TYPE 1 CIVILIZATION BUILDER

Please understand before reading the fancy language that I primarily wanted to clean up trash in my city, get people talking and employ kids in my neighborhood!

Type 1 Civilizations (T1Cs) are those described by astro-biologists, philosophers and futurists as theoretical groups of sentient beings that have obtained mastery over their planet’s resources- including efficient and productive use of all would-be waste materials (needless to say that on a scale of 1-3, humanity rates at a zero according to these same thinkers!)

While it may be obvious that no group or series of objects alone can prompt human beings to be truly “civil” towards each other- or develop an acknowledged conscious civilization for that matter- the optimized construction of dwellings and structures designed for integration with science learning, made specifically from non-perishable refuse, will greatly facilitate more than a few infrastructural, social and financial needs for our species.

All mass-produced objects Earthlings develop should be subject to re-puposing or serve as components for re-fabricating once its collective categorization as wholly unwanted trash becomes ubiquitous. As unused remnants of plastic containers, bags and bottles increasingly permeate much of our habitable landscape, we should vie to create tools with readily obtainable parts, that could- by their very creation and the best of associated social mechanisms– help further progress human beings towards a qualitatively new stage.

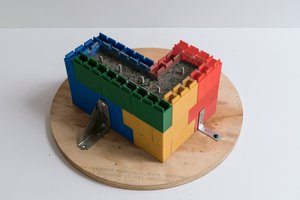

DYNABRIX (DBX) SYSTEM:

1) Users share dynamic data (images, description of materials and address) thru a smartphone app about where local trash and other, smaller area refuse is located- especially sites with bottles, cans, plastic bags and containers, as well as overgrown grasses in city lots.

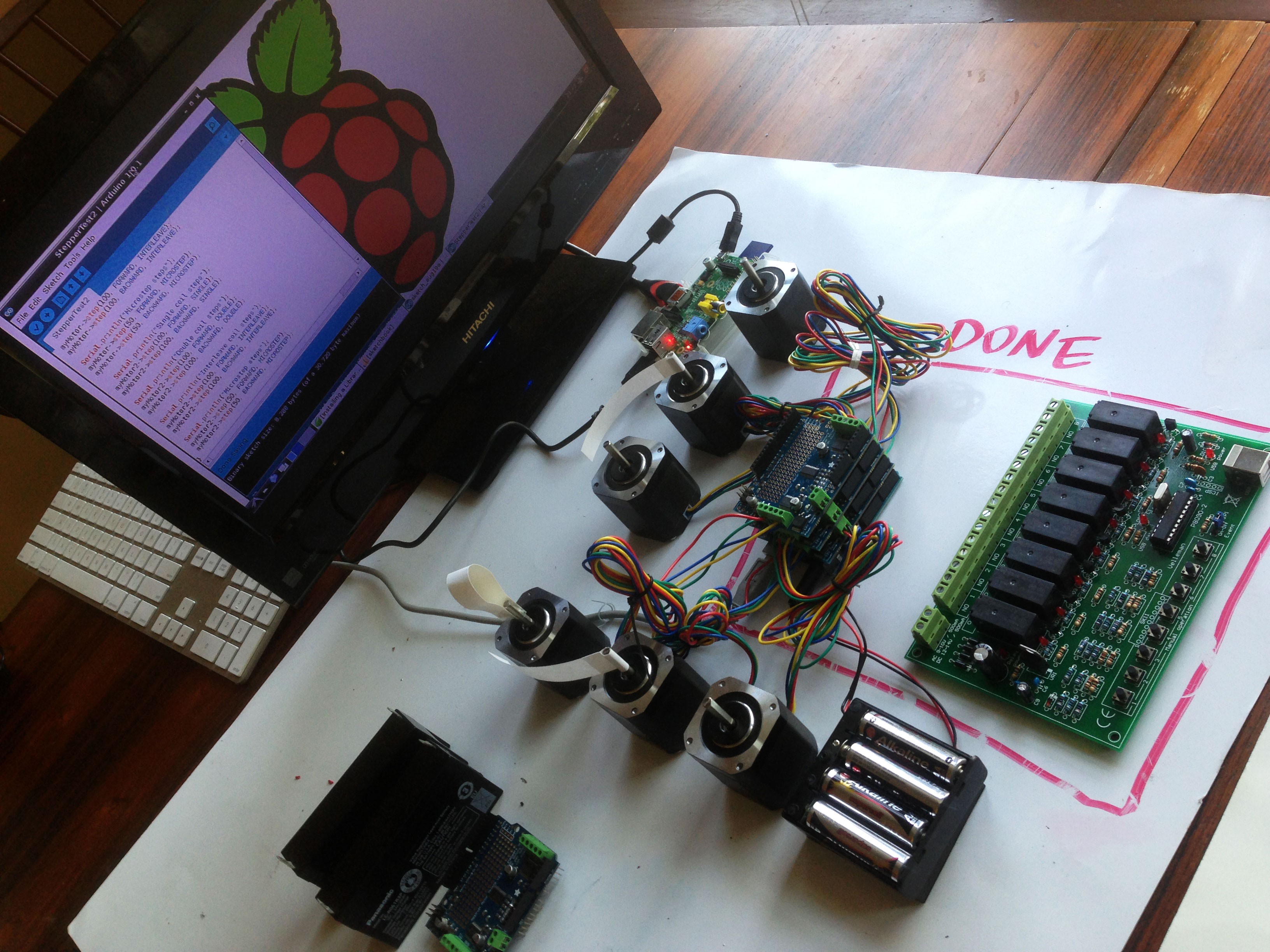

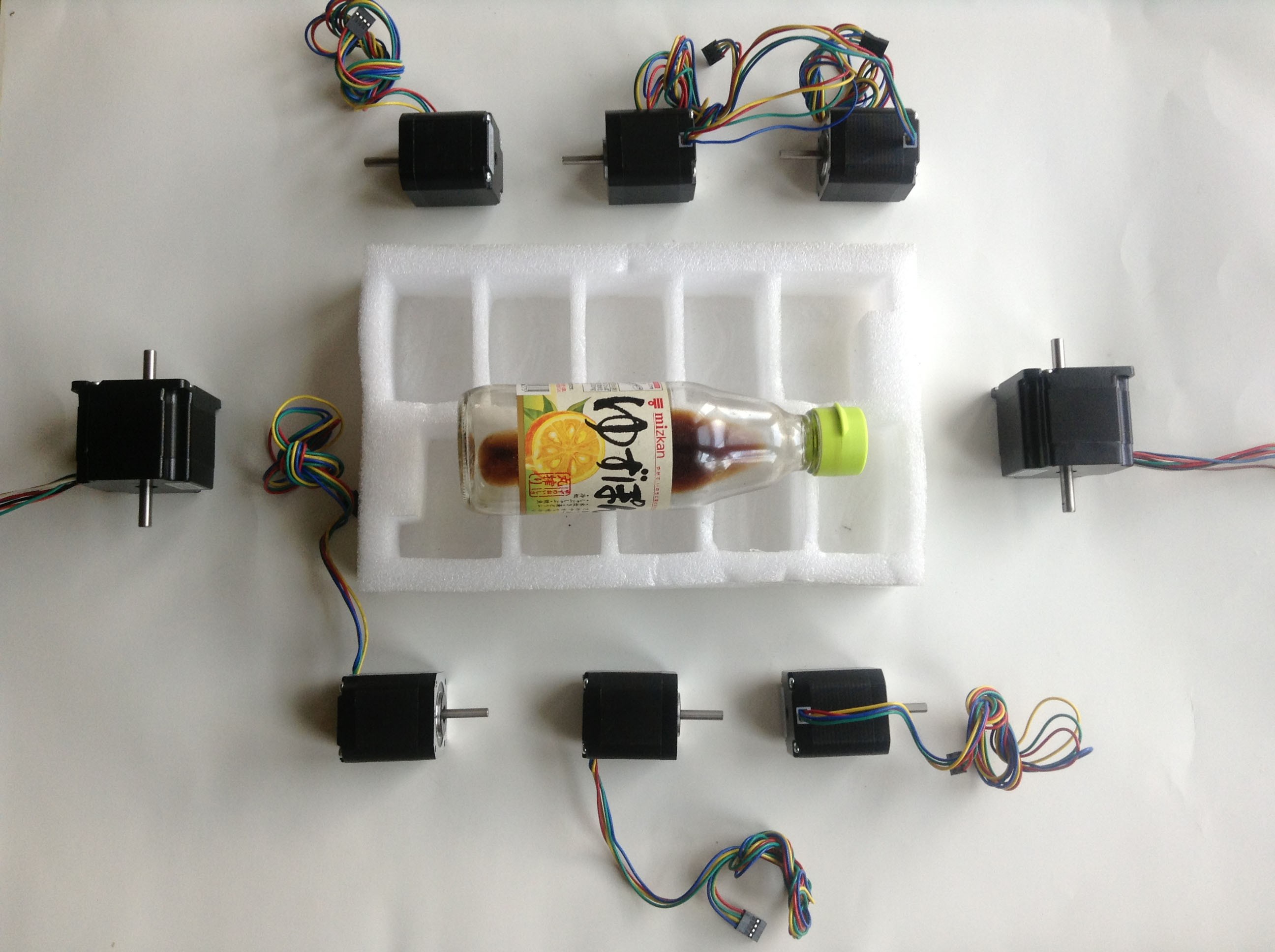

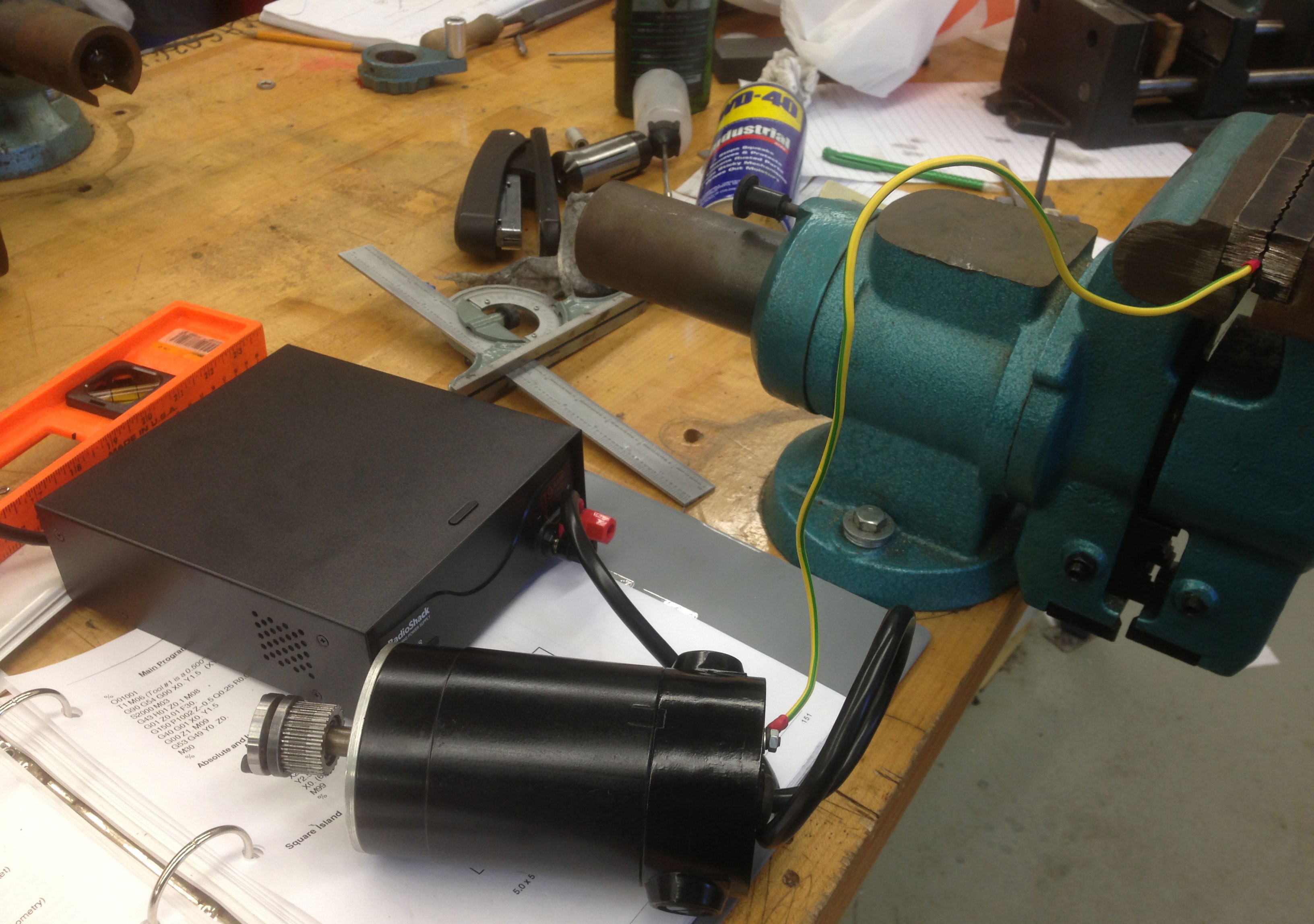

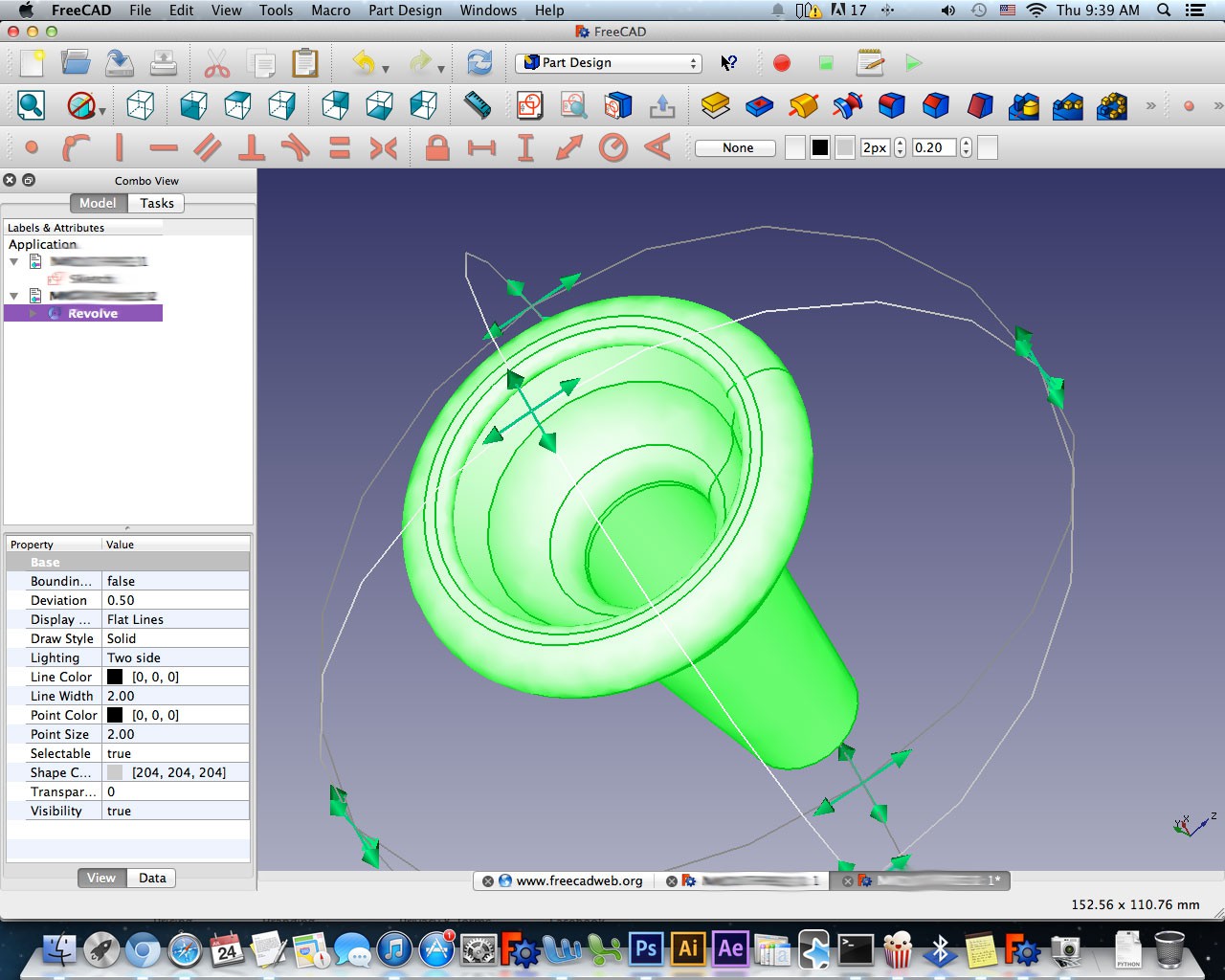

2) Persons equipped with open-source "Smash Unit" hardware visit best local sites to obtain materials and build based on network users' need of "Bottle Brix"- dynamically fabricated blocks formed into an array of components to build geodesic, ovoid and other efficiently shaped, semi-permanent structures. The Brix are basically other-than-rectangularly-shaped blocks of hardened aggregate and trash fibers suspended in a colloidal emulsion long enough to surround and solidify around common liquid containers. The Smasher could be understood as an optimized brick-making device hacked from paper shredders, trash compactors and other easily-obtained articles, preloaded with designs saved onto and controlled by an Arduino-Raspberry Pi unit, with updates on proximal need for various Brix forms being received remotely through the Smasher operator's phone, or other packet data sent through the cloud.

3) "Brix Inventory" is shared between app users over regional network for bartering, trading or delivery. Local businesses and organizations may both contribute to material aggregates used in making Bottle Brix, along with serving as outlets for Brix Distribution.

Mink Stacktrane

Mink Stacktrane

GuyisIT

GuyisIT

jlbrian7

jlbrian7

Patrick

Patrick

James Rowlands

James Rowlands

Cool Project. Can we do it for kitchen projects? I am already working on guides and tutorials for kitchen appliances on (https://blendersguide.com)