I am a software developer, but a novice at electronics and today's tiny programmable devices such as the Raspberry Pi Pico. In 1990 I wrote a how-to book on distributed systems, featuring C programming, Oracle SQL databases, IBM PCs, and mini computers. In the main example in the book, humans play a simple game against the computer. The computer learns to play by saving each completed game in an Oracle SQL database, and querying for the statistically best move before each play - a simple form of machine learning. The computer gradually gets better over time. Each game lasts about a minute.

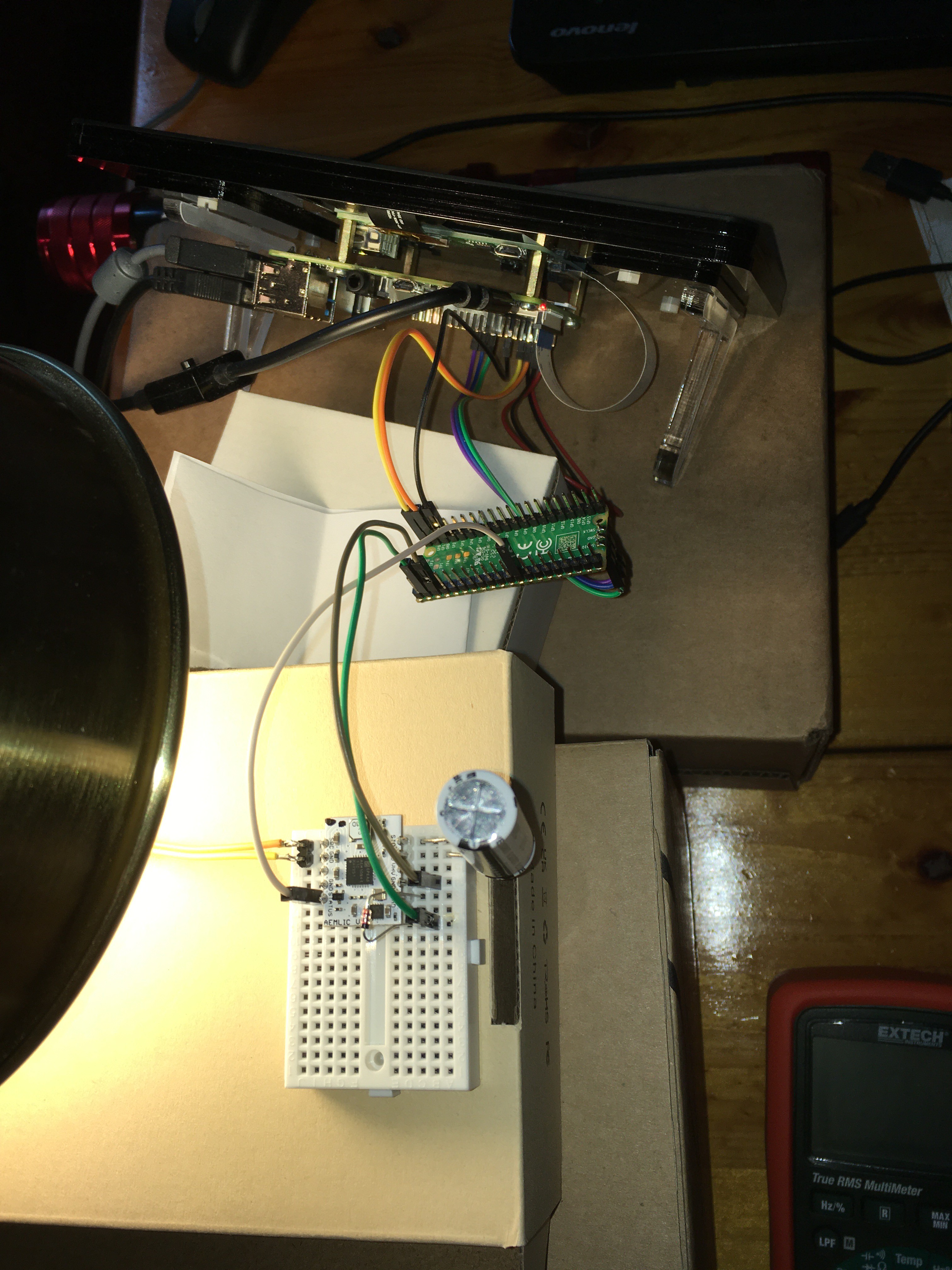

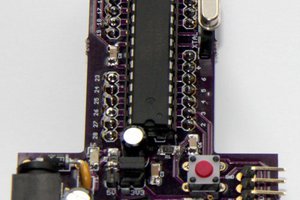

The original 1990 C code for the basic (non-database) version of the game compiles, with a few small modifications, on a Linux (or other) computer, and runs on a $4.00 21mm × 51mm Raspberry Pi Pico (https://www.raspberrypi.com/products/raspberry-pi-pico/). The UI, for initial prototyping, consists of a small joystick and a tiny OLED display. It's powered through a USB cable, or through a pair of wires from a larger Raspberry Pi 4.

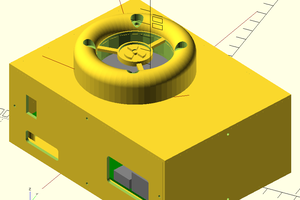

For now, this is a concept project, and a good way for me to learn a bunch of things. My goal is to run the complete game on the Pico, using energy harvested from the local environment, for example through a low-power solar cell. As a concept, imagine the small Pico attached inconspicuously to a tree in the woods. Anyone finding it could spend a minute or so playing a game, thus adding to the internal database. The Pico would harvest just enough energy between games to power the next game.

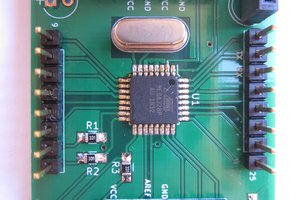

In this Hackaday project, I explore possibly using the AEMLIC Solar Harvesting board to harvest energy from a solar cell, store it in a 250F lithium ion capacitor, and provide the stored energy to a Raspberry Pi Pico. The Pico will sleep (some form of deep-sleep consuming little or no energy) between games.

I've started work on this and have already gone through some initial challenges. In this Hackaday project, I will write about some of these, starting with how to solder header pins onto the AEMLIC castellations (a significant challenge given my limited soldering ability).

TM

TM

Andrew Retallack

Andrew Retallack