The design is directly inspired by the very detailed build of the Roubo (a French woodworker that published in the 1770 years an encyclopedia about woodwork : http://roubo.art/planches/tablePl_p1.htm) bench found when looking at how to use that lead screw in an appropriate way : https://t2woodworksplus.wordpress.com/2016/12/29/roubo-est-arrive/ (it's in French but Deepl is your friend and there are a lot of pictures, quite long but very rich in hand tooling use).

Lying on the back before its too heavy.

One of the legs had been sanded by the neighbor, the other one will stay that way.

The height of the bench is around 830 mm, I’m not a tall guy and it’s just the right size for me.

The top board isn't thick enough with the table top 40 mm only, I don't have big enough pieces of oak to make the 100 mm thickness required so its thickened with some 16 mm and 23 mm thick wood floor. 16 mm every where and some 23 mm under strategic places.

The 16 mm wood floor has been glued together to make a big strong board of the size of the hole bench and everything is screw tightened.

An additional mid height spacer between the legs is necessary for sturdiness and also to hold a shelf for stock storage.

The top part of the leg is 40 mm thick also, so the thickness of the final top plate is between 56 and 80 mm, good enough.

As I can't make it long enough, it will be 700 mm wide at one end, so the two original legs are on both sides of the width, with additional heavy twin legs in the middle, assembly of a lot of 23 mm wood floor and parts of a rustic 30 mm door (about 80 mm square full oak) : it will have to stand the vise strength, and two smaller legs on the smaller end.

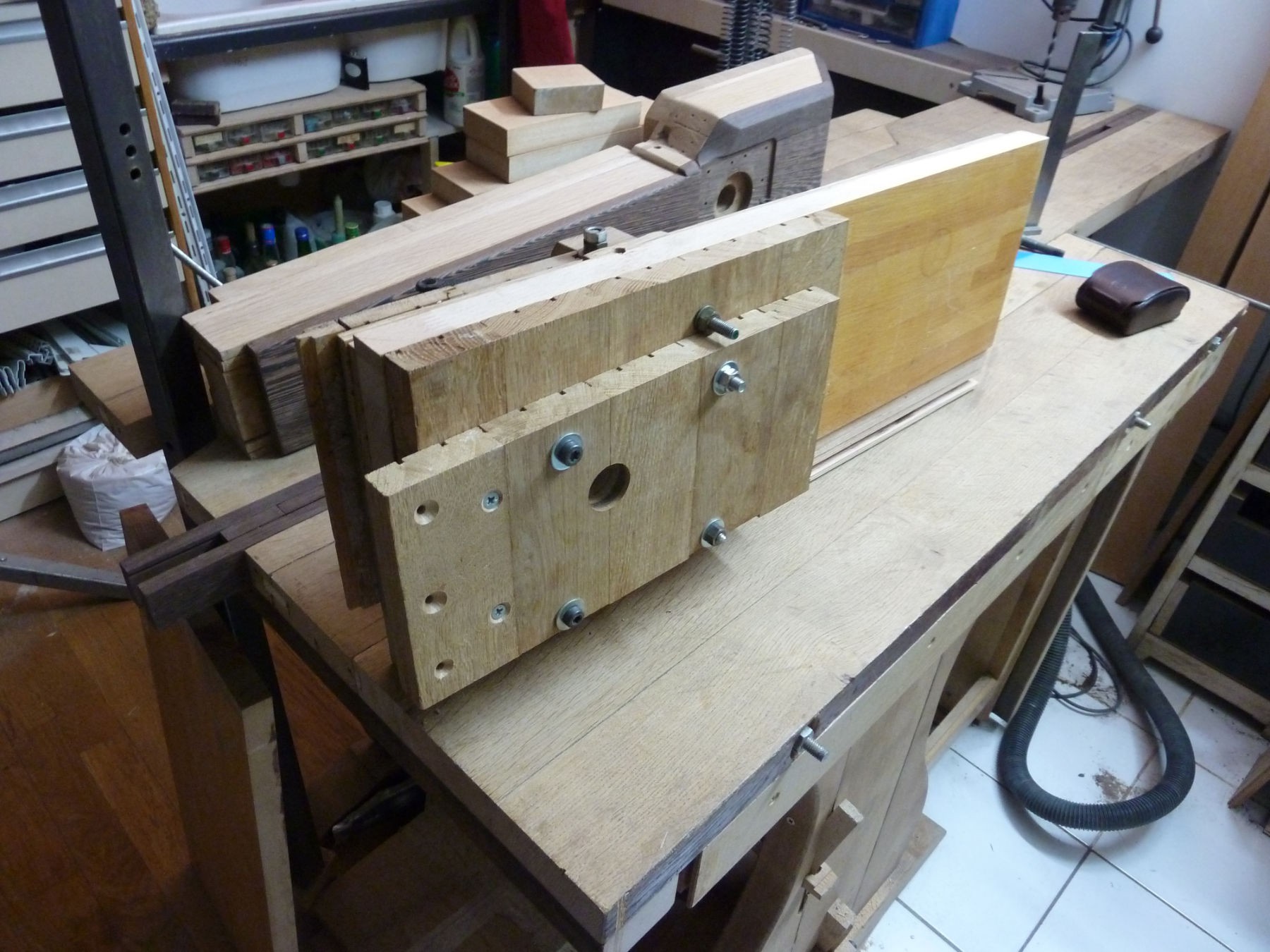

The front jaw of the press on the back, with wengue finish, the cross mechanism in front with the nut in place.

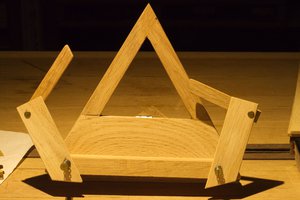

The center of the bench is occupied by a mobile wengue tool holding / woodwork stopper, it can be lifted like in the picture to give a good stop to a piece you're working on, or under, at the same height as the table top to give a full flat surface, it's been hand planned together with the top plate. Slots allow the (impermanent) storing of some tools. It slides on the 5 bolts that cross the table in the middle of the top board, with 45 ° angle grooves finishing flat.

A (blurry, my workshop camera isn't top when the light is poor) detail of the center moving part, wengue's knots are so beautiful !

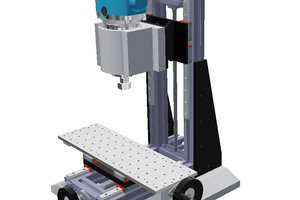

The cross mechanism is home made, a big bolt cutter in perfect shape has been sacrificed because drop forged steel was necessary to have a tight thing that will not bend under pressure (I still have a big bolt cutter, in worse shape, but it was too big for the need), and the simplest cross mechanism is sold 90 €, I had that bolt cutter for 10 €.

The two sliding ends have a big bearing to slip well, and there's a small one in between the two arms too.

Both front and back jaws are an assembly of 9 mm thick and 49 mm wide pieces cut from some plintes (the full size of the plinths is 68 mm but the the edges aren’t flat : one is rounded and the other has an angle, so it had to be reduced to 49 mm to have a square shape) glued together on an bigger central piece that was the link between the two legs of the table. Some pieces of a rustic 30 mm thick door recovered from an apartment left 30 years ago finally found a respectable use.

The front jaw is finished with some wengue recovered from another neighbor who changed the wood floor of his bathroom, it had been black tinted, so from the original 14 mm thickness it has lost around 1 or 2 mm after sanding, but that wood is so beautiful that I don’t regret the time spent on it to recover the natural color of the veins. And really don’t understand how you can buy such an expensive beautiful wood... and paint it black !

For the back of the rear jaw, a piece of 30 mm thick beechwood swedish brand kitchen counter top and two other 23 mm oak wood...

Read more » [zit] Olivier Gade

[zit] Olivier Gade

enrique

enrique

charliex

charliex