A Mystery

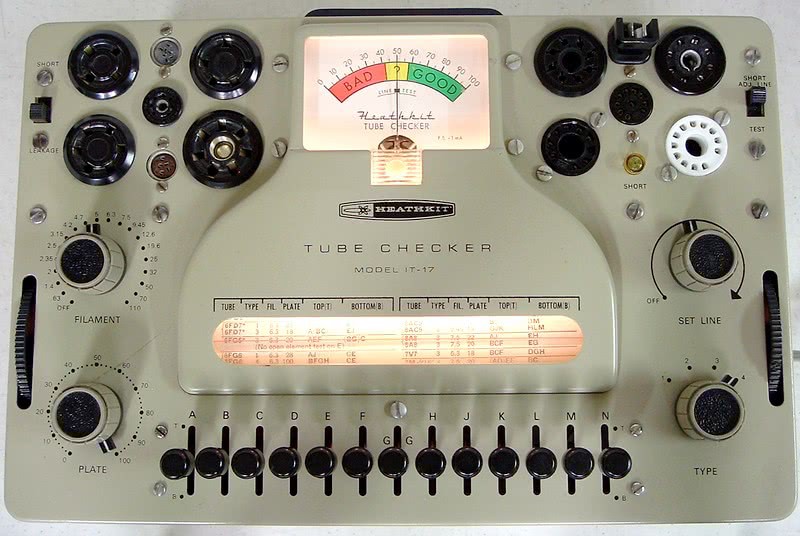

Vacuum tube testers present themselves as rather mysterious. You plug in a tube, look up some esoteric numbers, set some knobs, flip switches back and forth and watch a meter which is simply labeled with a fail to pass gradient, without any units or other info. So what is it doing and how does it work?

Thankfully, there are lots of reference designs out there with documentation. Perhaps the easiest to find are the Heathkit models. These were sold as kits to hobbyists to assemble themselves. Their instructions include schematics, BOMs and some theory information. Digging around shows that all the common versions use basically the same circuit, with some minor variations. I'll look at the IT-17 and IT-21 models.

Theory

The manuals outline the types of tube testing. I'll let you read them directly for more details, but the key take away is that these are like most common tube testers, which test for shorts, Leakage, Opens, and Emission (which covers filament as well)

HeathKit IT-17 This scan has easier to read schematics, but doesn't include the full assembly instructions.

HeathKit IT-21 This scan has the full assembly, but the fold out schematics are split between pages.

Images in this post are from these files.

Shorts and Leakage

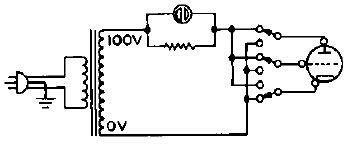

Buried into the details is a note that the short test checks for connections between pins that are less than 250Kohm and leakage check is for less than 2Mohm. So the word "short" is a little loose. Anyway, the simplified circuit for this:

This uses a 100V test voltage across pairs of pins, with a series neon bulb (there is also an R not shown) to test for shorts. If the neon illuminates, it means there is a resistance below a certain level(250k/2M). A neon is used here because it takes very little current. Switches are used to change which of the pins the circuit is connected to. This is why during a short test, you are flipping the switches back and forth, to get all the combinations. Given the wide range of number of tube pins supported, it explains why there are so many switches on the tester. (13 for this model)

Emission

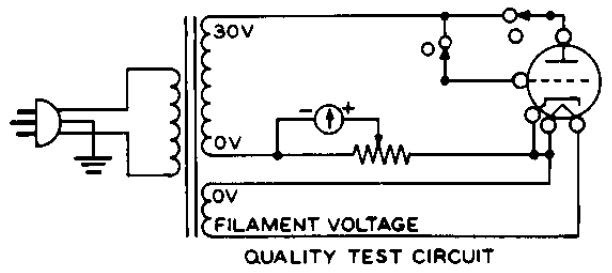

To test emission, the meter is used, along with a setting on the pot to check that the right amount of current is flowing from cathode to plate. But for those familiar with curve tracers, where is the seting for the grid(base/gate)? Digging through the theory section, we find that the common emission type tester doesn't test it as a 3/4/5 terminal device, instead wiring it as a 2 terminal diode. Here's the simplified circuit:

The switches are shown in the position for testing emission. You can see the filament is being run as normal, and the meter is measuring cathode current, while the plate and grid(s) are connected to the voltage source. Not shown are the series resistors, or selection of plate voltage and resistor

The pot acts like a range switch on a multimeter, more on this later.

Opens

But how do you measure opens, when most of the elements are open by design within the vacuum? The answer is to see if the emission test changes based on which elements are acting like the plate.

By connecting all the elements(besides cathode and heater) together and high, they are all acting like the plate. Obviously a grid isn't going to be very effective compared to the actual plate, but it has an effect. The emission test is run, and one at a time, each element is disconnected. With each disconnect, the cathode current(shown on meter) should change somewhat. When each is disconnected, that element is removed from the larger effective plate, changing the value. The instructions tell the user to look for any movement of the needle, no matter how small. If the meter doesn't move at all, it means that element is already disconnected.

In this way, we can check for opens on the plate and each of the grids. An open on the cathode would have resulted in a failure of the emission test.

For the filament, switches so that each of the filament pins are connected through the neon lamp, with it lighting for a good connection. Functionally this is the same as the short test, but measured through the low impedance filament.

Calibration/Alignment

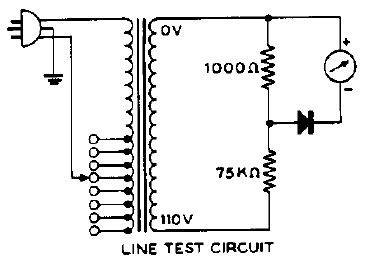

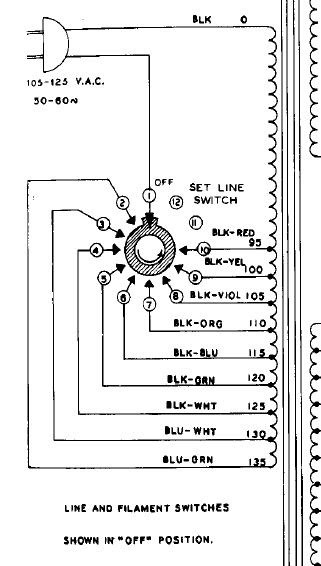

These devices use direct transformer outputs, without any regulation. Because of this, variation in wall line voltage would change the test voltage for the emission test, altering it's results. Today we'd just use a regulated voltage, but back then, it would have added way more complexity and cost as accurate voltage regulation wasn't simple. Instead, they use the meter, along with a rotary switch and lots of taps on the input side of the transformer. This allows the user to switch which input tap to match the voltage they have.

If you imagine a transformer which has 120 and 240 volt input taps, it's like that, but instead this has 95, 100, 105, 110, 115, 120, 125, 130 and 135 volt input taps. Kinda wild from a modern perspective.

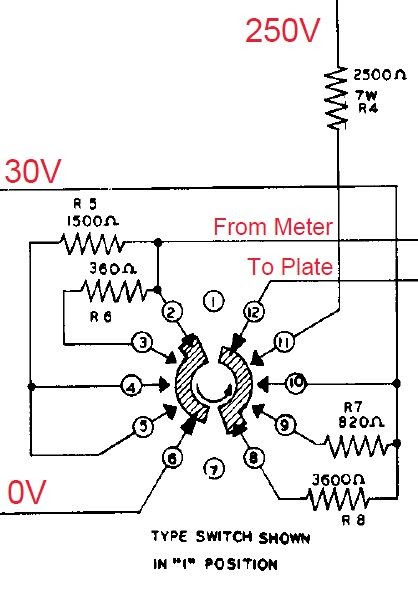

A simple voltage divider is used on a secondary for the ammeter.

Practical

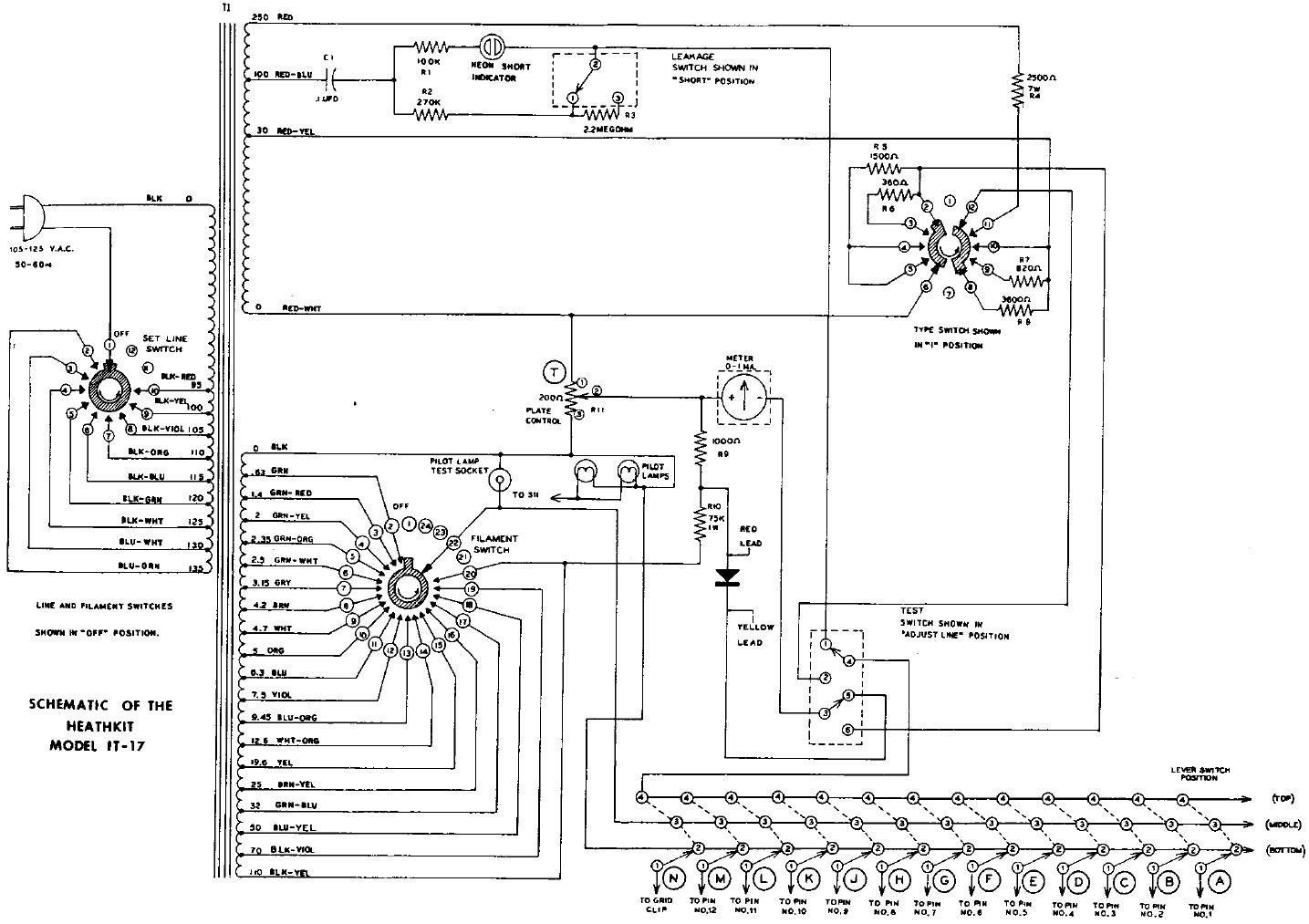

Now to the practical. Here is a handy picture of the full schematic. The original PDF is in the above/attached files.

We can break this circuit down into pieces.

Input line switch

The input line switch serves to calibrate the output voltages correctly. While we can use a regulated power supply and ignore the section, is worth at least looking at the details.

As described before, this is simply a rotary switch selecting which input tap to use. This switch also serves as the power switch. (Note the lack of fuse, yikes!

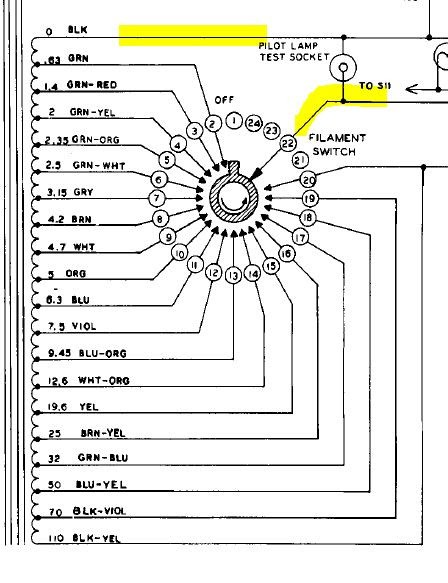

Heater switch

The heater switch works in a similar way in order to select which output tap to use to select a voltage for the heater.

I've highlighted in yellow the outputs. Again this switch allows turning the heater off separately. If we use a power supply for the heater, we don't need this. If you don't have a separate supply, and are using filament transformers, you'll just need to switch between them as appropriate.

Type switch

Plate connection for type:

- 3600 ohm to 30V

- 820 ohm to 30V

- 0 ohm to 30V

- 2500 ohm to 100V

The left side as shown in schematics selects the series resistor connected to the meter.

Meter series resistor for type:

- 0 ohm

- 360 ohm

- 1500 ohm

- 1500 ohm

Other elements

The other elements, including the neon and all the switches are not as important to analyze as they simply connect the relevant points for each test.

Minor notes:

- The neon has current limiting resistors, and is used as a low current indicator. A switch is used to adjust the tube resistance threshold to distinguish between as "short" and leakage.

- The long bank of switches serve to select what each pin of the tube is connected to. Either 0 (bottom), selected filament voltage (middle), or high test voltage (top). One switch per pin.

- The Plate control pot adjusts the scale of the meter. This, along with the charts, are the "secret sauce".

Secret Sauce

Here's a copy from 1979, which I'd have to guess is one of the latest, but certainly will do for most purposes.

For the plate control pot, we know from the schematics it is 200 ohms. Based on other sources, this is wire wound. To convert the setting to a position we need the labeling on the front panel. Helpfully there are plenty of clear pictures which show this to simply be 0-100.

Likewise for the meter, we can see the range in the picture, and knowing the meter is 0-1mA(some clearer pictures and other sources), we know that mid point is 0.5mA, and can estimate the threshold for good by angle/percentage.

And that should be everything we need. But there is one more important bit, the meter resistance. I have been unable to find that spec on these meters in all the sources I've looked. If we knew the value of the diode forward voltage we could figure it out based on the "set line" mode, but I can't find that number either. We'll come back to this based on a little testing later on. (and this will depend on your meter is as well)

Quinn

Quinn

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.