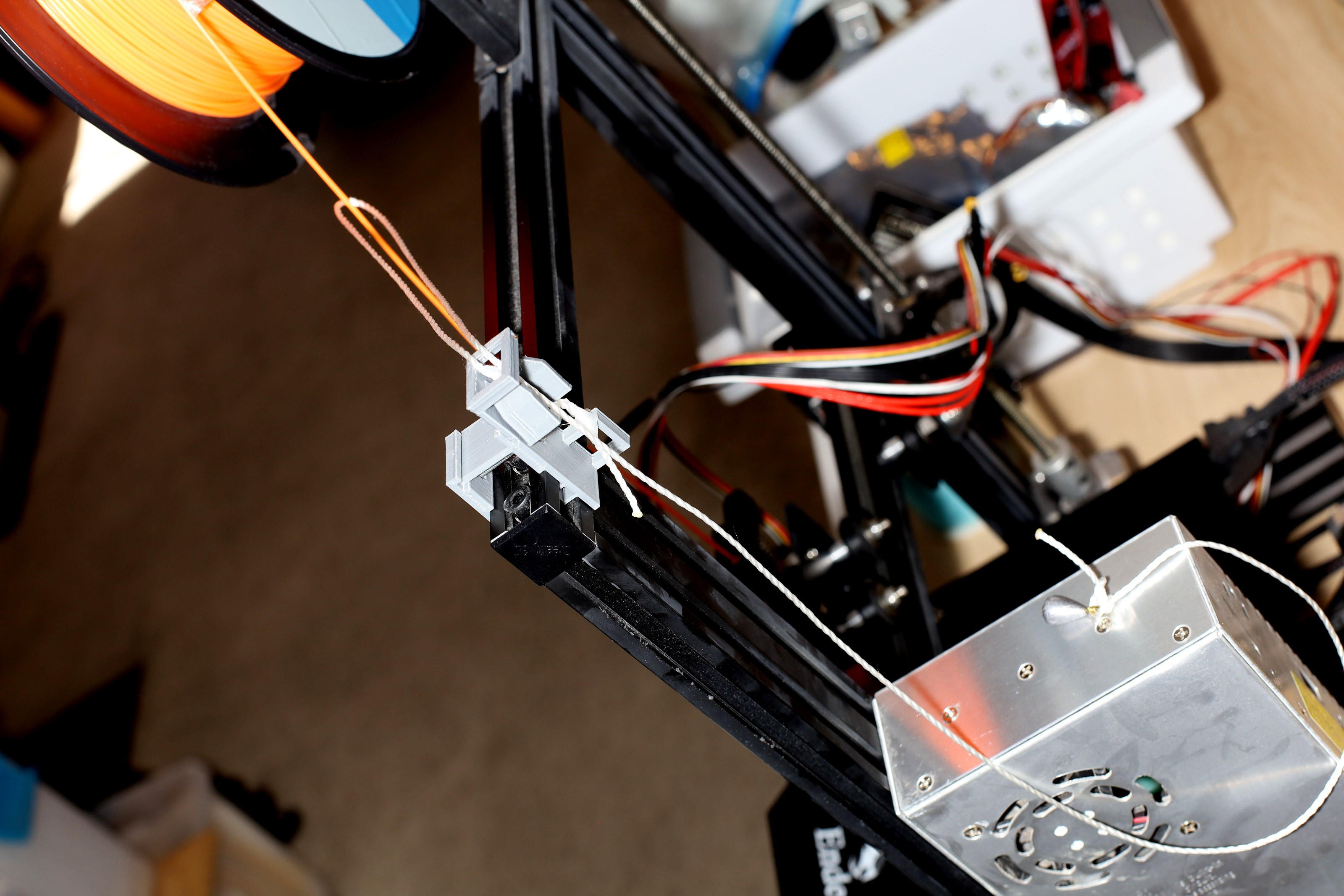

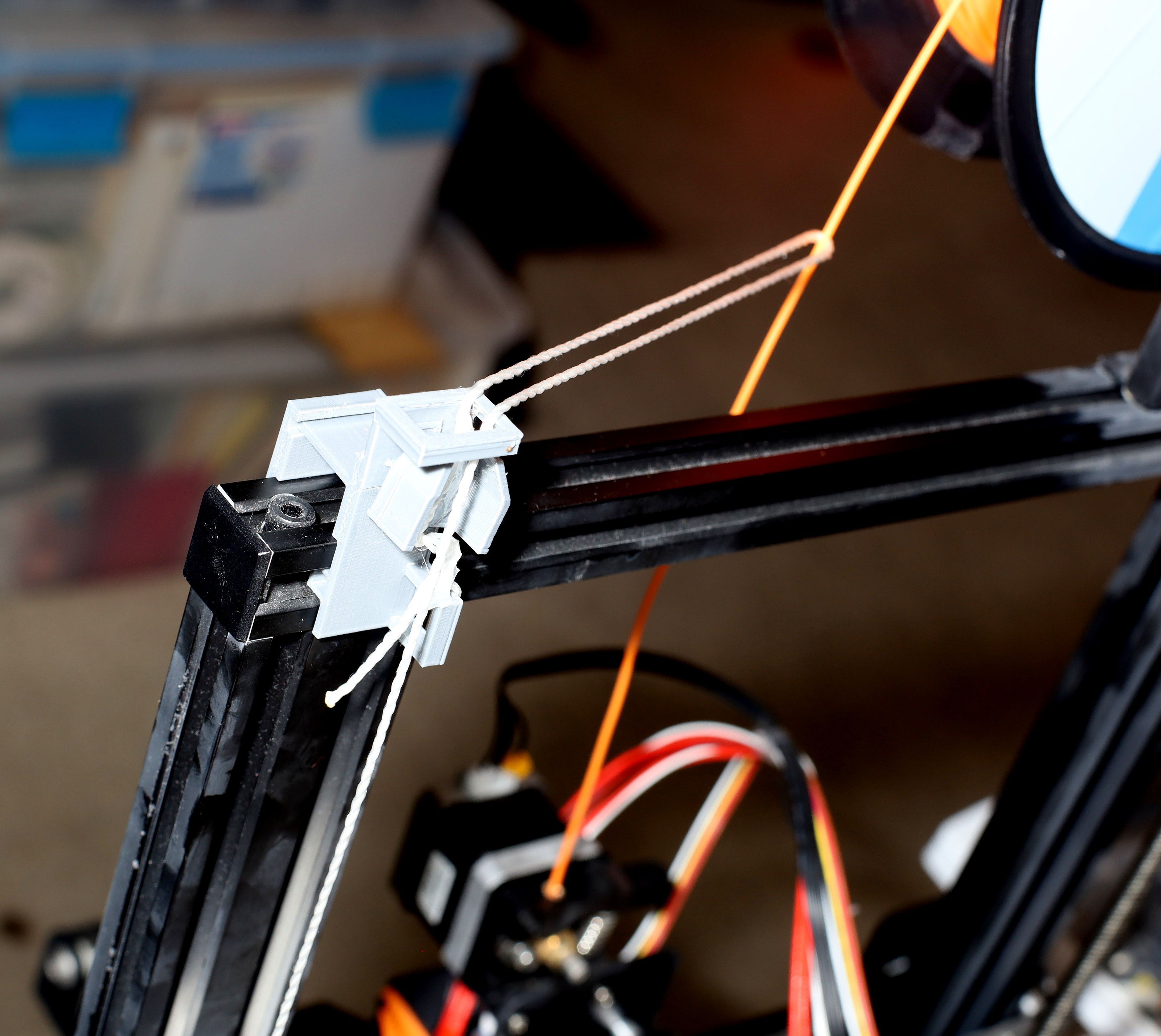

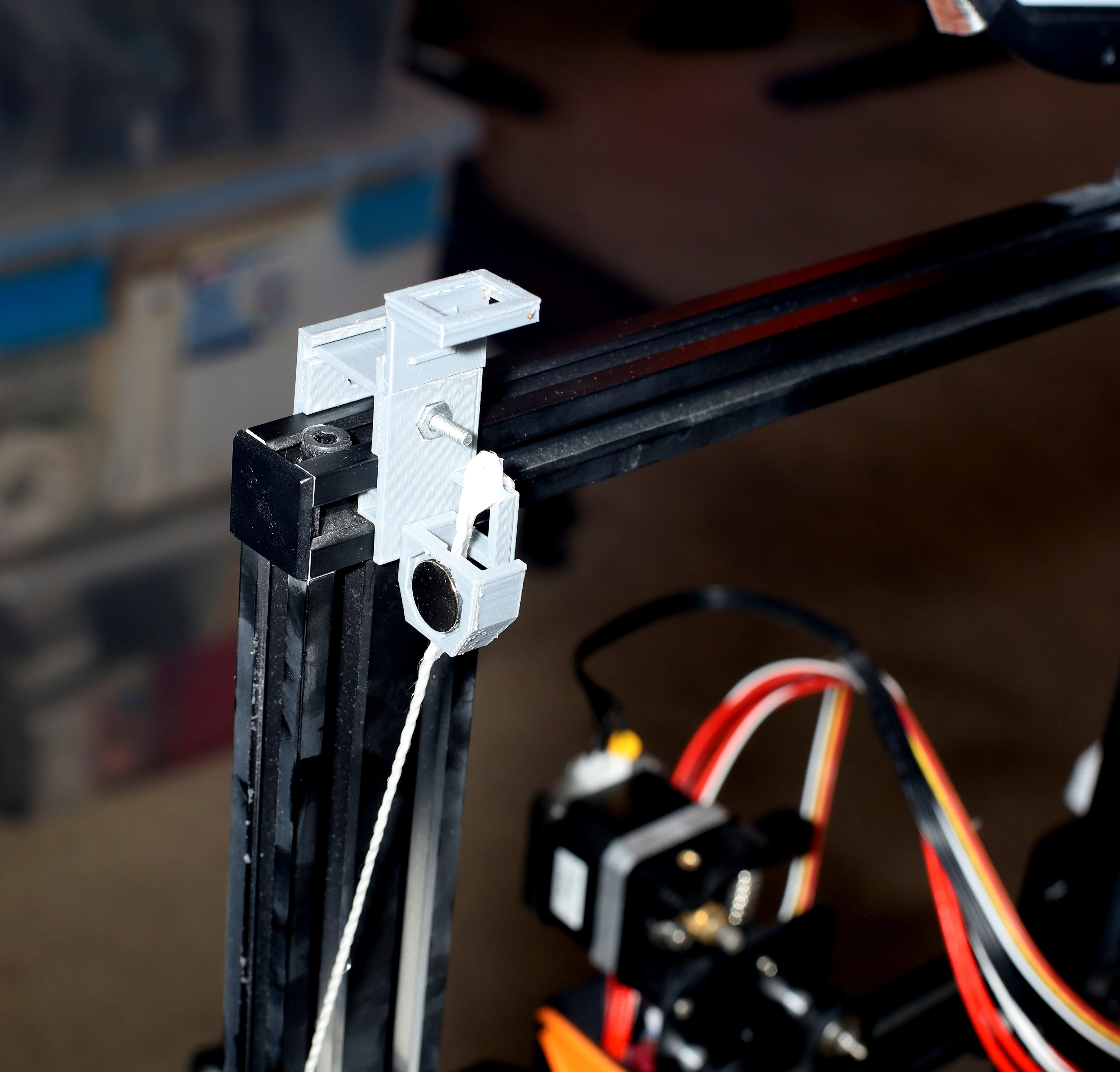

So then there was the idea of a lightly weighted string winding its way up the side of the printer, around a roller, around the filament, around the roller & down the side of the printer. When the filament ran out, the string would fall out of the roller. The trick is detecting when the string fell out of the roller. The leading candidate was the lion kingdom's favorite sensor: the magnet + hall effect sensor.

This had several problems. The string tends to jam during normal printing. The magnet doesn't stay in position during normal printing. The magnet doesn't always fall down when filament runs out. The mane thing it's trying to overcome is the need for the string to travel to a wide variety of angles. It's accepted that any kind of runout sensor is going to make loading filament like loading an IMAX projector.

lion mclionhead

lion mclionhead

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.