The content of this Hackaday project is mostly the project log documenting the exploration and design as it evolved. It doesn't have much in the way of a "how to".

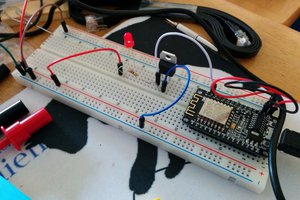

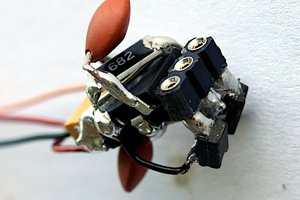

A detailed description of how to build this is in this Instructable: Ventbot, a DIY Home HVAC Vent Booster: Warm Side Cool, Cool Side Warm

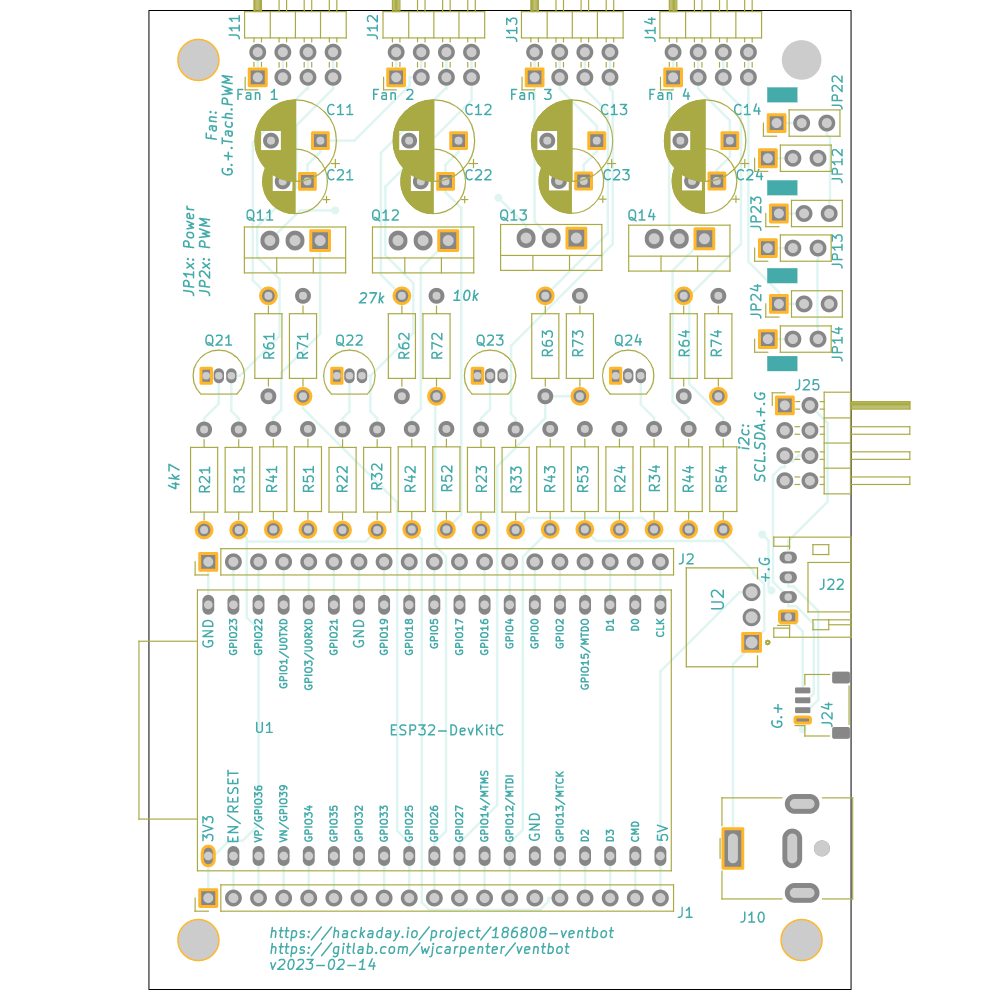

The repository for all project design files, both hardware and software is here: https://gitlab.com/wjcarpenter/ventbot

Finally, if you would like a to order the PCB that I designed and used with a couple of clicks, you can do that here:

Ventbot, a DIY HVAC Vent Booster: Warm Side Cool, Cool Side Warm

WJCarpenter

WJCarpenter

Mattijs

Mattijs

Ben Brooks

Ben Brooks