Time to change out the 4 main bearings on the spindle. There are lots of videos on these, but so far i've yet to see a complete one. They all go from here's the mil, til here's something then its done. We're got to a point where we were left scratching our heads a bit on the last step , which we still haven't solved...

Videos to watch

interesting formatting on the videos, first one if you use the button above, wide ones are if you press enter with the url

I have face spanners/wrenches and OTC toyota CAM removal tools, it did come in handy later but a face spanner that fits is useful, we just used two drill bits that fit in the holes and turned them.

Hoss seems to have some magical cnc that all the bearings are hand tightened, i'm guessing he removed them a few times.

I used the bearings that did about 10,00 RPM

Top bearing

Spend some time watching videos from hossmachine and russtuff, then ask yourself hey what about those two bearing you never covered.

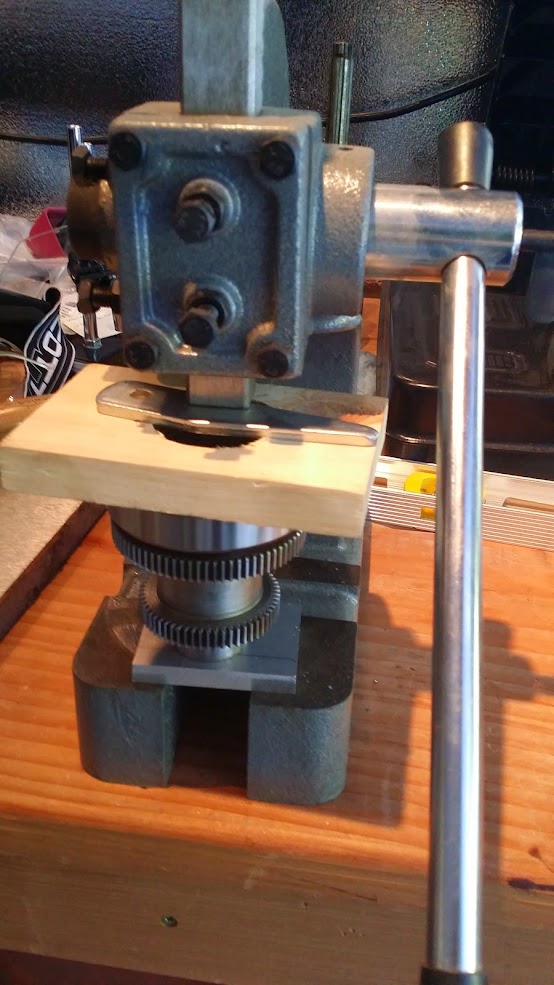

Small rig to pull the old bearing off the outer ( all the videos cover removal ) this just happens to be using the first thing we attempted to cut as a hemisphere and the gcode had a mistake, but as with all things you find a use for it in unexpected ways.

So I have loads of pulley pullers around for the car work, this is the cheaper HF 3 set, since we don't really care about the old bearing this gets it off nicely

To pull the inner bearings i flipped the hooks of the pulley puller to point outwards and then lever the, up slowly.

removed

re-install

Used this cutout to push it down.

Used this cutout to push it down.

The spindle bearing is a pita, we had the whole thing ready to finish and the last bearing just didn't make sense on how to get back in, since they're directional and if you knock them in one direction, it pops the bearings out, we ended up getting the bearing slightly at an angle and it took a while to get off, since there is no lip to grab on the new bearings, it is really difficult to remove . So we ground off two flats and got it off that way.

Taking photos you notice things like the gas lighter under the grinder, so yeah moved that :)

This is the first time we've gotten to where we couldn't get it back up and running in one day, since we trashed the lower bearing its just not worth taking a risk if a bearing feels wrong, it likely is so i just ordered a new one and we'll try to finish it up next week, and again try to take more pictures.

LayerOne is coming up soon, so some of the day was spent debugging and testing the new badge prototypes.

Bearings I used.

VXB

6209ZZE Nachi Bearing Shielded C3 Japan 45x85x19 Ball Bearings ( 1)

6007ZZE Nachi Bearing Shielded C3 Japan 35x62x14 Ball Bearings ( 1)

Bearings Direct

| 7005CP5 Precision 15 Degree Angular BallBearing ID 25 x OD 47 x W 12mm ABEC5 USBC/UBC |

|

|

McMaster-Carr

| Line | Product | Ordered | Shipped | Balance | Price | Total | |

|---|---|---|---|---|---|---|---|

| 1 | 98089A404 | Type 18-8 Stainless Steel Round Shim, 1MM Thick, 25MM ID, 36MM OD, Packs of 10 | 1Pack | 1 | 0 | 8.66 Per Pack | 8.66 |

| 2 | 98055A435 | Spring Steel Round Shim, 1MM Thick, 50MM ID, 62MM OD, Packs of 5 | 2 Packs | 2 | 0 | 4.66 Per Pack | 9.32 |

| 3 | 98055A346 | Spring Steel Round Shim, 1MM Thick, 35MM ID, 45MM OD, Packs of 10 | 1 Pack | 1 | 0 | 7.66 Per Pack |

charliex

charliex

Discussions

Become a Hackaday.io Member

Create an account to leave a comment. Already have an account? Log In.