I picked up a 1HP 56C ironhorse from automation direct motor and a 2HP VFD , the 1.5HP was out of stock, and i accidentally ordered the 2HP motor but changed it before they shipped, I should have kept it, but i'd rather swap out the general purpose motor to a inverter duty motor later.

The difference being the constant torque ratio being 20:1 vs 2:1 so a general purpose motor won't give anywhere close to the torque of an inverter duty motor at lower speeds. general vs inverter

These pop up on ebay often so i'm looking out for the killer deal . The inverter duty is generally 3-4x the cost.

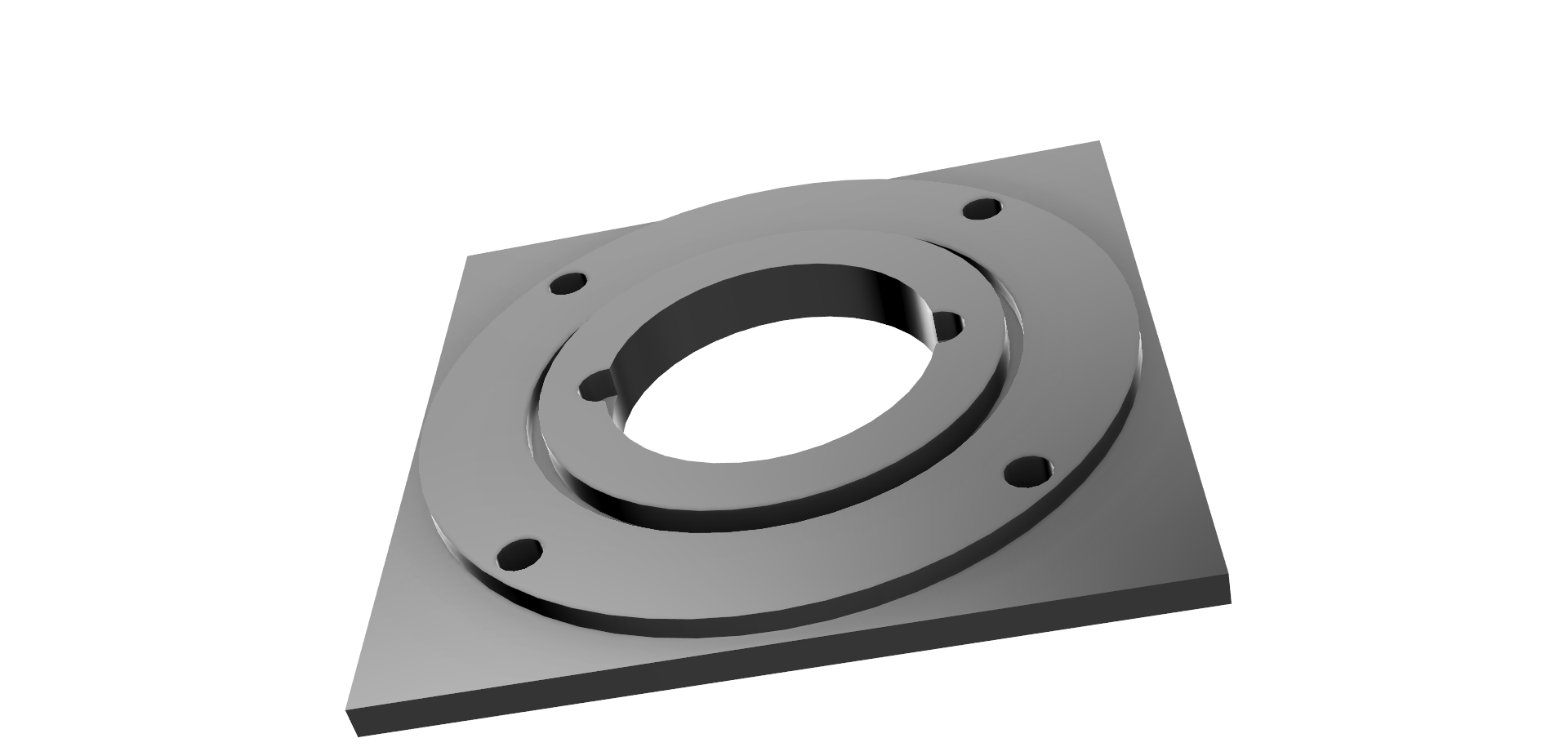

I designed a really nice motor plate in fusion 360, made it all fit the motor and then was told, thats no good since heat.. tsk tsk. well it taught me more of fusion360 so thats good, so i replaced the nice design with 5 holes and 4 slots...

Then milled it out on the C-Beam plate maker ( this is what this machine was designed to do )

Here it is mounted to the motor (the left side i'll cut off later) those are 3/8" 16 1"inch socket cap bolts.

the old motor looks like this, its tiny in comparison and works out to about .2HP

A360 for the 56C motor plate http://a360.co/1m4pLhK

the cool one looked like this, bad for heat though

i used this motor in my modelling https://grabcad.com/library/stainless-tenv-motor-56c-1 its a different motor but the base is right.

The we face milled a couple of long pieces, these will go along the side of the head and the motor plate will bolt on to it.

Likely will use a 2.2inch and a 1.2 inch pulley to give a 1.86 ratio. this all i had time for this Sunday night. more next week.

charliex

charliex

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.