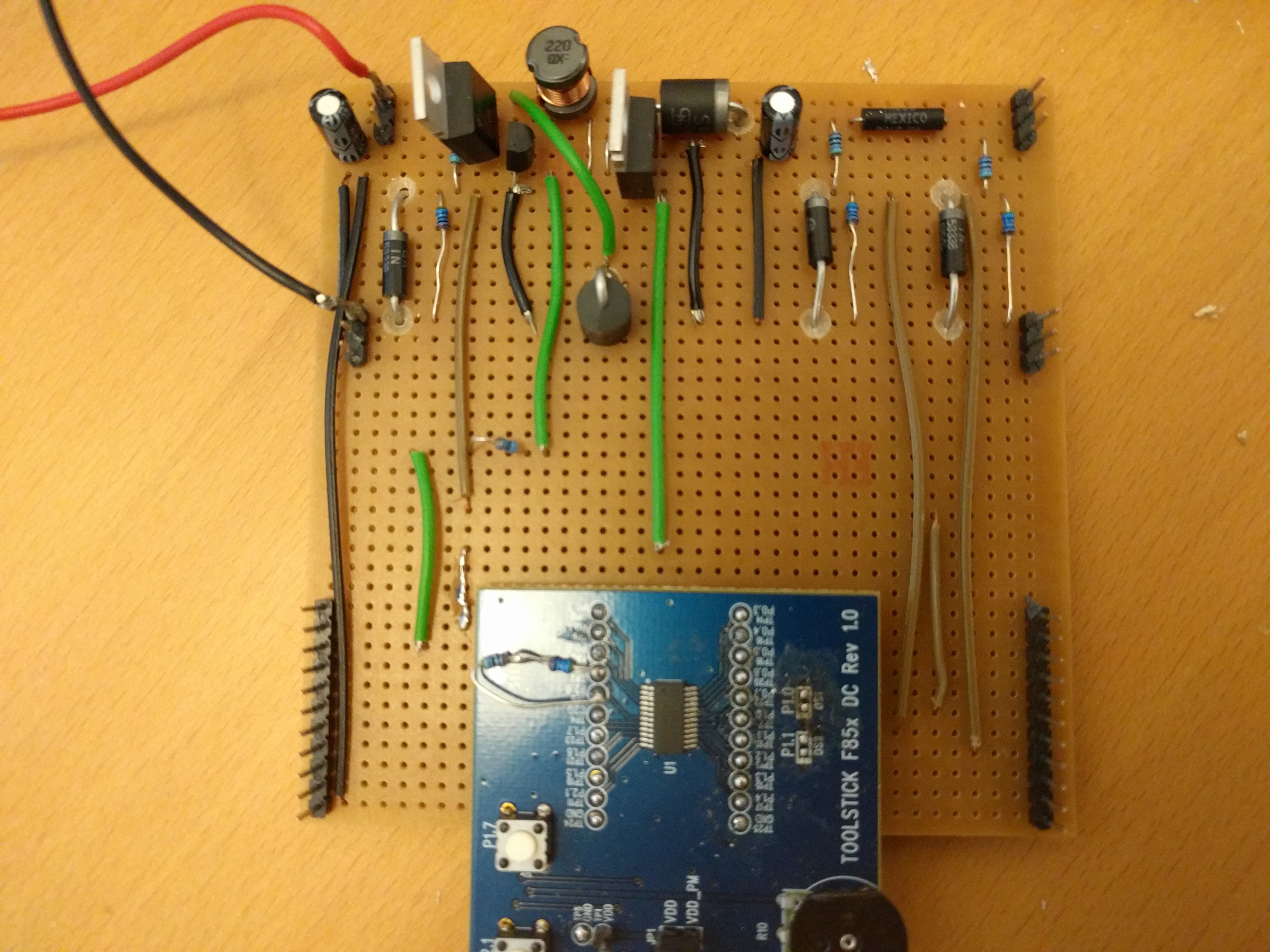

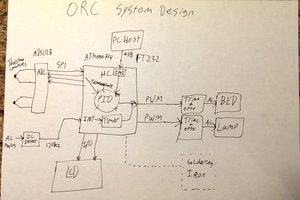

Architecture: 8051

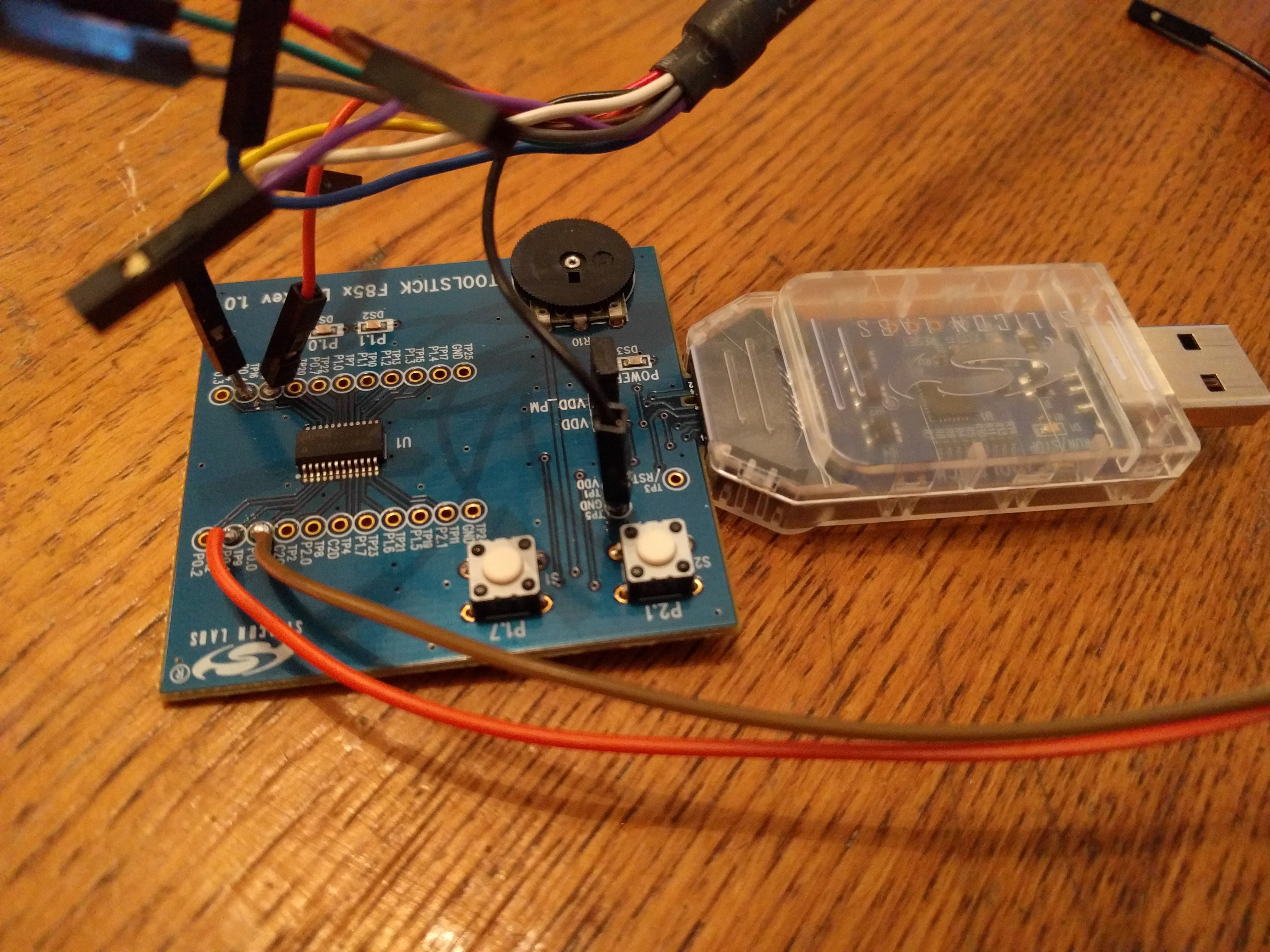

Microcontroller: Silicon Labs C8051F850-C-GU

Toolchain: Keil c51*

The 8051 processor is a popular architecture and Keil provide a comprehensive development environment allowing for simulation and in-system debug.

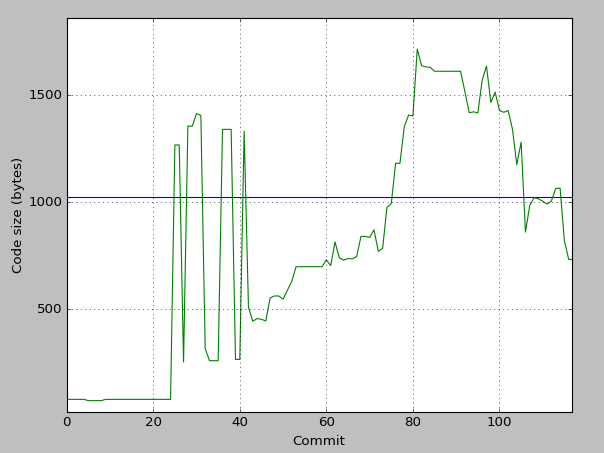

The approach is to implement a feature, optimise code size as much as possible and if it fits in less than 1KB repeat. At present these features include...

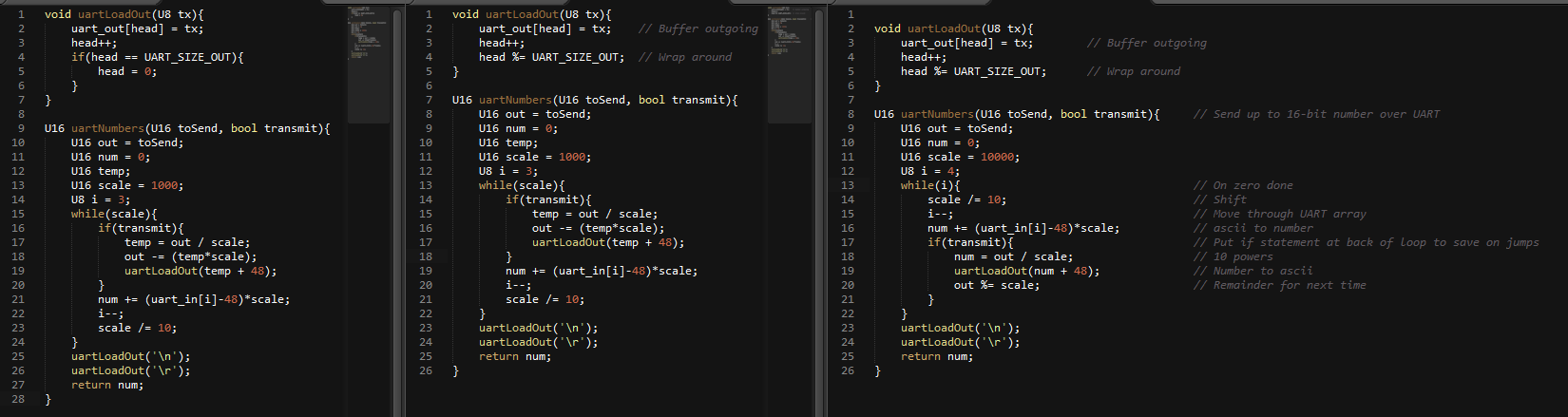

- Enable UART for debug

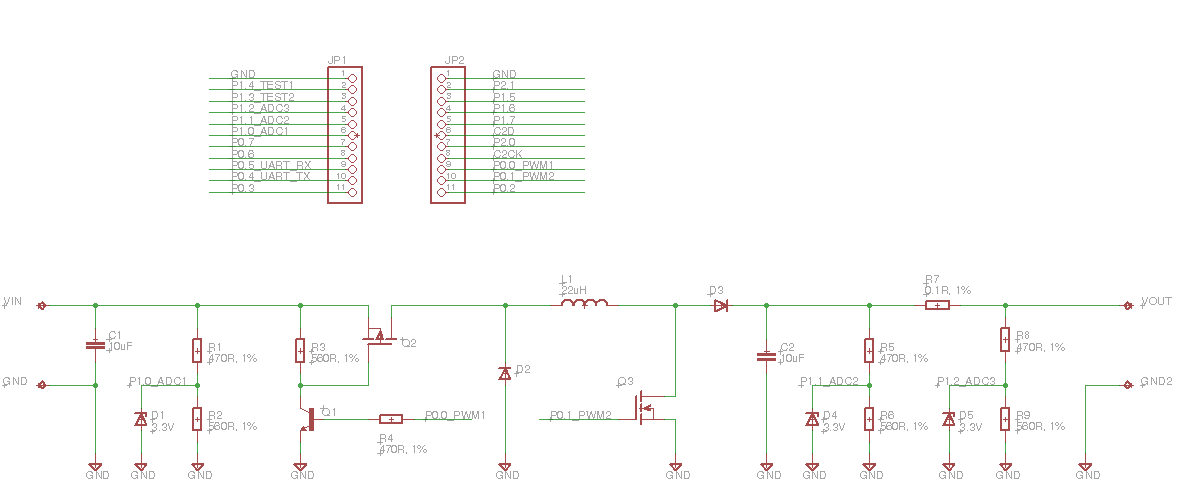

- Enable ADC

- Enable PWM

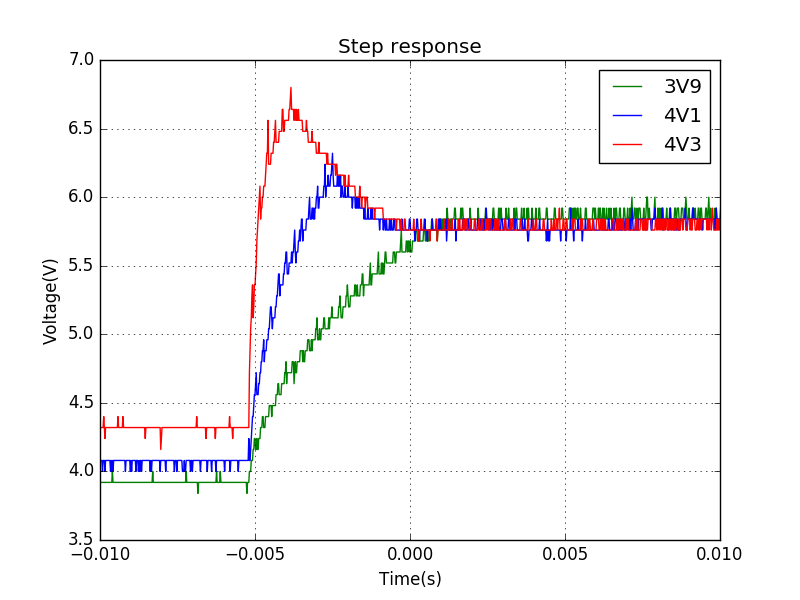

- Control PWM duty cycle from ADC input

- Implement PID controller

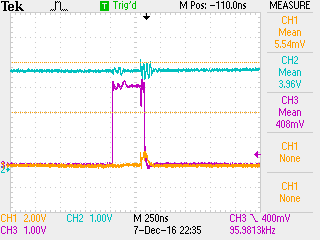

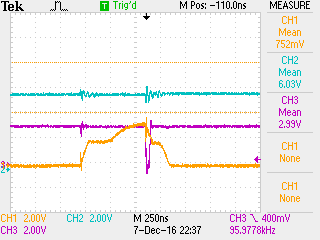

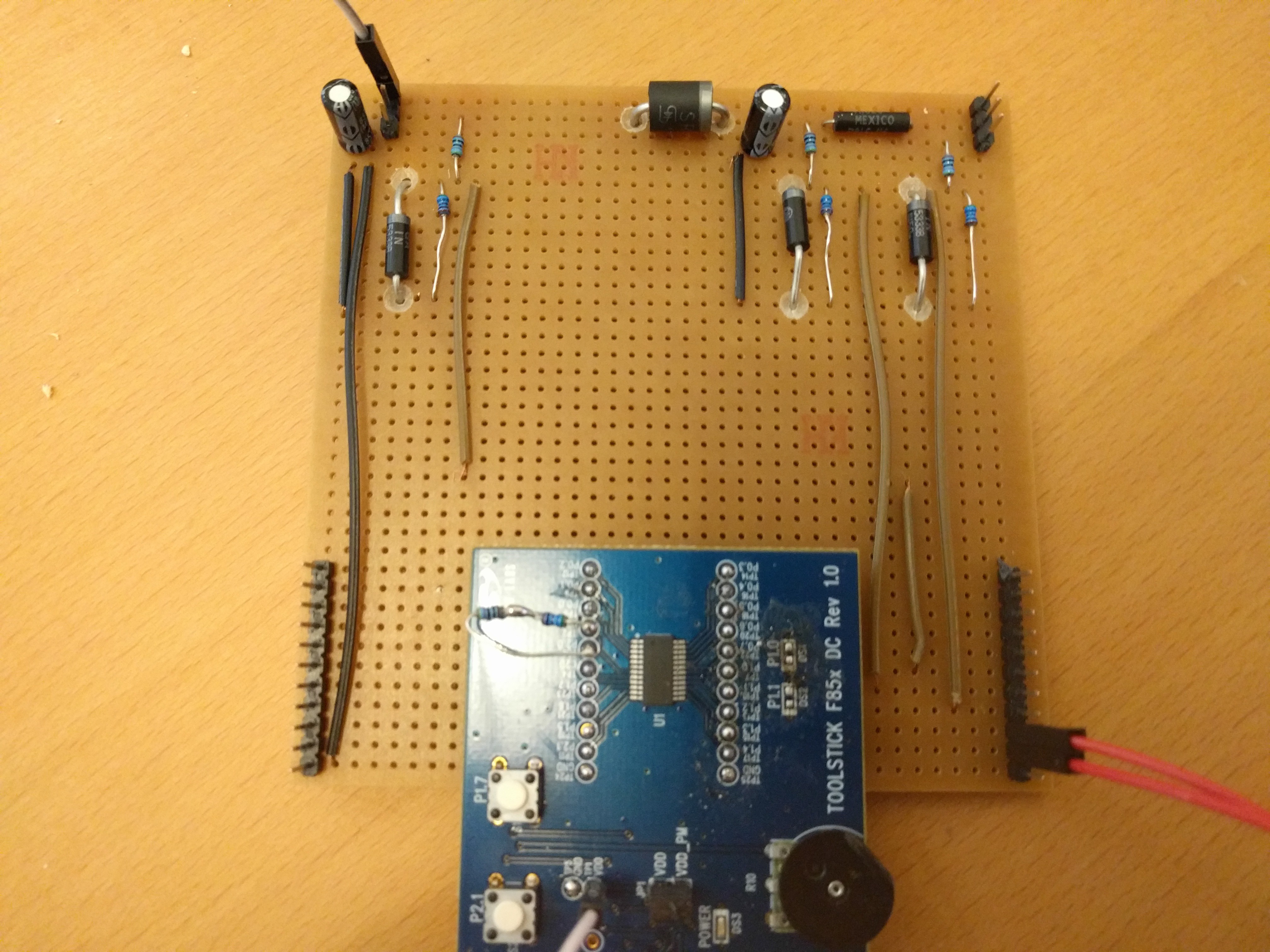

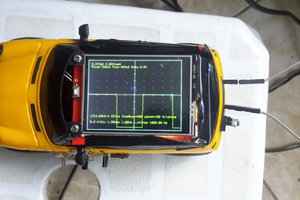

- Working boost convertor

- Working buck-boost convertor

- Implement constant current mode

- Digital (UART/SPI) interface for user to control voltage/current

- Change diodes to FETs switched by the microcontroller to improve efficiency

* The compiler limits machine code generation to 2KB (not a problem) however it also limits the use of memory less than 2KB by always jumping to address 0x0800 and then continuing with compiled assembler.

Ashley Robinson

Ashley Robinson

Jean-François Duval

Jean-François Duval

Vítor Barbosa

Vítor Barbosa

Jithin

Jithin

BTW you can also use a SEPIC buck-boost converter - basically a boost converter with an additional capacitor and inductor.

https://en.wikipedia.org/wiki/Single-ended_primary-inductor_converter