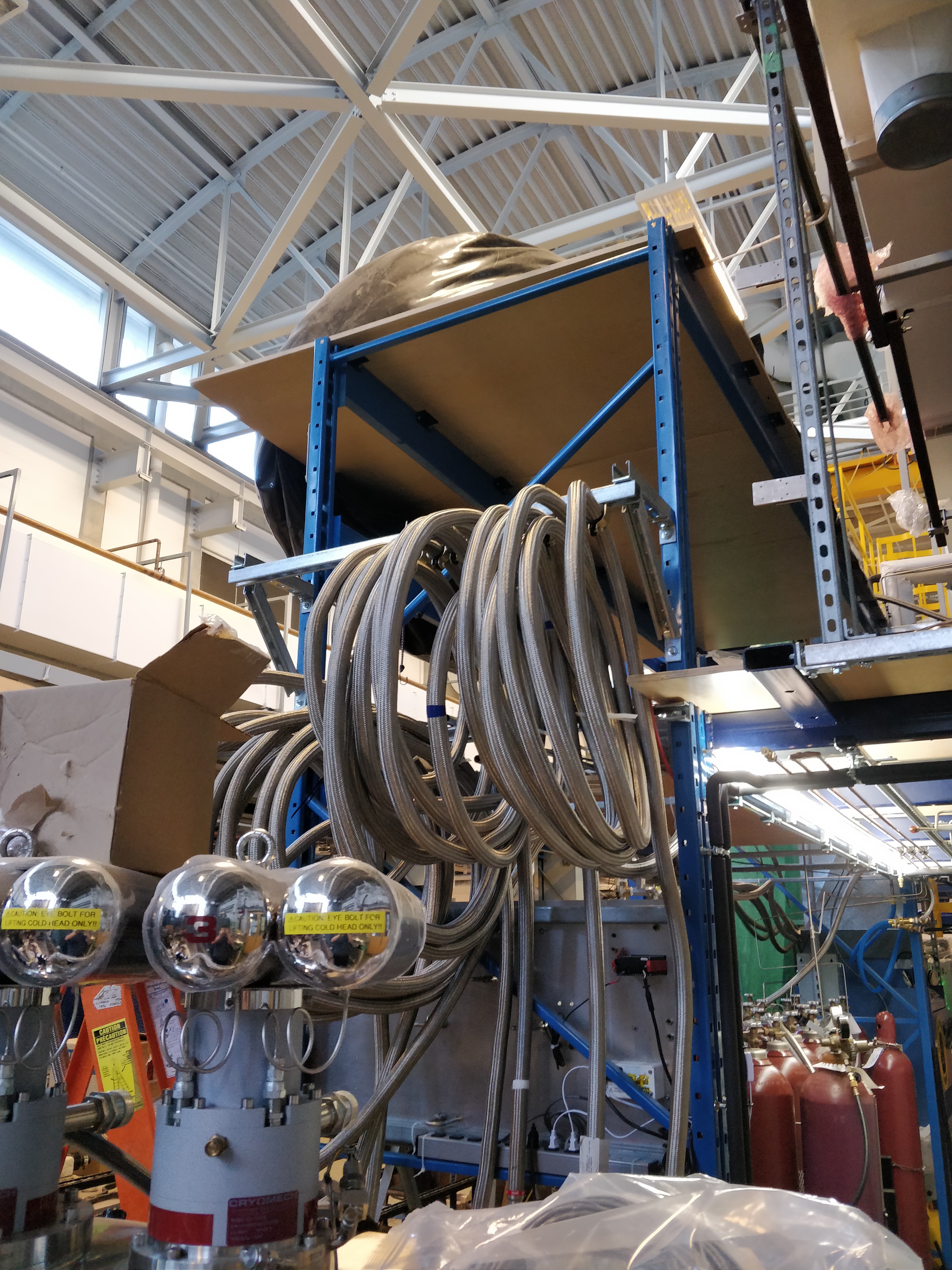

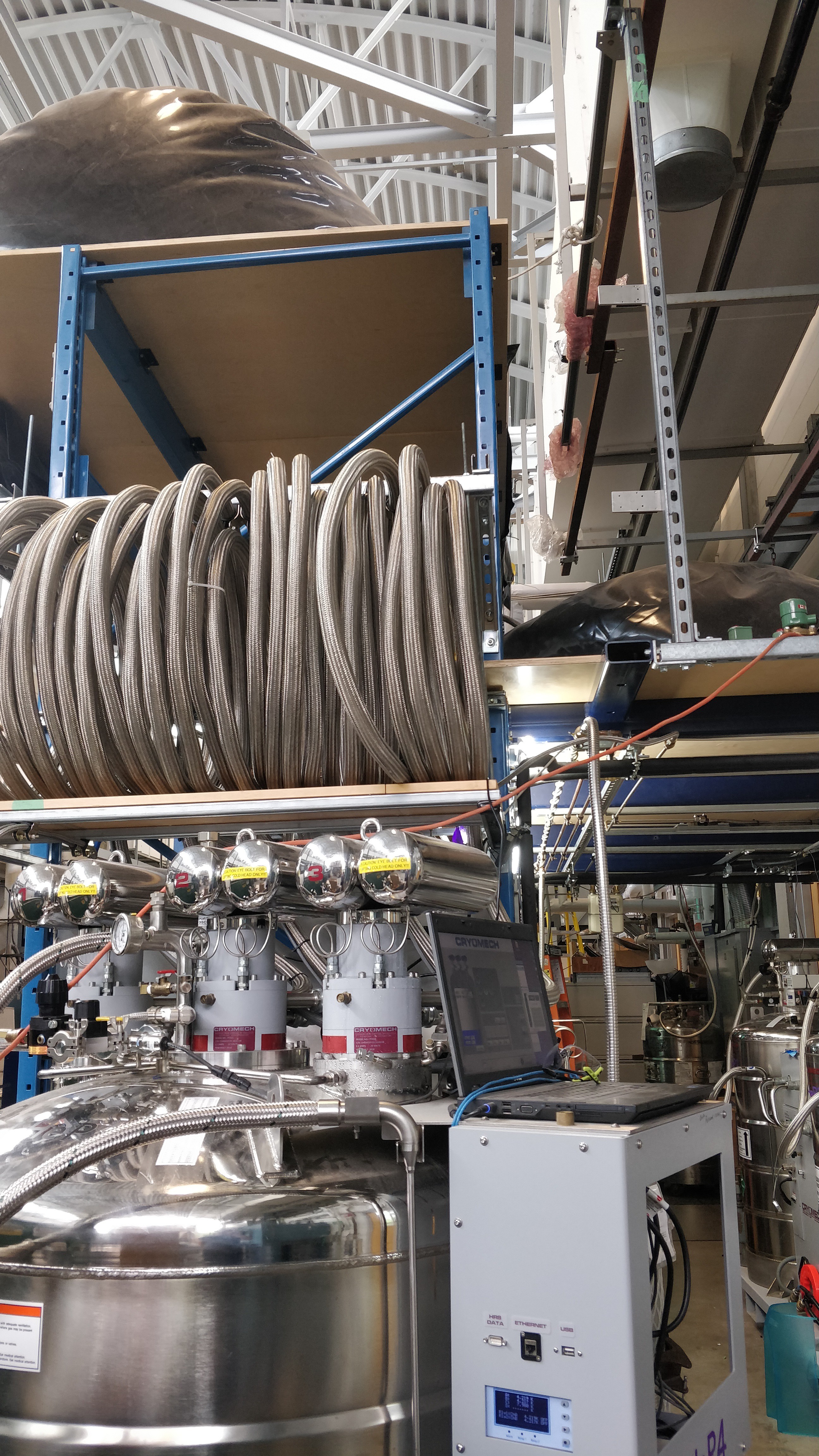

This is our bigger liquidfier. I installed this over a few months. We had to run braided stainless steel helium lines to the pulse tubes to the external compressors. The units are from CryoMech. It has a 500L dewar and it can liquidfy 60L a day.

More photos of the compressors. They use pulse tube refrigerators. The compressors are similar to a hvac style compressor. It has a Hitachi Scroll compressor unit inside modified for helium use. Each stainless steel line is pressurized to 200 PSI and it uses helium as a refrigerant.

This took place between 2020-2021 It took a few months to set up and fully finish. It took a while to run the electrical, set up plumbing for water and run the helium gas lines.

This took place between 2020-2021 It took a few months to set up and fully finish. It took a while to run the electrical, set up plumbing for water and run the helium gas lines. Meow

Meow

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.