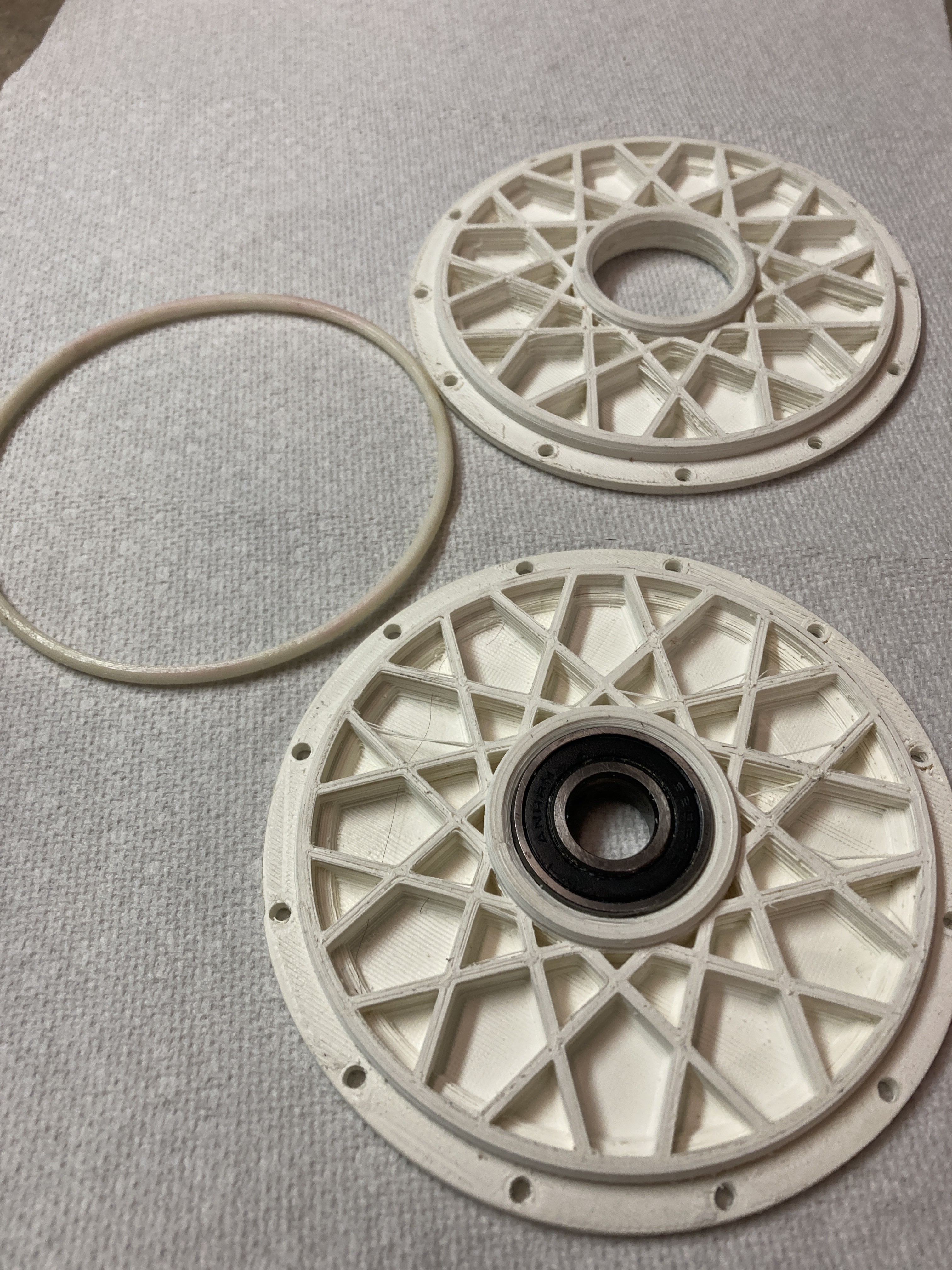

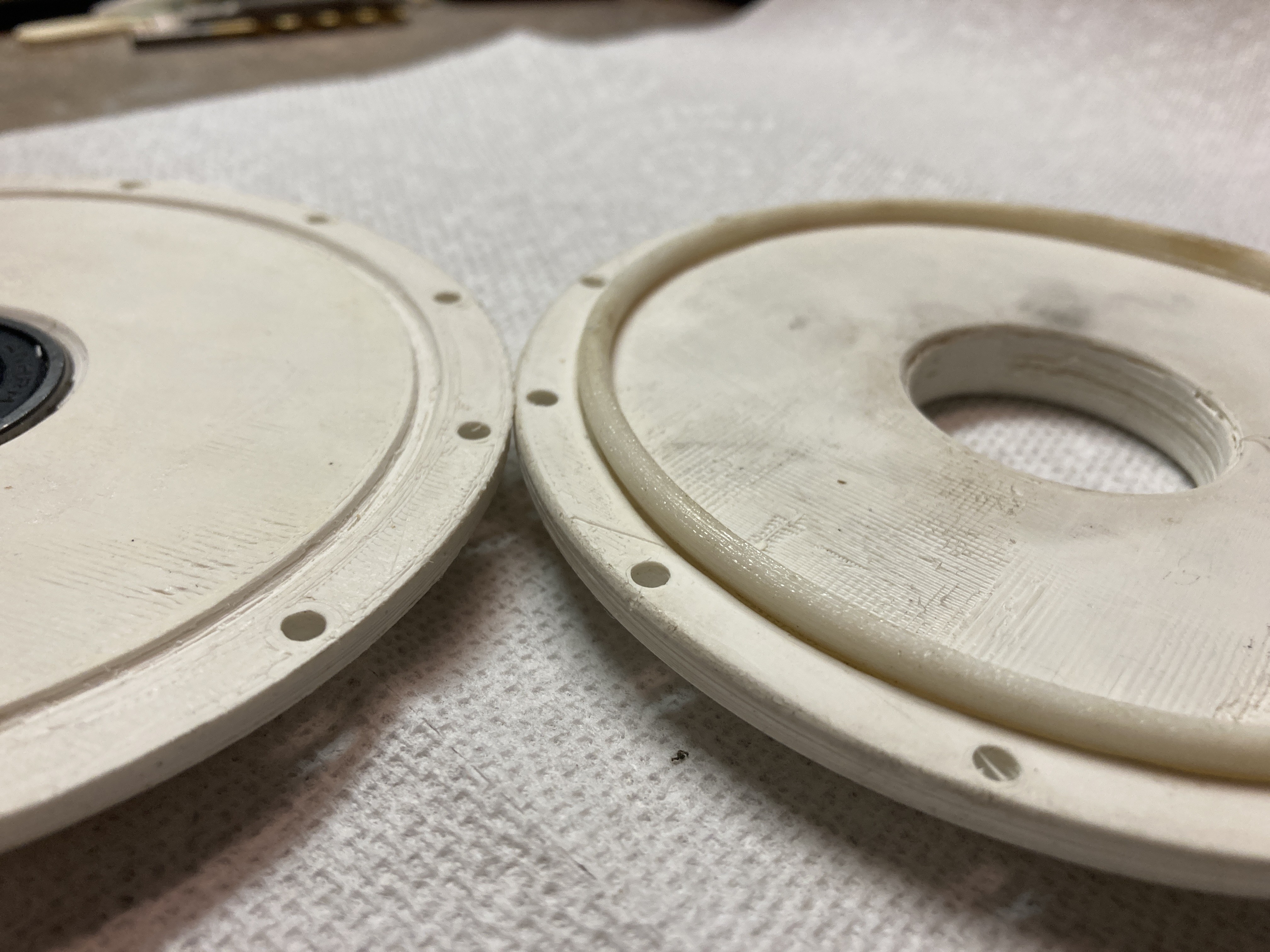

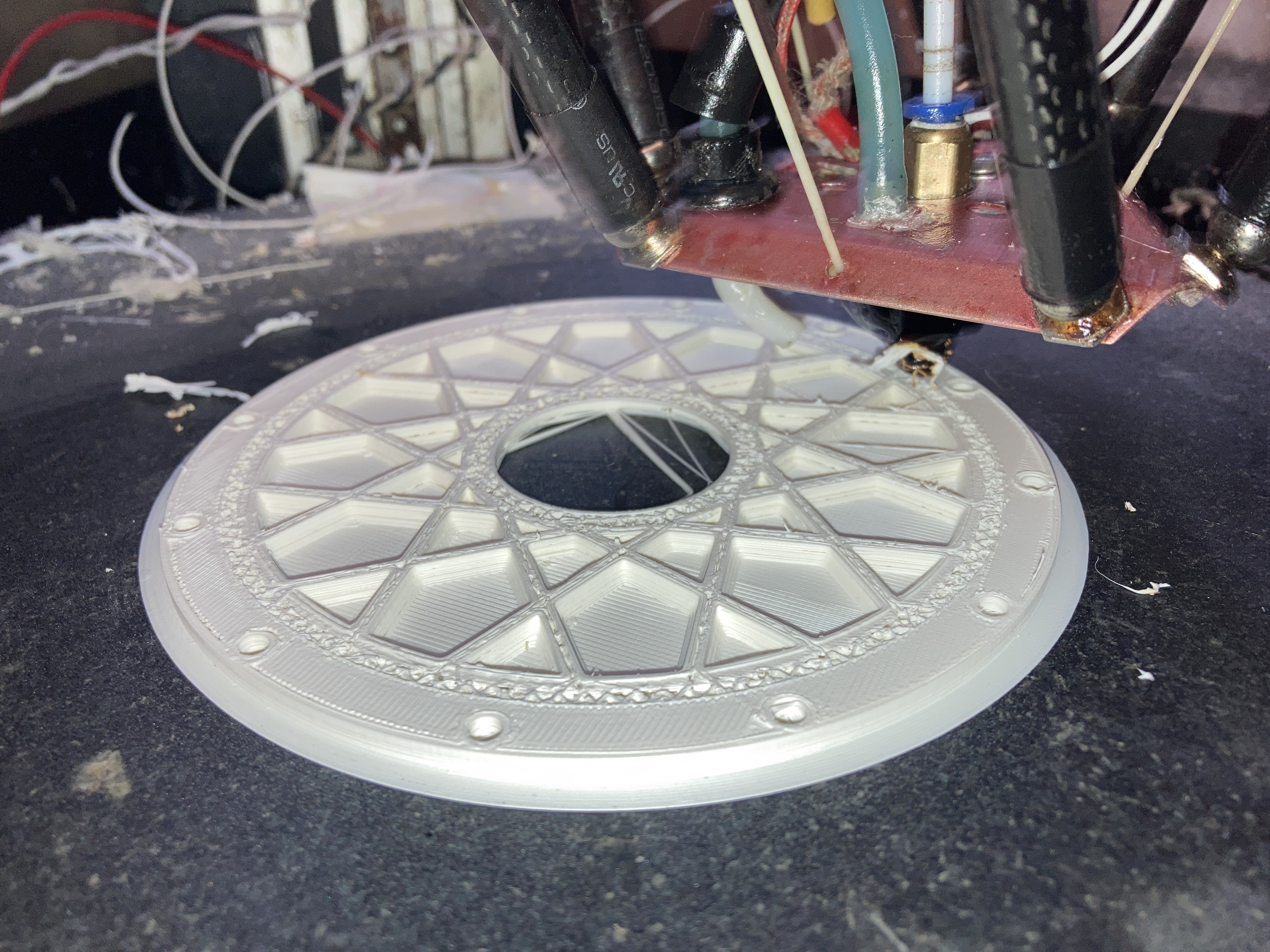

This is only one hub, and it is going in the wrong direction.. but it is a start.

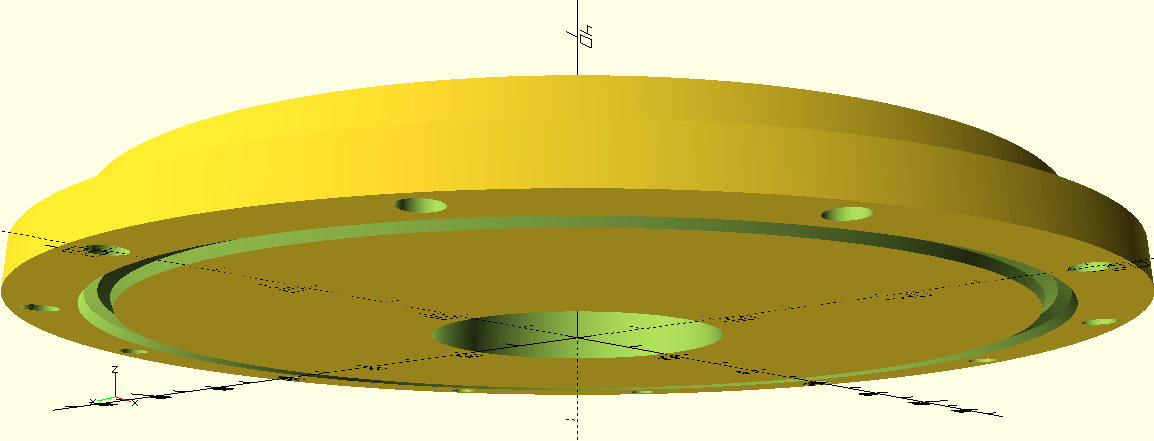

Estimated output per hub is at 390W by moving from a 7S to an 8S battery. So total power output should be 780W.

Not all of that will be usable as balance needs to be maintained.

Scaled up from the donor hoverboard tire dimensions this puts the top balanced speed at ~15mph, but this does not account for the voltage increase.

Soon to be measured.

Daren Schwenke

Daren Schwenke

Adam Curtis

Adam Curtis

jellmeister

jellmeister

ErikL

ErikL

Jorj Bauer

Jorj Bauer

I hope you will succeed and build a drivable one-wheel. I had to convert mine into a scooter https://hackaday.io/project/180964-diy-electric-one-wheeled-vehicle