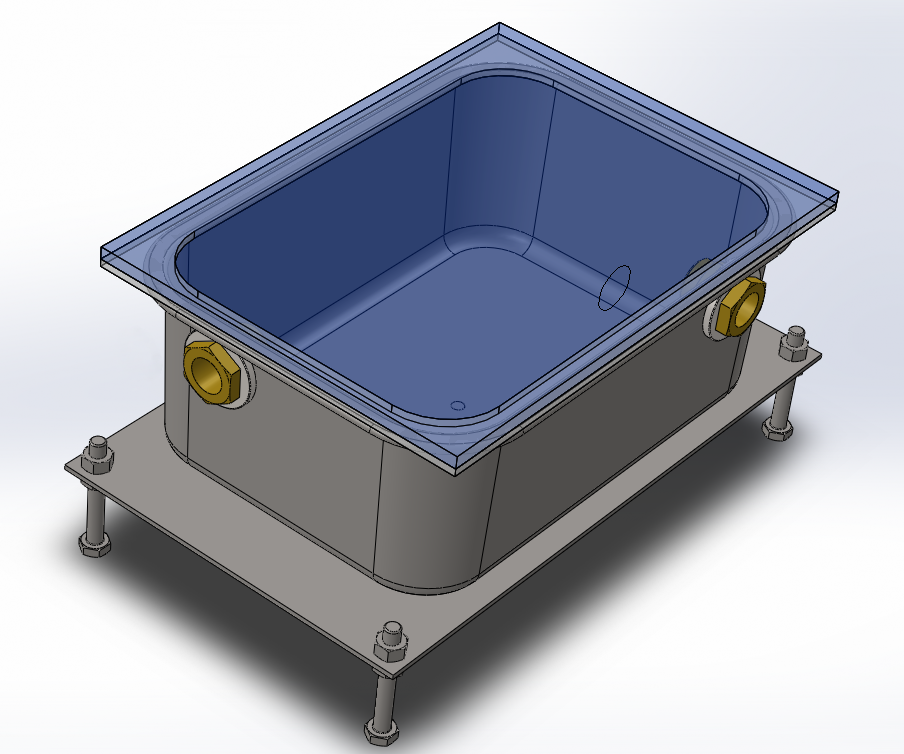

1. The vacuum chamber consists of a heat-resistant glass Tupperware with a plate holder, a copper-tungsten electrode, and an exhaust port on the base of a 250x250x5 A7075 plate with an O-ring groove.

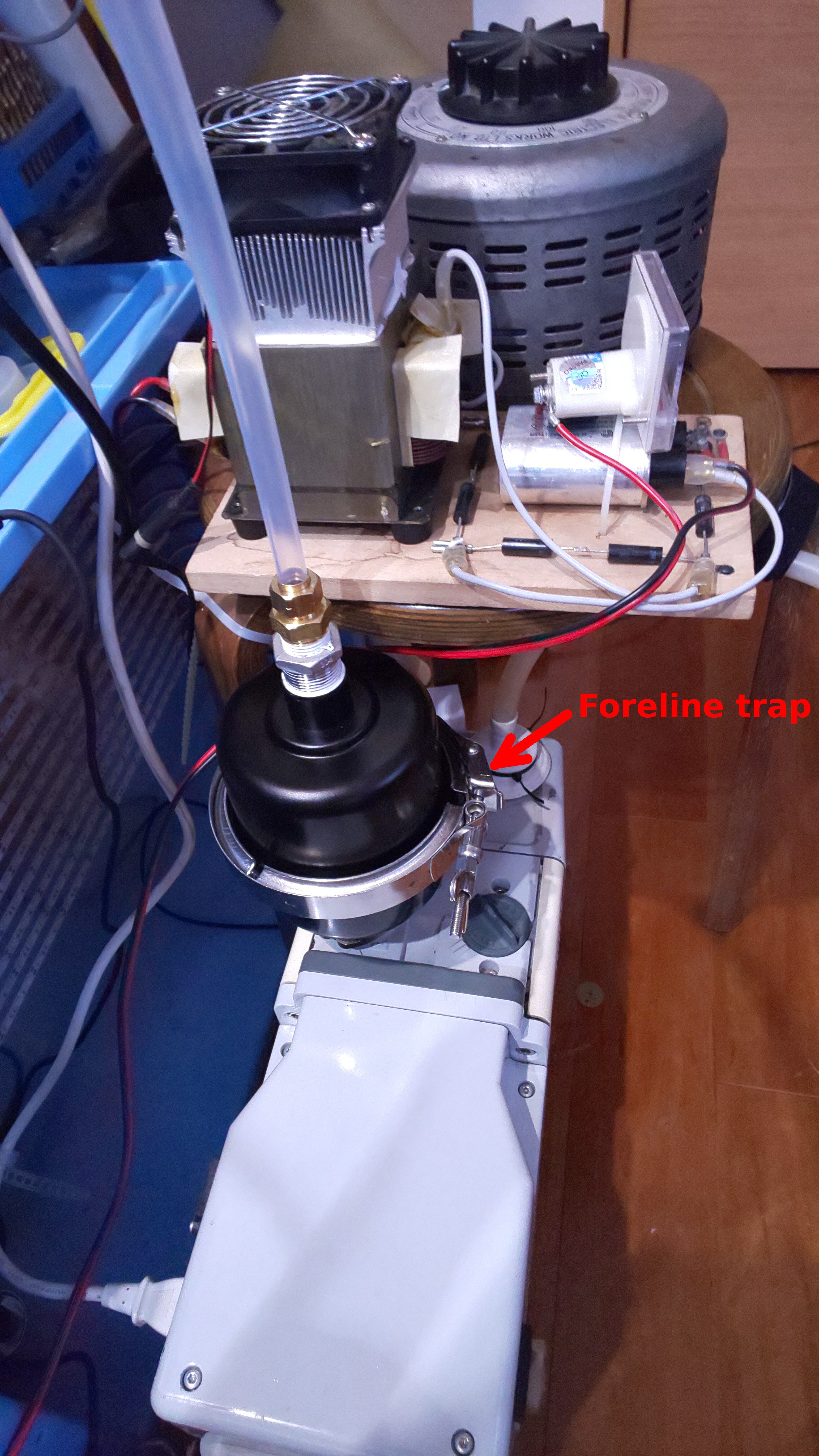

2. Prepare the plasma conditions by evacuating the chamber with a rotary vane vacuum pump through an oil mist trap, filling with argon gas, and evacuating repeatedly.

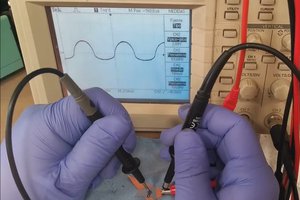

3. Boost AC50V to AC1500V with a step-up transformer for microwave ovens, convert it to DC with a diode bridge and apply it to the chamber to create a plasma atmosphere inside the chamber.

4. Inside the chamber, place a silver target on the base plate as the anode, and the electrode in the glass chamber as the cathode.

A 120x90x0.8mm copper plate is attached to the plate holder at a distance of 15-20mm from the anode.

5. Magnetron sputtering is started by inserting a magnetron consisting of OD34xID24xt10 doughnut-shaped and OD18xt10 cylindrical-shaped magnets directly under the base plate.

6. Since the above magnetron cannot cover the entire copper plate, the magnetron is driven in a grid pattern by a CNC modified from a pen plotter to proceed with sputtering. (See uploaded video)

7. All of these cooling rely on fan air cooling. :-P

Sputtering equipment for daguerreotype photography

Manufacture of photographic materials using home-made sputtering equipment.

Koji Tokura

Koji Tokura

Nixie

Nixie

Boris van Galvin

Boris van Galvin

Michael Barton-Sweeney

Michael Barton-Sweeney

rawe

rawe

Do daguerreotypes really need mercury to be developed? How can this be avoided by using something else instead?