Every Tuesday night my local makerspace (Kwartzlab) opens up to the public. People can get tours, seek member's advice, or apply for membership. Members come on Tuesdays to catch up with other members or work on their latest projects. I really missed Tuesday Open Nights (TON) when we had to suspend them during the height of Covid. Well TON is back baby, better than ever.

Last night, at TON, a maker friend told me about a company out of Spain called LaserBoost. They have a process to seamlessly combine laser cutting sheet metal with bending. You only need to submit a single STEP file of your part to get an instant quote. My friend showed me a part they had done with LaserBoost for a Famicom reproduction they are working on. Very cool (the service and the Famicom project). There are a few similar services in the US but after a quick sampling it looks like they are much more expensive.

So I started thinking about my Challenger 4P project. Don't get me wrong, I'm very happy with my 3D printed case top. It's solid (can support the weight of a monitor) and looks good. But I've always wondered how hard it would be to create a more authentic sheet metal skin. Kwartzlab does have tools for bending sheet metal but at this point no equipment for cutting sheet metal. LaserBoost gives me a way to produce a sheet metal skin with minimal effort (not that I am opposed to learning to work more directly with sheet metal at some future date).

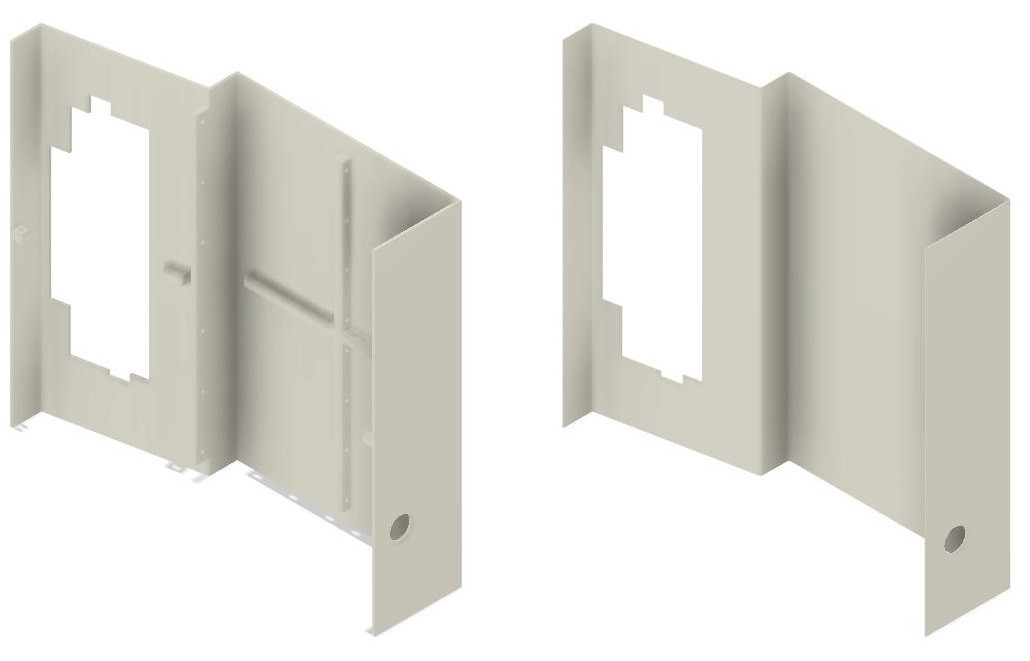

I started with my Fusion 360 3D printed skin model and removed all the braces (mostly just rolling back the Fusion 360 history). Then I reduced the case thickness from 3 mm to 1.2 mm.

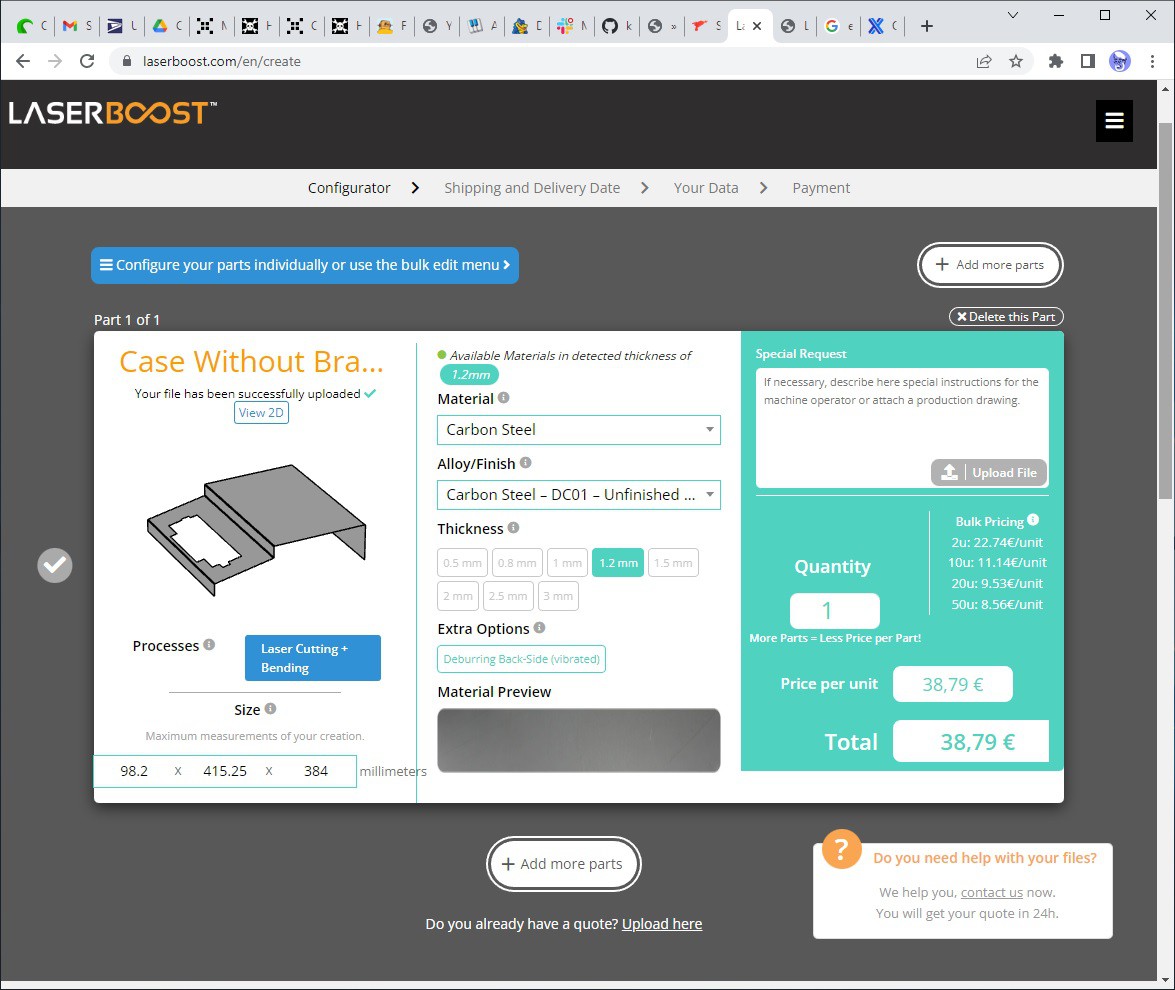

I saved the modified model as a STEP file which I loaded into the LaserBoost instant quote application. I only had to select the Material that I wanted to use (unfinished carbon steel). The application figured out everything else!

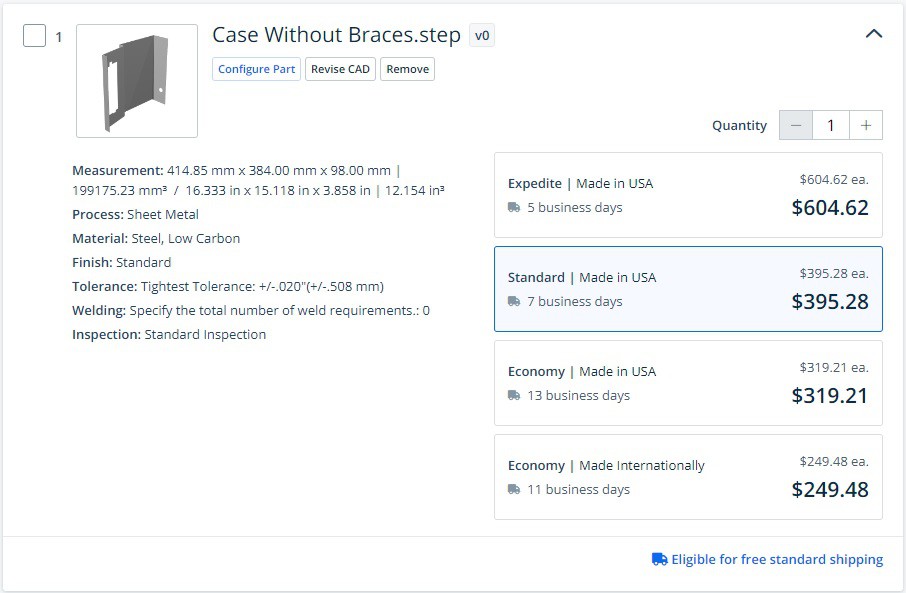

And voila my quote 38,79 € ($41.27 US or $55.77 CAD). In my eyes that is a very reasonable price for a one off, so what's the catch? I did mention that LaserBoost is located in Spain right? It turns out that shipping a largish piece of fabricated sheet metal via DHL (the only international shipping option) is 56,90 € ($60.32 US or $81.81 CAD). Having said this, the quotes I got from the US services that I sampled were so much higher that even with free shipping from the US could not offset the cost difference. For instance here is one of the other quotes from a US company which shall not be named.

Now I think the quotes are for the same outcome, but I'm new enough at this stuff to have messed up somehow.

At the end of the day I decided to place the order with LaserBoost. With shipping it's a little pricey but I'm anxious to see the result. To get the best price I have set a March 30th delivery date so I have a bit of a wait (like the second quote above, LaserBoost charges extra for "expedited" delivery on a sliding scale). Stay tuned.

Michael Gardi

Michael Gardi

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.

For sure. If you have a model their online quoting system is great. Shipping for you would be much more reasonable.

Are you sure? yes | no

Very interesting. I now immediately think of the Memotech MTX500. This would be exactly what is needed to replicate it's beautiful all-metal housing...

Are you sure? yes | no