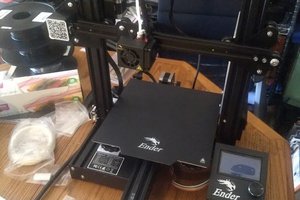

More time was sunk into waiting for the print bed to cool by 30c between every 9 tile batch so that the edges wouldn't curl when prying off the glass. Plus every 6-8 repeated batches of tiles, I'd have to print something else since the tiles printed in the same spots every time get more difficult to remove.

Laying the tiles down could only be done 3-4 rows or columns at most each day to avoid bumping a tile and having to correct too many previous rows. I started with the front rows and worked my way to the back walls. At the back walls, the final row needed dozens of unique tiles with 1-3mm variations to optimally fit flat against the wall.

My only regret is not having made a red piece with a signature to put in the bottom right corner before putting resin over the top.

Giovanni

Giovanni

cprossu

cprossu

Øystein

Øystein